Figure skates achieving high ratings represent the confluence of design, materials, and performance. These skates, recognized for their superior quality, provide optimal support, comfort, and control for skaters across various skill levels. For example, skates utilizing advanced blade technology and customized boot fitting consistently receive favorable assessments.

The selection of high-ranking figure skates offers significant advantages. Enhanced performance capabilities, including improved edge control and jump execution, are direct benefits. Historically, the pursuit of excellence in figure skating has driven manufacturers to innovate, leading to advancements in skate design and materials. These innovations translate to increased safety and a reduced risk of injury.

Understanding the characteristics that contribute to positive evaluations is crucial for prospective buyers. Factors such as boot stiffness, blade type, and manufacturer reputation significantly impact the overall assessment of a skate’s quality and suitability. Subsequent sections will delve into specific models and the criteria used to evaluate their performance.

Tips on Selecting High-Quality Figure Skates

This section offers guidance on choosing figure skates recognized for their superior performance. Careful consideration of these factors will facilitate a more informed purchase.

Tip 1: Prioritize Boot Support: The boot’s rigidity directly influences ankle stability. Stiffer boots are generally recommended for advanced skaters performing complex maneuvers, while more flexible options may suit beginners.

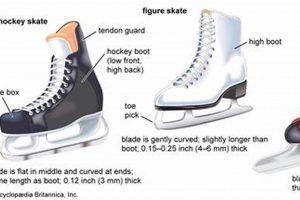

Tip 2: Evaluate Blade Quality: The blade’s steel composition and edge construction determine its ability to hold an edge. Look for blades crafted from high-carbon steel and featuring precision-engineered edges for optimal performance.

Tip 3: Consider Professional Fitting: A professionally fitted skate minimizes the risk of discomfort and injury. Seek guidance from a qualified skate technician to ensure proper sizing and customized adjustments.

Tip 4: Research Manufacturer Reputation: Established manufacturers with a history of producing reliable skates often represent a safer investment. Examine customer reviews and industry assessments to gauge the brand’s reputation.

Tip 5: Assess the Lining Material: The boot lining’s material impacts both comfort and moisture management. Breathable, moisture-wicking materials contribute to a more comfortable skating experience and prolong the boot’s lifespan.

Tip 6: Check for Ankle Padding: Adequate ankle padding provides essential cushioning and reduces the likelihood of blisters. Examine the thickness and density of the padding around the ankle area.

Tip 7: Inspect Lacing System: A secure and easily adjustable lacing system is crucial for achieving a snug and supportive fit. Ensure that the laces are durable and the eyelets are properly reinforced.

Adhering to these guidelines enhances the probability of selecting figure skates that offer optimal performance, comfort, and safety. The selection process warrants careful attention to detail.

The concluding section will synthesize the key points discussed and provide final recommendations.

1. Boot Stiffness

Boot stiffness is a primary determinant of a figure skate’s overall rating. It governs the level of support provided to the skater’s ankle, directly impacting control and the ability to execute complex maneuvers. Insufficient stiffness can lead to ankle instability, increasing the risk of injury and hindering the performance of jumps and spins. In contrast, excessive stiffness may restrict ankle mobility, hindering the skater’s ability to achieve deep edges and fluid movements. High-rated figure skates consistently demonstrate an optimal balance, providing the necessary support without unduly limiting flexibility. For example, advanced triple and quadruple jumps require a high degree of ankle stability, achievable only with a sufficiently stiff boot. The selection of boot stiffness is thus intrinsically linked to the skater’s skill level and the demands of their training regimen.

The cause-and-effect relationship between boot stiffness and performance is evident in the evolution of figure skate design. As skaters have pushed the boundaries of athletic achievement, manufacturers have responded by developing boots with increasingly sophisticated reinforcement technologies. These technologies, including carbon fiber layering and advanced synthetic materials, enable a greater degree of stiffness without compromising comfort or weight. Furthermore, heat-moldable boots allow for a customized fit, further enhancing support and minimizing pressure points. An understanding of the optimal stiffness level is crucial not only for skaters but also for coaches and skate technicians who play a vital role in equipment selection and maintenance.

