Skates featuring a boot constructed from hide offer a unique blend of aesthetics, comfort, and performance characteristics. These skates are typically favored for their durability and ability to mold to the wearer’s foot over time, resulting in a customized fit. The selection often involves considering factors such as the quality of the material, the construction of the frame, and the intended use, be it recreational skating, artistic disciplines, or roller derby.

The utilization of hide in skate construction provides advantages in terms of longevity and support. Historically, hide has been a preferred material due to its resilience and capacity to withstand the rigors of frequent use. The material’s breathability can also contribute to enhanced comfort during extended skating sessions. Furthermore, the aesthetic appeal is a significant factor, with many appreciating the classic and refined look that it provides.

The subsequent sections will delve into specific aspects to consider when evaluating these types of skates, including the different grades of material used, the impact of frame design on performance, and recommendations for proper care and maintenance to maximize the lifespan of the product. The information presented aims to provide a thorough understanding of the attributes that contribute to a high-quality skating experience.

Tips for Evaluating Hide-Based Roller Skates

Selecting roller skates with hide boots necessitates careful consideration to ensure optimal performance and longevity. The following tips offer guidance on key aspects to evaluate during the selection process.

Tip 1: Assess Hide Quality: Examine the grade and finish of the hide. Full-grain hide offers superior durability and develops a desirable patina over time. Avoid corrected-grain hide, which may be more prone to cracking.

Tip 2: Inspect Boot Construction: Verify the stitching quality and overall craftsmanship. Reinforced stitching in high-stress areas, such as the ankle and toe, indicates a higher level of durability.

Tip 3: Evaluate Frame Material: The frame material significantly impacts performance. Aluminum frames offer a balance of weight and rigidity, while steel frames provide increased durability for demanding applications.

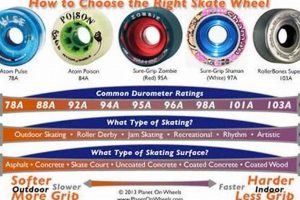

Tip 4: Consider Wheel Durometer: Wheel durometer affects grip and roll. Softer wheels (lower durometer) provide more grip on slick surfaces, while harder wheels (higher durometer) offer faster roll on smoother surfaces.

Tip 5: Prioritize Fit and Comfort: Ensure a snug, comfortable fit that allows for adequate ankle support without restricting movement. Improper fit can lead to discomfort and potential injuries.

Tip 6: Research Bearing Quality: Bearing quality affects rolling efficiency. ABEC ratings indicate bearing precision, with higher ratings generally indicating smoother and faster roll.

Tip 7: Evaluate Closure System: Assess the closure system (laces, buckles, straps) for ease of use and security. A reliable closure system is crucial for maintaining proper foot placement and support.

These considerations, encompassing material quality, construction integrity, and performance characteristics, are paramount when selecting skating equipment. A thorough evaluation process ensures a more satisfying and safer skating experience.

The subsequent section will explore the maintenance procedures essential for preserving the condition and extending the lifespan of this type of specialized footwear.

1. Material Grade

Material grade is a foundational element in determining the quality and performance of hide roller skates. The term refers to the section of the animal hide utilized, the tanning process, and the presence of imperfections. Higher grades, such as full-grain, are derived from the top layer of the hide, retaining its natural grain and possessing inherent strength. These materials exhibit greater resistance to wear and tear, contributing directly to the skate’s overall durability. Lower grades, like split-grain or bonded hide, undergo processes that reduce their natural strength and aesthetic appeal, often resulting in shorter lifespans and compromised performance. The quality of the skating experience is inextricably linked to the integrity of the material employed in the boot’s construction.

The selection of hide material influences the boot’s ability to conform to the skater’s foot over time. Full-grain hide, due to its natural fiber structure, exhibits superior molding properties compared to lower grades. This molding process leads to a customized fit, enhancing comfort and control. Skates constructed from inferior grades may lack this crucial characteristic, resulting in discomfort and reduced responsiveness. For example, a professional skater relying on precision movements would experience a noticeable degradation in performance with skates constructed from a lower grade of material, owing to compromised fit and responsiveness.

