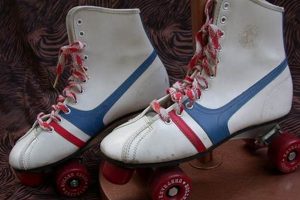

Footwear designed for gliding movement over surfaces, typically featuring four wheels arranged in pairs, is offered under the “Sulifeel” brand. These products provide a recreational and sporting activity option, enabling users to propel themselves across smooth terrains. A common example includes models suitable for both indoor rink skating and outdoor paved trails.

The utilization of such equipment promotes physical exercise, enhancing cardiovascular health and lower body strength. Historically, similar wheeled devices have evolved from simple in-line arrangements to the more stable quad designs, adapting to changing user preferences and technological advancements. The accessibility of recreational fitness activities is also improved with readily available and affordable models.

The following sections will delve into specific features, appropriate maintenance procedures, and target user demographics associated with this type of skating equipment. Factors such as wheel composition, bearing quality, and boot construction will be analyzed to provide a comprehensive understanding of selection criteria. Considerations for safety and proper usage will also be addressed.

Guidance for Optimum Use

The following guidelines provide instruction for achieving the best possible experience and ensuring the longevity of skating equipment. Adherence to these recommendations is essential for both safety and optimal performance.

Tip 1: Wheel Maintenance: Regularly inspect the wheels for wear and tear. Replace wheels exhibiting significant abrasion or uneven wear patterns to maintain stability and control.

Tip 2: Bearing Care: Clean and lubricate the bearings periodically. Use a solvent-based cleaner to remove dirt and debris, followed by a suitable lubricant to ensure smooth rolling and reduce friction.

Tip 3: Boot Support: Ensure the boot provides adequate ankle support. A properly fitted boot minimizes the risk of ankle injuries and improves overall control during use.

Tip 4: Surface Selection: Choose appropriate skating surfaces. Smooth, paved areas are ideal. Avoid surfaces with excessive debris, cracks, or uneven textures to prevent accidents and equipment damage.

Tip 5: Safety Gear: Always wear appropriate safety gear. A helmet, knee pads, elbow pads, and wrist guards are essential for protecting against injuries from falls.

Tip 6: Tighten Components: Regularly check and tighten all bolts and fasteners. Loose components can compromise stability and increase the risk of accidents.

Tip 7: Gradual Progression: Practice in a controlled environment to enhance skills gradually. Avoid attempting advanced maneuvers until proficiency is achieved with basic techniques.

Following these guidelines will contribute to a safer and more enjoyable skating experience, while also prolonging the life of the equipment. Consistent maintenance and adherence to safety protocols are paramount.

The subsequent sections will provide detailed information regarding the proper storage and transport of skating equipment to maintain its condition.

1. Wheel Durometer

Wheel durometer is a critical attribute that directly impacts the performance characteristics of wheeled footwear, influencing grip, speed, and suitability for various skating surfaces. Its relevance to the overall user experience with such skating equipment is substantial, meriting careful consideration during selection.

- Durometer Scale and Measurement

The durometer scale measures the hardness of a material, typically polyurethane in this context. Values are expressed in “A” units, ranging from 0A (softest) to 100A (hardest). For instance, wheels marked 78A provide significant grip, while those labeled 88A or higher offer increased speed and durability on smooth surfaces.

- Grip vs. Speed Trade-off

Softer wheels (lower durometer) provide greater grip, essential for slick surfaces or maneuvers requiring precise control. Harder wheels (higher durometer) offer less grip but allow for faster speeds and prolonged wear on smooth, consistent terrain. This represents a fundamental trade-off, influencing the type of skating experience.

- Surface Compatibility

Wheel durometer selection should align with the intended skating environment. Softer wheels excel on rougher surfaces, absorbing imperfections and maintaining contact. Harder wheels are best suited for smooth concrete or wooden floors, maximizing speed and minimizing rolling resistance. Using an inappropriate durometer can compromise performance and safety.

- Durability and Wear

Harder wheels generally exhibit greater resistance to wear and abrasion compared to softer wheels. Frequent use on abrasive surfaces will accelerate the wear rate of softer wheels. Therefore, selecting a suitable durometer based on anticipated usage patterns is important for optimizing the lifespan of the equipment.

