Footwear designed for skateboarding, constructed within the United States, and intended for athletic use represents a specialized segment of the shoe market. These products often prioritize durability, grip, and support to withstand the stresses of skateboarding. Examples include low-profile designs with reinforced stitching and vulcanized rubber soles.

Manufacturing domestically can provide several advantages, including tighter control over quality, support for local economies, and potentially faster response times to market demands. Historically, certain brands have maintained domestic production, emphasizing craftsmanship and appealing to consumers who value American-made goods. This can lead to increased consumer trust and brand loyalty due to the perception of higher quality and ethical labor practices.

This article will delve into the materials used, the production processes involved, brands known for this manufacturing approach, and the overall impact on the skateboarding community and related industries. Considerations of cost, sustainability, and evolving consumer preferences will also be addressed.

Guidance on Selecting American-Manufactured Skate Footwear

The following provides essential considerations when choosing skateboarding footwear originating from United States manufacturing facilities. Careful attention to these points can ensure optimal performance and product longevity.

Tip 1: Assess Material Composition: Verify the origin and quality of materials. Domestically sourced canvas, leather, and rubber contribute to overall durability and performance.

Tip 2: Examine Construction Techniques: Evaluate stitching density and reinforcement at stress points. Double or triple stitching enhances resistance to wear and tear during intense activity.

Tip 3: Confirm Sole Adhesion: Inspect the bonding between the upper and sole. A robust, vulcanized construction ensures a secure and lasting connection.

Tip 4: Evaluate Insole Support: Consider the level of arch support and cushioning provided by the insole. Adequate support minimizes fatigue and potential injuries during prolonged use.

Tip 5: Scrutinize Brand Reputation: Research the manufacturer’s history and commitment to domestic production. Established brands often uphold higher standards of quality and ethical practices.

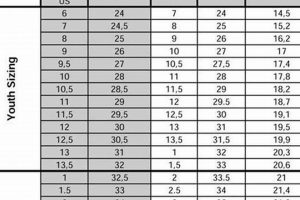

Tip 6: Verify Size and Fit: Precise sizing is crucial for comfort and performance. Consult size charts and consider trying on footwear before purchase to ensure a proper fit.

Tip 7: Consider Specific Skateboarding Style: Different styles of skateboarding may require specific footwear features. Select models tailored to the intended use case.

Selecting footwear produced domestically involves careful consideration of material quality, construction methods, and brand reputation. Attention to these details can significantly impact performance, longevity, and overall satisfaction.

The following sections will explore the market landscape for American-manufactured skateboarding footwear in greater detail.

1. American Manufacturing

The production of skateboarding footwear within the United States impacts product quality, supply chain dynamics, and consumer perceptions. Domestic manufacturing affects various facets of the product, influencing cost, materials, and overall value proposition.

- Quality Control and Standards

Domestic manufacturing allows for greater oversight and adherence to quality standards. This translates to footwear with consistent performance characteristics and reduced defect rates. Facilities operating within the U.S. are subject to regulatory frameworks that ensure product safety and durability, reducing potential liabilities for manufacturers and enhancing consumer confidence.

- Supply Chain Efficiency and Responsiveness

A geographically localized supply chain can reduce lead times and transportation costs. Proximity to material suppliers and distribution networks allows for more responsive adjustments to market demands and faster product iterations. This can be particularly advantageous in the dynamic skateboarding market, where trends and preferences evolve rapidly.

- Economic Impact and Job Creation

Manufacturing footwear within the U.S. contributes to domestic job creation and supports local economies. This generates tax revenue and fosters economic growth within communities where these facilities are located. Consumers who prioritize supporting American industries often seek out products manufactured within the country, creating a demand for domestically produced goods.

- Innovation and Technological Advancement

Domestic manufacturing fosters innovation and technological advancement within the footwear industry. Investment in research and development related to materials, manufacturing processes, and design can lead to improved product performance and sustainability. Proximity to research institutions and skilled labor pools can further accelerate the pace of innovation.

The interplay between American manufacturing practices and skateboarding footwear has tangible implications. Investing in local manufacturing may lead to better products. This also creates jobs in the US and promotes economic prosperity within American communities.