In conclusion, boot stiffness is a critical factor contributing to a figure skate’s overall rating and performance capabilities. Achieving the appropriate stiffness level is essential for maximizing control, minimizing injury risk, and facilitating the execution of advanced skating techniques. While individual preferences and skill levels may influence the optimal stiffness range, high-rated figure skates consistently demonstrate a superior balance of support and flexibility. Future advancements in materials and design are likely to further refine the relationship between boot stiffness and skater performance, driving continued innovation in the figure skating equipment market.

2. Blade Material

The composition of the blade is a critical determinant in evaluating figure skates. The material directly impacts edge quality, glide efficiency, and overall skate performance. Skates achieving high ratings consistently feature blades constructed from materials engineered for optimal functionality and durability.

- Steel Hardness and Edge Retention

The hardness of the steel dictates its ability to maintain a sharp edge. Blades crafted from high-carbon steel generally exhibit superior edge retention compared to those using lower-grade alloys. A sharper edge translates to improved control and precision during turns and jumps. Skates used in competitive figure skating, for example, frequently feature blades with a Rockwell hardness rating optimized for prolonged edge sharpness.

- Corrosion Resistance and Maintenance

Exposure to moisture and ice necessitates corrosion resistance. Blades treated with specialized coatings or manufactured from stainless steel alloys are less susceptible to rust and pitting. Corrosion compromises edge integrity and glide. Proper blade maintenance, including drying after each use and regular sharpening, is essential for preserving the material’s integrity and maximizing performance.

- Blade Geometry and Material Properties

The curvature and thickness of the blade influence its responsiveness and maneuverability. Materials with a high strength-to-weight ratio allow for the creation of blades that are both lightweight and robust. This balance enhances skater agility and reduces fatigue. Advanced blade designs may incorporate multiple materials with varying properties to optimize specific performance characteristics.

- Impact Resistance and Durability

Figure skating involves repetitive impacts and stresses on the blade. The material’s resistance to chipping, cracking, or bending is crucial for ensuring longevity and preventing catastrophic failure. Blades constructed from brittle materials are prone to damage, while those with excessive flexibility may lack the necessary precision. Skates intended for high-intensity training require blades capable of withstanding significant forces without compromising performance.

The selection of blade material represents a critical trade-off between hardness, durability, corrosion resistance, and cost. Skates earning high ratings demonstrate a meticulous consideration of these factors, resulting in blades that offer superior performance and extended lifespan. The advancements in metallurgical engineering continue to drive innovation in blade materials, contributing to ongoing improvements in figure skating equipment.

3. Ankle Support

Ankle support is a pivotal feature influencing the overall performance and safety of figure skates. The design and construction of this component directly impact a skater’s ability to control movements, execute jumps, and maintain balance. Top-rated figure skates prioritize robust and effective ankle support mechanisms.

- Lateral Stability

Lateral stability refers to the skate’s ability to resist sideways motion of the ankle. This is essential for maintaining edge control and preventing injuries during lateral movements and turns. Top-rated figure skates often incorporate reinforced ankle padding and rigid boot construction to enhance lateral stability. For example, skates used for advanced jumps typically feature a stiffer boot material that limits ankle pronation and supination.

- Range of Motion Control

While stability is crucial, controlled range of motion is also necessary for certain skating techniques. Excessive rigidity can hinder a skater’s ability to achieve deep edges or execute specific maneuvers. High-quality figure skates strive for a balance between support and flexibility, allowing for sufficient ankle movement while maintaining stability. This is often achieved through strategically placed flex points within the boot construction.