Understanding these facets of wheel durometer allows for more informed decision-making when purchasing skating equipment. The optimal durometer selection depends heavily on individual skating style, intended use, and the types of surfaces encountered. Careful consideration of these factors will contribute to a more enjoyable and effective skating experience.

2. Bearing Precision

The rotational efficiency of wheeled footwear is significantly influenced by bearing precision. Within “Sulifeel roller skates,” the bearings facilitate wheel movement, and their manufacturing tolerances directly correlate with the smoothness and speed achievable. A bearing with higher precision exhibits reduced friction, translating to increased velocity with less effort from the user. For example, bearings rated ABEC-7 or higher are commonly implemented in performance-oriented models, whereas recreational variants may employ ABEC-3 or ABEC-5 bearings. Variations in precision during bearing manufacture inevitably impact how the skate feels and performs. Higher precision contributes to smoother glide.

The performance of lower-quality bearings can be compromised by imperfections or inconsistencies in the bearing components. Consequently, these bearings may exhibit increased friction, premature wear, or even catastrophic failure under load. This can negatively impact the skating experience and potentially pose safety risks. Routine maintenance, including cleaning and lubrication, can mitigate some of these effects. However, the fundamental limitations of lower precision bearings remain. The cost of high-precision bearings directly reflects their performance. This provides an economic incentive for individuals to replace standard-issue bearings in entry-level to medium-quality products.

Ultimately, the relationship between bearing precision and skating performance is direct. Higher ABEC ratings generally correlate with a more fluid and efficient skating experience. Despite the higher cost associated with these components, the investment is often warranted for users seeking to maximize their speed and reduce the physical demands of skating. The quality of bearings affects the safety and durability of the product. The selection of these components reflects a balance between the users level of experience, style of skating, and budget.

3. Boot Material

The material composition of the boot component is a primary determinant of comfort, support, and durability in “Sulifeel roller skates.” Selection of appropriate materials is critical for optimizing performance and ensuring user safety. The range of available materials varies, each offering distinct advantages and disadvantages.

- Leather Construction

Leather boots offer a balance of flexibility, support, and breathability. The material conforms to the user’s foot over time, providing a customized fit. However, leather requires regular maintenance to prevent cracking and drying, and it is generally heavier than synthetic alternatives. Historically, leather was the primary boot material, but is less common in entry-level models due to cost.

- Synthetic Polymers

Synthetic boots, often constructed from materials such as nylon or polyurethane, offer increased water resistance and reduced weight compared to leather. These materials are generally less expensive and require less maintenance. However, synthetic boots may lack the breathability and customized fit of leather, potentially leading to discomfort during extended use. The increased use of synthetic polymers enables more affordable consumer products.

- Hybrid Designs

Hybrid boot designs combine leather and synthetic materials to leverage the benefits of both. For example, a boot may feature a leather outer shell for support and durability, combined with a synthetic liner for comfort and moisture management. These designs represent a compromise between cost, performance, and maintenance requirements.

- Rigid Shells

Some “Sulifeel roller skates,” particularly those intended for aggressive or high-impact skating, utilize rigid outer shells made from materials such as reinforced plastic or carbon fiber. These shells provide maximum support and protection, but offer limited flexibility and breathability. They are generally reserved for specialized applications where performance outweighs comfort considerations.

The choice of boot material significantly impacts the overall skating experience. Factors such as intended use, budget, and personal preferences should inform the selection process. Understanding the characteristics of each material type allows for a more informed decision, optimizing comfort, performance, and longevity.

4. Frame Strength

Frame strength, a critical structural attribute, directly influences the performance and safety of “Sulifeel roller skates.” The frame, typically constructed from metal alloys or reinforced polymers, serves as the chassis, connecting the boot to the wheels and transmitting forces generated during propulsion and maneuvering. Insufficient frame strength compromises stability, responsiveness, and durability, potentially leading to equipment failure and user injury.

