Footwear that integrates wheels, allowing the wearer to glide and roll along surfaces, can be referred to by a superlative descriptor. Such wheeled footwear provides a recreational and transportation option. A particular model lauded for its comfort, durability, performance, and features, such as superior ankle support or advanced braking systems, might be considered an example.

The appeal of integrated wheeled footwear lies in its portability and convenience, offering a blend of walking and skating capabilities. Its historical context encompasses a range of designs, from early rudimentary models to sophisticated contemporary versions. The advantages of well-designed models include enhanced maneuverability, improved fitness, and enjoyment of outdoor activities.

The subsequent sections will examine critical factors in selecting appropriate models, discuss the range of available styles, and explore the maintenance requirements for optimal performance and longevity.

Selection and Maintenance Guidance

This section provides important considerations for choosing and caring for integrated wheeled footwear, ensuring safety and maximizing product lifespan.

Tip 1: Prioritize Safety Features: Evaluate braking systems, ankle support mechanisms, and overall structural integrity before purchase. Models with robust safety features minimize the risk of injury.

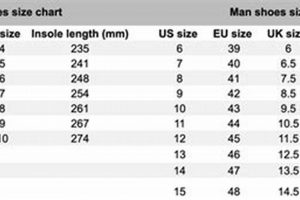

Tip 2: Assess Wheel Quality: Wheel material and durometer impact performance and durability. Polyurethane wheels are generally preferred for their grip and longevity, while durometer ratings should align with intended usage environment. Harder wheels are for outdoor and softer wheels are for indoor.

Tip 3: Consider Fit and Comfort: Proper fit is essential for control and prevents blisters. Try on footwear with the socks typically worn during use, ensuring a snug but not constricting fit.

Tip 4: Evaluate Bearing Performance: Bearings influence rolling efficiency. Higher ABEC ratings indicate tighter tolerances and smoother rolling, but regular cleaning and lubrication are necessary to maintain performance.

Tip 5: Inspect for Adjustability: Features like adjustable straps or buckles allow for a customized fit, enhancing comfort and stability. Verify the durability of adjustment mechanisms.

Tip 6: Implement Regular Maintenance: Routine maintenance extends the products lifespan. Clean wheels and bearings periodically, and inspect for signs of wear or damage. Replace components as needed.

Tip 7: Choose the Right Environment: The type of surface on which the skates are used impacts their performance and longevity. Avoid abrasive surfaces that can quickly wear down wheels and bearings.

Adhering to these guidelines promotes safer and more enjoyable use, while also preserving the functionality of the product.

The concluding section will offer a synthesis of the information presented, summarizing key considerations for optimal product selection and usage.

1. Durability and Longevity

The intrinsic connection between durability and longevity directly influences the perceived value and overall utility of integrated wheeled footwear. The selection of robust materials and the implementation of sound construction techniques are critical determinants of the product’s lifespan. Inferior materials or construction inevitably lead to premature wear, component failure, and a diminished user experience. For example, a model employing low-grade plastic in its chassis is susceptible to cracking under stress, whereas one utilizing reinforced polymers or metal alloys exhibits greater resistance to impact and fatigue.

The longevity of wheeled footwear extends beyond the structural integrity of the chassis. Wheel composition and bearing quality also play pivotal roles. Polyurethane wheels, known for their abrasion resistance, outperform cheaper alternatives such as PVC in terms of wear rate. Similarly, sealed bearings offer superior protection against contaminants, extending their operational life compared to unsealed varieties. Regular maintenance, including cleaning and lubrication, further contributes to the product’s long-term performance. A failure to maintain components leads to increased friction, diminished rolling efficiency, and accelerated wear.

In summary, durability and longevity are not merely desirable attributes but fundamental requirements for a product intended for repeated use and exposure to varying environmental conditions. Investing in models constructed with high-quality materials and employing proper maintenance practices maximizes the return on investment and minimizes the likelihood of premature replacement, thus supporting the designation of such products as representing the “best.”

