Specialized footwear, designed for executing complex maneuvers on ice, represents a crucial component for athletes engaged in advanced skating disciplines. These consist of a reinforced boot, providing substantial ankle support, permanently affixed to a tempered steel blade. A primary function is enabling intricate movements, jumps, and spins demanded by competitive performances.

The employment of such equipment is fundamental for achieving high levels of performance and minimizing the risk of injury. Historical development reflects ongoing refinements in blade design, boot construction, and materials science, all geared towards optimizing control, responsiveness, and comfort. This evolution facilitates increasingly challenging athletic feats while extending the lifespan of the gear under rigorous conditions.

The subsequent sections will delve into specific features, maintenance protocols, and considerations for selecting appropriate equipment. These details are essential for understanding the intricacies of maximizing performance and safety on the ice. Furthermore, we will explore the impact of technological advancements and emerging trends in this specialized equipment sector.

Optimizing Performance

The selection, fitting, and maintenance of specialized skating boots and blades are critical to achieving optimal performance and preventing injuries. Adhering to the following guidelines contributes to both athletic success and equipment longevity.

Tip 1: Prioritize Professional Fitting: A fitting conducted by a qualified professional ensures proper sizing and support. Ill-fitting boots can impede performance and lead to blisters or other foot injuries.

Tip 2: Evaluate Blade Curvature and Radius: Blade geometry influences maneuverability. A larger radius of rocker facilitates gliding, while a smaller radius allows for tighter turns. The appropriate choice depends on the skater’s style and skill level.

Tip 3: Maintain Blade Sharpness: Regular sharpening is essential for optimal edge control. Dull blades compromise grip and increase the risk of falls. Sharpening frequency depends on usage and ice conditions.

Tip 4: Secure Boot Lacing: Proper lacing provides necessary ankle support. Ensure laces are tightened firmly but not excessively, allowing for adequate circulation.

Tip 5: Regularly Inspect Equipment: Conduct routine inspections for signs of wear and tear, including cracks in the boot, loose blades, or damaged laces. Prompt repairs can prevent more significant problems.

Tip 6: Implement Proper Storage: After each use, thoroughly dry both the boot and the blade to prevent rust and deterioration. Store in a well-ventilated area, using blade guards to protect the edges.

Tip 7: Consider Blade Alignment: Confirm blade alignment is correct. Misalignment can affect balance and make maneuvers more difficult. Adjustments may be necessary over time.

Consistent application of these guidelines ensures the skater benefits from optimal performance, extended equipment lifespan, and minimized risk of injury. These practices constitute a fundamental component of advanced skating proficiency.

The ensuing segments will further address specific adjustments, troubleshooting common issues, and recognizing the importance of professional guidance in equipment maintenance.

1. Blade Material Composition

The composition of the blade directly influences performance characteristics, durability, and overall effectiveness in professional figure ice skates. The selected materials determine edge quality, resistance to wear, and the ability to maintain sharpness over extended use. Understanding these factors is crucial for optimizing skating performance and equipment longevity.

- Carbon Content and Hardness

The percentage of carbon present in the steel alloy affects the blade’s hardness and its capacity to hold an edge. Higher carbon content generally results in a harder blade that retains sharpness longer. However, excessive carbon can increase brittleness, making the blade more susceptible to chipping or breakage under stress. The optimal balance is essential for maintaining performance in demanding skating routines.

- Alloy Composition and Corrosion Resistance

The inclusion of alloying elements, such as chromium and vanadium, enhances corrosion resistance and overall blade durability. Chromium forms a protective oxide layer on the steel surface, preventing rust and oxidation. Vanadium improves the steel’s strength and toughness. The specific alloy composition is carefully selected to withstand the harsh conditions encountered during ice skating, including moisture, temperature fluctuations, and repeated impacts.

- Tempering and Heat Treatment

The blade undergoes tempering and heat treatment processes to achieve the desired hardness and ductility. Tempering reduces brittleness by relieving internal stresses within the steel. Heat treatment involves controlled heating and cooling cycles to modify the steel’s microstructure, optimizing its mechanical properties. These processes are critical for ensuring the blade can withstand the stresses of high-impact landings and intricate maneuvers.

- Surface Finish and Friction Reduction

The surface finish of the blade impacts its friction coefficient and glide efficiency. A highly polished surface reduces friction, allowing for smoother and faster skating. However, the surface must also provide sufficient grip to maintain edge control during turns and jumps. Achieving the optimal balance between glide and grip requires careful attention to surface finishing techniques and the selection of appropriate polishing compounds.

In conclusion, the selection of appropriate materials, coupled with precise manufacturing processes, ensures the blades used on professional figure ice skates meet the exacting demands of competitive skating. These factors contribute directly to a skater’s ability to perform complex maneuvers with precision and confidence, while also extending the lifespan of the equipment under rigorous conditions.

