The fundamental component described facilitates movement across surfaces through a rolling mechanism integrated into footwear or boards. These devices are typically constructed from durable materials such as polyurethane or rubber, and their dimensions and hardness vary based on the intended application. An example involves recreational activities and competitive sports.

This rolling technology offers individuals an efficient and enjoyable means of locomotion, contributing to physical fitness and recreational enjoyment. Historically, advancements in materials science and engineering have significantly improved the performance characteristics, resulting in enhanced speed, maneuverability, and durability. This, in turn, has broadened the appeal and accessibility of activities reliant on this technology.

The following sections will delve into the specific applications, maintenance procedures, and technological advancements surrounding the aforementioned mechanisms. Subsequent analyses will consider the impact of these developments on both recreational and competitive arenas.

Guidance on Utilizing Rolling Footwear and Boards

The following suggestions aim to optimize performance and safety when engaging with equipment employing rolling mechanisms for locomotion.

Tip 1: Equipment Assessment: Prior to each use, rigorously inspect all components for wear or damage. Pay specific attention to the integrity of the rolling elements and their attachment points. Replace compromised parts immediately.

Tip 2: Surface Selection: Exercise caution when selecting the terrain. Smooth, paved surfaces offer optimal conditions. Avoid areas with excessive debris, cracks, or unevenness, as these can impede motion and increase the risk of accidents.

Tip 3: Protective Gear: Always employ appropriate protective measures. Helmets, knee pads, elbow pads, and wrist guards significantly mitigate the potential for injury during falls or collisions.

Tip 4: Skill Progression: Develop proficiency incrementally. Begin with fundamental techniques in controlled environments. Gradually advance to more challenging maneuvers as competence increases. Avoid attempting complex stunts beyond current ability.

Tip 5: Environmental Awareness: Maintain constant vigilance of surroundings. Be cognizant of pedestrians, vehicles, and other potential hazards. Adhere to all applicable traffic regulations and local ordinances.

Tip 6: Weight Distribution and Balance: Practice maintaining proper weight distribution and balance. This enhances control, stability, and maneuverability. Distribute weight evenly across the feet, keeping the center of gravity low to the ground.

Tip 7: Maintenance Schedule: Implement a routine maintenance schedule. Regularly clean and lubricate the rolling components to ensure smooth operation and prolonged lifespan. Address any issues promptly to prevent further degradation.

Adherence to these guidelines promotes a safer and more enjoyable experience. Prioritizing safety and responsible utilization maximizes the benefits of this activity.

The subsequent section will address specific techniques and advanced considerations for proficient usage.

1. Rolling Resistance

Rolling resistance directly influences the efficiency and speed capabilities of equipment relying on rolling components. It is the force resisting motion when an element rolls on a surface. In the context of these devices, higher rolling resistance necessitates greater energy expenditure to maintain a given velocity, ultimately diminishing performance. Conversely, minimizing this resistance translates into improved speed and reduced exertion for the user. Several factors contribute to this phenomenon. These include the material properties of the roller and the surface it traverses, bearing efficiency, and overall mechanical construction. For instance, using rollers with a high coefficient of friction on a rough surface markedly increases energy loss due to deformation and friction. Similarly, inadequately lubricated or damaged bearings amplify resistance, hindering smooth rotation.

Understanding and mitigating rolling resistance is of paramount importance in various applications. In recreational contexts, a reduction in resistance allows for a more effortless and enjoyable experience. In competitive settings, even marginal improvements can translate to significant advantages. Optimizing tire inflation in cycling, for instance, directly reduces the contact area with the road, lowering resistance and improving speed. Choosing appropriate bearing types and conducting regular maintenance further contribute to minimizing frictional losses. Moreover, surface preparation plays a critical role; smooth, clean surfaces inherently present less resistance than rough or uneven ones. Therefore, the selection of the right component for the right environment is of paramount importance.

In summary, managing rolling resistance is essential for maximizing the performance and efficiency of equipment utilizing rolling locomotion. By carefully considering material properties, bearing quality, surface conditions, and maintenance practices, it is possible to significantly reduce energy losses and enhance both recreational and competitive experiences. Ignoring this factor can lead to decreased speed, increased exertion, and premature wear of components, highlighting the practical significance of this understanding in the context of these mobile devices. This understanding ultimately contributes to the refinement and evolution of designs and strategies.

