The action of converting conventional footwear into a mobile platform utilizing wheels is a modification process with the explicit purpose of enabling the wearer to glide or roll along a surface. An example of this is the adaptation of sneakers with detachable or permanently affixed roller skate components.

This conversion offers enhanced mobility and recreational opportunities. Historically, such adaptations represent a desire to integrate wheeled locomotion with everyday footwear, leading to innovations in both recreational equipment and personal transportation. This offers benefits of added fun, and easy of use to travel.

The subsequent sections will explore the various methods, materials, and safety considerations involved in this transformation, providing a detailed overview of the process and its implications.

Guidance for Footwear Conversion to Wheeled Mobility

The following guidelines offer crucial information for those undertaking the modification of shoes into roller skates. Prioritizing safety and structural integrity is paramount.

Tip 1: Frame Selection: Choose a frame that is compatible with the shoe’s sole structure. Ensure adequate surface area for secure attachment. Consider material strength and durability for long-term use.

Tip 2: Attachment Method: Employ robust attachment techniques such as bolting, riveting, or industrial-grade adhesives. Evaluate the weight-bearing capacity of each method and select accordingly.

Tip 3: Wheel and Bearing Quality: Opt for high-quality wheels and bearings designed for roller skating. Check the durometer (hardness) rating of the wheels to match the intended skating surface. High-quality bearings improve speed, control, and safety.

Tip 4: Sole Reinforcement: Reinforce the shoe’s sole with a rigid material like metal or composite plating. This prevents deformation and ensures a stable platform for the roller skate frame.

Tip 5: Secure Fastenings: Implement secure fastening systems such as buckles, straps, or laces to maintain a snug fit. Loose shoes compromise stability and control. Ensure that laces are tucked away from the wheels.

Tip 6: Professional Consultation: If unsure about any stage of the process, consult with a professional skate technician or cobbler. They can offer expert advice on material selection, attachment methods, and safety protocols.

Proper execution of these steps ensures both the functionality and safety of the converted footwear, increasing the enjoyment and security of the activity.

The subsequent sections of this article will detail specific conversion methods and associated safety precautions.

1. Frame Attachment Security

Frame attachment security is a foundational element in the conversion of shoes to roller skates. Its integrity directly impacts the safety and performance of the resulting wheeled footwear. Inadequate frame attachment presents a significant risk of detachment during use, leading to potential injuries.

- Material Compatibility and Adhesion Strength

The compatibility of materials used for both the shoe sole and the frame is critical. Utilizing mismatched materials can lead to weak adhesion and eventual failure under stress. Adhesion strength is determined by factors such as surface preparation, adhesive type (epoxy, polyurethane, etc.), and curing process. Real-world examples include frames detaching from shoes due to temperature fluctuations affecting adhesive bonds, resulting in loss of control during skating.

- Fastener Integrity and Distribution

The type, number, and distribution of fasteners (bolts, rivets, screws) play a crucial role in frame security. Insufficient fasteners or improper distribution can create stress concentrations, leading to premature failure. Examples include stripped bolt threads, cracked mounting points, and uneven weight distribution causing the frame to shear away from the shoe. Careful calculation of fastener load capacity and strategic placement are essential.

- Load Distribution and Stress Mitigation

The design of the frame attachment interface must effectively distribute load forces across the shoe sole to prevent localized stress concentrations. Sharp edges or abrupt transitions can act as stress risers, weakening the connection. Incorporating stress-relieving features, such as rounded corners, flexible interfaces, or reinforced mounting plates, can significantly improve attachment durability. Poor load distribution can cause sole cracking or frame deformation, particularly during high-impact activities.

- Regular Inspection and Maintenance

Even with a robust initial attachment, regular inspection and maintenance are crucial to identify and address potential issues before they escalate. Checking for loose fasteners, cracks, or delamination of adhesive bonds can prevent catastrophic failures. Periodic tightening of bolts, replacement of worn components, and reapplication of adhesive (if necessary) can extend the lifespan and safety of the converted skates. Neglecting maintenance increases the risk of sudden frame detachment during use.

The above facets of frame attachment security are integral to the successful and safe transformation of shoes into functional roller skates. Their proper implementation ensures that the converted footwear can withstand the stresses of regular use, minimizing the risk of accidents and maximizing the user’s enjoyment.

2. Wheel Bearing Quality

Wheel bearing quality is a critical determinant of the performance and safety when converting conventional shoes into roller skates. Bearings, positioned within the wheels, facilitate smooth rotation around the axle. Inferior bearings introduce friction, impeding speed and requiring greater exertion. Conversely, high-quality bearings minimize friction, enabling effortless gliding and increased efficiency. The quality of these components directly influences the ease of use and overall enjoyment of the converted footwear. For instance, skates equipped with precision bearings allow for longer coasting distances and enhanced maneuverability compared to those with standard or low-grade bearings.

