The components affixed to roller skate chassis that facilitate movement across surfaces are crucial. These circular elements, typically made of polyurethane, enable individuals to glide and maneuver. Variations in size, durometer (hardness), and profile influence the skating experience.

These components significantly impact the rider’s control, speed, and comfort. Selecting appropriate items enhances performance, reduces fatigue, and contributes to overall safety. Historically, these items evolved from rudimentary materials to sophisticated polymers, reflecting advancements in material science and skating technology. This evolution has expanded the possibilities for diverse skating styles and environments.

The following sections will detail the various types available, the factors influencing selection, and the maintenance practices necessary to ensure optimal performance and longevity. A comprehensive understanding of these aspects empowers users to make informed decisions for their specific needs and skating preferences.

Optimizing Performance

Maximizing the potential of roller skates relies on careful consideration of the wheels utilized. The following guidelines provide insights into selecting and maintaining these components for superior performance.

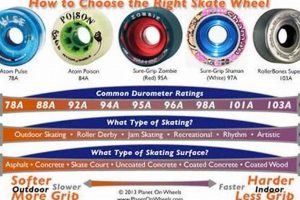

Tip 1: Durometer Assessment: The durometer rating, indicating hardness, significantly impacts grip and roll. Lower durometer wheels (e.g., 78A-85A) offer greater grip and are suitable for outdoor surfaces. Higher durometer wheels (e.g., 88A-101A) provide enhanced speed and are better suited for smooth indoor surfaces.

Tip 2: Diameter Consideration: Wheel diameter influences speed and maneuverability. Smaller diameter wheels offer greater agility, while larger diameter wheels provide increased speed and roll efficiency. Select a diameter appropriate for the intended skating style and environment.

Tip 3: Core Material Evaluation: The wheel core affects energy transfer and durability. Polycarbonate cores provide a balance of stiffness and affordability. Aluminum cores offer superior stiffness and are preferred for high-performance applications.

Tip 4: Regular Rotation: Uneven wear patterns can develop over time. Regular rotation of the wheels ensures even wear and prolongs their lifespan. A cross-pattern rotation is generally recommended.

Tip 5: Bearing Maintenance: Clean and lubricate bearings periodically to maintain optimal roll and reduce friction. Remove dirt and debris, and apply a suitable lubricant. This practice significantly improves performance and extends bearing life.

Tip 6: Surface Compatibility: The skating surface dictates the optimal wheel characteristics. Rough surfaces necessitate softer wheels for grip and vibration absorption. Smooth surfaces benefit from harder wheels for speed and efficiency.

Tip 7: Profile Evaluation: Wheel profile (the shape of the wheel’s contact surface) influences maneuverability and stability. Rounded profiles offer greater agility, while flat profiles enhance stability. Choose a profile that aligns with the intended skating style.

Proper selection and maintenance of the wheels contributes significantly to a safer, more enjoyable, and more efficient skating experience. Understanding the interplay of durometer, diameter, core material, and profile allows skaters to optimize their equipment for specific conditions and performance goals.

The subsequent sections will delve into advanced considerations for optimizing roller skate setups and addressing common issues encountered during use.

1. Durometer (Hardness)

Durometer, a critical property, measures the hardness of the polyurethane material from which the component is constructed. This measurement, typically expressed on the A scale, significantly influences the performance characteristics of roller skates.

- Grip and Traction

Lower durometer values (e.g., 78A – 85A) indicate softer materials that offer increased grip and traction. This is particularly advantageous when skating on uneven or slick surfaces. A softer wheel deforms more easily, conforming to surface irregularities and enhancing contact. Conversely, harder wheels offer less grip, potentially leading to slippage.

- Roll Speed and Efficiency

Higher durometer values (e.g., 88A – 101A) denote harder materials that provide superior roll speed and efficiency. These wheels deform less under load, reducing rolling resistance and enabling skaters to maintain momentum more effectively. However, this increased speed comes at the expense of grip, requiring smoother surfaces for optimal performance.

- Surface Compatibility

The selection of an appropriate durometer hinges on the intended skating surface. Outdoor skating, typically on asphalt or concrete, often necessitates softer wheels to compensate for surface imperfections. Indoor skating, particularly on polished floors, allows for the use of harder wheels to maximize speed and efficiency. Mismatched durometer and surface characteristics can lead to reduced performance and potential safety hazards.

