A piece of equipment designed for gliding across frozen bodies of water or prepared ice surfaces, typically featuring a blade attached to a supportive boot or shoe. This equipment allows individuals to engage in recreational or competitive activities on ice. For example, individuals might use this equipment for leisurely skating on a frozen lake or for participating in organized ice hockey games.

This form of recreation promotes physical fitness, enhances balance and coordination, and provides opportunities for social interaction. Its historical significance lies in its evolution from rudimentary bone skates used for transportation to the sophisticated models employed in modern sports and recreation. The activity’s benefits extend beyond physical health, encompassing mental well-being through engagement with nature and the enjoyment of outdoor activities.

This article will delve further into the specifics of selecting appropriate models, maintaining their condition for optimal performance, and exploring the various environments where their use is prevalent.

Essential Guidance for Optimal Performance

Ensuring a safe and enjoyable experience requires adherence to specific guidelines and maintenance procedures. The following provides insights into maximizing the utility and longevity of related equipment.

Tip 1: Blade Maintenance: Consistent sharpening is critical for maintaining edge control. Regular honing prevents excessive wear and ensures reliable grip on the ice surface. Employ a sharpening stone designed for this purpose and follow manufacturer instructions meticulously.

Tip 2: Proper Boot Fit: Ensure the boot fits snugly but comfortably. Ill-fitting boots can cause blisters, reduced control, and potential injury. Consult a professional fitter to determine the appropriate size and model for individual foot shape and size.

Tip 3: Ankle Support: Adequate ankle support is vital for stability and preventing injuries. Choose models with reinforced ankle supports and ensure they are properly laced to provide the necessary level of firmness without restricting movement.

Tip 4: Storage Considerations: Store equipment in a dry environment to prevent rust and corrosion. Use blade guards to protect the blades from damage when not in use. Avoid storing in direct sunlight, which can degrade the materials over time.

Tip 5: Pre-Skate Inspection: Prior to each use, thoroughly inspect the equipment for any signs of damage or wear. Check the tightness of the blade mounting hardware and the integrity of the boot. Address any issues before engaging in the activity.

Tip 6: Surface Assessment: Before venturing onto the ice, assess its condition. Be aware of potential hazards such as cracks, thin spots, or debris. Exercise caution and avoid areas that appear unsafe.

Tip 7: Layered Clothing: Dress in layers to maintain body temperature and prevent overheating or chilling. Moisture-wicking fabrics are recommended to keep the body dry and comfortable during physical exertion.

Adherence to these suggestions contributes to an enhanced and safer experience. Proper maintenance and responsible usage extend the lifespan of equipment and minimize the risk of accidents.

The subsequent sections will explore specific environmental considerations and the varying types available to accommodate diverse skill levels and purposes.

1. Blade Steel Quality

The quality of the steel used in the blade of the piece of equipment directly influences performance, safety, and longevity. The type of steel dictates the blade’s hardness, edge retention, resistance to corrosion, and overall structural integrity, all crucial elements for the user’s experience and the equipment’s lifespan. These factors are particularly pertinent when navigating the variable ice conditions often encountered in northern, wooded environments.

- Hardness and Edge Retention

Higher hardness in the steel allows for a sharper edge and improved edge retention. This characteristic provides enhanced control and maneuverability, especially important on uneven or textured ice surfaces commonly found in natural environments. A blade that dulls quickly compromises performance and increases the risk of accidents. High-carbon steel alloys are often employed to achieve this hardness.

- Corrosion Resistance

Blades are frequently exposed to moisture, which can lead to rust and corrosion if the steel is not properly treated. Corrosion weakens the blade and degrades its performance. Stainless steel or blades with protective coatings are necessary to withstand the corrosive effects of water and ice, prolonging the lifespan and maintaining consistent performance.

- Flexibility and Tempering

The steel must possess the right balance of hardness and flexibility. If the steel is too brittle, it may chip or break under stress. Proper tempering processes are necessary to ensure the blade can withstand the forces exerted during skating without fracturing. This is especially critical when navigating varied terrain or performing demanding maneuvers.

- Manufacturing Precision

The precision of the blade’s manufacturing process directly affects its performance. A blade that is not perfectly straight or properly ground will not make consistent contact with the ice, leading to reduced control and increased effort. Precision grinding and quality control are crucial to ensure consistent performance and safety.

Therefore, the selection of high-quality blade steel is paramount. The ideal material will provide superior edge retention, resist corrosion, possess appropriate flexibility, and be manufactured with precision. Compromises in steel quality inevitably translate to compromises in performance, safety, and the overall utility of the equipment, particularly when used in challenging environments and under varying conditions.

