Footwear designed explicitly for skateboarding, incorporating enhanced durability and performance features, constitute a specialized category. These shoes often include reinforced construction, improved cushioning, and superior grip to withstand the demands of skateboarding. An example would be a low-profile shoe with a suede and canvas upper, Duracap reinforcement in high-wear areas, and a vulcanized sole for optimal board feel.

The relevance of these specialized shoes lies in their ability to protect the wearer from injury and enhance their performance. The robust construction withstands the repeated abrasion and impact inherent in skateboarding. Improved cushioning absorbs shock, reducing fatigue and protecting joints. The specialized sole provides superior grip, enabling better board control and preventing slips. Historically, this footwear has been instrumental in the evolution of skateboarding, allowing skaters to push boundaries and innovate new tricks.

The following sections will delve into the specific features contributing to the performance and longevity of these shoes, exploring material science, construction techniques, and design considerations that cater to the unique requirements of skateboarding.

Optimizing Performance

The following guidelines are intended to maximize the lifespan and performance characteristics of purpose-built skateboarding footwear, ensuring sustained functionality under demanding conditions.

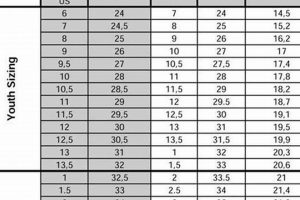

Tip 1: Prioritize Fit Assessment: Ensure proper sizing to avoid premature wear and tear. Ill-fitting shoes can lead to increased friction and pressure points, accelerating degradation. Measure foot length and width accurately before purchase.

Tip 2: Implement Regular Cleaning Protocols: Remove debris and dirt after each use to prevent material breakdown. Accumulated grime can compromise the integrity of stitching and adhesives. Utilize a soft brush and mild soap for cleaning.

Tip 3: Rotate Footwear: Employ multiple pairs to distribute wear. Consistent use of a single pair leads to accelerated degradation of impact absorption and support structures. Alternate between pairs to allow materials to recover.

Tip 4: Reinforce High-Abrasion Zones: Apply protective coatings or adhesive patches to areas prone to wear. Toe caps and ollie pads can extend the lifespan of footwear subjected to repetitive contact with abrasive surfaces.

Tip 5: Employ Proper Drying Techniques: Allow shoes to air dry naturally after exposure to moisture. Direct heat can damage adhesives and distort materials. Remove insoles to facilitate thorough drying.

Tip 6: Maintain Lacing Integrity: Replace worn or frayed laces promptly. Secure lacing contributes to overall support and prevents premature breakdown of eyelets and lace panels.

Tip 7: Inspect Soles Regularly: Monitor tread wear and structural integrity. Compromised soles diminish grip and increase the risk of slippage. Consider resoling options when feasible.

Adherence to these practices will contribute to the longevity and consistent performance of specialized skateboarding footwear, ultimately optimizing the skateboarding experience.

The subsequent section will explore the evolving landscape of skateboarding shoe technology and emerging innovations in materials and construction.

1. Durability

Durability, in the context of specialized skateboarding footwear, directly correlates to the lifespan and functional effectiveness of the shoe under demanding conditions. The abrasive nature of skateboarding surfaces, coupled with the repetitive impact forces involved in tricks and maneuvers, subjects footwear to extreme wear and tear. Consequently, insufficient durability leads to premature degradation, rendering the shoe ineffective and potentially unsafe. For example, a shoe lacking reinforced stitching or abrasion-resistant materials may exhibit accelerated wear in the ollie area or sole, compromising board feel and grip, respectively. Understanding this connection is crucial for both consumers and manufacturers in selecting and designing appropriate footwear.

The incorporation of specific materials and construction techniques directly addresses the need for enhanced durability. Suede and canvas, often augmented with reinforcing agents like Duracap, provide a balance between flexibility and abrasion resistance. Vulcanized soles, known for their superior bonding strength, resist separation from the upper under stress. Reinforced stitching and double-layered construction in high-wear areas mitigate the risk of tearing and premature failure. The selection and implementation of these design elements are pivotal in maximizing the lifespan of skateboarding footwear, directly affecting its cost-effectiveness and long-term performance.

