Wheels designed specifically for outdoor roller skating necessitate a durable construction and a softer durometer. This combination allows for effective shock absorption and enhanced grip on varied and often uneven outdoor surfaces such as asphalt, concrete, or paved trails. Consider, for instance, wheels with a durometer rating between 78A and 85A, which are generally suited for outdoor use due to their increased flexibility.

The advantages of using appropriate wheels extend to improved rider comfort, reduced vibration, and prolonged wheel lifespan. Historically, skaters often used indoor wheels regardless of location, leading to premature wear and a less enjoyable skating experience. The development of wheels tailored for outdoor conditions represents a significant advancement in roller skating technology, contributing to both performance and safety.

The subsequent discussion will delve into the key characteristics of outdoor roller skating wheels, exploring factors such as durometer, size, material composition, and bearing compatibility. Understanding these elements is crucial for selecting the optimal wheels to suit individual skating styles and environmental conditions, ultimately enhancing the overall roller skating experience.

Guidance on Roller Skate Wheels for Outdoor Use

The following recommendations offer practical advice for selecting and maintaining wheels designed for outdoor roller skating. Adherence to these guidelines will contribute to enhanced performance, safety, and longevity of equipment.

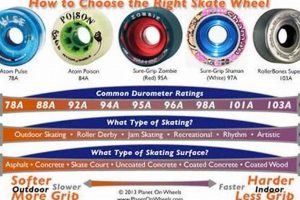

Tip 1: Prioritize Durometer Rating: Examine the durometer rating, typically denoted by a number followed by the letter “A”. Lower numbers indicate softer wheels, offering superior grip and shock absorption on rough outdoor surfaces. Wheels ranging from 78A to 85A are generally recommended for outdoor applications.

Tip 2: Consider Wheel Size: Larger diameter wheels generally roll more efficiently and maintain momentum better on outdoor terrain. Sizes between 62mm and 70mm are frequently selected for outdoor skating. However, ensure that the chosen size is compatible with the roller skate frame.

Tip 3: Evaluate Wheel Material: Polyurethane is the predominant material used in the manufacture of roller skate wheels. Formulations vary, affecting durability and performance. Seek out high-rebound polyurethane for optimal responsiveness and longevity.

Tip 4: Inspect for Wheel Wear Regularly: Periodic inspection of the wheels is essential to identify signs of wear, such as flat spots or uneven degradation. Rotate the wheels periodically to promote even wear patterns and extend their lifespan. Replacement should occur when performance is noticeably compromised.

Tip 5: Maintain Bearings Appropriately: Clean and lubricate the wheel bearings regularly to ensure smooth rolling and prevent premature failure. Accumulated dirt and debris can significantly impede performance. Use a bearing puller and appropriate cleaning solvents and lubricants.

Tip 6: Match Wheels to Skating Style: Aggressive skating styles or use on particularly rough surfaces may necessitate more durable wheels. Consider the specific demands of the intended application when making a selection.

The careful consideration of durometer, size, material, and regular maintenance practices will significantly enhance the outdoor roller skating experience. Implementing these recommendations contributes to improved performance, safety, and the overall lifespan of the equipment.

The subsequent sections will provide a detailed analysis of the technical specifications and performance characteristics of various wheel models available for outdoor roller skating.

1. Durometer (Softness)

Durometer, a measure of a wheel’s hardness, is a paramount consideration in selecting roller skate wheels for outdoor use. Its influence extends to grip, shock absorption, and overall riding comfort, impacting the skating experience significantly.

- Grip Optimization

Softer wheels, indicated by a lower durometer rating (e.g., 78A-82A), exhibit increased deformation upon contact with the ground. This deformation enhances the contact area, leading to greater grip on uneven or rough outdoor surfaces such as asphalt or concrete. This is particularly crucial for maintaining stability and control during maneuvers or while navigating varying terrain.

- Shock Absorption Capabilities

Outdoor surfaces typically present a greater degree of irregularities compared to indoor rinks. Softer durometer wheels provide improved shock absorption, mitigating the impact of bumps and vibrations. This reduces fatigue and enhances rider comfort during extended skating sessions. Stiffer wheels transmit more of the surface imperfections directly to the skater’s body.

