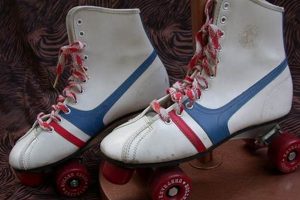

These components, typically constructed from polyurethane, exhibit a reduced diameter when compared to standard-sized options. Their smaller profile contributes to a lower center of gravity and enhanced maneuverability. For example, individuals engaged in artistic skating or those navigating crowded indoor environments often prefer them for their responsiveness and agility.

The utilization of reduced-size rolling elements provides several advantages, including increased control and faster acceleration. Historically, these were frequently adopted in rink skating, where quick turns and precise movements are paramount. The diminished size contributes to a more connected feel to the skating surface, allowing for nuanced adjustments and improved reaction times. This characteristic makes them well-suited for activities demanding intricate footwork.

The following sections will delve into the specific applications, material considerations, and performance characteristics associated with selecting appropriate rolling elements for various skating disciplines. Factors such as durometer, bearing compatibility, and intended usage significantly influence the overall skating experience and will be discussed in detail.

Tips for Selecting and Maintaining Small Roller Skate Wheels

This section provides guidance on choosing and maintaining smaller diameter rolling components for optimal performance and longevity. Proper selection and maintenance are critical for a safe and enjoyable skating experience.

Tip 1: Durometer Selection: A lower durometer rating (e.g., 78A) indicates a softer composition, offering superior grip but potentially reduced lifespan on abrasive surfaces. A higher durometer (e.g., 95A) provides greater speed and durability but less grip. Consider the skating environment and desired performance characteristics when selecting durometer.

Tip 2: Bearing Compatibility: Ensure that the bearings are compatible with the inner diameter of the selected rolling elements. Standard 608 bearings are commonly used, but variations may exist. Verify compatibility specifications before installation to prevent damage or malfunction.

Tip 3: Surface Considerations: Smooth, indoor surfaces generally benefit from harder compositions for increased speed. Rougher outdoor surfaces require softer compositions for enhanced grip and vibration absorption. Optimize selection based on the predominant skating environment.

Tip 4: Regular Cleaning: Periodically clean the rolling elements to remove dirt, debris, and accumulated grime. Use a mild soap and water solution and ensure thorough drying before reinstalling to prevent bearing corrosion.

Tip 5: Rotation Practices: Rotate the rolling elements periodically to ensure even wear. This practice extends their lifespan and maintains consistent performance characteristics. Consider rotating them in a cross pattern to distribute wear more evenly.

Tip 6: Axle Nut Torque: Verify that axle nuts are tightened to the appropriate torque specification. Over-tightening can damage bearings and impede rotation, while under-tightening can lead to instability and premature wear.

Effective selection and consistent maintenance practices contribute to enhanced performance, extended lifespan, and improved safety when utilizing small diameter rolling components. Careful attention to these details can significantly improve the overall skating experience.

The concluding section will summarize the key considerations discussed and offer recommendations for maximizing the benefits of smaller diameter rolling components in various skating disciplines.

1. Maneuverability

The reduced diameter of these rolling components directly enhances a skater’s ability to execute tight turns and rapid directional changes. This heightened maneuverability stems from a shorter contact patch with the skating surface, allowing for quicker transitions between edges and facilitating more agile movements. The cause-and-effect relationship is clear: decreased rolling element size results in increased agility. The importance of this characteristic is paramount in disciplines such as roller derby or freestyle skating, where navigating confined spaces and reacting swiftly to changing conditions are essential. For example, a roller derby skater utilizing smaller diameter elements can more effectively weave through opposing players and maintain positional advantage.

Furthermore, this maneuverability advantage extends to indoor environments, where space is often limited. Skaters utilizing rinks or indoor skate parks can benefit from the enhanced control afforded by the reduced size. The shorter wheelbase created by the smaller wheels allows for more precise movements and reduces the risk of collisions with obstacles or other skaters. This characteristic is particularly advantageous for beginners who are developing their balance and coordination skills, as the increased control provides a more stable and predictable skating experience. Artistic skaters also find the enhanced agility useful for intricate footwork sequences.

In summary, the enhanced maneuverability afforded by the reduced diameter provides a tangible performance advantage in various skating disciplines. The cause-and-effect relationship between size and agility is well-established, and the practical significance of this understanding is evident in the increased control, responsiveness, and reduced risk of collisions experienced by skaters utilizing these components. While other factors such as durometer and bearing quality also contribute to overall performance, the size remains a primary determinant of maneuverability.