2. Bearing Precision

Bearing precision significantly influences the performance and longevity of rolling footwear and boards. The term refers to the dimensional accuracy and manufacturing quality of the bearings integrated into these devices. High-precision bearings exhibit minimal internal clearances and consistent roundness, enabling smoother and more efficient rolling action. Conversely, bearings with poor precision introduce friction, vibration, and premature wear, diminishing the overall user experience and potentially compromising safety. The connection is causal: improved bearing precision directly results in reduced rolling resistance and increased speed capabilities. Consider two identical boards, one equipped with ABEC 1 rated bearings and the other with ABEC 7 rated bearings. The latter, possessing higher precision, will demonstrably exhibit superior rolling efficiency and a smoother ride due to reduced internal friction.

The practical implications of bearing precision extend beyond mere performance metrics. Precise bearings contribute to enhanced control and stability, particularly at higher velocities. This is crucial for activities where precise maneuvers and quick responses are required, such as competitive skating or navigating crowded environments. The durability of the equipment is also directly affected. Bearings subjected to excessive stress due to manufacturing imperfections are prone to early failure, necessitating frequent replacements and increased maintenance costs. Regular maintenance is also essential, however it will not compensate for poor intrinsic bearing quality. For example, bearings with low precision could become damaged from regular use and expose the interior to dust, dirt, and small particles that further degrade precision.

In summary, bearing precision constitutes a critical element in the design and functionality of rolling footwear and boards. Its influence spans performance, durability, safety, and user satisfaction. Prioritizing high-precision bearings, coupled with diligent maintenance practices, represents a sound investment that yields tangible benefits in terms of both enhanced performance and prolonged equipment lifespan. The continuous pursuit of advancements in bearing technology remains pivotal for optimizing the rolling experience and pushing the boundaries of performance in various recreational and competitive applications. The correlation is clear, and cannot be ignored if the objective is peak performance or simply a safer experience.

3. Material Hardness

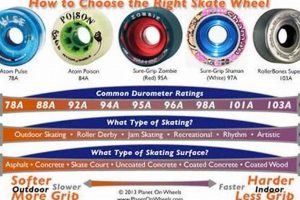

Material hardness is a critical determinant of performance and longevity in the context of rolling footwear and boards. Specifically, the durometer, measured on scales such as Shore A, quantifies a material’s resistance to indentation. Within these applications, the interplay between roller hardness and surface conditions dictates grip, speed, and wear characteristics. A softer roller compound, for example, deforms more readily upon contact, yielding increased frictional force and superior grip. This attribute is particularly advantageous on slick or uneven surfaces where enhanced traction is paramount. However, the trade-off involves elevated rolling resistance and accelerated abrasion, potentially shortening the lifespan of the roller. Conversely, a harder compound minimizes deformation, reducing rolling resistance and increasing speed potential. However, diminished grip may compromise control, particularly on challenging terrain. A practical illustration involves comparing rollers utilized in aggressive inline skating versus those employed in longboarding. Aggressive skating favors softer compounds (e.g., 88A-92A durometer) for improved grip on ramps and rails, while longboarding often utilizes harder compounds (e.g., 78A-82A durometer) to prioritize speed and glide over long distances.

The selection of an appropriate hardness grade also depends significantly on the intended application and the user’s skill level. Novice users often benefit from softer compounds that offer greater stability and control during initial learning phases. As proficiency increases, transitioning to harder compounds can unlock enhanced speed and responsiveness. The mechanical behavior extends beyond grip and speed considerations. Harder compounds generally exhibit superior resistance to abrasion and deformation under heavy loads, rendering them suitable for applications involving jumps, impacts, and prolonged use. Softer compounds, while offering enhanced grip, may be more susceptible to chunking or tearing under similar conditions. This leads to the replacement of rollers. This emphasizes the importance of assessing individual needs and environmental factors when selecting roller material hardness. The optimal selection is rarely a matter of pure performance but rather a balancing act between grip, speed, durability, and control based on the particular task.