- Wear Rate Considerations

While softer wheels offer enhanced grip and shock absorption, they generally exhibit a faster wear rate compared to harder wheels, especially on abrasive outdoor surfaces. This necessitates more frequent replacement. Conversely, harder wheels may last longer but provide a less comfortable and controlled ride. Selection involves a trade-off between performance characteristics and longevity.

- Rolling Resistance and Speed

Softer durometer wheels have a slightly higher rolling resistance compared to harder wheels on smooth surfaces. This can translate to a marginal reduction in speed and increased effort to maintain momentum. However, in outdoor environments with varied surface conditions, the increased grip and control afforded by softer wheels often outweigh the slight reduction in speed.

In conclusion, the selection of roller skate wheels for outdoor usage necessitates a careful evaluation of durometer based on the intended skating environment and individual preferences. A lower durometer promotes enhanced grip and shock absorption, crucial for safety and comfort, while acknowledging the trade-off of increased wear. The ideal durometer balances these factors to optimize the overall outdoor skating experience.

2. Wheel Size

Wheel size, measured in millimeters (mm), directly influences the performance characteristics of roller skate wheels designed for outdoor use. Larger diameter wheels, typically ranging from 62mm to 70mm for outdoor applications, exhibit a greater contact patch with the ground. This increased contact area enhances rolling efficiency and momentum maintenance, especially on irregular outdoor surfaces like asphalt or concrete. A smaller wheel, while offering increased maneuverability, may struggle to maintain speed and stability when encountering pebbles or cracks.

The practical significance of wheel size is evident in various outdoor skating scenarios. For instance, a skater utilizing smaller wheels (e.g., 58mm) on a smooth indoor rink might experience agility and responsiveness. However, when transitioning to an outdoor environment, the same skater could find that smaller wheels become easily obstructed by minor road imperfections, leading to a jarring ride and decreased speed. Conversely, a skater employing larger wheels (e.g., 65mm) outdoors would benefit from smoother roll-over capabilities and improved stability at higher speeds, though potentially sacrificing some agility in tighter turns.

The selection of appropriate wheel size for outdoor skating requires a compromise between maneuverability and rolling efficiency. Larger wheels are generally advantageous for distance skating and navigating uneven terrain, while smaller wheels may be preferable for skaters prioritizing agility and responsiveness. Understanding the cause-and-effect relationship between wheel size and skating performance empowers informed decisions, optimizing the outdoor skating experience. The challenge lies in determining the optimal balance point, tailored to individual skating style, skill level, and the typical skating environment.

3. Material Composition

The material composition of roller skate wheels exerts a decisive influence on their performance, particularly in outdoor environments. Polyurethane (PU) is the dominant material, but variations in its formulation impact durability, grip, rebound, and resistance to abrasion. High-rebound PU formulations, characterized by their ability to rapidly return to their original shape after deformation, are frequently employed in premium outdoor wheels. This property contributes to energy efficiency and reduces fatigue, as less energy is lost during each wheel rotation. The specific ester or ether base of the PU, as well as additives such as dyes or reinforcing agents, further modulate performance characteristics. For example, certain additives may enhance UV resistance, preventing premature degradation due to prolonged sun exposure, a significant concern for outdoor use.

Consider the contrasting performance of wheels made from generic or low-grade PU versus those utilizing specialized formulations. Lower-quality materials often exhibit reduced durability and a tendency to chunk or crack under stress, especially when encountering rough asphalt or debris. This leads to a compromised skating experience and necessitates more frequent wheel replacements. In contrast, wheels composed of high-rebound, abrasion-resistant PU maintain their integrity for a longer duration, providing a more consistent and predictable ride. Skaters navigating challenging outdoor terrains benefit directly from the superior performance characteristics of these advanced materials.

The material composition of outdoor roller skate wheels is not merely a static attribute; it’s a dynamic factor governing performance, durability, and overall skating experience. Selecting wheels crafted from high-quality, application-specific PU formulations is crucial for optimizing outdoor skating, maximizing the longevity of the wheels, and ensuring safety and control. While cost may be a consideration, the long-term benefits of superior materials often outweigh the initial investment. Further research into specific PU blends and their suitability for various outdoor skating conditions is ongoing, signifying the continued importance of material science in advancing roller skating technology.