2. Boot Ankle Support

Ankle support, provided by the boot component, is a critical determinant of performance and safety. Insufficient support compromises the skater’s ability to execute precise movements, increasing the risk of injury. Conversely, overly rigid support can restrict the skater’s range of motion, hindering artistic expression and technical execution. The construction materials, lacing system, and overall boot design collectively contribute to the level of support provided. For instance, boots crafted from multi-layered leather or synthetic materials, reinforced with strategically placed padding, offer a balanced combination of stability and flexibility. Similarly, a well-designed lacing system allows the skater to customize the fit, ensuring optimal ankle stabilization without restricting blood circulation.

The practical significance of effective ankle support is evident in the skater’s ability to perform demanding elements such as triple and quadruple jumps. These maneuvers require precise control over body alignment and edge pressure, both of which are directly influenced by the stability provided by the boot. Insufficient ankle support can lead to wobbling during take-off or landing, potentially resulting in falls or injuries. Furthermore, proper ankle support contributes to the skater’s overall comfort and endurance, enabling them to maintain peak performance throughout training sessions and competitive routines. Therefore, the design and construction of skating boots prioritize ankle support as a fundamental feature, reflecting its direct impact on both athletic achievement and injury prevention.

In summary, boot ankle support is inextricably linked to both the safety and performance capabilities in advanced skating. The selection of materials, boot design, and individualized fitting are all critical aspects that must be carefully considered. The balance between stability, flexibility, and customized fit is paramount. The understanding of this interplay between boot and athlete is key to realizing a skater’s true potential.

3. Rocker Profile Precision

The rocker profile is a critical geometric characteristic of the blade on professional figure ice skates. It fundamentally influences maneuverability, edge control, and overall performance. Precision in its design and execution is, therefore, of paramount importance.

- Definition and Measurement

The rocker refers to the curvature of the blade along its longitudinal axis. The curvature radius determines the effective skating surface at any given time. Precision in the rocker profile is achieved through meticulous manufacturing and adherence to specific curvature parameters, often measured in inches or millimeters.

- Influence on Edge Control

The rocker profile significantly impacts edge control. A well-defined rocker facilitates smooth transitions between edges, essential for executing turns, spins, and jumps. Conversely, an inconsistent or poorly designed rocker can lead to unpredictable edge behavior, impairing performance and increasing the risk of falls.

- Adaptation to Skating Style

The optimal rocker profile varies based on the skater’s style and skill level. A shallower rocker may be preferred by skaters emphasizing speed and gliding, while a more pronounced rocker is suitable for skaters focusing on intricate footwork and jumps. Customization options allow skaters to tailor the rocker to their specific needs.

- Relationship to Blade Placement

Rocker profile is deeply correlated to Blade placement on the skate. The blade is installed according to how the individual skater needs to utilize that rocker, meaning that is needs to be optimized or it will impede the athlete.

In summation, the rocker profile is an integral component of professional figure ice skates. Its precision directly impacts a skater’s control, agility, and overall success. Therefore, meticulous design, manufacturing, and individualized adjustment of the rocker profile are fundamental to optimizing performance.

4. Proper Fit Crucial

A precise and individualized fit is paramount when selecting professional figure ice skates. The skate functions as an extension of the athlete’s body; consequently, any deviation from a perfect fit negatively impacts performance and heightens the risk of injury. The skater’s foot must be securely and comfortably enveloped within the boot to facilitate optimal energy transfer during jumps, spins, and intricate footwork. A boot that is too large allows for excessive movement, compromising stability and control. Conversely, a boot that is too small restricts circulation and causes discomfort, impeding the skater’s ability to execute complex maneuvers effectively. Consider, for example, a triple Salchow, requiring precise edge control and coordinated muscle activation. An ill-fitting boot undermines the skater’s ability to maintain the necessary body alignment and balance, potentially leading to a fall or an incomplete rotation.

The fitting process should involve a qualified professional who can assess the skater’s foot dimensions, including length, width, and arch height. Furthermore, the fitter should consider the skater’s skating style, skill level, and any existing foot conditions. A heat-moldable boot offers a customized fit, conforming to the unique contours of the skater’s foot and minimizing pressure points. Lacing techniques also play a crucial role in achieving the ideal fit, allowing the skater to adjust the tightness in different areas of the boot. Skaters competing at the national and international levels often undergo multiple fittings to fine-tune the fit, ensuring maximum comfort and performance.

In summary, achieving a proper fit represents a foundational aspect of selecting and utilizing professional figure ice skates. Its importance extends beyond mere comfort; it directly influences the skater’s ability to perform at their peak potential while minimizing the risk of injury. This crucial relationship highlights the necessity of seeking expert guidance during the fitting process, recognizing that a well-fitted skate is an essential tool for achieving success in the competitive world of figure skating.

5. Maintenance Extends Life

The lifespan of professional figure ice skates is intrinsically linked to consistent and appropriate maintenance procedures. Neglecting such practices precipitates premature degradation, compromising both performance and safety. Proper maintenance preserves the structural integrity and operational efficiency of these specialized implements.

