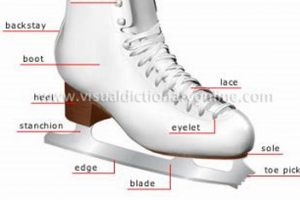

Footwear designed for gliding across ice surfaces, typically employed in sports such as ice hockey, figure skating, and recreational skating, enables users to maneuver and propel themselves on frozen water. These specialized boots are affixed to a sharpened metal blade, facilitating controlled movement and stability on the ice.

The equipment provides support and protection to the skater’s feet and ankles, influencing performance and safety. Innovations in materials and design have significantly improved the comfort, durability, and responsiveness of this type of skating equipment over time. The development of advanced blade technology allows for increased speed and precision, enhancing the overall skating experience. The brand in question has a long history of being favored by both professionals and amateurs alike due to it’s quality, durability, and comfort.

The following sections will delve into the specific features, models, and considerations when selecting appropriate equipment for various skating disciplines and skill levels. This will include an overview of key attributes such as fit, blade type, and construction materials.

Equipment Selection and Maintenance Tips

Proper selection and diligent maintenance are paramount to optimizing performance and prolonging the lifespan of skating equipment. The following guidelines offer crucial insights for users seeking to maximize the utility of their ice skates.

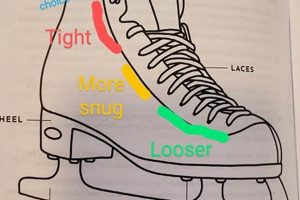

Tip 1: Ensure Proper Fit: Prioritize a snug yet comfortable fit. Ill-fitting footwear can compromise control and contribute to discomfort. Seek professional fitting assistance at a reputable retailer.

Tip 2: Consider Intended Use: Select equipment specifically designed for the intended discipline, whether it be hockey, figure skating, or recreational skating. Different disciplines require different blade profiles and boot stiffness.

Tip 3: Sharpen Blades Regularly: Maintain sharp blades for optimal edge control. The frequency of sharpening depends on usage and ice conditions. Dull blades significantly hinder performance.

Tip 4: Dry Blades After Each Use: Thoroughly dry the blades after each skating session to prevent rust and corrosion. Moisture accelerates blade degradation, reducing longevity.

Tip 5: Use Blade Guards: Employ blade guards when walking off the ice to protect the edges from damage. Walking on hard surfaces dulls blades rapidly.

Tip 6: Store Equipment Properly: Store equipment in a dry, well-ventilated area to prevent moisture buildup and odor. Avoid storing skates in airtight containers.

Tip 7: Inspect Regularly for Damage: Routinely inspect the boots, blades, and rivets for any signs of wear or damage. Address minor issues promptly to prevent them from escalating.

Adhering to these guidelines will contribute to enhanced performance, extended equipment lifespan, and a more enjoyable skating experience. Prioritizing proper fit, blade maintenance, and storage practices is essential.

The subsequent sections will provide a detailed overview of specific equipment models and technological advancements in skating equipment.

1. Fit and Comfort

The correlation between proper fit and comfort in skating equipment directly impacts a skater’s performance and overall experience. Ill-fitting footwear can lead to discomfort, blisters, and compromised control, hindering the skater’s ability to execute maneuvers effectively. Conversely, appropriately sized and comfortable equipment promotes a secure and responsive connection between the skater and the ice. A well-fitted boot allows for efficient energy transfer, enabling the skater to generate power and maintain balance with greater ease. For instance, a hockey player wearing equipment that is too large may experience a loss of agility and reduced responsiveness during critical plays.

The implementation of heat-moldable technology in higher-end models exemplifies the industry’s commitment to enhancing fit and comfort. This feature enables the user to customize the shape of the boot to conform to the unique contours of their feet, minimizing pressure points and maximizing support. Furthermore, advancements in liner materials, such as memory foam, provide additional cushioning and reduce friction, contributing to a more comfortable skating experience. A figure skater relying on consistent performance for complex routines requires the precision and stability offered by a well-fitting, comfortable boot, allowing them to focus on technique rather than foot discomfort.