2. Comfort and Support

The integration of comfort and support into integrated wheeled footwear directly impacts user experience, safety, and performance. Consideration of these factors is paramount in defining the qualities of well-designed products.

- Ankle Support and Stability

Ankle support mechanisms are essential for maintaining stability and preventing injuries. High-quality models incorporate reinforced ankle cuffs and secure lacing systems to minimize lateral movement. Insufficient support can lead to sprains or strains, particularly during sharp turns or uneven terrain. Rigid supports may increase stability, while flexible supports allow for a greater range of motion, impacting maneuverability.

- Internal Padding and Cushioning

Internal padding and cushioning enhance comfort during extended use. Materials such as memory foam or gel inserts conform to the foot’s contours, reducing pressure points and minimizing friction. Effective padding absorbs vibrations, lessening fatigue. Insufficient padding results in discomfort and blisters, detracting from the user experience.

- Breathability and Ventilation

Breathability and ventilation features mitigate moisture buildup and regulate temperature. Materials with moisture-wicking properties or strategically placed ventilation openings promote airflow, preventing overheating and discomfort. Inadequate ventilation leads to perspiration accumulation, which can cause blisters and reduce grip within the footwear.

- Arch Support and Footbed Design

The arch support and footbed design address the biomechanics of the foot, providing stability and distributing pressure evenly. Contoured footbeds cradle the arch, reducing strain on the plantar fascia. Adequate arch support minimizes pronation or supination, improving alignment and reducing the risk of overuse injuries. Improper arch support results in foot pain, fatigue, and potentially exacerbate existing conditions.

The synthesis of these elements contributes to an overall improvement in comfort and support. Designs prioritizing these factors allow for extended usage with reduced risk of discomfort or injury, thereby enhancing performance and overall product satisfaction. Superior comfort and support define the attributes most desirable in high-quality footwear.

3. Wheel Performance

Wheel performance constitutes a critical determinant in the overall functionality and user satisfaction associated with integrated wheeled footwear. Characteristics of the wheel directly influence speed, maneuverability, grip, and durability, thus significantly impacting the product’s suitability for various applications. Optimized wheel performance is a defining feature of high-quality models.

- Wheel Material and Durometer

The material composition and durometer, or hardness, of the wheel dictate its rolling efficiency and wear resistance. Polyurethane (PU) wheels are commonly favored due to their balance of grip and durability. The durometer rating, measured on the Shore A scale, indicates the wheel’s hardness. Lower durometer wheels (e.g., 78A-85A) provide enhanced grip and shock absorption, suitable for uneven surfaces. Higher durometer wheels (e.g., 88A and above) offer increased speed and wear resistance on smoother surfaces. The selection of an appropriate durometer depends on the intended use environment. Using a harder wheels are for outdoor and softer wheels are for indoor.

- Wheel Size and Profile

Wheel diameter influences rolling speed and agility. Larger wheels generally provide faster speeds and improved roll-over capability, while smaller wheels offer increased maneuverability. The wheel profile, or cross-sectional shape, affects grip and turning characteristics. Rounded profiles promote smoother turning, while flatter profiles offer increased stability and grip. The choice of wheel size and profile depends on the skating style and desired performance characteristics.

- Bearing Quality and Precision

Bearings facilitate wheel rotation, and their quality directly impacts rolling efficiency. ABEC (Annular Bearing Engineering Committee) ratings indicate the precision and tolerances of the bearing. Higher ABEC ratings (e.g., ABEC 5, ABEC 7, ABEC 9) signify tighter tolerances and smoother rolling. However, the relevance of ABEC rating diminishes without proper maintenance, i.e. cleaning and lubrication. Sealed bearings provide protection against contaminants, extending their lifespan. High-quality bearings minimize friction and maximize speed, contributing to a more efficient and enjoyable skating experience.

