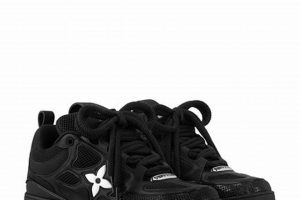

Footwear designed for skateboarding often incorporates a reinforced toe area for enhanced durability and protection. This specialized footwear merges the functionality of safety shoes with the aesthetic and performance requirements of skateboarding shoes. A rigid internal structure within the toe protects the wearer’s foot from impacts and abrasions commonly encountered during skateboarding activities.

The integration of a protective toe feature offers significant benefits to skateboarders, mitigating the risk of injuries from falls, collisions, and board impacts. Historically, skateboarders have sought ways to improve the longevity of their shoes and minimize foot injuries. This type of footwear represents a practical solution that addresses these needs, allowing skateboarders to pursue their activity with increased confidence and reduced potential for harm.

The subsequent sections will delve into specific aspects of this specialized footwear, including materials used, construction techniques, safety standards, and considerations for selecting the appropriate model for various skateboarding styles and environments. This comprehensive overview aims to provide a thorough understanding of this protective gear for skateboarders.

Selection and Maintenance Guidance

The following guidance is designed to assist in the appropriate selection and care of skateboarding footwear incorporating a reinforced toe. Adherence to these recommendations will contribute to enhanced safety and prolonged product lifespan.

Tip 1: Assess Impact Resistance Requirements: Evaluate the specific demands of the skateboarding style. More aggressive styles necessitating frequent board contact require footwear with a higher impact resistance rating.

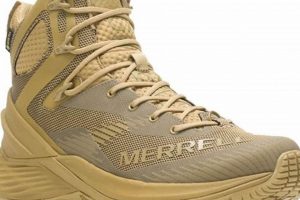

Tip 2: Examine Material Composition: Prioritize footwear constructed from durable materials such as reinforced leather or synthetic fabrics designed to withstand abrasion and repeated impacts.

Tip 3: Verify Compliance with Safety Standards: Ensure the footwear meets recognized safety standards for impact and compression resistance. Compliance information should be readily available from the manufacturer.

Tip 4: Consider Sole Construction: Select footwear with a durable outsole that provides adequate grip and board feel. Vulcanized rubber or similar high-traction materials are recommended.

Tip 5: Evaluate Fit and Comfort: Ensure a snug, comfortable fit that allows for adequate foot support and prevents excessive movement within the shoe. Proper fit is crucial for both performance and injury prevention.

Tip 6: Implement Regular Cleaning and Maintenance: Regularly clean the footwear to remove dirt and debris that can compromise material integrity. Promptly repair any damage to maintain protective capabilities.

Tip 7: Store Footwear Appropriately: When not in use, store the footwear in a dry, well-ventilated environment to prevent deterioration of materials.

Proper selection and diligent maintenance practices significantly contribute to the longevity and protective efficacy of this specialized skateboarding footwear. By adhering to these guidelines, skateboarders can mitigate the risk of foot injuries and maximize the lifespan of their protective equipment.

The subsequent sections will provide more detailed information on specific construction techniques and available product options. This will facilitate informed decision-making when selecting skateboarding footwear designed to offer enhanced protection.

1. Impact Resistance

Footwear integrating a reinforced toe, specifically designed for skateboarding, prioritizes impact resistance as a fundamental attribute. The causal relationship between skateboarding activities and potential foot injuries necessitates this design consideration. Falls, collisions, and direct impacts from the skateboard itself pose significant risks. The ability of the footwear to withstand and dissipate these forces directly determines the level of protection afforded to the wearer. For instance, a skateboarder attempting a rail grind who loses balance may experience a direct impact to the toe area; footwear with inadequate impact resistance would fail to protect against potential fractures or contusions.

Impact resistance testing simulates real-world scenarios to quantify the protective capabilities of the footwear. Standardized tests, such as those measuring compression and impact forces, provide objective data regarding the footwear’s ability to withstand specific levels of energy. Manufacturers often specify the impact resistance rating of their products, allowing consumers to make informed decisions based on their individual skateboarding style and risk assessment. Furthermore, the materials used in the toe reinforcement, such as hardened polymers or metal alloys, directly influence the overall impact resistance of the footwear. Different materials offer varying levels of protection based on their inherent properties and structural design.

In conclusion, impact resistance is a non-negotiable feature of reinforced toe skateboarding footwear. It provides a critical barrier against common skateboarding injuries, allowing participants to engage in the activity with a greater degree of safety. Understanding the principles of impact resistance, the materials utilized, and the testing methodologies employed empowers informed decision-making and promotes responsible participation in skateboarding. Choosing footwear with inadequate impact resistance exposes the wearer to unnecessary risk and undermines the intended protective function of the gear.

