Protective footwear integrating a reinforced toe cap into the design of skateboarding shoes offers impact resistance. These specialized shoes combine the functionality of safety footwear with the aesthetics and performance characteristics required for skateboarding. Such footwear aims to protect the wearer’s toes from injuries caused by impacts or compression, commonly encountered during skateboarding activities or in environments where foot protection is necessary. An example is footwear designed for warehouse work, also suitable for skateboarding after work hours.

The incorporation of a hardened toe provides a crucial safety feature, mitigating the risk of serious foot injuries in hazardous environments. This is particularly beneficial in settings where heavy objects may be present or where the potential for accidental impacts exists. Historically, the development of safety footwear has focused on industrial applications; however, the adaptation of these protective elements into recreational footwear reflects a growing awareness of the need for foot safety in various activities. The use of such footwear can provide peace of mind and reduce the likelihood of debilitating injuries.

The following sections will delve deeper into the construction, applications, and specific features of reinforced skateboarding footwear, along with considerations for selecting appropriate protective gear. Further, this article will examine relevant safety standards and explore the evolving landscape of foot protection in both occupational and recreational contexts.

Guidance on Reinforced Skate Footwear

This section provides essential considerations for selecting and utilizing footwear designed with integrated toe protection for skateboarding and related activities.

Tip 1: Assess Environmental Hazards: Prior to selecting footwear, carefully evaluate the potential hazards present in the intended environment. Consider the presence of heavy objects, impact risks, and compression dangers.

Tip 2: Prioritize Fit and Comfort: Ensure the selected footwear provides a secure and comfortable fit. Ill-fitting footwear can compromise safety and hinder performance. A proper fit minimizes foot movement within the shoe, reducing the risk of blisters and enhancing stability.

Tip 3: Examine Construction Quality: Thoroughly inspect the construction of the footwear, paying attention to the quality of materials and the integrity of the toe cap integration. Look for durable stitching and robust bonding between the upper and sole.

Tip 4: Verify Safety Standards Compliance: Confirm that the footwear meets relevant safety standards and certifications, such as ASTM F2413. This ensures that the toe cap provides adequate protection against impact and compression forces.

Tip 5: Consider Sole Traction: Evaluate the outsole’s traction capabilities. A slip-resistant sole is crucial for maintaining stability and preventing falls, particularly on smooth or uneven surfaces.

Tip 6: Evaluate Ankle Support: For activities involving higher levels of impact or potential for ankle injury, prioritize footwear that offers adequate ankle support. High-top designs generally provide greater stability than low-top alternatives.

Tip 7: Conduct Regular Inspections: Routinely inspect the footwear for signs of wear and tear, including cracks, abrasions, and loose components. Replace the footwear if significant damage is detected to maintain its protective capabilities.

Adhering to these guidelines can significantly enhance the safety and performance of skateboarding and related activities, minimizing the risk of foot injuries.

The following sections will delve into the proper maintenance and storage of reinforced skate footwear, as well as exploring advanced protective technologies.

1. Impact Resistance

Impact resistance is a fundamental attribute of reinforced skateboarding footwear, directly influencing its ability to safeguard the wearer’s feet. The inclusion of a hardened toe cap is specifically designed to mitigate the effects of forceful impacts, a common hazard in skateboarding environments. Direct contact with hard surfaces, collisions with objects, and the potential for dropped items all pose significant risks to the feet. The level of impact resistance, often measured in Joules and verified by industry standards, determines the maximum force the toe cap can withstand before deforming or failing, thus protecting the toes from serious injury.

The connection between impact resistance and these shoes is causal: the hardened toe cap provides the resistance, mitigating the potential for injury. Without adequate impact resistance, the footwear becomes significantly less effective in protecting the foot from trauma. For example, a skateboarder attempting a trick might misjudge their landing, resulting in the board impacting their foot with considerable force. Footwear with a sufficiently high impact resistance rating will absorb and disperse the energy of the impact, preventing fractures, contusions, or other severe injuries. In industrial settings, an employee using these shoes could be protected if a heavy item falls on their foot, reducing injury.

Understanding the practical significance of impact resistance is crucial for selecting appropriate protective footwear. Skaters and workers must prioritize footwear that meets or exceeds the relevant safety standards to ensure adequate protection in their specific environments. Challenges in achieving optimal impact resistance include maintaining flexibility and comfort, as stiffer materials may offer greater protection but reduce maneuverability. Further research and development efforts are continually focused on improving the balance between protection, comfort, and performance in reinforced skateboarding footwear.