4. Grip

Grip, defined as the frictional force between the wheel and the skating surface, is a critical determinant of performance and safety in roller skate wheels designed for outdoor use. The diverse nature of outdoor terrains, encompassing variations in texture, contaminants, and environmental conditions, necessitates a high degree of grip to maintain control and prevent slippage. Insufficient grip compromises maneuverability, braking effectiveness, and overall stability, increasing the risk of falls and injuries. The coefficient of friction between the wheel material and the ground directly influences grip, with softer durometer wheels generally providing superior traction on rough or uneven surfaces.

The significance of grip is demonstrably evident in various outdoor skating scenarios. For instance, traversing cracked asphalt or encountering loose gravel demands wheels capable of maintaining consistent contact with the surface. Wheels with inadequate grip would exhibit a tendency to slip or lose traction, particularly during turns or abrupt stops. This loss of control can lead to instability and potentially hazardous situations. Conversely, wheels with enhanced grip provide the skater with increased confidence and the ability to execute maneuvers safely and effectively, even on challenging terrains. Consider the application of specific wheel designs incorporating unique tread patterns or specialized compounds to maximize grip in wet or oily conditions, common occurrences in urban environments.

The optimization of grip in roller skate wheels for outdoor applications represents a continuing engineering challenge, balancing the trade-offs between grip, durability, and rolling resistance. While softer durometer wheels generally offer superior grip, they tend to exhibit accelerated wear rates, particularly on abrasive surfaces. Manufacturers often employ sophisticated material blends and innovative tread designs to mitigate this trade-off, striving to deliver wheels that provide both exceptional grip and extended lifespan. A comprehensive understanding of the principles governing grip, and its interplay with other performance parameters, is essential for selecting the optimal wheels to suit individual skating styles and environmental conditions, ultimately enhancing the overall roller skating experience.

5. Durability

Durability, representing the capacity of roller skate wheels to withstand wear, stress, and environmental factors over an extended period, is of paramount importance for outdoor applications. The abrasive nature of typical outdoor surfaces and exposure to diverse environmental conditions necessitate robust wheel construction. Premature wheel failure compromises safety, performance, and the overall skating experience.

- Material Hardness and Abrasion Resistance

The hardness and composition of the polyurethane material directly impact a wheel’s resistance to abrasion. Higher-quality polyurethane formulations with enhanced abrasion resistance will exhibit a slower wear rate when used on rough outdoor surfaces such as asphalt or concrete. Lower-grade materials are susceptible to chunking, cracking, and premature degradation, reducing wheel lifespan and performance.

- Environmental Degradation Resistance

Outdoor wheels are subject to prolonged exposure to sunlight, moisture, and temperature fluctuations. Formulations incorporating UV stabilizers and resistance to hydrolysis mitigate the damaging effects of these environmental factors. Wheels lacking these protective properties may exhibit premature cracking, discoloration, and a reduction in structural integrity.

- Bearing Housing Integrity

The integrity of the bearing housing within the wheel is crucial for maintaining proper bearing alignment and preventing premature bearing failure. Robust housing construction, utilizing high-strength materials and precise manufacturing tolerances, ensures that the bearings remain properly seated and protected from contaminants. Compromised bearing housings lead to increased friction, reduced rolling efficiency, and accelerated wear.

- Load-Bearing Capacity

Outdoor wheels must withstand significant dynamic loads imposed during skating, particularly during jumps, turns, and impacts with surface irregularities. Wheels with a high load-bearing capacity are less prone to deformation or structural failure under stress. Insufficient load-bearing capacity can result in wheel deformation, reduced rolling efficiency, and a potential safety hazard.

The facets of material hardness, environmental resistance, bearing housing integrity, and load-bearing capacity collectively define the durability of outdoor roller skate wheels. Selection of wheels incorporating robust materials and construction techniques is essential for ensuring longevity, safety, and sustained performance in demanding outdoor environments. The correlation between initial cost and long-term durability should be carefully considered, as higher-quality, more durable wheels may prove more economical over the lifespan of the equipment.