2. Material Durability

Material durability constitutes a critical factor in the performance and longevity of footwear designed for skateboarding that incorporates a reinforced toe. The abrasive nature of skateboarding, involving frequent contact with concrete, asphalt, and other rough surfaces, necessitates the use of materials capable of withstanding significant wear and tear. Premature failure of the footwear due to material degradation undermines its protective function and necessitates frequent replacement, incurring additional costs and potential safety risks. For example, a low-quality canvas upper may quickly tear and fray, exposing the foot to abrasion and impact, even if the toe area itself remains intact. The effectiveness of the reinforced toe is contingent upon the overall structural integrity of the shoe.

Specific examples of durable materials commonly employed in such footwear include reinforced leather, ballistic nylon, and specialized synthetic textiles. These materials exhibit high tensile strength and resistance to abrasion, extending the lifespan of the shoe and maintaining its protective qualities over extended periods. The choice of materials also impacts the weight and flexibility of the footwear, which are important considerations for skateboarding performance. Furthermore, the bonding agents and stitching techniques used in the construction of the shoe contribute significantly to its overall durability. Weak stitching or substandard adhesives can lead to delamination and separation of components, compromising the integrity of the reinforced toe area. The interplay between material selection, construction methods, and the specific demands of skateboarding determine the overall durability of the footwear.

In conclusion, material durability is an indispensable attribute of skateboarding footwear featuring a reinforced toe. The selection of robust materials, combined with sound construction techniques, ensures the longevity of the shoe and maintains its capacity to provide effective protection against impacts and abrasions. A comprehensive understanding of the materials utilized and their respective properties is essential for making informed purchasing decisions and maximizing the value and safety of this specialized footwear. Neglecting material durability results in compromised performance, increased risk of injury, and a diminished lifespan for the product.

3. Safety Standards

The integration of safety standards within the design and manufacturing of reinforced-toe skateboarding footwear is paramount. These standards serve as quantifiable benchmarks for performance, ensuring a baseline level of protection against common skateboarding-related injuries. Adherence to these established protocols translates to a reduced risk of foot trauma and contributes to a safer skateboarding experience.

- Impact Resistance Testing

Standardized impact resistance tests, such as ASTM F2413, evaluate the ability of the reinforced toe to withstand specific levels of force. These tests simulate real-world impact scenarios, providing quantifiable data on the footwear’s protective capabilities. Footwear that fails to meet minimum impact resistance requirements poses a significant risk of foot injury to the wearer.

- Compression Resistance Testing

Compression resistance tests assess the ability of the reinforced toe to withstand static loads without deformation or collapse. This is particularly relevant in situations where the skateboarder may experience direct pressure on the toe area, such as during landings or slides. Footwear lacking adequate compression resistance may fail to protect the foot from crushing injuries.

- Material Certification

Material certifications, such as those issued by recognized testing laboratories, verify the properties and performance characteristics of the materials used in the construction of the reinforced toe. These certifications ensure that the materials meet specific standards for strength, durability, and resistance to abrasion. The use of certified materials contributes to the overall reliability and protective capabilities of the footwear.

- Labeling and Disclosure Requirements

Safety standards often mandate specific labeling and disclosure requirements, providing consumers with clear and accurate information about the protective capabilities of the footwear. This information may include impact resistance ratings, compression resistance ratings, and details about the materials used in construction. Transparent labeling enables consumers to make informed purchasing decisions based on their individual needs and risk assessment.

The aforementioned facets of safety standards are intrinsic to the functionality and reliability of footwear designed for skateboarding incorporating reinforced toes. Compliance with these standards ensures a defined level of protection, contributing to a safer skateboarding environment. Disregarding these established protocols can result in compromised safety and increased potential for foot-related injuries.

4. Sole Traction

Sole traction is a critical attribute of skateboarding footwear, particularly in designs incorporating a reinforced toe. Adequate grip facilitates board control and maneuverability, directly influencing both performance and safety. The interplay between sole composition, tread pattern, and board surface dictates the effectiveness of traction. Inadequate grip can lead to slippage, resulting in loss of control and increased risk of falls, even with the protective features of a reinforced toe.

- Rubber Compound Composition

The rubber compound used in the outsole significantly impacts traction. Softer compounds offer enhanced grip but may exhibit reduced durability. Conversely, harder compounds provide increased wear resistance but may compromise traction, particularly on smooth or wet surfaces. The optimal balance between grip and durability is often achieved through proprietary rubber formulations designed specifically for skateboarding applications. For example, vulcanized rubber, known for its flexibility and grip, is a common choice for skateboard shoe outsoles.

