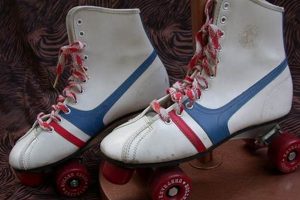

The items in question are foot-secured devices used for gliding movement across surfaces. These typically comprise a boot or shoe attached to a frame with four wheels, arranged in pairs, designed to provide mobility. An example would be a recreational tool employed for exercise, sport, or leisure activities.

The significance of these items lies in their contribution to physical fitness, offering a low-impact cardiovascular workout. They also foster coordination and balance. Historically, these have evolved from rudimentary in-line designs to the quad configurations commonly associated with rinks and recreational settings. The improved traction associated with specific models enhances control and safety.

The following discussion will delve into the selection criteria, maintenance procedures, and various applications related to these rolling devices, including their use in different disciplines and environments.

Essential Considerations for Enhanced Performance

This section outlines critical guidelines for optimizing the performance and longevity of your equipment, ensuring a safe and enjoyable experience.

Tip 1: Wheel Hardness Selection: Consider the surface type where usage will occur. Harder compounds are suitable for smooth, indoor surfaces, while softer compounds offer improved adhesion on outdoor, rougher terrains. Selecting the appropriate durometer optimizes roll and control.

Tip 2: Bearing Maintenance: Regularly clean and lubricate the internal components of the wheel’s mechanism. This action minimizes friction, improves speed, and extends the overall lifespan of the wheel assembly. Proper upkeep is critical for sustained performance.

Tip 3: Plate Material Evaluation: The material composing the chassis influences responsiveness and durability. Aluminum alloys offer a balance of strength and weight, while composite materials may prioritize vibration absorption. Understanding material properties is essential for suitability.

Tip 4: Toe Stop or Plug Inspection: Regularly assess the condition of the braking mechanism. Replace worn components promptly to ensure reliable stopping power and prevent accidents. The braking system’s integrity is paramount for user safety.

Tip 5: Proper Boot Fit: A snug, yet comfortable fit is essential for optimal control and stability. Ensure that the boot provides adequate ankle support and minimizes slippage. A secure fit prevents injuries and enhances maneuverability.

Tip 6: Truck Adjustment: The tightness of the truck influences turning radius and stability. Experiment with adjustments to find the optimal setting for preferred skating style and skill level. Fine-tuning the trucks is important for both comfort and control.

Key takeaways include prioritizing maintenance, selecting appropriate components for intended usage, and ensuring a secure and comfortable fit. Implementing these guidelines can significantly enhance the overall experience and extend the lifespan of the equipment.

The subsequent discussion will address specific applications and niche uses, catering to more advanced or specialized requirements.

1. Wheel Durometer

Wheel durometer is a critical characteristic that directly affects the performance and application of roller skates. It measures the hardness of the wheel’s material, influencing its grip, roll, and durability. The selection of an appropriate durometer is essential for optimizing the skating experience across various surfaces and disciplines.

- Durometer Scale and Measurement

The durometer scale, typically using the “A” scale for roller skate wheels, quantifies hardness from 0A (softest) to 100A (hardest). A higher number indicates a harder wheel, while a lower number denotes a softer wheel. Measurement is performed using a durometer gauge, which applies pressure to the wheel’s surface and records the indentation depth.

- Impact on Grip and Traction

Softer wheels (e.g., 78A-85A) offer enhanced grip, making them suitable for outdoor skating on rough or uneven surfaces. The increased compliance allows the wheel to conform to imperfections, maximizing contact area. Harder wheels (e.g., 95A-101A) reduce friction, promoting faster speeds on smooth, indoor surfaces. However, they provide less grip, potentially compromising control on slick surfaces.

- Influence on Roll and Speed

Harder wheels generally exhibit superior roll due to their reduced deformation under load. This translates to greater speed and efficiency, particularly on smooth surfaces. Softer wheels, while providing more grip, absorb more energy during each rotation, resulting in slower speeds and increased effort. The optimal balance between grip and roll depends on the intended skating style and environment.