- Material Composition

The type of material used in frame construction significantly impacts its strength-to-weight ratio. Aluminum alloys, commonly employed in mid-range to high-end models, offer a favorable balance of strength and weight. Steel frames, while more durable, are considerably heavier. Reinforced polymers provide a lightweight and cost-effective option, but may lack the rigidity and impact resistance of metallic alternatives. The selected material must withstand repeated stress cycles and impact forces without permanent deformation or fracture.

- Structural Design

Frame geometry and cross-sectional profiles contribute substantially to overall strength and stiffness. Ribs, gussets, and other reinforcing features can enhance the frame’s ability to resist bending and torsional loads. Frames designed with a lower center of gravity improve stability and control. The design must distribute stress evenly across the frame, minimizing stress concentrations that could lead to premature failure. Consider also, high-end models that are often custom-engineered through computer modeling.

- Load Capacity and Impact Resistance

Frame strength dictates the maximum load capacity of “Sulifeel roller skates.” Exceeding the rated load capacity can result in frame deformation or failure, compromising user safety. Impact resistance, the ability to withstand sudden shocks, is particularly important for aggressive skating styles. Frames intended for such applications typically feature thicker cross-sections and more robust construction to mitigate the risk of damage from jumps and landings. The load capacity should meet or exceed the user’s total weight.

- Manufacturing Process

The manufacturing process employed affects the structural integrity of the frame. Forged or extruded frames generally exhibit superior strength compared to cast frames due to the alignment of the material grain structure. Welding processes must be carefully controlled to ensure proper fusion and minimize the introduction of stress concentrations. Heat treatment processes can further enhance the strength and durability of metallic frames.

The interplay of material composition, structural design, load capacity, and manufacturing process collectively determines the overall frame strength of “Sulifeel roller skates.” Selecting a model with adequate frame strength, appropriate for the intended usage and user weight, is paramount for ensuring safety, performance, and longevity of the equipment.

5. Closure System

The closure system on “Sulifeel roller skates” is integral to both the safety and performance characteristics of the product. It secures the boot to the user’s foot, ensuring proper fit and support, which directly impacts control, stability, and comfort during use. Variations in closure system design influence ease of use, adjustability, and the overall security of the skate.

- Lace Systems

Traditional lace systems offer a high degree of adjustability, allowing the user to customize the fit across the entire foot. The tightness can be varied in different zones to provide targeted support or accommodate variations in foot shape. However, lace systems can be time-consuming to fasten and require periodic tightening during use. For example, a figure skater may prefer laces for precision adjustment, while a recreational skater might find them less convenient.

- Buckle Closures

Buckle closures provide a quick and secure method of fastening the boot. Ratcheting buckles offer incremental adjustments, allowing for a snug fit. These systems are generally easier to use than laces, particularly for younger users or those with limited dexterity. However, buckle systems may offer less precise adjustability compared to laces, potentially leading to pressure points or discomfort for some users. An example includes inline skates where buckles provide quick adjustments for varying terrains.

- Hook-and-Loop Straps

Hook-and-loop straps, such as Velcro, offer a simple and convenient closure option. These straps are easy to fasten and adjust, making them suitable for entry-level or recreational models. However, hook-and-loop systems may lose their grip over time due to wear or debris accumulation. Furthermore, they may not provide sufficient support for more demanding skating activities. For instance, children’s skates often utilize hook-and-loop for ease of use.

- Hybrid Systems

Hybrid closure systems combine multiple closure types to leverage their respective advantages. A skate may feature laces in the lower portion of the boot for precise fit adjustment, combined with a buckle or strap in the upper portion for quick and easy fastening. These systems aim to provide a balance of adjustability, security, and convenience. An example would be a skate with laces for fine-tuning fit and buckles for quick on/off.

The selection of an appropriate closure system depends on individual user preferences, skating style, and the intended use of the “Sulifeel roller skates.” Each type of closure system offers distinct advantages and disadvantages in terms of adjustability, security, ease of use, and durability. Consideration of these factors is essential for optimizing comfort and performance.

6. Brake Integrity

Brake integrity in “Sulifeel roller skates” constitutes a critical safety parameter. The braking system’s functionality directly influences a user’s ability to control deceleration and prevent collisions. Compromised brakes represent a significant hazard, increasing the likelihood of accidents and injuries. Consider, for example, a scenario where a skater descending an incline experiences brake failure; the inability to effectively reduce speed elevates the risk of uncontrolled impact with obstacles or other individuals. Thus, brake integrity is not merely a feature, but a primary safety mechanism.