- Customization and Fit

Effective ankle support relies heavily on a proper fit. Top-rated skates often offer customization options such as heat-moldable boots or adjustable lacing systems that allow skaters to tailor the fit to their individual anatomy. A poorly fitting skate, even with excellent support features, can lead to discomfort, blisters, and compromised performance. Precise fitting is therefore a hallmark of high-quality figure skates.

- Impact Absorption

Landing jumps generates significant impact forces on the ankle joint. Ankle support systems in top-rated skates often incorporate shock-absorbing materials to mitigate these forces and reduce the risk of stress injuries. This cushioning is typically integrated into the ankle padding or boot liner and contributes to a more comfortable and safer skating experience.

The characteristics of ankle support, encompassing lateral stability, range of motion control, customization, and impact absorption, are critical in distinguishing highly rated figure skates. These design elements directly impact the skater’s ability to perform advanced techniques safely and effectively, solidifying ankle support as a key factor in skate evaluation.

4. Heat moldability

Heat moldability, a feature increasingly prevalent in figure skate design, represents a significant advancement in achieving customized fit and enhanced performance. Its presence often correlates with a higher rating, reflecting its contribution to both comfort and control.

- Custom Contouring and Reduced Break-in Time

Heat moldability allows the skate boot’s materials to soften and conform to the individual skater’s foot shape when exposed to heat. This process minimizes pressure points and creates a more anatomical fit, significantly reducing the break-in period typically associated with new skates. The elimination of hot spots enhances comfort and reduces the risk of blisters or other foot-related issues, particularly crucial for skaters engaging in rigorous training schedules.

- Enhanced Ankle Support and Stability

The ability to mold the skate around the ankle provides a more secure and supportive fit. This is particularly beneficial for advanced skaters who require precise control and stability for complex jumps and spins. A customized ankle fit minimizes unwanted movement within the boot, maximizing the transfer of power and enhancing overall skating performance. By conforming precisely to the ankle’s contours, heat-moldable boots offer superior lateral support, reducing the risk of ankle strain and other injuries.

- Optimized Energy Transfer and Responsiveness

A close, custom fit ensures more efficient energy transfer from the skater’s foot to the blade. Any gaps or looseness within the boot can diminish responsiveness and reduce the skater’s ability to execute precise movements. Heat moldability minimizes these inefficiencies, allowing for a more direct and immediate connection between the skater and the ice. This enhanced responsiveness translates to improved control, greater precision, and a more fluid skating experience.

- Improved Circulation and Reduced Fatigue

By eliminating pressure points and providing a more anatomical fit, heat moldability contributes to improved circulation within the foot. Restricted blood flow can lead to discomfort, numbness, and fatigue, particularly during extended skating sessions. A well-molded skate promotes healthy circulation, reducing fatigue and allowing skaters to train for longer periods without experiencing discomfort. This is particularly valuable for competitive skaters who demand optimal performance over prolonged practice routines.

In conclusion, the inclusion of heat moldability in figure skate design contributes significantly to skater comfort, performance, and safety. Its ability to provide a customized fit, enhance ankle support, optimize energy transfer, and improve circulation makes it a highly desirable feature in high-ranking figure skates, reflecting a commitment to providing skaters with equipment that maximizes their potential.

5. Liner comfort

Liner comfort within figure skates significantly contributes to a skate’s overall rating. A comfortable liner impacts the skater’s ability to perform for extended periods and influences the precision of movements. This is a crucial consideration in the assessment of high-quality skating equipment.

- Moisture Management and Material Composition

Effective moisture management is essential for maintaining foot comfort and preventing blisters. Liners constructed from breathable, moisture-wicking materials, such as microfiber or specialized synthetic blends, facilitate the evaporation of sweat. This reduces friction within the boot and minimizes the risk of skin irritation. High-rated skates often feature liners with advanced wicking properties, contributing to a drier and more comfortable skating experience.