In summary, the enduring functionality of skateboarding shoes is intrinsically linked to its resistance to degradation. Prioritizing durability through strategic material selection and robust construction extends the shoe’s useful life, optimizes performance, and ultimately provides a safer and more cost-effective experience for the skateboarder. The ongoing pursuit of enhanced durability remains a key driver of innovation in the skateboarding footwear industry.

2. Grip

Grip, in the context of skateboarding footwear, constitutes a fundamental performance parameter. The ability of a shoe to adhere effectively to the skateboard deck directly impacts control, stability, and the execution of maneuvers. The connection between the sole and the board serves as the primary interface for transferring energy and maintaining balance, thereby influencing overall skateboarding performance. Inadequate grip compromises control and increases the risk of slippage and injury.

- Sole Composition and Durometer

The rubber compound utilized in the sole construction plays a critical role in determining grip. Softer rubber compounds, measured using a durometer scale, tend to offer superior traction on the abrasive surface of a skateboard deck. A higher durometer rating indicates a harder, more durable rubber, but often results in reduced grip. Balancing durability with optimal grip characteristics is a key consideration in sole design. For example, a sole with a relatively soft durometer reading (e.g., 60A) may provide enhanced grip in dry conditions but may wear more quickly. A harder compound (e.g., 78A) will last longer but may be less effective on smooth or damp surfaces.

- Tread Pattern Design

The pattern embossed into the sole contributes significantly to the grip performance. Deep, intricate patterns with a high surface area provide more points of contact with the board, enhancing traction. Herringbone, waffle, and diamond patterns are commonly employed. The directionality and spacing of these patterns influence the shoe’s ability to grip in various directions and under different loading conditions. A well-designed tread pattern can channel away water and debris, maintaining grip even in suboptimal environments. Shoes with flat, featureless soles offer minimal grip and are unsuitable for skateboarding.

- Vulcanization Process

The method by which the sole is attached to the upper directly influences the bond’s integrity and long-term grip performance. Vulcanization, a process involving heat and pressure to fuse the rubber sole to the upper, creates a strong and durable bond that resists separation under stress. This robust bond ensures that the sole remains firmly attached to the upper, maintaining consistent grip even after prolonged use and exposure to abrasive surfaces. Poorly vulcanized soles are prone to delamination, significantly reducing grip and compromising the shoe’s overall performance.

- Sidewall Construction and Integration

The sidewall of the sole, the portion that wraps up the side of the shoe, also contributes to grip, particularly during angled board maneuvers. A higher sidewall provides more surface area for contact with the board, improving grip during ollies, kickflips, and other tricks that require lateral control. The integration of the sidewall with the upper is also critical. A seamless and robust integration prevents separation and ensures that the sidewall remains firmly connected to the upper, maintaining consistent grip and stability.

These facets collectively underscore the importance of grip in skateboarding footwear. The selection of appropriate sole materials, tread patterns, vulcanization techniques, and sidewall construction directly impact the skater’s ability to control the board and execute tricks effectively. Consequently, a focus on grip optimization remains a central theme in the design and development of high-performance skateboarding shoes.

3. Cushioning

Cushioning within specialized skateboarding footwear, particularly in the context of models designed for professional use, represents a critical component impacting performance and injury prevention. The repetitive high-impact nature of skateboarding subjects the musculoskeletal system to considerable stress. Inadequate cushioning can result in increased fatigue, joint pain, and a higher risk of injuries such as heel bruises, stress fractures, and ankle sprains. Therefore, the presence and effectiveness of cushioning systems directly influence the skater’s ability to perform consistently and safely over extended periods. For example, landing a series of jumps or navigating rough terrain places significant load on the heels and joints. Without sufficient impact absorption, the force is transmitted directly to the body, leading to discomfort and potential damage.