- Core Design and Material

The wheel core provides structural support and influences the wheel’s responsiveness. Cores constructed from rigid materials, such as nylon or aluminum, transfer energy more efficiently, enhancing acceleration and power transfer. The design of the core, including its shape and spoke configuration, impacts the wheel’s weight and flexibility. Lighter cores reduce rotational inertia, while flexible cores absorb vibrations. The interplay between core design and material properties influences the overall feel and performance of the wheel.

These interconnected facets of wheel performance collectively determine the quality and suitability of the integrated wheeled footwear. A balanced approach, considering material properties, size, bearing quality, and core design, is crucial in selecting models that offer optimal performance characteristics and align with individual user preferences and intended applications. The careful consideration of wheel performance contributes to the overall perception of the wheeled footwear.

4. Braking Effectiveness

Braking effectiveness is a paramount safety consideration in the context of integrated wheeled footwear. The capacity to decelerate and stop reliably and predictably directly influences the potential for injury and the overall control afforded to the user. Effective braking systems are fundamental to the safe operation of such devices.

- Brake Pad Material and Design

The material composition and design of the brake pad significantly impact stopping power. Rubber compounds offer a balance of friction and durability, while harder materials provide increased stopping force but may exhibit reduced lifespan or increased wear on the wheel surface. The surface area and pattern of the brake pad influence heat dissipation and grip. Larger surface areas provide greater stopping force, while patterned surfaces channel away debris and water, maintaining consistent performance in varying conditions.

- Brake Mechanism Type and Actuation

Various braking mechanisms are employed in integrated wheeled footwear, each with distinct advantages and disadvantages. Heel brakes, activated by tilting the foot backward, are common due to their simplicity and ease of use. However, their effectiveness can be limited by the user’s skill and reaction time. Front brakes, engaged by pressing a lever or button, offer more controlled deceleration but may require greater dexterity and familiarity. The actuation mechanism, whether mechanical or electronic, impacts the responsiveness and precision of the braking system.

- Braking Distance and Response Time

Braking distance, or the distance required to come to a complete stop from a given speed, is a critical metric for evaluating braking effectiveness. Shorter braking distances indicate superior stopping power. Response time, the interval between initiating the braking action and the commencement of deceleration, also influences safety. Shorter response times allow for more immediate control and reduce the likelihood of collisions. Factors such as wheel material, surface conditions, and user weight affect braking distance and response time.

- Brake Pad Wear and Maintenance

Brake pad wear is an inevitable consequence of usage and directly affects braking performance. Regular inspection of brake pads is essential to identify signs of wear, such as reduced thickness or surface damage. Worn brake pads should be replaced promptly to maintain optimal stopping power. Improper maintenance, such as neglecting to clean the brake mechanism or lubricate moving parts, can lead to reduced braking efficiency and premature failure.

The integration of effective braking systems is a defining characteristic of models intended for safe and controlled use. A comprehensive evaluation of brake pad material and design, braking mechanism type, braking distance, and maintenance requirements is crucial in determining the suitability of the product. The ability to reliably and predictably decelerate contributes significantly to user confidence and reduces the risk of accidents, thereby enhancing the overall enjoyment and safety.

5. Adjustability and Fit

The relationship between adjustability, fit, and the designation of “best shoe skates” is causal and critical. A properly fitting skate, augmented by adjustability features, directly enhances user comfort, control, and safety. Ill-fitting skates, even with advanced features, can lead to discomfort, blisters, reduced maneuverability, and an increased risk of injury. Adjustability mechanisms mitigate these risks by allowing users to tailor the skate’s fit to their specific foot dimensions and preferences.

Consider a scenario where two skaters use identical models of integrated wheeled footwear. One skater, with average foot proportions, experiences a secure and comfortable fit, enabling precise control and prolonged usage. The second skater, with wider feet or higher arches, finds the standard fit constricting and uncomfortable, leading to reduced performance and potential foot pain. A model with adjustable straps, buckles, or liners would permit the second skater to customize the fit, achieving a similar level of comfort and control to the first skater. Such adaptability distinguishes superior models from those with limited accommodation.