- Wear Resistance

Harder wheels generally exhibit greater wear resistance than softer wheels. The increased durability of higher durometer compounds extends the lifespan of the components, particularly when used on abrasive surfaces. However, extremely hard wheels can transmit more vibration to the skater, potentially causing discomfort or fatigue over extended periods.

In summation, durometer is a fundamental parameter governing the performance and suitability of these skating components. Careful consideration of surface conditions, desired speed, and grip requirements is essential for selecting the optimal durometer to maximize the skating experience.

2. Diameter (Size)

Diameter, referring to the size of wheels for roller skates, is a critical parameter influencing performance characteristics. Measured in millimeters, this dimension directly affects speed, maneuverability, and overall skating experience. Understanding the implications of varying diameters is crucial for selecting appropriate components.

- Acceleration and Speed

Smaller diameter facilitates quicker acceleration. Reduced rotational inertia allows for rapid changes in speed and direction. Conversely, larger diameter promotes higher top-end speed. Greater circumference translates to increased distance covered per revolution, enabling skaters to maintain momentum more effectively. The selection balances the need for responsive acceleration versus sustained velocity.

- Maneuverability and Agility

Smaller wheels enhance maneuverability, allowing for tighter turns and more agile movements. Reduced height provides a lower center of gravity, improving stability and responsiveness. Larger wheels decrease agility, increasing the turning radius and requiring more effort for directional changes. The trade-off is between nimble handling and straight-line stability.

- Surface Contact and Roll Efficiency

Smaller diameter results in less surface contact. Reduced friction minimizes drag and enhances roll efficiency on smooth surfaces. Larger diameter provides greater surface contact, improving grip and traction on uneven terrain. This increased contact area can also enhance shock absorption, mitigating vibrations and improving ride comfort. Surface conditions dictate the optimal contact area for balancing efficiency and control.

- Frame Compatibility and Clearance

Wheel diameter must be compatible with the skate frame design. Insufficient clearance can lead to wheel rub, hindering performance and potentially causing damage. Exceeding the maximum recommended diameter can compromise structural integrity. Frame specifications dictate the allowable range of wheel sizes, ensuring safe and efficient operation. Selecting the appropriate diameter ensures compatibility and optimizes performance within the design constraints.

In conclusion, diameter is a pivotal attribute in the selection process, impacting acceleration, maneuverability, surface contact, and frame compatibility. Selection requires a balance between speed, agility, and stability to cater to the skater’s preference. Understanding the performance implications of diameter contributes to an enhanced and tailored skating experience.

3. Core Material

The core material of these wheels is a fundamental element influencing the wheel’s performance, durability, and overall suitability for different skating styles and conditions. The core provides structural integrity and dictates how efficiently energy is transferred from the skater to the rolling surface.

- Polycarbonate Cores

Polycarbonate cores represent a cost-effective option, balancing stiffness and weight. These cores provide adequate support for recreational skating and beginner-level activities. Polycarbonate offers sufficient rigidity for efficient energy transfer at moderate speeds. However, it may flex excessively under high stress, potentially compromising performance in advanced maneuvers or aggressive skating styles.

- Aluminum Cores

Aluminum cores offer superior stiffness and durability compared to polycarbonate. They provide enhanced energy transfer, resulting in increased speed and responsiveness. Aluminum cores are commonly found in high-performance wheels designed for speed skating, aggressive skating, and roller derby. The increased rigidity minimizes energy loss, allowing skaters to maintain momentum more effectively. However, aluminum cores are typically more expensive than polycarbonate cores.

- Nylon Cores

Nylon cores offer a flexible middle-ground in cost and performance between polycarbonate and aluminum. This provides ample support for energy transfer, while giving more flex than aluminum options. This gives a smoother ride with more shock absorbtion, while giving enough support for skaters looking to advance in their ability.

- Two-Piece Core Designs

Some high-end wheels incorporate two-piece core designs, combining different materials to optimize performance characteristics. For example, a wheel might feature an aluminum inner core for stiffness and a softer outer core for improved shock absorption. This approach allows manufacturers to fine-tune the wheel’s properties, catering to specific skating disciplines. Two-piece core designs often result in higher costs but can provide a significant performance advantage for serious skaters.