2. Boot Ankle Support

The effectiveness of equipment intended for use on ice, particularly in environments like the northwoods, is intrinsically linked to the design and construction of its boot ankle support. This component directly influences the skater’s ability to maintain balance and control, especially when navigating uneven or unpredictable ice surfaces. Insufficient ankle support can result in instability, increasing the risk of falls and injuries. Conversely, a well-designed support system provides the necessary rigidity to transfer the skaters movements to the blade efficiently, enhancing performance and maneuverability. For instance, a skater traversing a frozen, snow-covered lake relies on robust ankle support to compensate for variations in the ice and snow depth, ensuring a stable and controlled glide.

The type of activities engaged in further dictates the required level of support. Recreational skating may necessitate a more flexible support system to allow for a greater range of motion, while activities such as ice hockey or speed skating demand rigid support to optimize power transfer and minimize ankle strain. The materials used in the construction of the boot also contribute to the overall effectiveness of the ankle support. Stiff, durable materials like reinforced polymers or leather provide greater stability, while softer materials may offer increased comfort but compromise support. Proper lacing techniques and closure systems are equally critical, as they allow the skater to customize the fit and optimize the level of support provided by the boot.

In summary, boot ankle support constitutes a critical component of equipment designed for use on ice, particularly in challenging environments. Its design and construction significantly impact a skaters stability, control, and safety. The level of support required varies depending on the intended activity and the conditions encountered. Understanding the relationship between boot ankle support and its influence on performance enables informed equipment selection and contributes to a safer and more enjoyable skating experience.

3. Fit Precision

Fit precision is paramount when selecting equipment for traversing frozen landscapes. Inadequate fit compromises control, efficiency, and safety, negating the potential benefits of otherwise high-quality construction. Therefore, meticulous attention to sizing and contour is critical for optimal performance and minimizing risk.

- Ankle Circumference and Support Alignment

Accurate measurement of ankle circumference is essential to ensure the boot provides proper support without constriction. Misalignment of the ankle within the boot can lead to instability, fatigue, and increased susceptibility to injury. Precise fit in this area promotes efficient transfer of power from the skater’s leg to the blade, enhancing control and maneuverability across varied ice surfaces.

- Toe Box Volume and Circulation

Adequate toe box volume allows for natural foot splay and maintains proper circulation. A cramped toe box can lead to discomfort, numbness, and decreased sensitivity, hindering the skater’s ability to feel the ice and react accordingly. Ensuring sufficient room for the toes prevents cold-related injuries and optimizes foot function.

- Heel Lock and Preventative Friction

A secure heel lock prevents unwanted movement of the foot within the boot, minimizing friction and the risk of blisters. Slippage of the heel reduces control and can lead to inefficient energy expenditure. Proper heel lock, coupled with appropriately thick socks, contributes to a comfortable and secure fit, essential for prolonged use in cold conditions.

- Arch Support and Foot Alignment

Incorporating adequate arch support within the boot aligns the foot properly, distributing weight evenly and reducing strain on the joints. Insufficient arch support can lead to pronation or supination, increasing the risk of injury and reducing efficiency. Matching the arch support to the individual’s foot type optimizes comfort and performance, especially during extended periods of use.

These facets of fit precision underscore the importance of personalized selection. The benefits of superior materials and construction are diminished without a meticulous fit. Investing time and resources in ensuring equipment contours precisely to the individual’s foot translates directly to enhanced performance, comfort, and safety on the ice.

4. Environmental Suitability

The operational effectiveness and longevity of any equipment designed for ice surfaces are profoundly influenced by the congruence between its design specifications and the environmental conditions in which it is deployed. Concerning equipment used in northern, wooded regions, the environmental parameters introduce specific demands that necessitate careful consideration during the design and selection phases.

- Ice Surface Variability

Naturally occurring ice in wooded environments presents considerable variability in surface texture and consistency. Snow cover, freeze-thaw cycles, and the presence of organic debris contribute to uneven surfaces. Equipment with blades designed for smooth, prepared ice may perform poorly, requiring greater effort and increasing the risk of instability. Robust blade designs with enhanced edge control are crucial for navigating these variable conditions. An example is a longer blade with a more pronounced rocker, which provides better stability and maneuverability on rough or snow-covered ice.

- Temperature Fluctuations

Extreme temperature fluctuations are characteristic of northern climates. These fluctuations affect both the ice surface and the materials used in the equipment. Repeated freezing and thawing can weaken ice integrity and create hazards. Similarly, materials used in the construction of the boot and blade mount must withstand repeated exposure to sub-zero temperatures without becoming brittle or losing their structural integrity. Polymers and adhesives should be selected for their resistance to cracking and delamination under these conditions.