The practical significance of understanding this connection lies in informed consumer decision-making and product design. Consumers seeking optimal performance should prioritize models with comprehensive adjustability features and ensure a precise fit before purchase. Manufacturers should invest in designs that accommodate a wider range of foot shapes and sizes, incorporating intuitive and durable adjustment mechanisms. By emphasizing adjustability and fit, both consumers and manufacturers contribute to a safer and more enjoyable skating experience, solidifying the product’s claim as representing the “best.”

Frequently Asked Questions About Integrated Wheeled Footwear

This section addresses prevalent inquiries regarding integrated wheeled footwear, providing factual responses to promote informed understanding.

Question 1: What are the primary safety considerations when using integrated wheeled footwear?

Emphasis should be placed on protective gear, including helmets, knee pads, elbow pads, and wrist guards. A thorough understanding of braking mechanisms and techniques is essential. Selecting appropriate environments, free from obstacles and hazards, is also crucial.

Question 2: How does wheel durometer affect performance?

Wheel durometer, measured on the Shore A scale, indicates hardness. Lower durometer wheels offer greater grip and shock absorption, suitable for rough surfaces. Higher durometer wheels provide increased speed and wear resistance, ideal for smooth surfaces. The selection of appropriate durometer values depends on the intended environment and skating style.

Question 3: What maintenance procedures are necessary to prolong the lifespan of the product?

Regular cleaning of wheels and bearings removes dirt and debris. Lubrication of bearings reduces friction and prevents corrosion. Inspection of brake pads and replacement when worn is essential. Tightening loose hardware and addressing any structural damage promptly also contributes to longevity.

Question 4: How does bearing quality influence performance?

Bearing quality, often indicated by ABEC ratings, affects rolling efficiency. Higher ABEC ratings signify tighter tolerances and smoother rolling. However, proper maintenance, including cleaning and lubrication, is paramount, irrespective of the ABEC rating. Sealed bearings offer improved protection against contaminants.

Question 5: What are the key features to consider when evaluating fit and comfort?

Ankle support mechanisms are essential for stability. Internal padding should provide cushioning and reduce pressure points. Breathability features mitigate moisture buildup. Adjustable straps or buckles allow for customized fit. Proper arch support is critical for foot alignment and comfort.

Question 6: Are integrated wheeled footwear suitable for all age groups?

Suitability depends on individual skill levels and physical capabilities. Younger users require closer supervision and may benefit from models designed specifically for beginners. Older users should consider physical limitations and select models that prioritize stability and ease of use.

These responses provide a foundational understanding of key aspects related to the use and maintenance. Further exploration of specific product features and intended applications is recommended.

The subsequent segment will synthesize the information presented, providing a conclusive summary and call to action.

Concluding Remarks on Integrated Wheeled Footwear

This exploration has illuminated critical facets pertaining to the selection, maintenance, and utilization of integrated wheeled footwear. Evaluation of durability, wheel performance, braking systems, adjustability, and fit are paramount in determining product suitability. Prioritization of safety, adherence to maintenance protocols, and judicious selection based on individual needs remain essential considerations for all users. The designation of footwear as representing the “best shoe skates” is contingent upon a confluence of these factors.

In light of the presented information, individuals are encouraged to approach the selection process with diligence, prioritizing models that demonstrably prioritize safety, performance, and longevity. Future advancements in materials science and engineering may further refine the capabilities and utility of integrated wheeled footwear. Continued research and development are essential to optimize the user experience and enhance the inherent benefits of this transportation and recreational modality.

![Top Rated: Best Skate Shoe Company Guide [2024] Learn to Surf & Skate: A Beginner's Step-by-Step Guide Top Rated: Best Skate Shoe Company Guide [2024] | Learn to Surf & Skate: A Beginner's Step-by-Step Guide](https://universitysurfandskate.com/wp-content/uploads/2026/02/th-230-300x200.jpg)