2. Toe Protection Standard

The Toe Protection Standard constitutes a critical benchmark for safety footwear, particularly relevant in the design and manufacture of reinforced skateboarding shoes. This standard dictates the minimum requirements for impact and compression resistance that the toe cap of such footwear must meet to ensure adequate protection against workplace or recreational hazards.

- Impact Resistance Rating

The Impact Resistance Rating, typically defined by standards like ASTM F2413, specifies the amount of impact energy the toe cap must withstand without collapsing or fracturing. For instance, a shoe certified under this standard might be required to resist an impact of 101.7 Joules (75 foot-pounds). In the context of reinforced skateboarding shoes, this rating is vital for protecting the wearer’s toes from injuries caused by collisions with skateboards, obstacles, or dropped objects.

- Compression Resistance Rating

The Compression Resistance Rating establishes the minimum compressive load the toe cap must endure without deforming to a specified extent. This rating is equally crucial, as it safeguards the toes from injuries resulting from compressive forces, such as when a heavy object rolls onto the foot. An example would be a requirement to withstand a static load of 11,121 Newtons (2,500 pounds). When manufacturing skate shoes, it means safeguarding against injuries from dropped or rolled-over objects.

- Material Specifications

The standard also dictates the materials used in the construction of the toe cap, ensuring they possess the necessary strength and durability to meet the required impact and compression ratings. Common materials include steel, aluminum alloy, and composite materials. These materials must undergo rigorous testing to verify their compliance with the standard. For skate shoes, maintaining the structural integrity of the toe cap during skateboarding maneuvers depends on the selection of high quality materials.

- Testing Protocols

Adherence to the Toe Protection Standard involves standardized testing protocols to assess the performance of the toe cap under various conditions. These tests typically include impact tests, compression tests, and puncture resistance tests. The results of these tests are used to determine whether the footwear meets the minimum requirements of the standard. Skate shoes undergo rigorous testing to ensure they comply with safety regulations. Testing is a measure for preventing injuries.

These aspects collectively contribute to the overall effectiveness of skateboarding shoes in protecting the wearer’s feet. By adhering to the Toe Protection Standard, manufacturers can ensure that their products provide a reliable level of safety, reducing the risk of foot injuries in hazardous environments. The certification of skate shoes ensures safety and injury prevention in skating activities.

3. Sole Grip Composition

The composition of the sole in reinforced skateboarding footwear significantly influences the wearer’s ability to maintain control and stability during skateboarding activities. In this context, sole grip is not merely a feature; it is an integral safety component, especially when combined with the protective elements of a hardened toe.

- Rubber Compound Formulation

The specific formulation of the rubber compound dictates the coefficient of friction between the sole and the skateboard deck or ground surface. Formulations incorporating higher levels of silica or specialized polymers tend to exhibit enhanced grip properties. For example, vulcanized rubber compounds are frequently employed due to their superior grip and durability. In reinforced skateboarding shoes, this translates to improved board feel and control, reducing the risk of slippage and enhancing maneuverability.

- Tread Pattern Design

The tread pattern design further contributes to the sole’s grip capabilities. Deep, multi-directional grooves or sipes can improve traction on various surfaces, including smooth concrete or rough asphalt. Herringbone or waffle patterns are commonly used to maximize surface contact and enhance grip. The presence of such patterns on a reinforced skateboarding shoe provides additional stability and reduces the likelihood of losing control during tricks or maneuvers.

- Sole Hardness and Flexibility

The hardness and flexibility of the sole impact its ability to conform to the surface and maintain consistent contact. Softer, more flexible soles generally offer better grip, particularly on uneven surfaces. However, excessive flexibility can compromise stability and reduce the lifespan of the sole. A balance between hardness and flexibility is crucial for optimizing grip and durability in reinforced skateboarding shoes. For example, a slightly stiffer sole may be preferred for performing ollies, as it provides a more stable platform.

- Bonding and Construction Techniques

The methods used to bond the sole to the upper of the shoe also play a role in its overall grip performance. A secure and durable bond prevents separation between the sole and upper, ensuring consistent contact and grip. Vulcanization, a process that bonds the rubber sole to the shoe through heat and pressure, is often used to create a strong and lasting connection. With the enhanced toe, its important to make sure that the overall structure is well built to prevent injury.