- Considerations for Skating Discipline

Different skating disciplines necessitate different durometer choices. Artistic skaters often prefer harder wheels for precise control and edge work on smooth rinks. Outdoor recreational skaters benefit from softer wheels for shock absorption and grip on varied terrains. Speed skaters typically opt for the hardest wheels available to minimize rolling resistance and maximize velocity.

The selection of wheel durometer is an integral aspect of optimizing performance. By understanding the relationship between durometer, grip, roll, and skating discipline, skaters can make informed decisions that enhance their control, speed, and overall experience. Experimentation and adaptation to specific surface conditions are often necessary to achieve optimal results.

2. Bearing Precision

Bearing precision plays a vital role in the performance characteristics of roller skates. It directly influences rolling efficiency, speed, and the overall skating experience.

- ABEC Rating System

The Annular Bearing Engineering Committee (ABEC) rating system is an industry standard for classifying the dimensional tolerances of bearings. Higher ABEC ratings (e.g., ABEC-7, ABEC-9) indicate tighter tolerances and, theoretically, greater precision. However, the ABEC rating primarily addresses manufacturing tolerances and does not necessarily guarantee superior performance in skating applications. It provides a benchmark for quality control and expected performance levels.

- Impact on Rolling Resistance

Bearings with higher precision generally exhibit lower rolling resistance. Reduced internal friction within the bearing allows for smoother rotation and increased rolling efficiency. Lower rolling resistance translates to less effort required to maintain speed, contributing to a more efficient and enjoyable skating experience. This is particularly noticeable during longer skating sessions or when attempting higher speeds.

- Material Composition and Construction

Bearing materials significantly influence performance and durability. Chrome steel is a common material for bearing races due to its hardness and wear resistance. Ball bearings can be made from steel, ceramic, or hybrid materials. Ceramic bearings are lighter, smoother, and more resistant to heat, potentially offering superior performance in high-speed applications. The design of the bearing cage, which separates and guides the balls, also affects performance and durability. Nylon cages are lightweight and quiet, while metal cages are more durable and heat-resistant.

- Maintenance and Lubrication

Proper maintenance and lubrication are crucial for preserving bearing precision and performance. Regular cleaning removes dirt and debris that can increase friction and wear. Lubrication reduces friction, protects against corrosion, and extends the lifespan of the bearings. Different types of lubricants are available, each with specific properties and suitability for various skating conditions. Synthetic lubricants generally offer superior performance compared to petroleum-based lubricants.

The selection of bearings with appropriate precision and the implementation of a consistent maintenance schedule are critical factors in optimizing the performance and longevity of roller skates. While ABEC ratings provide a useful guideline, real-world performance is also influenced by material composition, construction quality, and regular upkeep.

3. Plate Material

The plate, also referred to as the chassis or frame, represents a foundational element in the construction of roller skates. It serves as the primary interface between the boot and the wheels, directly influencing responsiveness, stability, and overall performance. Material selection for the plate is therefore a critical determinant of skate characteristics.

- Aluminum Alloys

Aluminum alloys offer a favorable strength-to-weight ratio, rendering them a common choice for roller skate plates. These alloys provide adequate stiffness for efficient energy transfer during skating while minimizing overall weight. Different aluminum grades and heat treatments can further tailor the plate’s mechanical properties, such as stiffness and fatigue resistance. Examples include 7075 aluminum, often used in high-performance plates, and 6061 aluminum, a more cost-effective option for recreational models.

- Magnesium Alloys

Magnesium alloys provide an even greater weight reduction compared to aluminum. While offering superior damping characteristics, these alloys typically exhibit lower strength and corrosion resistance. Therefore, magnesium plates are less common and primarily found in specialized applications where weight minimization is paramount, such as speed skating. Protective coatings are often necessary to mitigate corrosion concerns.