- Padding Density and Anatomical Support

The density and placement of padding within the liner play a vital role in providing anatomical support and cushioning. Strategically positioned padding around the ankle bones and metatarsal heads reduces pressure points and enhances comfort. Top-rated skates typically utilize multi-density padding systems, offering varying levels of support and cushioning in different areas of the foot. This tailored approach promotes a more natural and comfortable fit.

- Seamless Construction and Reduced Friction

Seams within the liner can create friction and irritation, particularly during repetitive movements. Seamless construction techniques minimize these potential friction points, resulting in a smoother and more comfortable fit. High-quality skates often employ seamless liners or strategically placed seams away from high-pressure areas. This attention to detail enhances overall comfort and reduces the likelihood of blisters or chafing.

- Thermal Regulation and Insulation

Liners contribute to thermal regulation within the skate boot. Insulating materials help to maintain a consistent temperature, preventing the foot from becoming excessively cold or overheated. Liners in top-rated skates often incorporate thermal insulation technologies that provide warmth without compromising breathability. This is particularly important for skaters training in cold environments or for extended periods.

The interconnected elements of moisture control, padding density, seamless construction, and thermal regulation underscore the importance of liner comfort in determining a figure skate’s overall rating. These features collectively contribute to a more enjoyable and productive skating experience. Skates that prioritize liner comfort enhance performance and minimize the risk of discomfort-related issues.

6. Manufacturer Reputation

The reputation of a figure skate manufacturer is a significant factor influencing the perceived and actual quality of its products. A manufacturer’s history of innovation, product durability, customer service, and adherence to industry standards directly affects consumer confidence and the likelihood of their skates achieving high ratings.

- Brand Heritage and Legacy

Manufacturers with a long-standing presence in the figure skating industry often possess a deep understanding of skater needs and performance requirements. Their legacy is built upon years of research, development, and feedback from skaters, resulting in products that are refined and optimized for specific skill levels and skating disciplines. The mere name of certain manufacturers acts as a quality assurance in the figure skating community.

- Technological Innovation and Materials Science

Reputable manufacturers invest heavily in research and development, exploring new materials and technologies to enhance skate performance. This may include the development of advanced boot materials, blade designs, and fitting systems. Their commitment to innovation directly impacts the quality, performance, and durability of their skates, contributing to higher ratings. For example, manufacturers who pioneered heat-moldable boot technology gained a competitive edge and improved the overall skater experience.

- Quality Control and Manufacturing Processes

Consistent quality control throughout the manufacturing process is paramount. Reputable manufacturers adhere to stringent quality standards, ensuring that each skate meets precise specifications. This includes rigorous testing of materials, meticulous assembly, and thorough inspection of finished products. Skates from manufacturers with robust quality control processes are more likely to deliver consistent performance and durability, positively influencing customer satisfaction and ratings.

- Customer Service and Support

A manufacturer’s commitment to customer service and support plays a crucial role in shaping its reputation. Prompt and responsive assistance with fitting issues, warranty claims, and technical inquiries fosters customer loyalty and positive word-of-mouth referrals. Manufacturers who provide comprehensive customer support are more likely to receive favorable reviews and maintain a positive brand image.

The reputation of a figure skate manufacturer serves as a valuable indicator of product quality and performance. Skates from established and well-regarded manufacturers are generally perceived as more reliable and capable of meeting the demands of serious skaters, resulting in a greater likelihood of achieving top ratings and positive customer experiences.

7. Durability

Durability forms a cornerstone of the criteria by which figure skates achieve high ratings. The longevity of a figure skate, encompassing both the boot and the blade, directly influences its overall value and user satisfaction. Skates experiencing premature degradation necessitate frequent replacements, increasing costs and disrupting training schedules. Consequently, materials and construction techniques that enhance resilience against wear and tear are paramount in the design and evaluation of top-performing models. For example, a skate boot constructed with multiple layers of reinforced leather and a blade crafted from high-carbon steel is demonstrably more resistant to deformation and corrosion than a skate utilizing lower-quality materials.