In summary, prioritizing fit and comfort when selecting skating equipment is paramount. A properly fitted and comfortable skate translates directly into enhanced performance, reduced risk of injury, and increased enjoyment of the sport. Ignoring these critical elements can lead to compromised performance and a diminished skating experience. The technology employed in modern skates aims to bridge the gap between high-performance requirements and the user’s anatomical needs, therefore fit and comfort are the foundation to maximizing the equipment value.

2. Blade Quality

Blade quality is a crucial determinant of performance characteristics in ice skating equipment, directly influencing glide, edge control, and overall responsiveness. In the context of specialized ice skates, blade composition, construction, and maintenance requirements become essential considerations for both recreational and professional skaters.

- Steel Composition and Hardness

The type of steel used in blade construction significantly affects its hardness, edge retention, and resistance to corrosion. High-carbon steel alloys, often employed in premium equipment, offer superior hardness and edge durability compared to lower-grade steels. Skates intended for competitive use typically feature blades with enhanced steel composition to withstand the rigors of frequent use and demanding maneuvers. The choice of steel directly impacts the frequency with which the blade needs sharpening and its ability to maintain a clean, precise edge.

- Blade Profile and Radius of Hollow (ROH)

The blade profile, encompassing its curvature and overall shape, dictates its maneuverability and stability on the ice. The radius of hollow (ROH), a concave groove ground into the bottom of the blade, determines the amount of bite and edge control a skater experiences. A deeper ROH provides more aggressive grip, suitable for advanced techniques and tighter turns, while a shallower ROH offers greater glide and speed. The appropriate ROH selection is dependent on the skater’s skill level, skating style, and ice conditions.

- Blade Mounting and Alignment

The method of blade mounting and the precision of its alignment relative to the boot are critical for ensuring proper balance and efficient power transfer. A securely mounted blade with accurate alignment minimizes energy loss and reduces the risk of ankle strain. Premium skates often feature advanced mounting systems that allow for fine-tuning of blade position to accommodate individual skating styles and biomechanics. Misaligned or loosely mounted blades can compromise stability and hinder performance.

- Blade Maintenance and Sharpening

Regular blade maintenance, including drying and sharpening, is essential for preserving blade quality and extending its lifespan. Moisture can lead to rust and corrosion, degrading the blade’s performance characteristics. Professional sharpening, performed by a skilled technician, restores the blade’s edge and optimizes its cutting efficiency. Neglecting blade maintenance can result in dull edges, reduced glide, and compromised control, ultimately impacting the skater’s performance and safety.

The interplay between steel composition, blade profile, mounting, and maintenance collectively defines the overall quality and performance characteristics of the blade. Selecting a skate with high-quality blades, tailored to the skater’s specific needs and meticulously maintained, is paramount for maximizing skating enjoyment, performance, and safety on the ice. The blade quality enhances the skating experience by influencing glide, control, and maneuverability.

3. Ankle Support

Adequate ankle support is a critical component in ice skating equipment, directly impacting performance, stability, and injury prevention. In skating, the ankle joint is subjected to significant stresses, particularly during complex maneuvers and high-impact landings. The boot’s design and construction must provide sufficient lateral and medial stability to prevent excessive pronation or supination, which can lead to ankle sprains and other injuries. A skate with insufficient ankle support compromises the skater’s ability to maintain balance and control, especially during rapid changes in direction and speed. Therefore, the design of the boot directly affects how effectively the equipment meets the demands of ice skating.

Specific design elements contribute to enhanced ankle support. Stiffer boot materials, such as reinforced polymers or composite materials, provide greater resistance to deformation under stress. Lacing systems that extend higher up the ankle and incorporate power straps further augment stability. The internal padding and contouring of the boot around the ankle bone also play a crucial role in minimizing movement and maximizing support. For example, high-end hockey skates often feature strategically placed reinforcements to protect the ankle from impacts and provide a more secure fit. Similarly, figure skating boots prioritize ankle support to facilitate precise movements and reduce the risk of injury during jumps and spins.

In summary, ankle support is a vital feature in ice skating equipment. Skates with inadequate ankle support pose a significant risk of injury. Selecting a skate that provides the appropriate level of support, tailored to the skater’s skill level and intended use, is essential for maximizing performance, safety, and overall enjoyment of the sport. Skates provide support via design elements such as stiff materials, lacing system, and padding.