- Tread Pattern Design

The tread pattern influences the contact area between the sole and the skateboard deck, affecting the coefficient of friction. Deeper treads generally provide better grip on uneven surfaces, while shallower treads may offer improved board feel. Herringbone patterns, geometric shapes, and variations in tread depth are commonly employed to optimize traction for different skateboarding styles. The design considerations extend to the placement and orientation of the tread elements, ensuring consistent grip during various maneuvers.

- Vulcanization Process

The vulcanization process, commonly used in the manufacturing of skateboard shoe soles, involves heating rubber compounds with sulfur to enhance their strength, elasticity, and resistance to abrasion. Proper vulcanization ensures a durable and grippy outsole that can withstand the stresses of skateboarding. Inadequate vulcanization can result in a brittle or slippery sole, compromising both performance and safety. The quality control of the vulcanization process is crucial for maintaining consistent traction characteristics across different batches of footwear.

- Surface Texture

The surface texture of the sole also contributes to traction. Microscopic irregularities in the rubber compound create additional points of contact with the skateboard deck, enhancing grip. Some manufacturers employ specialized surface treatments to further improve traction, such as adding fine particles to the rubber compound or texturing the sole during the molding process. The effectiveness of surface texture is influenced by factors such as cleanliness and surface conditions, with dust or moisture potentially reducing grip.

These facets highlight the significance of sole traction in skateboarding footwear, particularly models with a reinforced toe. The interplay between rubber compound, tread pattern, vulcanization, and surface texture ensures optimal grip and board control, mitigating the risk of slips and falls. The integration of a reinforced toe provides added protection, but its effectiveness relies on the foundation of reliable traction. Therefore, the selection of skateboarding footwear should prioritize sole traction as a fundamental attribute, complementing the protective features of the reinforced toe.

5. Proper Fit

Footwear designed for skateboarding that incorporates a reinforced toe necessitates a precise fit to ensure both safety and performance. The rigidity of the reinforced toe area can exacerbate discomfort or create pressure points if the internal dimensions of the shoe are not properly matched to the wearer’s foot shape and size. Ill-fitting footwear can compromise the protective benefits of the reinforced toe, leading to blisters, chafing, or even restricted blood flow. Furthermore, an improper fit can negatively impact board feel and control, increasing the risk of falls and injuries. For instance, a shoe that is too loose may cause the foot to shift during maneuvers, reducing responsiveness and stability. Conversely, a shoe that is too tight may restrict movement and impede circulation, leading to fatigue and discomfort. The proper internal volume and shape are crucial for accommodating the foot comfortably and securely within the reinforced structure.

The selection process should prioritize accurate foot measurements and consideration of individual foot characteristics, such as width and arch height. Trying on the footwear while wearing appropriate skateboarding socks is essential for determining the optimal fit. The wearer should be able to wiggle toes freely without experiencing excessive pressure or slippage. The heel should be securely held in place to prevent unwanted movement during dynamic activities. Lacing systems play a critical role in fine-tuning the fit and providing adjustable support. Properly adjusted laces can enhance stability and minimize friction within the shoe. Moreover, the internal construction of the shoe, including cushioning and arch support, should complement the wearer’s foot anatomy to promote comfort and prevent fatigue. The integration of breathable materials helps to regulate moisture and minimize the risk of blisters. The cumulative effect of these fit-related factors directly impacts the skateboarder’s experience and safety.

In conclusion, achieving a proper fit in skateboarding footwear with a reinforced toe transcends mere comfort; it is integral to maximizing both protection and performance. Careful consideration of foot measurements, individual foot characteristics, and the nuances of the shoe’s internal construction is paramount. The potential consequences of an improper fit range from discomfort and reduced board feel to an increased risk of injury. Consequently, the selection process should prioritize a precise and comfortable fit that allows for unrestricted movement, optimal support, and the full realization of the reinforced toe’s protective capabilities. Prioritizing fit enhances overall safety and enjoyment in skateboarding.

6. Maintenance Regimen

Adherence to a rigorous maintenance regimen is crucial for preserving the protective integrity and extending the operational lifespan of footwear designed for skateboarding that incorporates a reinforced toe. The demanding nature of skateboarding subjects the footwear to considerable stress, necessitating proactive care to mitigate wear and tear and ensure continued performance.

- Regular Cleaning

Accumulation of dirt, debris, and moisture can degrade the materials comprising skateboarding footwear. Regular cleaning, utilizing appropriate cleaning agents and techniques, removes these contaminants and prevents premature deterioration. Neglecting this step can compromise the integrity of the reinforced toe area and accelerate overall wear. For instance, abrasive particles embedded in the fabric can gradually wear down stitching and weaken the bonding agents securing the reinforced toe. A consistent cleaning schedule prolongs the footwear’s usability and protective qualities.