6. Rolling Resistance

Rolling resistance, the force opposing the motion of a rolling object, significantly impacts the efficiency and ease of outdoor roller skating. Wheels designed for external surfaces encounter a complex interplay of factors influencing this resistance. Surface irregularities, material deformation, and bearing friction all contribute to the energy dissipation experienced during each rotation. Consequently, skaters exert additional effort to maintain speed, potentially leading to fatigue and reduced skating distance.

The selection of wheel materials and design features profoundly affects rolling resistance. Softer durometer wheels, beneficial for grip on rough surfaces, tend to exhibit higher rolling resistance due to increased deformation and energy loss as they conform to surface imperfections. Conversely, harder wheels, while offering lower resistance on smooth surfaces, may provide inadequate grip on uneven terrain. Optimal wheel selection for outdoor skating necessitates a compromise, balancing the benefits of grip and shock absorption with the need for efficient rolling. Wheel size also plays a role; larger diameter wheels generally exhibit lower rolling resistance than smaller wheels, contributing to improved speed and reduced energy expenditure. For example, long-distance skaters prioritize larger diameter wheels with harder durometer to maximize efficiency, while recreational skaters may opt for softer wheels with greater shock absorption, accepting a slight increase in rolling resistance.

Understanding the relationship between rolling resistance and wheel characteristics is crucial for optimizing the outdoor skating experience. Selecting wheels appropriate for the intended skating environment, considering factors such as surface roughness, distance, and desired speed, enables skaters to minimize energy expenditure and maximize performance. Furthermore, proper maintenance, including regular bearing lubrication and wheel cleaning, reduces friction and contributes to lower rolling resistance. The practical significance of this understanding lies in the ability to make informed equipment choices, leading to enhanced comfort, efficiency, and overall enjoyment of outdoor roller skating.

Frequently Asked Questions

The following questions address common inquiries regarding roller skate wheels designed for outdoor use. This information aims to clarify misconceptions and provide a better understanding of relevant performance characteristics.

Question 1: What durometer range is most suitable for roller skate wheels used outdoors?

The generally accepted durometer range for optimal outdoor performance is between 78A and 85A. This range provides a balance of shock absorption and grip necessary for navigating varied outdoor surfaces.

Question 2: How does wheel size influence the outdoor roller skating experience?

Larger diameter wheels (62mm to 70mm) tend to roll more efficiently and maintain momentum better on outdoor terrain, while smaller wheels offer increased maneuverability. Selection depends on individual skating style and environmental conditions.

Question 3: Are all polyurethane formulations equally suitable for outdoor roller skate wheels?

No. High-rebound polyurethane is generally preferred for its responsiveness and longevity. Specialized formulations may also offer enhanced UV resistance and abrasion resistance.

Question 4: How frequently should outdoor roller skate wheels be inspected for wear?

Wheels should be inspected regularly for signs of wear, such as flat spots or uneven degradation. Frequency depends on usage intensity and the abrasiveness of the skating environment.

Question 5: Is bearing maintenance important for outdoor roller skate wheels?

Yes. Regular cleaning and lubrication of wheel bearings are essential for maintaining smooth rolling and preventing premature failure due to accumulated dirt and debris.

Question 6: Does skating style influence the choice of roller skate wheels for outdoor use?

Yes. Aggressive skating styles or frequent use on rough surfaces may necessitate more durable wheels compared to recreational skating on smoother surfaces.

Selecting appropriate roller skate wheels for outdoor use requires careful consideration of durometer, size, material, and intended skating style. Regular maintenance is crucial for optimizing performance and extending equipment lifespan.

The subsequent section will explore specific wheel models and provide a comparative analysis of their technical specifications.

Conclusion

This discussion has provided an in-depth exploration of roller skate wheels for outside, emphasizing the critical factors influencing performance, durability, and safety. Key considerations include durometer, wheel size, material composition, grip, rolling resistance, and environmental resilience. Understanding the interplay of these factors enables informed selection, optimizing the outdoor skating experience.

The continued development of advanced materials and innovative designs promises further enhancements in the performance and longevity of these wheels. Careful evaluation and appropriate maintenance remain essential for maximizing safety and enjoyment. A commitment to informed decision-making will ensure that roller skating remains a safe and rewarding activity for all participants.