In conclusion, material grade exerts a profound influence on the performance, durability, and comfort of hide roller skates. While skates constructed from lower grades may offer a lower initial cost, the long-term benefits of selecting skates featuring high-grade material, such as full-grain hide, outweigh the initial investment. The choice of material grade directly impacts the skater’s experience, potentially determining whether the skates provide years of reliable performance or become a source of frustration and discomfort. The correlation between material grade and the overall quality of the skating experience is undeniable.

2. Boot Construction

Boot construction is a critical determinant of the overall quality and performance characteristics of leather roller skates. The manner in which the components of the boot are assembled directly affects its durability, support, and comfort. Superior construction techniques, such as reinforced stitching in high-stress areas and the use of durable linings, contribute to the longevity of the skates and minimize the risk of structural failure. Conversely, substandard construction methods, such as loose stitching or the use of low-quality adhesives, can compromise the integrity of the boot, leading to premature wear and reduced support. A well-constructed boot provides a stable and secure platform for the skater, enabling precise control and maximizing power transfer.

An example of the impact of boot construction can be seen in the difference between hand-welted and machine-stitched boots. Hand-welting, a traditional technique, involves carefully stitching the upper leather, insole, and outsole together, creating a durable and water-resistant bond. This method is often found in high-end skates and significantly enhances the boot’s lifespan. Machine-stitched boots, while more cost-effective to produce, may not offer the same level of durability or water resistance. The choice of construction technique directly influences the boot’s ability to withstand the stresses of skating and maintain its structural integrity over time. The design and attachment of the heel counter also play a crucial role. A robust heel counter provides essential ankle support, preventing excessive pronation or supination, which can lead to injuries.

In summary, boot construction represents a fundamental aspect of the overall quality and performance of the skating equipment. Careful attention to construction techniques, material selection for linings and reinforcement, and the integration of structural elements such as heel counters is essential for producing skates that offer durability, support, and comfort. A robustly constructed boot enhances the skater’s performance and provides a more enjoyable and safer skating experience. Understanding the significance of boot construction allows consumers to make informed decisions and select skating equipment that meets their specific needs and preferences.

3. Frame Rigidity

Frame rigidity, in the context of hide roller skates, refers to the resistance of the skate’s frame to deformation under applied forces. The frame’s stiffness directly influences the skater’s control, power transfer, and overall skating experience. A frame that exhibits minimal flex allows for more precise movements and efficient propulsion, while a frame that is too flexible can result in a loss of energy and diminished responsiveness. Thus, frame rigidity is a crucial factor in discerning the desirable characteristics of these skates.

- Material Composition

The materials used in frame construction significantly impact rigidity. Aluminum alloys are commonly employed due to their favorable strength-to-weight ratio, offering a balance of stiffness and maneuverability. Steel frames, while heavier, provide enhanced durability and resistance to bending, catering to more demanding applications. The specific alloy and its treatment processes determine the ultimate rigidity of the frame.

- Frame Design and Geometry

The physical design of the frame contributes significantly to its rigidity. Factors such as frame thickness, bridge structures, and the presence of reinforcing elements affect its ability to withstand bending forces. For instance, frames with integrated bridges or strategically placed ribs tend to exhibit higher rigidity compared to simpler designs. The frame’s geometry influences how forces are distributed, thereby impacting its overall stiffness.

- Mounting System

The method used to attach the frame to the boot influences the overall system rigidity. A secure and well-aligned mounting system minimizes play and ensures efficient transfer of energy from the skater’s foot to the wheels. Systems utilizing multiple mounting points and robust hardware contribute to a more rigid connection, reducing energy loss and improving control. In contrast, a poorly designed or loosely mounted system can compromise the frame’s rigidity and responsiveness.

- Skating Discipline and Style

The ideal frame rigidity is contingent on the intended skating discipline and the skater’s style. For example, speed skaters typically prefer frames with high rigidity to maximize power transfer and minimize energy loss during sprints. Artistic skaters may favor frames with a moderate degree of flex to facilitate nuanced movements and enhance maneuverability. Roller derby players often require frames with a balance of rigidity and durability to withstand the demands of aggressive gameplay.

The connection between frame rigidity and the overall performance of hide roller skates is undeniable. Skates offering optimal frame rigidity, appropriate for the skater’s intended use, translate to enhanced control, efficient power transfer, and an improved skating experience. Therefore, prospective buyers should carefully consider the material composition, design, mounting system, and intended application when evaluating these products. Selecting a frame with appropriate rigidity is a critical step in optimizing skating performance.