Specific materials and technologies are incorporated into the construction of skateboarding shoes to address cushioning needs. Polyurethane (PU) and ethylene-vinyl acetate (EVA) foams are commonly used as midsole materials due to their shock-absorbing properties and lightweight nature. These materials compress under impact, dissipating energy and reducing the force transmitted to the foot and lower limbs. Gel inserts, strategically placed in high-impact areas such as the heel, can provide additional cushioning and support. For instance, many pro-model skateboarding shoes feature molded sockliners or footbeds incorporating advanced cushioning technologies designed to provide targeted support and impact absorption. These features contribute to a more comfortable and protected skateboarding experience, allowing skaters to push their limits without undue risk.

In summary, the strategic implementation of cushioning technologies within skateboarding shoes serves as a vital element in mitigating impact stress and enhancing overall performance. The selection of appropriate cushioning materials and construction techniques is paramount in ensuring skater comfort, reducing the risk of injury, and enabling sustained participation in the sport. Continuous innovation in cushioning systems remains a key focus for manufacturers seeking to optimize the performance and safety characteristics of specialized skateboarding footwear.

4. Boardfeel

Boardfeel, within the realm of skateboarding footwear, represents the tactile sensitivity and proprioceptive awareness transmitted from the skateboard deck to the skater’s foot. This sensory feedback allows for precise control and nuanced adjustments during riding and trick execution. Footwear design significantly influences boardfeel, with variations in sole thickness, construction materials, and outsole patterns directly impacting the level of connection between the skater and the board. A diminished boardfeel inhibits the skater’s ability to sense the board’s position and movement, compromising control and potentially increasing the risk of miscalculations or failed maneuvers. For instance, a skater attempting a technical trick requires acute awareness of the board’s angle and orientation; reduced boardfeel impairs this sensory input, making successful execution more challenging.

The construction of skateboarding footwear directly impacts boardfeel. A thinner sole, typically constructed from vulcanized rubber, enhances sensitivity and allows for greater responsiveness to the board’s movements. Thicker, cushioned soles, while providing superior impact absorption, often reduce boardfeel by isolating the foot from the board’s surface. The choice between enhanced cushioning and optimal boardfeel represents a design trade-off that manufacturers must carefully consider. Moreover, the outsole pattern influences boardfeel; a flatter, less aggressive pattern generally provides a more direct connection to the board compared to a deeply lugged or heavily textured outsole. Modifications to the shoe can impact boardfeel. The use of aftermarket insoles can either increase the padding and decreased the overall boardfeel experience.

Ultimately, boardfeel is a critical determinant of performance and control in skateboarding. Designs that prioritize a sensitive and responsive connection between the skater’s foot and the board enable greater precision and confidence, while designs that compromise boardfeel may hinder performance and increase the likelihood of errors. The ideal balance between boardfeel, cushioning, and support depends on the skater’s individual preferences and the specific demands of their riding style. Understanding these trade-offs is crucial for skaters seeking to optimize their footwear selection for enhanced performance and control.

5. Support

Support, in the context of specialized skateboarding footwear, directly influences stability, injury prevention, and overall performance. Skateboarding inherently involves dynamic movements and high-impact landings, placing considerable stress on the feet, ankles, and lower limbs. The structural integrity of a skate shoe, therefore, plays a crucial role in mitigating these forces and providing the necessary stability for executing tricks and navigating varied terrain.

- Ankle Support and Collar Padding

Ankle support is achieved through the design and construction of the shoe’s collar and surrounding areas. Higher collars, often incorporating padding, provide increased stability and reduce the risk of ankle sprains, particularly during lateral movements and landings. The padding cushions the ankle joint, minimizing friction and impact. Shoes lacking sufficient ankle support can leave the wearer vulnerable to injuries, especially when attempting complex or high-impact maneuvers. Real-world applications frequently involve skaters selecting mid- or high-top models specifically for their enhanced ankle support capabilities, prioritizing stability over the unrestricted movement offered by low-top designs.