These interconnected elements of sole grip composition collectively determine the effectiveness of reinforced skateboarding footwear in providing traction, stability, and control. A well-designed sole enhances both safety and performance, enabling skaters to execute maneuvers with greater confidence and reducing the risk of accidents. The integration of a hardened toe underscores the importance of comprehensive foot protection in skateboarding, where injuries are a persistent concern.

4. Durability and Construction

The longevity and protective capacity of reinforced skateboarding shoes are intrinsically linked to the durability of their constituent materials and the robustness of their construction. These factors collectively determine the footwear’s ability to withstand the rigorous demands of skateboarding while providing essential toe protection.

- Material Selection for Uppers

The selection of materials for the uppers directly influences the shoe’s resistance to abrasion, tearing, and weathering. High-quality leather, suede, or reinforced synthetic fabrics are often employed to provide a durable and protective outer layer. For instance, a reinforced nylon canvas can offer enhanced abrasion resistance compared to standard cotton canvas. The choice of upper material affects not only the shoe’s lifespan but also its ability to shield the foot from impacts and environmental hazards, particularly in conjunction with a hardened toe cap.

- Toe Cap Integration Techniques

The method used to integrate the hardened toe cap into the shoe’s construction is crucial for maintaining its structural integrity. Secure stitching, bonding, or molding techniques are employed to ensure that the toe cap remains firmly attached to the upper, even under extreme stress. For example, a molded polyurethane toe cap that is directly fused to the upper provides a more durable and seamless connection than a toe cap that is simply stitched on. The integration technique directly impacts the toe cap’s ability to provide consistent protection over the lifespan of the shoe.

- Sole Attachment Methods

The manner in which the sole is attached to the upper affects the shoe’s overall durability and resistance to separation. Vulcanization, a process that bonds the rubber sole to the upper through heat and pressure, is commonly used to create a strong and lasting connection. Alternatively, stitching or adhesive bonding may be employed. A well-executed sole attachment method ensures that the sole remains firmly connected to the upper, even during high-impact activities, thereby maintaining the shoe’s structural integrity and protective capabilities. With a steel toe, the rest of the shoe must be built to last.

- Reinforcement and Stitching Patterns

Strategic reinforcement in high-stress areas, such as the ollie pad and heel counter, can significantly enhance the shoe’s durability. Similarly, the use of reinforced stitching patterns, such as double or triple stitching, can prevent seams from unraveling or tearing under stress. The placement and density of stitching directly influence the shoe’s ability to withstand the forces generated during skateboarding, extending its lifespan and maintaining its protective qualities.

The durability and construction of reinforced skateboarding shoes are not merely aesthetic considerations; they are fundamental determinants of safety and longevity. The careful selection of materials, the integration of protective elements, and the implementation of robust construction techniques all contribute to the footwear’s ability to withstand the rigors of skateboarding while providing essential protection to the wearer’s feet.

5. Comfort and Fit

The aspects of comfort and fit are crucial when considering reinforced skateboarding shoes. These factors impact not only the wearer’s performance but also their long-term foot health and safety. A poorly fitting shoe can negate the protective benefits of the reinforced toe, leading to discomfort, blisters, and potential injuries.

- Internal Shoe Volume and Shape

The internal volume and shape of reinforced skateboarding shoes must accommodate the natural contours of the foot while also providing adequate space for the toes. Insufficient volume can result in pressure points and discomfort, while an ill-suited shape can lead to instability and impaired foot mechanics. For instance, a shoe with a narrow toe box may compress the toes, increasing the risk of blisters or nerve damage. Proper volume and shape are essential for maintaining foot health and maximizing comfort during extended periods of wear.

- Insole Design and Material

The insole plays a significant role in cushioning and supporting the foot. Insoles made from high-density foam or gel materials can absorb impact forces and reduce stress on the joints. The design of the insole, including arch support and heel cup contours, can further enhance comfort and stability. A poorly designed or worn-out insole can compromise foot support, leading to fatigue and potential injuries. A high-quality insole is essential for maintaining foot comfort and reducing the risk of overuse injuries.

- Padding and Lining Materials

The padding and lining materials used in the construction of reinforced skateboarding shoes directly affect comfort and breathability. Soft, moisture-wicking materials can minimize friction and prevent the buildup of sweat, reducing the risk of blisters and skin irritation. Adequate padding around the ankle collar and tongue can provide additional comfort and support. The selection of appropriate padding and lining materials is critical for maintaining foot comfort and preventing skin issues during prolonged use.