The core material is a significant determinant of wheel performance, impacting energy transfer, durability, and overall suitability. The choice of material depends on the skater’s skill level, skating style, and budget. Upgrading to a higher-performance core material can significantly enhance the skating experience.

4. Bearing Fit

The integration of bearings within roller skate wheels constitutes a crucial aspect of functionality. This relationship, termed “Bearing Fit,” directly affects the rolling efficiency, speed, and longevity of the wheel assembly. Incorrect bearing fit, whether too tight or too loose, introduces friction and compromises performance. Bearings must seat squarely within the wheel’s designated housing to ensure optimal alignment and minimize energy loss. An overly tight fit can deform the bearing, increasing internal friction. Conversely, a loose fit allows for excessive play, causing vibration and premature wear on both the bearing and the wheel core. For example, a skater experiencing reduced roll time despite using high-quality wheels may be encountering issues related to inadequate bearing fit.

Proper bearing fit is typically achieved through precise manufacturing tolerances in both the wheel core and the bearing itself. Standard bearing sizes (e.g., 608) are designed to be compatible with most roller skate wheels. However, variations in manufacturing can sometimes lead to compatibility issues. Skaters can utilize bearing presses to ensure proper seating and alignment. Furthermore, specialized tools are available to remove bearings without damaging the wheel core. Inspection of the wheel core for any signs of damage or deformation prior to bearing installation is critical. Using improperly sized or damaged wheels can increase the risk of bearing failure, leading to abrupt stops or instability.

In summary, bearing fit is inextricably linked to the performance and reliability of roller skate wheels. Inadequate fit introduces friction, reduces speed, and accelerates wear. By ensuring proper seating and alignment, skaters can maximize rolling efficiency, extend the lifespan of their equipment, and enhance their overall skating experience. Addressing fit-related problems requires precise installation and appropriate tooling, helping skaters ensure a smooth and safe ride.

5. Surface Type

The performance of wheels is inextricably linked to the surface upon which they operate. Different surfaces present varying degrees of friction, roughness, and debris, necessitating careful consideration when selecting appropriate components. The cause-and-effect relationship between surface type and wheel performance is readily apparent: a hard wheel on a rough surface results in a jarring ride with reduced grip, while a soft wheel on a smooth surface offers minimal speed and premature wear. This connection highlights surface type as a critical component of the overall wheel selection process. For example, skaters using outdoor rinks typically require softer wheels to absorb vibrations and maintain traction on the often-uneven asphalt. Conversely, skaters on smooth indoor surfaces can benefit from harder wheels that maximize speed and efficiency. Understanding this interaction significantly enhances skating performance and safety.

The practical implications of this understanding extend beyond mere comfort. Proper surface-wheel matching improves energy efficiency, reduces fatigue, and minimizes the risk of falls. Consider a skater attempting speed work on a rough outdoor surface with hard wheels; the increased vibration and reduced grip would impede performance and increase the likelihood of injury. Conversely, a skater attempting artistic routines on a smooth surface with overly soft wheels would struggle with precise movements due to the lack of responsiveness. By recognizing the unique demands of each surface, skaters can optimize their equipment for enhanced performance, control, and safety. Professional skaters often carry multiple sets of wheels to adapt to different venue conditions, underscoring the importance of surface-specific wheel selection.

In conclusion, the surface type exerts a profound influence on wheel performance, dictating the optimal durometer, diameter, and profile for a given environment. Mismatched surface and wheel characteristics compromise efficiency, control, and safety. Informed wheel selection, based on a thorough understanding of surface properties, is essential for maximizing skating performance. This connection highlights the need for skaters to consider the specific demands of each environment when choosing their equipment. The challenges involve accurately assessing surface conditions and selecting appropriate components to optimize the skating experience. This connection ties directly into the overall theme of optimizing performance by matching equipment to environmental demands.

6. Wheel Profile

Wheel profile, a significant yet often overlooked parameter, describes the cross-sectional shape of a roller skate wheel. This geometric characteristic profoundly influences maneuverability, grip, and overall skating experience. Varying the profile alters the contact patch between the wheel and the skating surface, thereby modulating friction and control.