2. Acceleration

The application of smaller diameter rolling elements directly influences the acceleration profile of a skater. Reduced rotational inertia, a consequence of the diminished size, permits a quicker attainment of peak velocity from a standstill. This is because less force is required to initiate and sustain the rotation of smaller, lighter components. The resultant effect is improved responsiveness during starts and short bursts of speed. The magnitude of this effect becomes particularly evident in scenarios demanding rapid changes in velocity, such as sprinting on a track or navigating obstacle courses. A real-world manifestation of this principle is observed in speed skating events, where skaters may strategically choose smaller diameter configurations to optimize their initial acceleration from the starting line.

Furthermore, the enhanced acceleration characteristics translate into an advantage in dynamic situations requiring frequent speed adjustments. For instance, a hockey player utilizing smaller diameter rolling elements can gain a competitive edge by reacting more swiftly to changes in game play. The ability to rapidly accelerate and decelerate facilitates improved agility and responsiveness in both offensive and defensive maneuvers. While the absolute top speed achievable may be marginally reduced compared to larger diameter options, the gains in acceleration more than compensate in scenarios requiring rapid and repeated changes in velocity. This trade-off underscores the importance of selecting rolling elements that align with the specific demands of the intended skating discipline.

In summary, the connection between reduced size and enhanced acceleration is grounded in fundamental physics principles governing rotational inertia. This relationship translates into tangible performance benefits in a variety of skating contexts, ranging from competitive racing to recreational activities. Understanding the trade-offs associated with different rolling element sizes is crucial for optimizing performance and ensuring a positive skating experience. The principles outlined are applicable across various skating disciplines, allowing skaters to make informed decisions based on their specific needs and objectives. Challenges in selection arise when surface conditions vary, requiring careful consideration of durometer in conjunction with size to achieve the desired performance balance.

3. Surface Contact

The degree of contact between a rolling element and the skating surface is a critical determinant of traction, control, and energy transfer. Employing smaller diameter options intrinsically alters this interaction. With a reduced circumference, the contact patch the area directly interfacing with the ground diminishes. This smaller area concentrates pressure, which can enhance grip on certain surfaces, especially when coupled with appropriate durometer selections. The effect of concentrated pressure translates into increased responsiveness, enabling skaters to feel more connected to the skating surface. An example of this is observable in indoor artistic skating, where the polished surface demands maximum grip for executing intricate maneuvers. The smaller contact patch allows for precise control, a necessity for maintaining balance and accurately translating intended movements into action.

However, the reduced contact area also presents limitations. On rougher surfaces, the smaller contact patch can result in diminished stability and increased susceptibility to vibrations. The consequence is a less comfortable and potentially less efficient skating experience. Therefore, selecting smaller rolling elements necessitates a careful evaluation of the intended skating environment. For instance, skaters frequently traversing outdoor surfaces may prioritize larger rolling elements or softer durometers to maximize surface contact and mitigate the adverse effects of uneven terrain. The interplay between surface texture and rolling element size becomes a crucial consideration in optimizing performance and ensuring a safe and enjoyable experience. Further, the type of skating discipline plays a role; speed skaters prioritize minimal rolling resistance, potentially benefiting from a reduced contact patch on smooth surfaces.

In summary, surface contact constitutes a fundamental performance characteristic directly affected by the size of the rolling element. The smaller contact patch offered by reduced-diameter options enhances responsiveness and grip on smooth surfaces but can compromise stability on rougher terrain. Optimal utilization mandates a thorough understanding of the intended skating environment and a careful consideration of the trade-offs involved. The challenge lies in balancing the benefits of increased responsiveness with the potential drawbacks of reduced stability, a decision ultimately driven by the skater’s specific needs and preferences.

4. Application Specificity

The selection of rolling elements is inextricably linked to the intended application. The benefits derived from reduced-size components are maximized when aligned with the specific demands of a particular skating discipline. A cause-and-effect relationship exists: employing inappropriately sized elements leads to suboptimal performance. Application specificity dictates that considerations extend beyond mere size, encompassing durometer, bearing compatibility, and surface conditions. For instance, artistic skating necessitates enhanced maneuverability within a controlled rink environment; smaller diameter components facilitate intricate footwork and precise movements. Conversely, long-distance outdoor skating may favor larger diameters for improved roll-over capabilities and reduced energy expenditure. Ignoring these specific application requirements results in diminished efficiency and potentially increased risk of injury.

Practical applications demonstrate the critical importance of this understanding. In roller derby, where rapid acceleration and agility are paramount, smaller wheels offer a distinct advantage in navigating crowded tracks and executing quick turns. This contrasts sharply with speed skating, where larger diameter elements are often favored to maximize top-end velocity on smooth, flat surfaces. Moreover, recreational skating, encompassing diverse environments from paved trails to skate parks, demands a more nuanced approach. Skaters must consider the predominant surface type and prioritize either enhanced grip or increased rolling efficiency. The selection process, therefore, requires a comprehensive assessment of the application’s inherent characteristics and a corresponding matching of rolling element specifications.