2. Material Sourcing

Material sourcing represents a critical determinant in the quality, sustainability, and overall value proposition of skateboarding footwear manufactured within the United States. The selection and origin of raw materials directly influence product durability, performance characteristics, and environmental impact. For example, domestic production often allows for closer scrutiny of leather tanning processes, ensuring compliance with stricter environmental regulations compared to overseas facilities. This has a ripple effect: higher quality material reduces waste.

The strategic sourcing of materials also impacts the economic viability of domestic manufacturing. While utilizing American-made materials can increase production costs, it simultaneously supports local industries, reduces reliance on global supply chains, and potentially shortens lead times. For example, a manufacturer prioritizing U.S.-grown cotton for canvas uppers may face higher material expenses but benefits from enhanced supply chain transparency and reduced carbon footprint associated with long-distance shipping. Also, it promotes USA farming.

Ultimately, material sourcing for American-made skateboarding footwear involves navigating a complex interplay of factors, including cost, quality, ethical considerations, and environmental sustainability. Transparent sourcing practices and a commitment to utilizing domestically produced materials represent key differentiators for brands seeking to appeal to consumers who prioritize both performance and responsible manufacturing. Without a commitment to using quality materials that can endure skating, there is no value.

3. Skateboarding Functionality

Skateboarding functionality, encompassing performance characteristics and design elements directly influencing a skater’s ability to execute maneuvers and maintain control, is a critical consideration in the context of footwear manufactured within the United States. The interplay between design, materials, and construction methods dictates the suitability of footwear for the demands of skateboarding.

- Board Feel and Control

Footwear construction significantly influences the skater’s connection with the board. Thinner soles, often achieved through vulcanized construction, enhance tactile feedback, allowing for precise adjustments during tricks. The choice of materials, such as suede or canvas uppers, impacts grip and board control. Domestically produced footwear offers potential advantages in material selection and quality control, directly impacting a skater’s ability to execute technical maneuvers. For instance, consistent sole durometer ensures predictable grip, crucial for maintaining board control during landings.

- Impact Absorption and Protection

Skateboarding involves repeated impact forces, necessitating adequate cushioning and protection. Footwear with reinforced midsoles and strategically placed padding mitigates the risk of injuries. Domestic manufacturing allows for greater customization and integration of advanced cushioning technologies, such as gel inserts or foam compounds optimized for impact absorption. This customization enhances comfort and reduces the strain on joints during high-impact activities, safeguarding skaters from potential injuries. The type of shoe insert can prevent ankle injuries.

- Durability and Longevity

Skateboarding footwear endures significant abrasion and stress. Reinforced stitching, durable materials, and robust construction are essential for withstanding the demands of the sport. Domestically manufactured footwear can leverage specialized manufacturing techniques and access to high-quality materials to enhance durability. For example, double or triple stitching at stress points minimizes the risk of premature failure, extending the lifespan of the footwear and reducing the need for frequent replacements. A durable shoe will save skaters money in the long run.

- Ankle Support and Stability

Proper ankle support minimizes the risk of sprains and injuries. Footwear design, incorporating features such as padded collars and reinforced heel counters, provides stability and prevents excessive ankle movement. Domestic manufacturers have the flexibility to experiment with innovative designs and materials to optimize ankle support without compromising flexibility. This combination of support and flexibility allows skaters to maintain control and execute complex maneuvers with confidence, reducing the risk of injuries related to ankle instability.

These facets of skateboarding functionality are intrinsically linked to the manufacturing processes employed in producing footwear. The ability to control material selection, manufacturing techniques, and quality control measures directly impacts the performance, durability, and safety of skateboarding footwear. Therefore, the origin of manufacturing plays a significant role in determining the suitability of footwear for the demanding nature of skateboarding.

4. Durability and Longevity

The connection between durability and longevity in skateboarding footwear manufactured within the United States centers on the interplay of material selection, construction methods, and quality control measures. Footwear designed for skateboarding endures substantial abrasion and stress, necessitating resilience to withstand the rigors of the sport. The use of premium materials, such as high-grade suede, reinforced canvas, and durable rubber compounds, directly contributes to the extended lifespan of the product. For instance, some manufacturers utilize double or triple stitching at key stress points, mitigating the likelihood of seam failure and extending the overall lifespan of the footwear.