- Midsole Stability and Arch Support

The midsole contributes significantly to overall support by providing cushioning and stability underfoot. A well-designed midsole incorporates arch support, which helps to maintain proper foot alignment and prevent overpronation or supination, common biomechanical issues that can lead to fatigue and injury. Stability features, such as medial posts or reinforced sidewalls, further enhance support by limiting excessive foot movement. A flat, unsupportive midsole can lead to arch pain, plantar fasciitis, and other lower limb problems. Many pro skate shoes include custom-molded footbeds with enhanced arch support, catering to individual foot anatomies and promoting optimal biomechanics.

- Reinforced Heel Counters

The heel counter, a rigid or semi-rigid structure surrounding the heel, provides crucial rearfoot stability. A reinforced heel counter prevents excessive heel movement, maintaining proper alignment and reducing the risk of ankle rolling. The stiffness and shape of the heel counter directly impact the level of support provided. Inadequate heel counter support can lead to heel slippage, instability, and an increased risk of ankle injuries. Premium skate shoe models often feature molded heel counters made from durable materials, ensuring long-lasting support and stability.

- Lacing Systems and Fit Adjustment

The lacing system plays a vital role in securing the foot within the shoe and providing a customized level of support. A well-designed lacing system allows the wearer to adjust the tightness and fit of the shoe, optimizing support and stability. Features such as ghillie loops or reinforced eyelets enhance lacing durability and prevent the laces from loosening during activity. Inadequate lacing can result in foot slippage, reduced support, and an increased risk of blisters and other foot problems. Pro skate shoes often incorporate strategically placed lace loops or reinforced panels to provide targeted support and prevent lace breakage.

These facets of support, when integrated effectively into the design and construction of skateboarding footwear, contribute to a safer and more comfortable skateboarding experience. Skaters often prioritize models offering a combination of ankle support, midsole stability, reinforced heel counters, and customizable lacing systems to maximize performance and minimize the risk of injury. The balance between support, flexibility, and boardfeel remains a key consideration in the selection of appropriate skateboarding footwear.

6. Impact Resistance

Impact resistance, in the context of skateboarding footwear, directly relates to the capacity of the shoe to withstand and dissipate forces generated during high-impact activities such as jumping, landing, and bailing. This characteristic is paramount for mitigating the risk of injuries to the feet, ankles, and lower limbs. Deficient impact resistance can lead to acute trauma, chronic stress, and reduced performance due to pain and discomfort.

- Midsole Composition and Density

The midsole, typically constructed from materials like ethylene-vinyl acetate (EVA) or polyurethane (PU), serves as the primary impact absorption layer. The density and composition of the midsole material dictate its capacity to attenuate impact forces. Higher-density materials offer greater resistance to compression and deformation, effectively dissipating energy and protecting the foot. For instance, dual-density midsoles, featuring a firmer material in the heel and a softer material in the forefoot, provide targeted impact protection and cushioning. The choice of midsole material and density is a critical determinant of impact resistance in these specialized shoes.

- Insole Technology and Cushioning Placement

The insole, also known as the sockliner or footbed, provides an additional layer of cushioning and support. Specialized insoles, often incorporating gel or foam inserts strategically placed in high-impact areas such as the heel and forefoot, enhance impact absorption. These inserts compress under pressure, dissipating energy and reducing the force transmitted to the foot. Insole technology contributes significantly to overall impact resistance, supplementing the performance of the midsole. Examples of insole technologies include molded footbeds with enhanced arch support and targeted cushioning zones.

- Outsole Construction and Material

While the outsole primarily provides traction and durability, it also contributes to impact resistance. The outsole material, typically a vulcanized rubber compound, absorbs some of the impact force and distributes it across a wider area. The thickness and pattern of the outsole influence its impact resistance characteristics. Thicker outsoles and those with strategically placed grooves or patterns provide greater impact absorption. The integration of the outsole with the midsole and upper further enhances overall impact resistance, creating a cohesive and protective structure.