The practical significance of understanding wheel bearing quality extends to safety considerations. Substandard bearings are prone to premature failure, potentially causing wheels to lock up or wobble unexpectedly. Such occurrences can result in loss of control and increase the risk of falls or collisions. Investing in durable, high-precision bearings mitigates these risks, ensuring a more stable and predictable skating experience. Moreover, superior bearings often exhibit greater resistance to wear and tear, extending the lifespan of the converted skates and reducing the need for frequent replacements. Regular maintenance, including cleaning and lubrication, further contributes to the longevity and performance of these critical components.

In summary, wheel bearing quality constitutes an indispensable aspect of converting shoes into roller skates. It affects not only the skater’s performance and enjoyment but also their safety. Selecting high-quality bearings, coupled with diligent maintenance, optimizes the functionality and extends the usability of the converted skates. Understanding this connection is paramount for anyone seeking to transform ordinary shoes into a reliable and enjoyable mode of wheeled locomotion.

3. Sole Reinforcement Integrity

Sole reinforcement integrity is a critical factor determining the success and safety of converting shoes into roller skates. The shoe’s original sole structure is typically not designed to withstand the concentrated stresses imposed by the attachment of a roller skate frame and the dynamic forces generated during skating. Without adequate reinforcement, the sole may deform, crack, or detach from the shoe upper, leading to instability and potential injury. Therefore, the integrity of the sole reinforcement directly affects the usability and lifespan of the modified footwear.

Effective sole reinforcement involves integrating a rigid, load-bearing material into or onto the original sole. This material, often metal, composite, or high-density polymer, distributes the forces across a wider area and provides a secure anchor point for the skate frame. Real-world examples demonstrate the consequences of inadequate reinforcement. Shoes converted without proper sole strengthening frequently exhibit premature wear and tear, resulting in wobbly wheels, compromised control, and eventual failure. Conversely, shoes with robust reinforcement exhibit enhanced stability, improved energy transfer, and increased resistance to damage from impacts and vibrations.

In summary, sole reinforcement integrity is not merely an optional modification but a necessary component for transforming shoes into functional and safe roller skates. Its presence ensures the structural stability of the converted footwear, improving performance and minimizing the risk of accidents. Neglecting this crucial aspect compromises the entire conversion process, rendering the modified shoes unreliable and potentially hazardous.

4. Ankle Support Provision

Ankle support provision directly affects stability and control during wheeled locomotion when converting conventional shoes into roller skates. The inherent design of most athletic or casual shoes lacks the rigid structure necessary to counteract the lateral forces experienced during skating. Consequently, insufficient ankle support can lead to instability, increased risk of ankle sprains, and diminished control over movement. The absence of adequate support forces the skater to rely on leg muscles to compensate, leading to fatigue and reduced performance. The addition of external ankle bracing mechanisms, high-cut shoe designs or integrated support structures directly addresses this deficiency.

Several methodologies exist for improving ankle support in converted roller skates. These include incorporating rigid plastic or composite shells around the ankle area, implementing reinforced padding, and utilizing adjustable straps to secure the foot and ankle within the shoe. Examples include modifications seen in aggressive inline skates, where high, supportive cuffs are integrated to provide maximum ankle stability for complex maneuvers. Conversely, conversions lacking robust ankle support are often associated with increased incidents of ankle instability, requiring users to exert greater effort to maintain balance, and increasing the probability of injury. Proper provision of ankle support significantly enhances maneuverability, enabling the skater to execute turns and stops with greater precision.

In summation, the adequate provision of ankle support represents an essential component in the successful conversion of shoes into roller skates. It directly influences the user’s safety, control, and overall skating experience. The lack of this crucial element not only increases the risk of injury but also compromises the functionality and usability of the converted footwear, directly influencing ease of use and maneuverability.

5. Braking System Integration

Effective braking system integration is paramount to the safe and controlled operation of footwear converted into roller skates. The absence of a reliable braking mechanism significantly increases the risk of accidents, particularly when navigating varied terrain or encountering unexpected obstacles. A thoughtfully implemented braking system offers the operator the means to modulate speed and affect complete stops, critical functionalities often absent in unmodified footwear.

- Heel Brake Mechanisms

Heel brake mechanisms, commonly found on inline skates, represent a prevalent approach to integrating braking systems. The system typically involves a brake pad attached to the heel of one skate, activated by tilting the foot backward. Such systems are relatively straightforward to implement, but require a specific skating posture to engage effectively. Practical considerations include brake pad wear, which necessitates periodic replacement, and the learning curve associated with mastering the braking technique. The effectiveness of heel brake mechanisms is directly influenced by the skater’s skill level and the quality of the brake pad material.