- Snow Accumulation

Significant snow accumulation is common in wooded environments, impacting both the ice surface and the user’s mobility. Deep snow reduces visibility of potential hazards on the ice and increases resistance to movement. Equipment with wider blades or specialized snow-clearing features may be necessary to maintain adequate traction and prevent excessive fatigue. Additionally, the boot design should incorporate features to minimize snow ingress, preventing discomfort and reduced thermal insulation.

- Vegetation and Obstacles

Proximity to vegetation and submerged obstacles presents unique challenges. Limbs, branches, and other debris can be embedded in the ice or obscured by snow, creating hazards that are not present on prepared ice surfaces. Equipment used in these environments should be durable enough to withstand incidental impacts with these obstacles without sustaining critical damage. Furthermore, the user must exercise increased vigilance to identify and avoid these hazards, emphasizing the importance of controlled speed and awareness of the surroundings.

These environmental facets underscore the importance of selecting equipment specifically designed and constructed to withstand the rigors of northern, wooded environments. A mismatch between the equipment’s design and the prevailing conditions can compromise performance, safety, and the overall user experience. Thus, a thorough assessment of the intended use and environmental context is crucial for informed equipment selection.

5. Sharpening Frequency

The rate at which a blade requires sharpening directly impacts its performance and safety, particularly when used in a northwoods environment. The variable ice conditions prevalent in such areas accelerate blade dulling compared to prepared indoor rinks. The presence of snow, debris, and rough ice textures acts as an abrasive, eroding the blade’s edge more rapidly. Thus, determining an appropriate sharpening schedule is crucial for maintaining optimal grip and control, which are essential for safe navigation in these challenging conditions.

Consider a scenario where equipment is used frequently on a frozen lake in a northwoods setting. The ice surface may be uneven, covered with granular snow, and potentially contain hidden debris. In such instances, the blade’s edge can degrade significantly after only a few uses. Conversely, less frequent use on smoother, cleaner ice might extend the interval between sharpenings. The sharpness of the blade influences the skater’s ability to execute controlled turns and stops, critical maneuvers for avoiding obstacles or preventing falls on unpredictable surfaces. A dull blade necessitates increased effort to maintain directional control, leading to fatigue and heightened risk of accidents. Professional skaters in outdoor environments typically sharpen their blades far more often than those who exclusively use indoor rinks.

Optimal sharpening frequency is therefore a function of both usage intensity and environmental conditions. Regular inspection of the blade’s edge for signs of dulling or damage is recommended. Implementing a proactive sharpening regimen, tailored to the specific ice conditions and frequency of use, ensures consistent performance and mitigates safety risks. Failure to maintain a sharp blade compromises control and increases the likelihood of accidents, underscoring the importance of integrating sharpening frequency into routine equipment maintenance.

6. Ice Surface Condition

The characteristics of the frozen surface directly influence the performance and safety of equipment designed for ice traversal, especially in regions with naturally formed ice. Understanding and adapting to the nuances of ice is critical for optimal utilization of the device.

- Roughness and Texture

The degree of roughness on the surface affects traction and glide efficiency. Irregularities caused by freeze-thaw cycles, snow accumulation, or embedded debris create friction, impeding smooth movement. For instance, skating on a textured surface after a light snowfall requires more effort and reduces speed compared to gliding on a smooth, refrozen surface. Equipment with blades engineered for enhanced edge control becomes essential in managing such conditions.

- Ice Thickness and Integrity

Ice thickness dictates structural stability and load-bearing capacity. Insufficient thickness poses a risk of breakage, leading to potential submersion. Factors such as water currents, thermal springs, and variations in snow cover can create localized thin spots. Prior assessment of ice thickness using appropriate tools is paramount to ensure safe passage.

- Temperature and Surface Moisture

Ice temperature influences its hardness and slipperiness. Warmer temperatures near the freezing point result in a thin layer of surface water, reducing friction and increasing glide. Conversely, colder temperatures create a harder, more resistant surface. These variations affect the responsiveness of the equipment, necessitating adjustments in technique and blade sharpness.

- Contaminants and Debris

The presence of organic matter, sediment, or pollutants on the ice surface compromises glide quality and accelerates blade wear. Debris can scratch or dull the blade’s edge, diminishing performance. Routine cleaning of the ice surface, when feasible, and regular blade maintenance are essential for mitigating these effects.

These considerations highlight the interplay between environmental conditions and the device. Adapting equipment selection and usage practices to account for specific ice surface attributes is crucial for ensuring safe, efficient, and enjoyable operation in natural settings.