4. Wheel Durometer

Wheel durometer is a crucial specification influencing the performance characteristics of roller skates, especially when considering skates with hide boots. Durometer, measured on the “A” scale, quantifies a wheel’s hardness. The selection of an appropriate durometer significantly impacts grip, roll speed, and wear resistance, thereby affecting the skater’s experience.

- Grip and Surface Interaction

Lower durometer wheels (e.g., 78A-85A) are softer, offering increased grip, particularly on slick or uneven surfaces. The softer compound deforms more readily, maximizing contact area. This is advantageous for beginners or skaters prioritizing stability and control. In contrast, harder wheels (e.g., 95A-101A) provide less grip but faster roll speeds on smooth surfaces. Examples would include rink skating where the hard, smooth surface lends itself to the harder wheels, allowing for less resistance when rolling.

- Roll Speed and Efficiency

Higher durometer wheels typically exhibit lower rolling resistance on smooth surfaces, translating to faster speeds. The harder compound deforms less, minimizing energy loss. Speed skaters often opt for harder wheels to maximize efficiency and achieve higher velocities. This consideration is paramount for competitive environments or skaters focusing on speed training.

- Wear Resistance and Durability

Wheel durometer influences wear characteristics. Softer wheels tend to wear down more quickly, especially on abrasive surfaces. Harder wheels offer greater resistance to abrasion and typically provide a longer lifespan. Recreational skaters who primarily skate outdoors may benefit from harder wheels, as they are less susceptible to wear from rough pavement.

- Skating Style and Discipline

The optimal wheel durometer is contingent on the skating style and discipline. Artistic skaters may prefer a medium durometer (e.g., 88A-92A) to balance grip and roll for performing intricate maneuvers. Roller derby players often utilize wheels with specific durometers tailored to the track conditions and the demands of competitive gameplay. The skater’s skill level and personal preferences also influence the selection process.

The relationship between wheel durometer and skates featuring hide boots is intrinsic. As the boots are typically chosen for their fit and aesthetic qualities, the wheels themselves offer another avenue to customize the skate’s performance. Whether prioritizing control, speed, or durability, the judicious selection of wheel durometer is crucial to optimizing the skating experience.

5. Bearing Precision

Bearing precision directly influences the rolling efficiency and overall performance of leather roller skates. Bearings facilitate the smooth rotation of the wheels around their axles. The precision with which bearings are manufactured and assembled impacts the level of friction generated during rotation. High-precision bearings exhibit reduced friction, translating to faster roll speeds and less energy expenditure for the skater. Conversely, low-precision bearings generate more friction, resulting in slower speeds and increased effort to maintain momentum. Therefore, bearing precision is a significant factor in determining the quality and performance of roller skates, especially those featuring hide boots where the boot itself contributes to the comfort and fit but doesn’t inherently affect rolling speed.

Bearing precision is typically indicated by the Annular Bearing Engineers’ Committee (ABEC) rating. ABEC ratings range from 1 to 9, with higher numbers signifying tighter tolerances and greater precision. For example, skates equipped with ABEC-7 or ABEC-9 bearings will generally offer smoother and faster roll compared to those with ABEC-1 or ABEC-3 bearings. However, ABEC rating is not the sole determinant of bearing quality; factors such as material quality, lubrication, and proper maintenance also play crucial roles. Furthermore, certain skating disciplines may benefit more from specific bearing types. Speed skaters often prioritize high-precision bearings for maximum velocity, while recreational skaters may find that mid-range bearings offer an adequate balance of performance and cost. Roller derby may require tougher, less precise, bearings for increased resilience to impacts.

In summary, bearing precision constitutes a crucial element in the performance profile of leather roller skates. Higher precision translates to improved rolling efficiency and a more effortless skating experience. While ABEC ratings provide a useful guideline, skaters should also consider other factors, such as material quality and maintenance, when selecting bearings. The optimal bearing choice depends on the intended skating discipline and the skater’s individual preferences. Understanding the significance of bearing precision empowers consumers to make informed decisions and select roller skates that align with their specific performance goals. The performance advantages derived from high bearing precision directly improve overall skate performance.