In summary, material hardness is a pivotal characteristic governing the performance and durability of rollers in rolling footwear and boards. The selection of an appropriate hardness grade necessitates careful consideration of surface conditions, user skill level, intended application, and the inherent trade-offs between grip, speed, and wear resistance. Ignoring this aspect can lead to suboptimal performance, compromised safety, and premature equipment failure. Ongoing research and development efforts continue to explore novel polymer blends and manufacturing techniques aimed at optimizing roller properties across a broader spectrum of applications. The understanding and meticulous selection of roller hardness remain fundamental to both recreational enjoyment and competitive success.

4. Wheel Diameter

Wheel diameter is a critical specification in the design and selection of rolling footwear and boards. This dimension directly influences speed, acceleration, maneuverability, and overall performance characteristics. Its impact stems from the physical relationship between circumference, rotational velocity, and linear distance traveled. Changes in wheel diameter necessitate corresponding adjustments in other design parameters to achieve desired performance outcomes.

- Speed and Momentum

Larger diameter wheels generally exhibit greater top-end speed due to the increased linear distance covered per revolution. The trade-off involves a higher moment of inertia, requiring more force to initiate movement and achieve rapid acceleration. Conversely, smaller diameter wheels facilitate quicker acceleration but may sacrifice top speed due to a reduced distance covered per revolution. For example, downhill skaters often prefer larger wheels for maintaining high velocities, while park skaters often prioritize smaller wheels for rapid starts and stops.

- Maneuverability and Responsiveness

Smaller wheel diameters typically enhance maneuverability and responsiveness. The reduced size translates to a lower moment of inertia, enabling quicker turns and directional changes. This characteristic is particularly advantageous in environments requiring precise control and agility, such as skate parks or slalom courses. Larger wheels, while offering superior stability, may feel less responsive and require more effort to execute sharp turns. This difference in responsiveness can influence the choice of equipment depending on the user’s skating style and the demands of the environment.

- Surface Contact and Grip

Wheel diameter influences the contact patch between the roller and the surface. Larger diameter wheels tend to have a larger contact patch, potentially increasing grip and stability, especially on uneven surfaces. A larger contact patch disperses weight over a greater area, reducing pressure and improving traction. Smaller diameter wheels have a smaller contact patch, which may decrease grip but can improve responsiveness on smooth surfaces. The relationship between contact patch and performance is also influenced by wheel durometer (hardness), as softer wheels tend to deform more, increasing the contact patch regardless of diameter.

- Obstacle Clearance and Roll-over Ability

Larger wheel diameters inherently offer improved obstacle clearance and roll-over capability. Their increased size allows them to more easily navigate over cracks, pebbles, and other minor surface irregularities. This is particularly relevant in urban environments or on surfaces with imperfections. Smaller wheels are more susceptible to being impeded by these obstacles, potentially leading to instability or falls. The ability to roll over obstacles smoothly contributes to a more comfortable and safer riding experience, particularly for long-distance or recreational skating.

These facets illustrate the significance of wheel diameter as a design parameter in rolling footwear and boards. The optimal diameter is contingent upon the intended application, user skill level, and desired performance characteristics. Selection requires balancing speed, maneuverability, grip, and obstacle clearance to meet specific needs. Understanding these considerations is crucial for maximizing performance and optimizing the user experience.

5. Axle Integrity

Axle integrity is a critical factor governing the safe and efficient operation of any rolling mechanism, including those used in rolling footwear and boards. The axle serves as the central pivot point around which the wheel or rolling element rotates. Its structural soundness directly affects the stability, maneuverability, and overall safety of the equipment. A compromised axle, exhibiting bends, cracks, or material fatigue, can lead to catastrophic failure, resulting in loss of control and potential injury. Consider a scenario where an axle fractures during high-speed use; the sudden loss of wheel support would almost certainly precipitate a fall, potentially with severe consequences. Thus, the integrity of this component is paramount.