- Composite Materials

Composite materials, such as fiberglass or carbon fiber reinforced polymers, can be engineered to provide specific performance characteristics. These materials offer vibration damping, reducing fatigue and improving comfort, but generally lack the stiffness of metal alloys. Composite plates are frequently found in recreational skates or models designed for long-distance skating where comfort is prioritized over maximum responsiveness. The layup and fiber orientation can be tailored to optimize strength and stiffness in specific directions.

- Steel

Steel plates, historically common, offer high strength and durability. However, steel’s increased weight is a significant disadvantage compared to lighter alternatives. Consequently, steel plates are now primarily found in entry-level or rental skates where robustness and cost-effectiveness are more important than performance. Steel offers a very rigid and strong plate but compromises speed and maneuverability due to the added weight.

The selection of plate material represents a trade-off between weight, stiffness, durability, and cost. The intended use of the roller skates dictates the optimal choice. High-performance applications often prioritize lightweight alloys for maximum responsiveness, while recreational skating may favor composite materials for enhanced comfort. The plate material’s impact on overall skate performance and durability is undeniable.

4. Boot Construction

Boot construction is a pivotal aspect of the overall performance and safety of “sure grip roller skates.” The boot’s design and materials directly affect ankle support, stability, and energy transfer, all of which are critical for maintaining control and preventing injuries. A well-constructed boot enhances the skater’s ability to execute maneuvers with precision and confidence. Conversely, a poorly designed boot can compromise stability, leading to discomfort or even falls. For example, a boot with inadequate ankle support may allow excessive lateral movement, making it difficult to maintain balance during turns or when encountering uneven surfaces.

The materials used in boot construction also play a significant role. Leather boots, while offering durability and a degree of customization through molding to the foot, can be less breathable and heavier than synthetic alternatives. Synthetic boots, often made from materials like nylon or microfiber, can provide better ventilation and reduce weight, but may lack the long-term durability of leather. The stiffness of the boot material also impacts energy transfer; a stiffer boot will transmit more power from the skater’s leg to the skates, enabling more efficient propulsion and control. The internal padding and lining contribute to comfort and prevent chafing, particularly during extended use. Consider the design of speed skates, which utilize very rigid boots to ensure maximum power transfer for acceleration and maintaining high speeds.

In summary, the selection of appropriate boot construction is vital for optimizing performance and safety in roller skating. A boot offering sufficient ankle support, constructed from durable and comfortable materials, and designed for efficient energy transfer contributes significantly to control and stability. Therefore, understanding the interplay between boot construction and skating performance is paramount for both recreational and competitive skaters, and is a major contribution to a “sure grip” experience.

5. Toe Stop Design

The toe stop serves as a crucial braking and stability component in quad roller skates. Its design significantly influences the skater’s ability to control speed, execute stops, and perform certain maneuvers. The effectiveness of this component directly contributes to the overall safety and maneuverability associated with the skating experience.

- Material Composition and Friction

Toe stops are typically constructed from rubber or composite materials, with variations in hardness and texture influencing their frictional properties. Softer compounds offer greater stopping power on smooth surfaces but may wear more rapidly. Harder compounds provide increased durability but potentially reduced grip. The selection of material should align with the intended skating environment and user preferences. For example, a skater who primarily skates outdoors may require a more durable compound to withstand abrasive surfaces.

- Shape and Surface Area

The shape and surface area of the toe stop impact the distribution of pressure and the effectiveness of braking. Larger surface areas generally provide greater stopping power but can also increase the risk of accidental engagement. Smaller, more streamlined designs may offer improved maneuverability and reduced interference during certain skating techniques. Rounded or angled designs can facilitate smooth transitions between rolling and braking.

- Adjustability and Positioning

Adjustable toe stops allow the skater to customize the height and angle of the stop, optimizing its position relative to the skating surface. Proper positioning ensures efficient braking and enhances stability. The toe stop should be positioned such that it engages the surface with minimal effort, allowing for quick and controlled stops. Incorrect positioning can compromise braking effectiveness and increase the risk of injury.