- Lacing System and Adjustability

The lacing system and overall adjustability of the shoe contribute to a secure and customized fit. A well-designed lacing system allows the wearer to fine-tune the fit, providing optimal support and stability. Features such as padded tongues and gusseted construction can further enhance comfort and prevent debris from entering the shoe. A properly adjusted lacing system is essential for ensuring a secure and comfortable fit, maximizing performance and minimizing the risk of injuries.

These elements of comfort and fit are not merely secondary considerations in reinforced skateboarding shoes; they are integral to the overall performance and safety of the footwear. A shoe that fails to provide adequate comfort and fit can compromise the protective benefits of the reinforced toe, increasing the risk of foot injuries and hindering performance. Prioritizing comfort and fit is essential for ensuring long-term foot health and maximizing the effectiveness of reinforced skateboarding shoes.

Frequently Asked Questions About Steel Toe Skate Shoes

This section addresses common inquiries concerning protective skateboarding footwear, providing clarity on their features, benefits, and applications.

Question 1: Are steel toe skate shoes suitable for all types of skateboarding?

Steel toe skate shoes are generally suitable for skateboarding activities where there is an elevated risk of foot injury due to impact or compression. However, their added weight and stiffness may affect board feel and maneuverability, potentially making them less ideal for technical skateboarding requiring maximum flexibility.

Question 2: Do steel toe skate shoes comply with safety standards?

Reputable manufacturers of steel toe skate shoes ensure their products comply with relevant safety standards, such as ASTM F2413 in the United States. Compliance with these standards guarantees that the footwear provides a minimum level of protection against impact and compression forces.

Question 3: Can steel toe skate shoes be used in industrial or construction settings?

Steel toe skate shoes may be suitable for use in certain industrial or construction settings, provided they meet the specific safety requirements of the work environment. However, it is essential to verify that the footwear is certified for the intended application and provides adequate protection against all potential hazards.

Question 4: How do steel toe skate shoes affect board feel and performance?

The presence of a steel toe cap can alter the board feel and performance of skateboarding shoes. The added weight and stiffness may reduce sensitivity and make it more challenging to perform certain tricks. Skateboarders should consider these factors when selecting protective footwear and prioritize models that balance safety with performance.

Question 5: What materials are commonly used in the construction of steel toe skate shoes?

Steel toe skate shoes typically incorporate a combination of durable materials, including leather, suede, canvas, and synthetic fabrics. The toe cap itself is usually made of steel or a composite material, while the outsole is often constructed from vulcanized rubber for enhanced grip and durability.

Question 6: How should steel toe skate shoes be maintained and cared for?

Steel toe skate shoes should be cleaned regularly to remove dirt and debris. Avoid harsh chemicals or abrasive cleaners that could damage the materials. Allow the shoes to air dry completely after use, and store them in a cool, dry place to prevent deterioration. Inspect the shoes periodically for signs of wear and tear, and replace them as needed to maintain their protective capabilities.

The implementation of protective skateboarding footwear significantly minimizes the risk of injury. These answers cover the essential aspects of these shoes.

The next section will delve into relevant safety standards and explore the evolving landscape of foot protection in both occupational and recreational contexts.

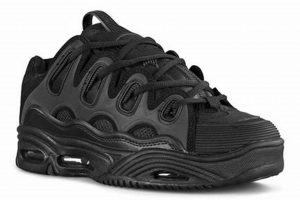

Steel Toe Skate Shoes

This exploration has delineated the multifaceted nature of footwear designed to combine skateboarding functionality with industrial safety. The integration of a hardened toe cap, while offering a critical layer of protection against impact and compression, necessitates careful consideration of comfort, fit, and performance characteristics. Adherence to established safety standards, such as those set forth by ASTM, remains paramount in ensuring the efficacy of these specialized shoes. Key considerations include material selection, construction techniques, and the influence of design elements on both board feel and maneuverability.

The adoption of steel toe skate shoes represents a conscious decision to mitigate risk without entirely sacrificing the nuances of skateboarding. While these shoes may not be universally optimal for all skateboarding disciplines, they offer a viable solution for environments where the potential for foot injury is elevated. Moving forward, continued innovation in materials and construction is essential to further refine the balance between protection, performance, and user experience. Prioritizing foot safety should remain a central tenet in both occupational and recreational pursuits.