- Blade Sharpening and Edge Integrity

Regular blade sharpening is paramount for maintaining optimal edge control. Dull blades impede the skater’s ability to execute precise turns and jumps. The frequency of sharpening depends on usage and ice conditions; however, neglecting this essential task results in increased force exertion, potential loss of control, and accelerated blade wear. Conversely, proper sharpening preserves the blade’s geometry, extending its usable life and enhancing performance.

- Boot Care and Structural Preservation

Skate boots, subjected to repeated stresses and moisture exposure, require diligent care to prevent structural deterioration. After each use, thorough drying of both the interior and exterior minimizes microbial growth and material degradation. Proper storage, utilizing boot trees, maintains the boot’s shape and prevents creasing or warping. Regular inspection of stitching, eyelets, and lacing systems allows for timely repairs, averting more significant damage.

- Blade Rust Prevention

The steel composition of skate blades renders them susceptible to rust formation, particularly in humid environments. After each use, meticulously drying the blades and applying a thin layer of rust-inhibiting lubricant mitigates corrosion. Blade guards, constructed from absorbent materials, further protect against moisture accumulation during storage. Ignoring these precautions leads to pitting, edge degradation, and ultimately, blade failure.

- Hardware Inspection and Replacement

Screws, rivets, and other hardware components securing the blade to the boot can loosen or corrode over time. Routine inspections identify potential points of failure, allowing for timely tightening or replacement. Loose hardware compromises blade stability, affecting the skater’s ability to maintain balance and control. Neglecting such maintenance can lead to dangerous equipment malfunctions.

In conclusion, the longevity and performance of professional figure ice skates are inextricably tied to consistent and meticulous maintenance practices. These procedures, encompassing blade care, boot preservation, rust prevention, and hardware management, collectively safeguard the skater’s investment and ensure optimal functionality. Adherence to these guidelines represents a fundamental aspect of responsible equipment stewardship.

Frequently Asked Questions

The following questions address common inquiries regarding specialized skating equipment, aiming to provide clarity on selection, maintenance, and performance considerations.

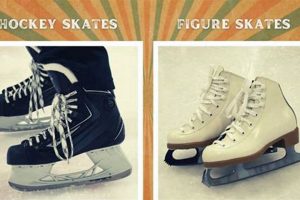

Question 1: What distinguishes specialized skating boots from recreational models?

Specialized skating boots incorporate significantly more rigid ankle support, constructed from multiple layers of reinforced leather or synthetic materials. This structural enhancement facilitates precise control and minimizes the risk of injury during advanced maneuvers. Recreational models typically offer less support, prioritizing comfort over performance.

Question 2: How frequently should the blades of specialized skating equipment be sharpened?

Sharpening frequency depends on several factors, including usage intensity, ice conditions, and skater weight. However, as a general guideline, blades should be sharpened after approximately 20-40 hours of skating time. Reduced edge quality is a primary indicator of the need for sharpening.

Question 3: What is the purpose of blade guards and how should they be utilized?

Blade guards protect the sharp edges of the blades from damage during off-ice transport and storage. They should be used immediately after skating, ensuring any moisture is thoroughly removed from the blades prior to placement within the guards. Soft guards are recommended for storage to absorb residual moisture and prevent rust.

Question 4: How does the rocker profile influence skating performance?

The rocker profile, the curvature of the blade along its longitudinal axis, dictates maneuverability and edge control. A more pronounced rocker facilitates tighter turns and quicker transitions, while a flatter rocker promotes gliding speed. The optimal rocker profile is contingent on the skater’s style and preferences.

Question 5: What are the key considerations when fitting professional figure ice skates?

Accurate foot measurement, accounting for both length and width, is paramount. The boot should provide a snug yet comfortable fit, allowing for adequate toe room without heel slippage. Professional fitting ensures proper ankle support and minimizes the risk of blisters or other foot-related injuries.

Question 6: Can blade alignment be adjusted, and what is its significance?

Blade alignment can be adjusted to optimize balance and edge control. Misalignment can impede performance and increase the risk of falls. Qualified technicians can assess and correct blade alignment using specialized tools and techniques. This procedure ensures the blade is properly positioned relative to the skater’s center of gravity.

Understanding these fundamental aspects contributes to informed equipment selection and maintenance, ultimately enhancing performance and minimizing potential risks.

The subsequent article segment will explore emerging technologies in skating boot and blade design, shedding light on innovations driving advancements in the sport.

Concluding Remarks on Professional Figure Ice Skates

This exploration of professional figure ice skates has underscored the critical interplay between design, materials, maintenance, and fitting. The inherent demands of competitive figure skating necessitate equipment engineered for precision, durability, and optimal performance. From the nuanced composition of the blades to the structural integrity of the boots, each element contributes to the athlete’s capacity to execute complex maneuvers with control and safety.

The pursuit of excellence in figure skating hinges, in part, on a thorough understanding of these specialized tools. Continuous refinement in materials science, manufacturing techniques, and fitting methodologies ensures ongoing advancements in this domain. Therefore, informed selection, meticulous maintenance, and a commitment to understanding the technical specifications of professional figure ice skates are paramount for both aspiring and established athletes seeking to maximize their potential within this challenging and visually compelling discipline.