- Internal Reinforcements and Protective Elements

Internal reinforcements, such as heel counters and toe caps, provide additional structural support and impact protection. The heel counter, a rigid or semi-rigid structure surrounding the heel, prevents excessive heel movement and absorbs impact forces during landings. The toe cap protects the toes from abrasion and impact. These reinforcements, often constructed from durable materials like leather or synthetic polymers, enhance the overall impact resistance of the shoe. Strategic placement of these protective elements contributes to a safer and more comfortable skateboarding experience.

In summary, impact resistance in specialized skateboarding shoes is achieved through a combination of material selection, construction techniques, and strategic placement of cushioning and reinforcement elements. The effectiveness of these features directly influences the skater’s ability to perform consistently and safely, reducing the risk of injuries and enhancing overall performance. The continual refinement of impact resistance technologies remains a key focus in the design and development of high-performance skateboarding footwear.

Frequently Asked Questions

The following addresses common inquiries regarding specialized skateboarding footwear designed for professional use. These questions aim to clarify performance characteristics, material composition, and appropriate application.

Question 1: What distinguishes professional-grade skateboarding footwear from standard athletic shoes?

Professional-grade skateboarding footwear incorporates reinforced construction, enhanced cushioning systems, and specialized sole compounds optimized for the demands of skateboarding. Standard athletic shoes typically lack these features and are not designed to withstand the abrasion, impact, and grip requirements of skateboarding.

Question 2: What specific materials contribute to the durability of professional skateboarding footwear?

Durable materials commonly found in this footwear include suede, reinforced canvas, and vulcanized rubber. Strategic placement of reinforcing agents, such as Duracap, further enhances resistance to wear and tear in high-abrasion areas.

Question 3: How does the sole construction enhance grip in professional skateboarding shoes?

The sole employs a vulcanized construction process, which bonds the rubber sole to the upper for enhanced durability and grip. The rubber compound itself is formulated to provide optimal traction on skateboard decks. The tread pattern, often a waffle or herringbone design, further increases surface contact and grip.

Question 4: What types of cushioning systems are typically incorporated into professional skateboarding shoes?

Cushioning systems commonly include polyurethane (PU) or ethylene-vinyl acetate (EVA) midsoles, often augmented with gel inserts in high-impact areas. Molded sockliners or footbeds with enhanced arch support may also be present to provide additional comfort and impact absorption.

Question 5: How does the design of skateboarding footwear impact boardfeel?

Boardfeel, the tactile sensitivity between the foot and the board, is influenced by sole thickness and construction. Thinner soles generally enhance boardfeel, allowing for greater responsiveness and control. However, this often comes at the expense of cushioning and impact absorption.

Question 6: What role does support play in professional skateboarding footwear?

Support, encompassing ankle support, midsole stability, and heel counter reinforcement, is crucial for preventing injuries and maintaining stability during skateboarding. These features limit excessive foot movement, reducing the risk of ankle sprains and other lower limb injuries.

In summary, professional-grade skateboarding footwear prioritizes durability, grip, cushioning, boardfeel, and support to meet the specific demands of skateboarding. Understanding these attributes is essential for selecting appropriate footwear for optimal performance and injury prevention.

The subsequent section will explore emerging trends and innovations in the design and technology of skateboarding shoes.

vans pro skate shoes

This exploration has elucidated the core attributes defining skateboarding footwear designed for professional use. It underscored the interdependence of durability, grip, cushioning, boardfeel, support, and impact resistance, demonstrating how these elements contribute to performance enhancement and injury mitigation. Furthermore, the analysis detailed specific materials, construction techniques, and technological innovations employed to optimize these characteristics, emphasizing the ongoing evolution of skate shoe design.

As skateboarding continues to evolve, so too will the demands placed on its specialized footwear. A continued commitment to research, development, and innovation remains crucial for ensuring that footwear technology keeps pace with the evolving needs of skateboarders, furthering both performance and safety. Such advancements ultimately contribute to the progression of skateboarding as a whole.