Assessing the braking system involves evaluating several factors, including the condition of the brake pad, the responsiveness of the actuation mechanism, and the security of the attachment points. A worn brake pad diminishes braking effectiveness, requiring increased force to achieve the same level of deceleration. A sluggish or unresponsive actuation mechanism delays braking response, reducing the time available to avoid hazards. Loose or damaged attachment points compromise the structural integrity of the braking system, potentially leading to complete brake failure. The maintenance is often neglected and impacts safety.

In summary, brake integrity is indispensable for safe operation of “Sulifeel roller skates.” Regular inspection and maintenance of the braking system are crucial to ensuring its continued functionality. Users must proactively address any signs of wear or damage to prevent accidents and injuries. Emphasizing the significance of this aspect contributes directly to user safety and responsible skating practices, but also prolongs the life of the skate itself.

Frequently Asked Questions

This section addresses common inquiries regarding the use, maintenance, and selection of skating equipment, providing clarity on critical aspects related to these products.

Question 1: What is the recommended frequency for replacing the wheels on “Sulifeel roller skates?”

Wheel replacement frequency depends on usage intensity, skating surface, and wheel durometer. Regular inspection for wear is crucial. Replacement is indicated when wheels exhibit significant abrasion, uneven wear patterns, or a noticeable reduction in grip.

Question 2: How should bearings be cleaned and lubricated for optimal performance?

Bearing maintenance requires disassembly, cleaning with a solvent-based cleaner to remove dirt and debris, followed by thorough drying. Lubrication with a bearing-specific lubricant is essential to reduce friction and ensure smooth rolling. Avoid using harsh chemicals that may damage the bearing components.

Question 3: What factors should be considered when selecting the appropriate size of skating equipment?

Proper sizing is critical for comfort, support, and control. Foot length and width should be accurately measured. The boot should provide a snug fit without restricting circulation. Consult the manufacturer’s sizing chart to ensure proper selection.

Question 4: What safety precautions should be observed while using “Sulifeel roller skates?”

Adherence to safety protocols is paramount. Always wear appropriate protective gear, including a helmet, knee pads, elbow pads, and wrist guards. Select appropriate skating surfaces, avoiding areas with heavy traffic or hazardous conditions. Practice in a controlled environment to develop proficiency before attempting advanced maneuvers.

Question 5: What is the recommended storage procedure for skating equipment when not in use?

Proper storage protects the equipment from damage and prolongs its lifespan. Store in a dry, cool place away from direct sunlight. Loosen laces or straps to prevent deformation of the boot. Consider using a skate bag to protect the equipment from dust and scratches.

Question 6: How does wheel durometer impact the skating experience, and what durometer range is suitable for different surfaces?

Wheel durometer, a measure of hardness, influences grip and speed. Softer wheels (lower durometer) provide greater grip, ideal for rough surfaces. Harder wheels (higher durometer) offer faster speeds on smooth surfaces. A durometer range of 78A-85A is generally suitable for outdoor recreational skating, while 85A and above are preferred for indoor rink skating.

Consistent adherence to these guidelines ensures user safety, prolongs equipment lifespan, and optimizes skating performance. Prioritize safety, regular maintenance, and informed equipment selection for a positive skating experience.

The following article section will focus on best practices for transportion of the “Sulifeel roller skates.”

Sulifeel Roller Skates

This exposition has provided a detailed analysis of skating equipment, underscoring the significance of key components such as wheel durometer, bearing precision, boot material, frame strength, closure systems, and brake integrity. Proper maintenance, informed selection, and adherence to safety protocols are paramount for optimizing performance and mitigating risks associated with the use of these products. The information presented serves as a comprehensive guide for both novice and experienced users.

The continued evolution of skating technology promises advancements in safety and performance. A commitment to understanding the fundamental principles outlined herein will contribute to a safer and more enjoyable experience. Prioritize informed decision-making to ensure that skating activities remain a source of recreation and fitness, free from preventable accidents and injuries. Regular evaluation of equipment and techniques are necessary.