6. Fit Security

Fit security, in the context of hide roller skates, represents the degree to which the skate remains securely and comfortably affixed to the foot during use. It is a critical component of overall performance, influencing control, stability, and the prevention of injuries. A skate with inadequate fit security can lead to compromised maneuverability, increased risk of ankle strain, and diminished power transfer. The term encompasses several aspects, including the lacing system, internal padding, and the anatomical design of the boot itself. Skates claiming to be high-quality must address these facets effectively.

One illustrative scenario involves a skater attempting a complex artistic maneuver. If the skate lacks adequate fit security, the foot may shift within the boot during the execution of the maneuver. This slippage diminishes control and increases the likelihood of a misstep or fall. Conversely, a skate with a secure fit allows for precise control and efficient transfer of energy, enabling the skater to execute the maneuver with confidence and accuracy. The lacing system is a primary contributor to the stability. High-end models employ sophisticated systems to ensure even pressure distribution, preventing localized pressure points. Poorly executed lacing systems may result in localized discomfort and a decrease in stability, counteracting the benefits of the material. Padding also contributes to the internal environment providing greater comfort to the skater.

Ultimately, fit security constitutes a non-negotiable attribute of high-performing hide roller skates. A well-designed boot, coupled with a reliable lacing system and appropriate padding, provides the foundation for secure and comfortable skating. Compromises in fit security can lead to diminished performance and an increased risk of injury. Understanding the importance of secure fit allows consumers to make informed decisions, prioritizing skates that offer optimal stability and control. Therefore, skates claiming to be high-quality must ensure the foot remains stable and secured within the boot at all times, or the quality is greatly reduced. The interplay between boot construction, lacing mechanisms, and internal cushioning is fundamental to achieving this goal.

Frequently Asked Questions

This section addresses common inquiries regarding roller skates featuring boots constructed from hide, providing clear and concise answers to facilitate informed decision-making.

Question 1: What distinguishes full-grain hide from other hide grades used in skate boots?

Full-grain hide retains the natural grain and possesses greater tensile strength compared to corrected-grain or split-grain alternatives. This translates to enhanced durability and a longer lifespan for the skate boot.

Question 2: How does frame material influence the performance of hide roller skates?

Frame material affects the skate’s rigidity, weight, and power transfer. Aluminum frames offer a balance of these characteristics, while steel frames provide increased durability for demanding applications.

Question 3: What is the significance of wheel durometer in roller skate performance?

Wheel durometer dictates the wheel’s hardness, impacting grip, roll speed, and wear resistance. Softer wheels offer greater grip, while harder wheels provide faster roll speeds on smooth surfaces.

Question 4: How do bearing ABEC ratings relate to the speed and efficiency of roller skates?

ABEC ratings indicate bearing precision. Higher ABEC ratings generally correspond to smoother and faster roll, although factors such as lubrication and maintenance also play a crucial role.

Question 5: What are the key considerations for achieving a secure and comfortable fit in hide roller skates?

A secure fit necessitates a snug but non-restrictive boot, a reliable lacing system, and adequate internal padding. Proper fit is essential for control, stability, and injury prevention.

Question 6: How can one properly maintain hide roller skates to maximize their lifespan?

Proper maintenance involves regular cleaning, lubrication of bearings, inspection of hardware, and appropriate storage to prevent moisture damage. Consistent care can significantly extend the useful life of the skates.

These FAQs provide fundamental insights into the critical aspects of hide roller skates. Understanding these factors facilitates informed purchasing decisions and promotes optimal skating performance.

The subsequent section provides a detailed summary of the key factors discussed throughout the previous sections, serving as a consolidation of information of what to consider when evaluating “best leather roller skates”.

Discerning Superior Hide Roller Skates

The preceding analysis has underscored the multifaceted considerations inherent in the selection of high-quality roller skates featuring hide boots. Factors such as material grade, boot construction, frame rigidity, wheel durometer, bearing precision, and fit security have been identified as critical determinants of performance, durability, and user satisfaction. Each element contributes uniquely to the overall skating experience, necessitating a comprehensive evaluation process.

The pursuit of superior hide roller skates requires a discerning approach, prioritizing objective assessment over superficial aesthetics or unsubstantiated claims. Informed consumers should leverage the insights presented herein to make sound judgments, ensuring that their investment yields a product that meets their specific needs and performance expectations. Further research and diligent consideration will lead to an informed purchase.