- Toe Stop Implementation

Toe stops, traditionally utilized on quad skates, provide an alternative braking solution. These rubber or composite stoppers are positioned at the front of the skate and are engaged by tilting the foot forward. Toe stops offer greater control and modulation compared to heel brakes, allowing for more nuanced speed adjustments. However, their implementation on converted footwear can be challenging, requiring a robust mounting structure and precise positioning to ensure optimal performance. Real-world applications include artistic skating and roller derby, where precise footwork and controlled stops are essential.

- Material Selection and Durability

The materials utilized in the construction of the braking system directly influence its effectiveness and longevity. Brake pads composed of high-friction rubber or composite compounds provide superior stopping power compared to less durable materials. Similarly, the mounting hardware and structural components must be capable of withstanding repeated stress and impact forces. Selecting appropriate materials is critical to ensure the braking system remains reliable under various conditions. Examples of material failure include cracked brake mounts and prematurely worn brake pads, both of which compromise braking performance and safety.

- Integration with Footwear Structure

The method by which the braking system is integrated with the footwear structure is crucial to its overall functionality and stability. Secure and properly aligned mounting points are essential to prevent the brake from detaching or shifting during use. Furthermore, the braking system should not interfere with the skater’s natural range of motion or create undue stress on the footwear. Examples of poor integration include brake systems that rub against the wheels, restrict ankle movement, or cause discomfort to the wearer. A well-integrated braking system enhances the overall skating experience and promotes safety.

The aspects of braking system integration are intertwined with footwear conversion. The application of braking to roller skates affects control and maneuverability. These factors increase functionality in converted roller skates.

Frequently Asked Questions

The following addresses prevalent inquiries regarding the modification of shoes into functional roller skates. Information provided is intended to offer clarity and guidance based on established practices and safety considerations.

Question 1: What types of shoes are most suitable for conversion to roller skates?

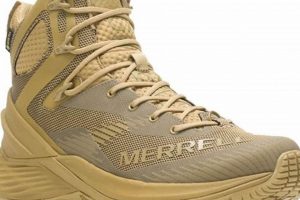

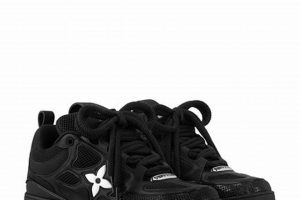

Shoes with flat, rigid soles and robust construction are preferable. Athletic shoes, particularly those designed for skateboarding or similar activities, often provide a stable platform for mounting roller skate components. Avoid shoes with significant cushioning or flexible soles, as these may compromise stability and control.

Question 2: Is specialized equipment required to perform this conversion?

Yes. Specific tools, including drills, wrenches, and appropriate fasteners, are necessary for securing the roller skate frame to the shoe. Additionally, safety equipment such as eye protection and gloves is recommended to prevent injury during the modification process.

Question 3: What safety precautions should be observed during and after the conversion?

Prior to use, rigorously inspect all fasteners and attachment points to ensure they are secure. Wear appropriate protective gear, including a helmet, knee pads, and elbow pads. Begin skating in a controlled environment to assess the stability and maneuverability of the converted skates.

Question 4: How does the weight of the shoe impact the performance of the converted roller skates?

Heavier shoes can increase fatigue and reduce agility. Lighter shoes, while potentially improving maneuverability, may compromise durability and structural integrity. A balance between weight and robustness is essential for optimal performance and safety.

Question 5: Can any standard roller skate frame be attached to any shoe?

No. The roller skate frame must be appropriately sized and compatible with the shoe’s sole dimensions and shape. Mismatched frames can lead to instability, uneven weight distribution, and increased risk of failure.

Question 6: How often should the converted roller skates be inspected and maintained?

Regular inspection is crucial. Before each use, examine all fasteners, wheels, and bearings for wear or damage. Lubricate bearings as needed and replace worn components promptly. Neglecting maintenance can compromise safety and reduce the lifespan of the converted skates.

The information above outlines key considerations for converting shoes into roller skates. Adherence to these guidelines promotes safety and maximizes the functionality of the modified footwear.

The following section will delve into advanced conversion techniques and customization options.

Summary

This exploration of the practice to turn shoes into roller skates has illuminated critical aspects ranging from structural reinforcement to braking system integration. The analysis emphasizes the necessity of robust construction, secure attachment methods, and diligent maintenance to ensure the safety and functionality of such conversions.

Given the inherent complexities and potential risks involved, pursuing this transformation demands a thorough understanding of engineering principles and safety protocols. Any undertaking to adapt footwear for wheeled locomotion warrants careful consideration of the potential consequences and a commitment to responsible execution. Further investigation and adherence to professional guidelines are strongly encouraged.