The practical significance of durability extends beyond mere cost savings. A durable skate provides a consistent performance platform, allowing skaters to develop and refine their skills without the variability introduced by equipment failures. A boot that maintains its stiffness and shape over time provides reliable ankle support, reducing the risk of injury. Similarly, a blade that retains its edge sharpness and resists bending ensures consistent glide and precise control. Numerous examples exist where the extended lifespan of a well-constructed skate has enabled skaters to achieve significant performance milestones. Moreover, durable skates hold their value better, making them a more sustainable investment for both amateur and professional athletes.

Ultimately, durability is not merely a desirable attribute, but a fundamental requirement for figure skates aspiring to achieve top ratings. The selection of robust materials, the implementation of advanced construction methods, and rigorous quality control measures are all essential components in ensuring a skate’s ability to withstand the rigors of intensive training and competition. While other factors such as comfort, fit, and performance characteristics also contribute to a skate’s overall ranking, durability serves as the foundation upon which these qualities are built. The focus on durability minimizes equipment-related setbacks and facilitates the skater’s long-term progress.

Frequently Asked Questions About Top Rated Figure Skates

The following section addresses common inquiries regarding high-performing figure skates, offering clarity on aspects related to their selection, maintenance, and performance characteristics.

Question 1: What defines a figure skate as “top rated?”

A high rating signifies exceptional performance characteristics, durable construction, superior comfort, and positive user feedback. Key factors include boot stiffness, blade quality, ankle support, and overall build quality.

Question 2: How often should figure skates be sharpened to maintain optimal performance?

Sharpening frequency depends on skating frequency and ice conditions. Generally, sharpening is recommended every 20-40 hours of skating. Signs of dullness include reduced edge control and a diminished ability to hold turns.

Question 3: What is the lifespan of highly rated figure skates?

Lifespan is contingent upon usage intensity, skater weight, and maintenance practices. With proper care, top-rated figure skates can last several years. Regular inspections and prompt repairs can extend their usability.

Question 4: Is professional fitting essential for figure skates, even with high ratings?

Professional fitting is highly recommended, irrespective of the skate’s rating. A customized fit optimizes comfort, enhances performance, and minimizes the risk of injuries. Expert fitting ensures appropriate sizing and addresses individual anatomical variations.

Question 5: How does boot stiffness impact figure skating performance?

Boot stiffness dictates ankle support and influences the ability to execute complex maneuvers. Stiffer boots provide enhanced support for advanced jumps, while more flexible boots offer greater range of motion for intricate footwork. Selecting the appropriate stiffness level is crucial for optimal performance and injury prevention.

Question 6: What are the key considerations when choosing figure skate blades?

Blade material, edge quality, and curvature are paramount considerations. Blades constructed from high-carbon steel offer superior edge retention. The appropriate blade curvature enhances agility and control during turns and jumps.

Selecting and maintaining figure skates involves informed decision-making. Consideration of these FAQs assists in optimizing skate performance and longevity.

The subsequent section concludes with comprehensive summary and conclusive recommendations.

Conclusion

The foregoing analysis demonstrates that achieving a high rating in figure skates requires a confluence of design, materials, and meticulous manufacturing. Critical attributes include boot stiffness, blade quality, ankle support, heat moldability, liner comfort, manufacturer reputation, and long-term durability. These factors, when optimized, collectively contribute to superior performance, enhanced safety, and prolonged equipment lifespan. The pursuit of excellence in figure skating necessitates a corresponding commitment to selecting equipment that meets these stringent standards. The selection process, therefore, demands diligent research and careful consideration.

As technology continues to evolve, future advancements in materials science and biomechanical engineering will undoubtedly lead to further refinements in figure skate design. It is imperative that skaters, coaches, and industry professionals remain informed about these developments to ensure the selection of equipment that maximizes potential and promotes safe and effective training. The dedication to procuring and maintaining superior equipment reflects a commitment to the art and athleticism inherent in figure skating, furthering the pursuit of excellence on the ice.