4. Heat Molding

Heat molding, a process employed in the customization of ice skating equipment, significantly enhances fit and performance, particularly with brands such as Bauer. The process involves applying heat to the skate boot, typically within a specialized oven or using a heat gun, to soften the materials and allow them to conform more closely to the unique contours of the skater’s foot. This customized fit improves comfort, reduces pressure points, and optimizes energy transfer during skating.

- Customized Fit and Comfort

Heat molding enables a personalized fit that addresses individual anatomical variations. Skaters often experience pressure points and discomfort due to the inherent differences in foot shape. The heat molding process allows the skate’s internal and external materials to adapt to the specific contours of the foot, alleviating pressure points and enhancing overall comfort. For example, a skater with a prominent ankle bone can benefit from heat molding to create a recessed area, preventing irritation and improving stability.

- Enhanced Performance and Responsiveness

A customized fit improves the skater’s connection to the skate, resulting in more efficient energy transfer and enhanced responsiveness. When the foot is securely and comfortably encased within the boot, the skater can exert more precise control over movements and generate greater power. This is particularly advantageous in disciplines such as hockey and figure skating, where split-second reactions and precise edge control are paramount. A well-molded skate minimizes internal slippage, allowing for more direct transmission of force from the skater’s body to the ice.

- Improved Circulation and Reduced Fatigue

A properly fitted skate, achieved through heat molding, promotes healthy circulation and reduces fatigue during prolonged skating sessions. Ill-fitting skates can constrict blood flow, leading to discomfort, numbness, and decreased performance. By conforming to the natural shape of the foot, heat-molded skates minimize pressure on sensitive areas, allowing for unimpeded circulation and reduced muscle fatigue. This is particularly beneficial for skaters who spend extended periods on the ice, such as competitive athletes and recreational skaters who enjoy long sessions.

- Optimized Support and Stability

Heat molding can enhance the structural integrity and support provided by the skate. The process allows for a more uniform distribution of pressure across the foot, improving overall stability and reducing the risk of ankle roll. The customized fit ensures that the skate provides adequate support in critical areas, such as the ankle and heel, minimizing the likelihood of injury and enhancing the skater’s confidence. A well-molded skate acts as an extension of the skater’s foot, providing a secure and stable platform for executing complex maneuvers.

In conclusion, heat molding is an integral feature that enhances the performance and comfort of ice skating equipment. The ability to customize the fit of equipment significantly improves the overall skating experience, while also addressing individual anatomical considerations and specific needs. In regard to the brand in question, implementing heat molding allows the product to mold the equipment for maximum comfort.

5. Durability

The longevity of skating equipment is paramount, particularly in high-performance contexts. In the case of specialized equipment, durability translates directly to long-term cost-effectiveness and reliable performance under demanding conditions. Material selection, construction techniques, and the incorporation of protective features significantly influence the overall lifespan of the equipment. Failures due to inadequate durability can lead to compromised performance and increased risk of injury. This skating equipment is often subjected to rigorous use and must withstand impacts, abrasion, and environmental stressors, such as fluctuating temperatures and moisture.

High-density polymers, reinforced stitching, and robust blade mounting systems are examples of design elements contributing to increased durability. The implementation of abrasion-resistant materials in high-wear areas, such as the toe box and ankle supports, mitigates the effects of repeated impacts and friction. Additionally, the quality of the blade steel and the method of its attachment to the boot are critical factors affecting the equipment’s ability to withstand stress and maintain its structural integrity. A hockey player relying on equipment during intense gameplay requires the reliability and durability afforded by high-quality construction, reducing the likelihood of equipment failure during critical moments. Figure skaters, similarly, need equipment that withstands repetitive stress of landings, therefore quality equipment is vital to the skater.

The durability of the equipment directly correlates with its suitability for sustained use, particularly in professional or competitive settings. A lack of durability can lead to frequent replacements, resulting in increased costs and potential disruptions in training or competition. Proper maintenance, including regular cleaning, drying, and blade sharpening, can extend the lifespan of even the most durable equipment. Ultimately, the combination of high-quality materials, robust construction, and diligent maintenance practices ensures that specialized skating equipment provides reliable performance and long-term value.