Furthermore, rigorous quality control protocols implemented during the manufacturing process directly influence the durability and longevity of the final product. Domestic manufacturing often allows for closer monitoring of each stage of production, ensuring adherence to stringent standards and minimizing defects. This can include meticulous inspection of material integrity, stitch quality, and sole adhesion. Brands emphasizing domestically produced goods may cite examples of prolonged product lifespan compared to footwear manufactured overseas with less stringent quality control. The result is reduced costs long term.

In conclusion, the pursuit of durability and longevity in skateboarding footwear manufactured within the U.S. represents a confluence of deliberate material choices, robust construction techniques, and stringent quality assurance measures. While such practices may incur higher initial production costs, the resulting product offers enhanced resilience, extended lifespan, and ultimately, greater value for the consumer. This emphasis on durability aligns with a growing consumer demand for sustainable products and responsible manufacturing practices. The overall result is greater confidence that you will have a good product that will not break quickly.

5. Economic Contribution

The economic contribution linked to skateboarding footwear manufactured within the United States extends beyond the immediate revenue generated from sales. Domestic production initiates a cascade of economic activity, influencing employment, material sourcing, and regional development.

- Job Creation and Retention

Manufacturing within the U.S. directly creates employment opportunities in production facilities, design studios, and distribution centers. Furthermore, it supports indirect employment in related industries, such as material suppliers and transportation services. The presence of a domestic manufacturing base can also lead to the retention of skilled labor, fostering expertise and innovation within the footwear sector. For example, a factory employing 100 workers represents 100 families that can sustain their economic standing within their town, as well as helping local businesses with regular sales.

- Support for Local Economies

Domestic manufacturing stimulates local economies through the purchase of materials and services from regional suppliers. This fosters a network of interconnected businesses, strengthening the economic fabric of the community. Tax revenues generated from manufacturing activity contribute to local government funding, supporting public services and infrastructure development. When there is local business, there is more opportunity to flourish.

- Increased Export Potential

Products labeled as “Made in USA” often command a premium in international markets due to perceptions of higher quality and ethical labor practices. This can increase the export potential of skateboarding footwear, generating additional revenue for domestic manufacturers and contributing to the national trade balance. Brands utilizing domestic manufacturing as a marketing differentiator may experience increased demand from consumers in countries with a preference for American-made goods. The brand image is enhanced if the business sells overseas.

- Reduced Reliance on Global Supply Chains

Domestic manufacturing reduces dependence on complex and potentially volatile global supply chains. This mitigates risks associated with international trade disputes, currency fluctuations, and geopolitical instability. A localized supply chain enhances supply chain transparency and allows for greater control over production processes, leading to increased efficiency and responsiveness to market demands. The business may be able to get a higher volume, as well.

These interconnected facets of economic contribution underscore the significance of supporting skateboarding footwear manufacturing within the United States. By prioritizing domestic production, consumers and industry stakeholders contribute to job creation, local economic growth, increased export potential, and reduced reliance on global supply chains, strengthening the national economy and fostering sustainable development within the footwear industry. Therefore, even with higher costs, there are good reasons to buy american made.

6. Brand Heritage

Brand heritage, in the context of skateboarding footwear produced within the United States, embodies the historical legacy, core values, and distinctive characteristics that define a brand’s identity. This heritage often serves as a significant differentiator, influencing consumer perception and purchase decisions. For those seeking american made shoes, there must be a strong reason for doing so.

- Authenticity and Craftsmanship

Brands with a long-standing commitment to U.S. manufacturing often emphasize authenticity and craftsmanship as central tenets of their heritage. This commitment reflects a dedication to preserving traditional skills and upholding high standards of quality. Examples include brands that have maintained domestic production facilities for decades, showcasing a lineage of skilled artisans and meticulous manufacturing processes. The continued maintenance of U.S. production can show to consumers that the brand is dedicated to being one of the best shoes on the market.

- Association with American Culture

Footwear brands manufactured within the United States frequently evoke a sense of American cultural identity and values. This association can resonate with consumers who seek products that embody ideals such as independence, innovation, and rugged individualism. Brands leverage this connection through marketing campaigns that highlight their American roots, utilizing imagery and messaging that appeals to a sense of national pride. The “made in USA” stamp is an example of brand imagery that is important to some skateboarders.