The connection between axle integrity and the performance of rolling footwear and boards is both direct and consequential. A properly functioning axle ensures smooth and consistent rotation, minimizing friction and maximizing energy transfer. Deviations from perfect alignment or structural weaknesses introduce resistance, reducing speed and responsiveness. The material selection, manufacturing processes, and regular maintenance procedures are all critical determinants of axle lifespan. For example, axles constructed from high-strength alloys and subjected to rigorous quality control standards are inherently more resistant to fatigue and failure than those made from inferior materials or manufactured with inadequate precision. Regular inspection for signs of wear or damage is essential for identifying potential problems before they escalate into critical failures.

In summary, axle integrity is an indispensable element for ensuring the safety, performance, and longevity of rolling footwear and boards. The structural integrity of this component directly impacts the stability, maneuverability, and overall reliability of the equipment. Regular inspections, coupled with the use of high-quality materials and sound manufacturing practices, are essential for maintaining axle integrity and mitigating the risk of catastrophic failure. The practical significance of understanding this relationship cannot be overstated, as it directly contributes to user safety and enhances the overall riding experience.

Frequently Asked Questions

The following section addresses common inquiries regarding the selection, maintenance, and safe usage of devices equipped with rolling mechanisms.

Question 1: What factors should influence the selection of rolling footwear or a board for a beginner?

For novice users, stability and control are paramount. Select equipment with smaller diameter wheels and a softer durometer. This configuration provides enhanced maneuverability and grip, facilitating easier learning and reducing the risk of falls. Ample protective gear should also be mandatory.

Question 2: How often should the bearings in rolling footwear or boards be cleaned and lubricated?

Bearing maintenance frequency depends on usage intensity and environmental conditions. However, a general guideline suggests cleaning and lubrication every 20-40 hours of use, or more frequently if exposed to dirt, water, or abrasive surfaces. Neglecting maintenance can lead to increased friction and premature bearing failure.

Question 3: What are the potential risks associated with using rolling footwear or boards on uneven or rough surfaces?

Uneven or rough surfaces can significantly impair control, increase the risk of falls, and accelerate wear on wheels and bearings. Operating on such surfaces requires heightened awareness and advanced skills. Protective gear becomes even more critical in these conditions.

Question 4: How does wheel diameter affect the performance of rolling footwear or boards?

Larger wheel diameters generally provide increased speed and momentum, but reduced acceleration and maneuverability. Smaller wheel diameters offer quicker acceleration and enhanced maneuverability, but may limit top speed. The optimal wheel diameter depends on the intended application and the user’s skating style.

Question 5: What safety precautions should be taken when using rolling footwear or boards in urban environments?

Urban environments present numerous hazards, including pedestrian traffic, vehicular traffic, and obstacles. Users must exercise extreme caution, maintain constant vigilance, and adhere to all applicable traffic regulations. Wearing bright clothing and using reflective gear can enhance visibility.

Question 6: How can the lifespan of rollers on rolling footwear and boards be maximized?

Roller lifespan can be extended through proper maintenance practices, including regular cleaning, lubrication, and rotation. Avoidance of abrasive surfaces and excessive exposure to water or chemicals also contributes to longevity. Prompt replacement of worn or damaged rollers prevents further damage to other components.

Prioritizing safety, maintenance, and informed equipment selection is essential for a positive and sustainable experience with rolling footwear and boards.

The subsequent segment will explore advanced techniques and specialized applications within this domain.

Conclusion

The preceding analysis has comprehensively examined the functionalities and factors impacting equipment relying on rolling mechanisms. Key elements, including rolling resistance, bearing precision, material hardness, wheel diameter, and axle integrity, were dissected to provide a thorough understanding of their individual and collective influence on performance and safety. Furthermore, a series of frequently asked questions were addressed to clarify common points of concern for both novice and experienced users of these devices. The objective was to provide a clear, informative resource on the properties of a skate roller.

Continued advancements in material science, engineering design, and safety standards will undoubtedly shape the future of activities that rely on the skate roller. It is incumbent upon users, manufacturers, and regulatory bodies to remain informed of these developments and to prioritize safety, performance, and environmental responsibility in their respective roles. The pursuit of innovation should always be tempered with a commitment to ensuring the well-being of individuals and the sustainability of the activity itself. It should also be noted that this document should not be seen as complete. There are multiple other considerations to take into account when designing, building or using equipment based on rolling technology.