6. Performance Level

The designated performance level of skating equipment directly correlates with its suitability for specific user skill sets and intended applications. In the context of the brand, products are segmented into tiers reflecting varying degrees of technological sophistication, material quality, and design features. This segmentation enables consumers to select equipment that aligns with their skating proficiency and the demands of their chosen discipline. The performance level serves as a critical determinant of equipment cost, features, and overall performance characteristics. A recreational skater would not need or likely want an expensive professional-level skate; while a professional would not perform well in an entry-level skate.

Equipment designed for entry-level users typically prioritizes comfort, ease of use, and affordability. These skates incorporate softer materials, simplified construction, and features that enhance stability and control for novice skaters. Conversely, professional-level equipment emphasizes performance optimization, utilizing advanced materials, heat-moldable construction, and specialized blade designs to maximize power transfer, edge control, and responsiveness. Intermediate-level equipment bridges the gap between these two extremes, offering a balance of performance features and user-friendliness. An example is a young hockey player transitioning from youth leagues to higher levels will require equipment that supports more aggressive skating and more robust protection.

The connection between performance level and specialized skating equipment ensures that skaters of all abilities can access equipment tailored to their specific needs. Proper alignment between a skater’s skill level and the designated performance tier of their equipment promotes safety, enhances performance, and contributes to a more enjoyable skating experience. The correct performance level of a Bauer ice skate enhances performance and contributes to a more enjoyable skating experience. This strategic alignment facilitates skill development and minimizes the risk of injury associated with using inappropriate or inadequate equipment.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, maintenance, and performance characteristics of specialized ice skating equipment. The information provided aims to clarify misconceptions and offer practical guidance for users of all skill levels.

Question 1: How does the “fit” of skating equipment impact performance?

Proper fit is paramount. Ill-fitting equipment compromises control, energy transfer, and comfort, leading to suboptimal performance. A snug, yet comfortable fit allows for efficient power transfer and minimizes the risk of blisters and discomfort.

Question 2: What factors determine the quality of the blade?

Blade quality hinges on steel composition, profile, and maintenance. High-carbon steel alloys offer superior edge retention and resistance to corrosion. The blade profile dictates maneuverability, while regular sharpening ensures optimal performance.

Question 3: Why is ankle support so critical in skating equipment?

Adequate ankle support prevents excessive pronation or supination, reducing the risk of ankle sprains and injuries. Stiffer boot materials, lacing systems, and internal padding contribute to enhanced stability.

Question 4: What is “heat molding,” and what benefits does it provide?

Heat molding is a customization process involving the application of heat to the boot to conform it to the user’s foot. This enhances comfort, reduces pressure points, and optimizes energy transfer.

Question 5: What materials contribute to the overall “durability” of skating equipment?

Durability is influenced by material selection and construction techniques. High-density polymers, reinforced stitching, and robust blade mounting systems enhance the equipment’s ability to withstand impacts and abrasion.

Question 6: How does the “performance level” rating affect equipment selection?

The performance level rating reflects the equipment’s suitability for specific skill sets and applications. Entry-level equipment prioritizes comfort, while professional-level equipment emphasizes performance optimization. Selecting the appropriate performance level is crucial for maximizing safety and performance.

The information provided offers a concise overview of key considerations in specialized ice skating equipment. Proper selection and maintenance practices are essential for ensuring optimal performance, safety, and equipment longevity.

The next section will delve into specific models and product lines available from leading manufacturers.

Conclusion

This exploration of specialized skating equipment has underscored the multifaceted considerations inherent in equipment selection and utilization. From the critical importance of proper fit and blade quality to the influence of ankle support, heat molding, durability, and designated performance levels, each element contributes significantly to the skater’s experience and performance. This is especially relevant when considering a choice of equipment from the brand in question.

The understanding and application of these principles are essential for ensuring skater safety, optimizing performance, and maximizing the lifespan of specialized skating equipment. Continued advancements in materials and design promise further refinements, demanding ongoing vigilance and informed decision-making within the skating community. Prioritizing these factors translates to a safer and more rewarding experience on the ice for all levels of skaters.