7. Maintenance Procedures

The longevity and operational effectiveness of equipment employed in the northwoods environment directly correlate with adherence to consistent and thorough maintenance procedures. The harsh conditions prevalent in these settings, including fluctuating temperatures, abrasive snow and ice, and exposure to moisture and debris, accelerate wear and degradation of components. Consequently, neglect of routine maintenance diminishes performance and increases the risk of equipment failure, potentially leading to hazardous situations for the user. For instance, a blade left uncleaned and unprotected after use on a frozen lake is susceptible to corrosion, which weakens the steel and impairs its ability to maintain a sharp edge. This, in turn, compromises the user’s control and increases the likelihood of accidents.

Specific maintenance tasks include regular cleaning and drying of the blade to prevent rust, sharpening the blade to maintain optimal edge, inspecting the boot for signs of wear or damage, and ensuring that all fasteners are secure. The frequency of these tasks depends on the intensity of use and the severity of the environmental conditions. For example, an individual who uses the equipment daily in snowy conditions will need to perform maintenance more frequently than someone who uses it sparingly on clear, smooth ice. Furthermore, specialized lubricants and protectants may be necessary to safeguard components against corrosion and premature wear. These measures ensure reliable and predictable performance across a range of environmental challenges.

In summary, a proactive approach to maintenance is not merely a matter of prolonging the lifespan of the equipment; it is an integral component of ensuring user safety and maximizing performance in the demanding northwoods environment. Consistent adherence to established maintenance protocols mitigates the risks associated with equipment failure and contributes to a safer and more enjoyable experience. Understanding this connection and implementing appropriate maintenance practices is essential for anyone utilizing this specialized equipment in such environments.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, maintenance, and usage of equipment designed for traversing frozen surfaces, particularly within challenging environments.

Question 1: What steel hardness is recommended for blades used on natural ice surfaces?

A steel hardness rating of 60-62 HRC (Rockwell Hardness Scale) is generally recommended. This range provides a balance between edge retention and resistance to chipping, crucial for navigating the uneven and often abrasive conditions of natural ice.

Question 2: How frequently should blades be sharpened when used primarily on outdoor ice?

Sharpening frequency varies depending on usage intensity and ice conditions. However, as a general guideline, blades used frequently on outdoor ice should be sharpened every 5-10 hours of use. Regular inspection for nicks and dull spots will provide a more accurate indication of when sharpening is required.

Question 3: What type of ankle support is most appropriate for skating on uneven, snow-covered ice?

A boot with rigid or semi-rigid ankle support is recommended. This provides the necessary stability to compensate for uneven surfaces and maintain balance. Adjustable lacing systems allow for customization of support based on individual needs and terrain.

Question 4: What is the recommended boot fit for optimal performance and comfort?

The boot should fit snugly around the foot, providing support without restricting circulation. There should be minimal heel lift during forward motion, and the toes should have sufficient room to avoid cramping. Consulting a professional fitter is recommended to ensure proper sizing and fit.

Question 5: How should the blades be stored to prevent corrosion?

After each use, the blades should be thoroughly dried with a clean cloth. Blade guards, preferably made of moisture-wicking material, should be used during storage to protect the blades from physical damage and prevent the accumulation of moisture. Storing in a dry environment is also essential.

Question 6: What safety precautions should be taken when skating on natural ice surfaces?

Prior to skating, the ice thickness should be assessed using an ice auger or other appropriate tool. Always skate with a companion and inform others of the intended route and estimated return time. Carry safety equipment such as ice picks, a rope, and a whistle. Avoid skating on ice near moving water or known thin spots.

These answers provide a foundation for informed decision-making. However, seeking professional guidance is advisable for specific needs and circumstances.

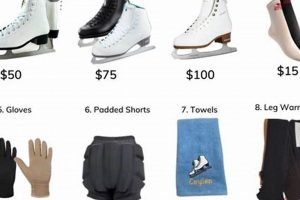

The next section will present a buyer’s guide to assist in selecting appropriate equipment based on various criteria.

Northwoods Ice Skate

This exposition has presented the multifaceted considerations surrounding the selection, maintenance, and responsible usage of equipment designed for traversing frozen terrain in a northwoods environment. The importance of blade quality, boot construction, precise fit, and environmental awareness has been underscored. Rigorous maintenance schedules and careful assessment of ice conditions have also been emphasized as critical components of safe and effective operation.

Given the inherent challenges and potential hazards associated with engaging in such activities, informed decision-making is paramount. The selection of equipment should not be viewed as a mere transaction, but rather as a deliberate investment in personal safety and the preservation of equipment integrity. Continued education and adherence to established best practices will ensure the enduring enjoyment of this activity while minimizing risk and promoting responsible engagement with the natural environment.