In summary, application specificity represents a cornerstone in the effective utilization of rolling elements. Prioritizing this factor ensures that the chosen components contribute optimally to the skater’s performance and overall experience. The challenge lies in accurately assessing the demands of a given application and translating those requirements into specific rolling element characteristics. This approach is critical for maximizing the benefits of reduced-size options and avoiding performance compromises. Failure to acknowledge the importance of application specificity undermines the potential advantages offered by careful component selection, thus emphasizing its critical role in optimizing skating performance.

5. Durometer Selection

Durometer, a measure of a rolling element’s hardness, directly influences performance when combined with reduced diameter designs. A softer durometer rating, typically below 85A, provides increased grip, particularly advantageous on slick indoor surfaces where the smaller contact patch of these rolling elements might otherwise compromise traction. A real-world example includes artistic skaters selecting softer durometers to maintain control during complex maneuvers on polished rink floors. Conversely, a harder durometer, exceeding 90A, minimizes rolling resistance, making it suitable for smoother surfaces where speed is prioritized. The interaction between durometer and size determines overall maneuverability, acceleration, and control.

The selection process requires careful consideration of surface conditions and intended skating discipline. Smaller diameter rolling elements with lower durometers enhance grip for activities like roller derby on indoor tracks. In contrast, when utilizing smaller diameter components for recreational skating on varied outdoor surfaces, a mid-range durometer balances grip and durability. Bearing performance and skater weight also influence optimal durometer choice; heavier skaters often benefit from harder components to prevent excessive compression and maintain roll speed. Proper selection ensures efficient energy transfer and minimizes premature wear, extending the lifespan of the rolling elements.

Ultimately, durometer selection constitutes a crucial component in maximizing the benefits of small roller skate wheels. Incorrectly matching durometer to the skating environment and discipline can lead to compromised performance and decreased safety. Understanding the cause-and-effect relationship between durometer, surface conditions, and skating style enables informed decision-making, ensuring optimal performance characteristics and a positive skating experience. The challenge lies in adapting durometer choices to specific needs, underscoring the importance of informed selection for any skating application.

Frequently Asked Questions

This section addresses common inquiries regarding the selection and application of reduced-size rolling components, offering concise and informative responses to guide informed decision-making.

Question 1: What are the primary advantages of utilizing reduced-size rolling elements?

Reduced-size rolling elements offer enhanced maneuverability and quicker acceleration compared to larger counterparts. This characteristic is particularly beneficial in environments requiring rapid directional changes and agility.

Question 2: Under what circumstances are smaller diameter rolling elements most suitable?

These components are ideally suited for indoor skating rinks, artistic skating, and roller derby, where tight turns and precise movements are paramount. The smaller contact patch provides heightened responsiveness and control.

Question 3: How does durometer affect the performance of reduced-size rolling elements?

Durometer dictates the hardness of the rolling element. Softer durometers (lower numerical values) offer increased grip, while harder durometers (higher numerical values) prioritize speed and durability. Selection should align with surface conditions and skating style.

Question 4: Are there any disadvantages associated with using small rolling elements?

On rough or uneven surfaces, the reduced contact patch can compromise stability and increase vibration. This may result in a less comfortable skating experience compared to using larger diameter elements.

Question 5: How does bearing compatibility influence the selection process?

Ensure that the bearings are compatible with the inner diameter of the rolling elements. Standard 608 bearings are commonly used, but variations may exist. Verifying compatibility prevents damage and ensures optimal performance.

Question 6: How can the lifespan of reduced-size rolling elements be maximized?

Regular cleaning, periodic rotation, and proper axle nut torque are essential for extending the lifespan. Avoid skating on abrasive surfaces and consider durometer selection to mitigate wear and tear.

These FAQs provide a foundational understanding of rolling element selection. Addressing these factors aids in optimizing performance and ensuring a positive skating experience. Proper application enhances safety and longevity of rolling components.

The subsequent section delves into the historical development and technological advancements relating to this technology, tracing the evolution of rolling element design and materials.

Conclusion

The preceding discussion has examined the multifaceted characteristics of rolling elements characterized by their reduced dimensions. Key considerations, including maneuverability, acceleration, surface contact dynamics, application specificity, and durometer selection, have been thoroughly analyzed. The interrelationship between these factors and their impact on skating performance has been established, providing a comprehensive understanding of their function and selection criteria. The benefits of smaller options have been clarified, with specific focus on indoor and specialized applications.

Ultimately, the informed selection and responsible application of these rolling elements are paramount. A commitment to understanding these nuances fosters optimal performance, enhances safety, and extends the lifespan of the equipment. The continuing advancement of materials and designs promises further refinements, solidifying their role in skating across a variety of disciplines and recreational activities. Future study should concentrate on specific applications to find the precise conditions of rolling for users.