- Legacy of Innovation and Performance

Certain brands have cultivated a heritage of innovation and performance within the skateboarding community. This involves a consistent track record of introducing new technologies, materials, and designs that enhance the functionality and durability of their footwear. Domestic manufacturing can facilitate this innovation by allowing for closer collaboration between designers, engineers, and production teams, leading to faster prototyping and iteration cycles. This is important because skateboarders need to have a shoe that works for them.

- Ethical Labor Practices and Sustainability

Brands committed to U.S. manufacturing often adhere to stricter labor standards and environmental regulations compared to those operating overseas. This can enhance their reputation among consumers who prioritize ethical sourcing and sustainable production practices. Brands may emphasize their commitment to fair wages, safe working conditions, and environmentally responsible manufacturing processes as integral components of their brand heritage. Knowing you are supporting business practices that make business a better place is an important factor to shoppers.

The brand heritage associated with skateboarding footwear produced within the United States encompasses a constellation of factors, including authenticity, cultural association, innovation, and ethical practices. These elements collectively shape consumer perceptions and contribute to the enduring appeal of brands that have maintained a steadfast commitment to domestic manufacturing. The most important point is whether they have a quality product.

Frequently Asked Questions

The following addresses common inquiries regarding the production, characteristics, and advantages associated with skateboarding footwear manufactured within the United States.

Question 1: What defines skateboarding footwear as “Made in USA”?

To qualify as “Made in USA,” a significant portion of the manufacturing process, including assembly, must occur within the United States. The Federal Trade Commission (FTC) provides specific guidelines regarding this designation, requiring that products advertised as “Made in USA” be “all or virtually all” made in the United States.

Question 2: Are “Made in USA” skateboarding shoes necessarily of higher quality?

Domestic manufacturing does not automatically guarantee superior quality. However, it allows for closer monitoring of production processes, potentially leading to enhanced quality control and adherence to stricter standards. The quality ultimately depends on the brand’s commitment to using high-grade materials and employing skilled labor.

Question 3: Why is domestically manufactured skateboarding footwear often more expensive?

Higher labor costs, stricter environmental regulations, and potentially higher material costs within the United States contribute to increased production expenses. These costs are often reflected in the retail price of the footwear.

Question 4: What are the potential benefits of purchasing skateboarding shoes produced in the United States?

Potential benefits include supporting domestic jobs, fostering local economies, reducing reliance on global supply chains, and potentially benefiting from enhanced quality control. Consumers may also prioritize ethical labor practices and environmental standards often associated with domestic manufacturing.

Question 5: Are specific brands known for manufacturing skateboarding shoes in the USA?

Certain brands have maintained a commitment to domestic production, either entirely or for select product lines. Researching individual brands and verifying their manufacturing practices is advisable to confirm the origin of specific models.

Question 6: How can consumers verify the origin of skateboarding footwear?

Consumers should examine product labels, packaging information, and brand websites for details regarding manufacturing origin. Contacting the manufacturer directly to inquire about their production practices is also recommended.

Understanding the nuances of domestic manufacturing enables informed purchasing decisions. Factors beyond simply the place of production influence overall product value and suitability.

The following section will explore alternative considerations when selecting skateboarding footwear.

Made in USA Skate Shoes

This exploration has illuminated the multifaceted aspects of “made in USA skate shoes,” encompassing manufacturing processes, material sourcing, economic impact, brand heritage, and skateboarding functionality. Emphasis has been placed on objective analysis, avoiding subjective claims. Domestically produced footwear offers potential advantages in quality control, supply chain efficiency, and support for local economies. However, increased production costs often translate to higher retail prices, necessitating a careful evaluation of value proposition for consumers. This detailed description provides an overview of the key factors in determining whether buying these shoes is something that matters to a person.

The future trajectory of the domestic skateboarding footwear industry hinges on continued innovation, consumer demand for ethically and sustainably produced goods, and strategic adaptation to evolving market dynamics. The ongoing discourse surrounding domestic manufacturing, coupled with a discerning consumer base, will ultimately shape the landscape of this specialized product category. Continued research in this area can help build interest with those that support the industry.