- Thread Type and Compatibility

Toe stops utilize various thread types and sizes to ensure compatibility with different skate plates. It is crucial to select a toe stop with the correct thread type to ensure secure attachment and prevent damage to the plate or the stop itself. Incompatible thread types can lead to instability and potential failure of the braking system.

The design attributes of the toe stop are inextricably linked to the performance and safety of the equipment. Careful consideration of material, shape, adjustability, and compatibility is essential for selecting a toe stop that meets the specific needs of the skater and the intended skating environment. The toe stop’s effectiveness directly impacts the skater’s ability to maintain control and execute maneuvers safely and confidently.

6. Truck Adjustability

Truck adjustability represents a critical feature influencing the performance and handling characteristics of quad roller skates. Its role in determining turning responsiveness and stability directly impacts the skater’s control and maneuverability.

- Kingpin Tension and Turning Radius

The kingpin, a central bolt securing the truck assembly, dictates the compression of the truck’s cushions (bushings). Adjusting the kingpin nut alters the tension on these cushions, thereby influencing turning radius. Looser kingpin settings allow for easier turning and greater maneuverability, facilitating tighter turns and quicker responses. Conversely, tighter settings increase stability and straight-line tracking, but reduce turning agility. Examples include jam skaters favoring looser trucks for rapid footwork and dance routines, while recreational skaters may prefer tighter trucks for added stability at higher speeds.

- Cushion (Bushing) Durometer and Rebound

Truck cushions, typically made from polyurethane, are available in varying durometers (hardness). Softer cushions offer greater compression and rebound, enhancing responsiveness and turning ease, but may feel less stable at higher speeds. Harder cushions provide more resistance to compression, increasing stability and control at speed, but requiring more effort to initiate turns. A skater experimenting with different durometers may find that softer cushions improve their ability to execute quick pivots, while harder cushions give them a more planted feel during long strides.

- Truck Angle and Steering Response

The angle of the truck in relation to the skate plate affects the steering response. Steeper truck angles generally result in more responsive steering, allowing for quicker initiation of turns. Shallower truck angles offer greater stability and predictability, reducing the likelihood of unintended directional changes. Skaters using high rebound and aggressive forward stance will find steeper angles enable them to roll their weight forward and maintain balance at top speed.

- Impact on Grip and Control

Proper truck adjustment enhances grip and control by optimizing the contact between the wheels and the skating surface. Adjusting kingpin tension and selecting appropriate cushion durometers allows skaters to fine-tune the skate’s response to their movements, maximizing control and minimizing the risk of wheel slippage. A skater experiencing wheel chatter or loss of control may benefit from adjusting their trucks to improve the skate’s overall grip.

In essence, truck adjustability provides skaters with the ability to customize the handling characteristics of their skates to suit their individual preferences, skill levels, and skating styles. This customization promotes a “sure grip” experience by enhancing control, stability, and maneuverability.

7. Grip Integrity

Grip integrity is a foundational element for safe and effective use of roller skates, directly influencing control, stability, and maneuverability. The relationship between grip integrity and roller skates is causal: compromised grip leads to reduced control and an increased risk of falls. The design and maintenance of the skates, specifically the wheels and their interaction with the skating surface, determine the level of grip integrity. For example, worn or damaged wheels exhibit reduced grip, making it difficult to execute turns or maintain balance, especially on slick or uneven surfaces. Regularly inspecting and replacing wheels are crucial maintenance practices that maintain grip integrity.

The importance of grip integrity extends beyond basic safety. High-performance skating maneuvers, such as those seen in artistic or speed skating, demand reliable grip for precise execution. Skates with compromised grip integrity limit a skater’s ability to perform complex moves, reducing overall performance. Furthermore, varying skating surfaces (indoor vs. outdoor, smooth vs. rough) necessitate different wheel compounds to optimize grip integrity. Choosing wheels designed for specific surfaces ensures maximum contact and control, promoting safety and performance. The wheel’s durometer scale, measured in “A”, indicates its hardness: Softer wheels provide better grip on rough surfaces, while harder wheels enhance speed on smooth surfaces.