- Rounded Profile

Rounded profiles exhibit a curved contact surface. This geometry promotes quick turning and enhances agility. With a smaller contact patch than other profiles, rounded wheels allow for effortless transitions between edges. Speed skaters often favor rounded profiles for their responsiveness and reduced rolling resistance on smooth surfaces. This design facilitates rapid adjustments in direction and contributes to efficient energy transfer during high-speed maneuvers.

- Flat Profile

Flat profiles present a broad, planar contact surface. This configuration maximizes grip and stability, particularly on slick surfaces. Flat wheels offer enhanced control and predictability, making them suitable for recreational skating and beginner-level activities. The increased contact area distributes weight more evenly, reducing pressure points and minimizing the risk of slippage. However, flat profiles can sacrifice agility and increase rolling resistance compared to rounded designs.

- Elliptical Profile

Elliptical profiles represent a hybrid design, blending the characteristics of rounded and flat shapes. These wheels offer a balance of maneuverability and stability, making them versatile for a wide range of skating styles. The elliptical shape provides a moderately sized contact patch, offering adequate grip without sacrificing responsiveness. Elliptical profiles are often found in recreational and fitness skates, catering to skaters seeking a compromise between agility and control.

- Conical Profile

Conical profiles feature a tapered shape, with a wider inner edge and a narrower outer edge. This design enhances grip during angled maneuvers, such as carving and sliding. Conical wheels are popular among aggressive skaters and roller derby participants, enabling them to execute sharp turns and maintain control during high-impact situations. The angled shape also facilitates controlled slides, allowing skaters to manipulate their position and trajectory with precision.

The choice of wheel profile significantly impacts the handling and performance of roller skates. Understanding the trade-offs between maneuverability, grip, and stability allows skaters to optimize their equipment for specific skating styles and surface conditions. Matching the profile to the intended use ensures a safer, more enjoyable, and more efficient skating experience. Proper integration of the profile is essential for the overall riding experience.

Frequently Asked Questions

This section addresses common inquiries regarding wheels, providing detailed information to enhance comprehension.

Question 1: What is the significance of durometer in wheel selection?

Durometer indicates wheel hardness and directly impacts grip and speed. Lower durometer values provide greater grip, suitable for outdoor surfaces, while higher values offer increased speed, optimized for smooth indoor environments.

Question 2: How does diameter affect skating performance?

Diameter influences acceleration and top speed. Smaller diameters facilitate quicker acceleration, while larger diameters enable higher maximum speeds and improved roll efficiency.

Question 3: What core material is most suitable for high-performance skating?

Aluminum cores offer superior stiffness and energy transfer, making them ideal for high-performance applications such as speed skating and roller derby. Polycarbonate cores provide a more economical choice for recreational skating.

Question 4: How frequently should wheels be rotated?

Wheels should be rotated regularly to ensure even wear patterns and prolong lifespan. A cross-pattern rotation is generally recommended to distribute wear evenly across all wheels.

Question 5: What are the key considerations when selecting wheels for outdoor skating?

Outdoor skating necessitates softer wheels with lower durometer values to absorb vibrations and maintain grip on uneven surfaces. Durability is also a crucial factor due to the abrasive nature of outdoor environments.

Question 6: Can bearing fit impact wheel performance?

Improper bearing fit introduces friction, reduces speed, and accelerates wear. Ensuring bearings are properly seated within the wheel core is crucial for optimizing rolling efficiency and extending the lifespan of both wheels and bearings.

The selection and maintenance of wheels is vital for optimal skating. Understanding various properties contributes to performance.

The subsequent section delves into advanced customizations of roller skates, enhancing performance further.

Conclusion

The exploration of “wheels for roller skates” has revealed critical considerations impacting performance, safety, and the overall skating experience. From the significance of durometer and diameter to the influence of core material and wheel profile, each attribute contributes uniquely to the final outcome. A comprehensive understanding of these elements empowers skaters to make informed decisions tailored to their specific needs and environments.

Continued advancements in materials science and manufacturing processes promise further enhancements. As technology evolves, so too will the capabilities, offering improved performance and durability. The careful assessment and maintenance of “wheels for roller skates” remains paramount, ensuring both enjoyment and safety in the pursuit of the sport.