- Inspection for Damage

Routine inspection of the footwear for signs of damage, such as tears, fraying, or delamination, enables early detection of potential problems. Prompt repair of minor damage prevents escalation and preserves the footwear’s structural integrity. Neglecting to address these issues can lead to compromised protection and necessitate premature replacement. For example, a small tear in the upper material can quickly expand, exposing the foot to abrasion and reducing the effectiveness of the reinforced toe in impact scenarios. Timely inspection and repair are crucial for maintaining the footwear’s protective functionality.

- Moisture Management

Exposure to moisture can compromise the materials used in skateboarding footwear, leading to weakening of adhesives, corrosion of metallic components (if present), and the growth of mold or mildew. Proper drying and storage techniques mitigate these risks. Allowing the footwear to air dry thoroughly after exposure to moisture prevents material degradation and preserves its structural integrity. The use of moisture-absorbing materials within the footwear can further enhance moisture management. Addressing moisture-related issues proactively extends the lifespan of the footwear and prevents the development of unpleasant odors.

- Reinforcement as Needed

Wear and tear in high-stress areas may necessitate reinforcement to prolong the footwear’s lifespan. Applying patches, protective coatings, or additional stitching can strengthen weakened areas and prevent further damage. This proactive approach extends the usability of the footwear and maintains its protective capabilities. For example, applying a durable adhesive to reinforce the edges of the reinforced toe area can prevent delamination and maintain structural integrity. Targeted reinforcement enhances the longevity and performance of skateboarding footwear.

The aforementioned facets of a comprehensive maintenance regimen underscore the importance of proactive care in preserving the protective functionality and extending the operational lifespan of skateboarding footwear featuring a reinforced toe. By adhering to these guidelines, skateboarders can maximize the value of their investment, reduce the risk of injuries, and ensure continued performance. Neglecting maintenance results in compromised protection, increased risk of equipment failure, and a diminished skateboarding experience.

Frequently Asked Questions

The following addresses common inquiries regarding skateboarding footwear incorporating a reinforced toe. This information aims to clarify prevalent concerns and misconceptions surrounding its purpose, construction, and proper utilization.

Question 1: What is the primary function of a reinforced toe in skateboarding footwear?

The reinforced toe serves to protect the foot from impacts, abrasions, and compression forces encountered during skateboarding activities. It mitigates the risk of injuries such as contusions, fractures, and lacerations in the toe and forefoot area.

Question 2: Are there standardized safety ratings for this specialized footwear?

While specific skateboarding standards may vary, look for certifications referencing ASTM F2413, indicating compliance with impact and compression resistance tests. These standards provide a benchmark for protective capabilities.

Question 3: What materials are typically employed in the construction of the reinforced toe?

Common materials include hardened polymers, composite materials, and, in some instances, metallic elements. The selection depends on the desired balance between protection, weight, and flexibility.

Question 4: Does a reinforced toe impede skateboarding performance or board feel?

Modern designs strive to minimize any negative impact on performance. However, a reinforced toe inherently alters the flexibility and responsiveness compared to traditional skateboarding footwear. Individual preferences vary.

Question 5: How does one properly maintain skateboarding footwear with a reinforced toe?

Regular cleaning to remove debris and prompt repair of any damage are essential. Allowing the footwear to air dry thoroughly after exposure to moisture prevents material degradation.

Question 6: Is skateboarding footwear featuring a reinforced toe suitable for all skateboarding styles?

While beneficial for most styles, it may be particularly advantageous for more aggressive skateboarding disciplines involving frequent board contact and higher potential for impacts.

In summary, footwear integrating a reinforced toe represents a practical solution for mitigating foot injuries in skateboarding. Adherence to proper selection and maintenance practices maximizes its protective capabilities.

The subsequent section will explore the historical evolution of protective skateboarding gear.

Conclusion

This exploration has detailed the functionality, construction, and maintenance considerations associated with steel cap skate shoes. The examination encompassed impact resistance, material durability, applicable safety standards, sole traction characteristics, the importance of proper fit, and the necessity of a consistent maintenance regimen. Each facet directly impacts the protective capabilities and operational lifespan of this specialized footwear.

The information presented serves to underscore the critical role protective gear plays in mitigating the risks associated with skateboarding. Prudent selection and diligent maintenance of steel cap skate shoes contribute to a safer skateboarding environment. Continued innovation and adherence to stringent safety protocols are essential for advancing the safety and performance of skateboarding footwear.