Understanding and maintaining grip integrity is paramount for a safer and more enjoyable skating experience. By regularly inspecting and replacing worn wheels, choosing appropriate wheel compounds for different surfaces, and considering the intended skating style, users can significantly enhance grip and minimize the risk of accidents. Prioritizing grip integrity is not merely a matter of preference; it is a fundamental aspect of responsible skating, contributing directly to control, stability, and overall performance. Therefore grip integrity should be a basic requirement that consumers look into when purchasing roller skates.

Frequently Asked Questions Regarding “Sure Grip Roller Skates”

This section addresses common inquiries and misconceptions regarding these specific rolling devices, providing factual information to assist in informed decision-making.

Question 1: Are all roller skate wheel compounds suitable for outdoor use?

No, wheel compounds vary significantly in their abrasion resistance and grip characteristics. Outdoor surfaces typically necessitate softer compounds with enhanced grip to compensate for irregularities and debris. Using harder, indoor-specific wheels outdoors may compromise control and accelerate wear.

Question 2: How frequently should roller skate bearings be cleaned and lubricated?

Bearing maintenance frequency depends on usage conditions. Regular cleaning and lubrication are recommended after exposure to dirt, water, or excessive wear. A schedule of monthly maintenance may suffice for casual indoor use, while more frequent attention may be needed for outdoor or competitive applications.

Question 3: Does a higher ABEC rating guarantee superior roller skate bearing performance?

While the ABEC rating indicates manufacturing tolerances, it does not encompass all aspects of bearing performance. Material quality, lubrication, and proper maintenance significantly impact a bearing’s overall performance and longevity. A higher ABEC rating alone does not guarantee superior speed or durability.

Question 4: Can roller skate plate material significantly affect skating performance?

Yes, the plate material directly impacts responsiveness, stability, and energy transfer. Lighter materials, such as aluminum alloys, enhance agility, while stiffer materials improve power transfer. The choice of plate material should align with the skater’s skill level and intended skating style.

Question 5: Is proper boot fit essential for safety and performance?

Absolutely. A secure and comfortable boot fit is paramount for preventing injuries and maximizing control. A boot that is too loose can compromise ankle support, while a boot that is too tight can restrict circulation and cause discomfort. Proper boot fit ensures optimal energy transfer and responsiveness.

Question 6: How should roller skate trucks be adjusted for optimal performance?

Truck adjustment depends on individual preferences and skating style. Looser trucks provide greater maneuverability but may sacrifice stability at higher speeds. Tighter trucks enhance stability but reduce turning agility. Experimentation with truck tension and cushion durometer is recommended to find the optimal setting.

Key takeaways include the importance of selecting appropriate components for specific skating conditions, maintaining equipment regularly, and prioritizing proper fit for safety and performance.

The next section will explore advanced topics related to customization and performance enhancement.

This exploration has delved into the multifaceted nature of “sure grip roller skates,” examining the critical elements that contribute to performance, safety, and overall user experience. Wheel durometer, bearing precision, plate material, boot construction, toe stop design, truck adjustability, and grip integrity each play a significant role in determining the effectiveness and suitability of these devices for diverse applications.

A thorough understanding of these technical considerations enables informed decision-making, promoting optimal utilization and responsible operation. Continued advancements in materials and design principles promise further refinement, enhancing both the performance and safety characteristics of “sure grip roller skates” for future generations. Therefore, we encourage users to prioritize a commitment to learning and exploration.

![Buy Roller Skate Wheels Near Me: [Shop Name] Offers! Learn to Surf & Skate: A Beginner's Step-by-Step Guide Buy Roller Skate Wheels Near Me: [Shop Name] Offers! | Learn to Surf & Skate: A Beginner's Step-by-Step Guide](https://universitysurfandskate.com/wp-content/uploads/2026/03/th-51-300x200.jpg)