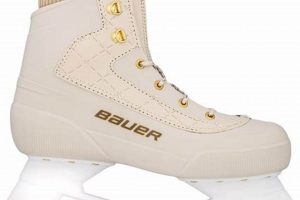

The process of applying a specific shade of light blue paint, reminiscent of a winter landscape, to ice skates is a customization technique. This involves using aerosol-based paint to alter the original color of the skates, achieving a visually appealing and personalized aesthetic. For example, skaters might choose this color to match a costume, express individuality, or simply update the appearance of older skates.

Customizing athletic equipment, including ice skates, allows for individual expression and can enhance the skater’s overall presence on the ice. Choosing this particular color can evoke feelings of winter, ice, and elegance, contributing to a more cohesive and visually impactful performance. Historically, customization of sporting equipment has been a way for athletes to distinguish themselves, showing team or individual identity. In doing so, it provides a new identity to the ice skates.

Therefore, the artistic treatment of skates introduces a number of considerations, ranging from surface preparation to sealant application. The following sections will discuss these aspects in detail, providing information on the required materials, optimal painting techniques, and preventative measures to ensure a durable and aesthetically pleasing result.

Tips for Achieving a Professional Finish

When undertaking the application of a winter blue shade to ice skates via aerosol paint, adherence to specific techniques will significantly influence the final outcome and longevity of the finish. Proper preparation and execution are critical for achieving a smooth, durable, and visually appealing result.

Tip 1: Surface Preparation is Paramount: Prior to the application of any paint, ensure the skate’s surface is meticulously cleaned and lightly abraded. Use fine-grit sandpaper (220 grit or higher) to create a slightly textured surface that promotes paint adhesion. Remove all dust and debris with a tack cloth.

Tip 2: Employ a Primer Coat: Applying a primer specifically designed for the skate’s material (e.g., metal or synthetic leather) is crucial. The primer provides a uniform base, improves paint adhesion, and prevents the original color from bleeding through. Allow the primer to dry completely according to the manufacturer’s instructions.

Tip 3: Opt for Thin, Even Coats: Apply the winter blue paint in several thin, even coats rather than one thick coat. This prevents drips, runs, and uneven coverage. Hold the spray can approximately 6-10 inches from the surface and use a consistent, sweeping motion. Allow each coat to dry thoroughly before applying the next.

Tip 4: Temperature and Humidity Considerations: Aerosol paints perform optimally within specific temperature and humidity ranges. Consult the paint manufacturer’s recommendations and avoid painting in extreme conditions, as this can affect drying time and finish quality.

Tip 5: Masking Critical Areas: Protect areas of the skate that should not be painted, such as blades or logos, by carefully masking them off with painter’s tape and paper or plastic sheeting. Ensure the masking is secure and covers all unwanted areas completely.

Tip 6: Curing Time is Essential: Allow the painted skates ample time to cure properly. This may take several days, depending on the paint formulation and environmental conditions. Avoid handling the skates excessively during the curing process to prevent damage to the finish.

Tip 7: Consider a Protective Clear Coat: To enhance durability and protect the paint from scratches and abrasion, apply a clear coat specifically formulated for painted surfaces. Choose a clear coat with UV protection to prevent fading over time. Apply in thin, even coats, following the same technique as the winter blue paint.

By adhering to these guidelines, one can increase the likelihood of achieving a professional-quality finish, resulting in a visually striking and durable custom color application. Careful attention to detail and proper technique are essential for a successful outcome.

With a solid understanding of these foundational aspects, the subsequent stages of skate preparation, painting, and protection can be approached with greater confidence, ensuring the skates are not only aesthetically enhanced but also maintain their functionality and longevity.

1. Preparation

Effective preparation is a foundational element in achieving a professional-quality finish when altering the color of ice skates with an aerosolized winter blue coating. The degree of preparation directly influences the paint’s adhesion, uniformity, and overall longevity on the skate’s surface.

- Cleaning and Degreasing

The removal of any existing dirt, oils, or waxes from the skate’s surface is critical. Residual contaminants can impede the paint’s ability to bond effectively, leading to peeling or chipping. Isopropyl alcohol or specialized degreasers are typically employed. Failure to thoroughly clean the surface will compromise the adhesion of the aerosolized coating.

- Sanding or Abrasion

Lightly abrading the surface with fine-grit sandpaper (typically 220-grit or higher) creates a textured profile that enhances mechanical adhesion. This process is particularly important for smooth surfaces, where the paint may have difficulty establishing a strong bond. The abrasion should be uniform to ensure consistent paint adhesion across the entire surface.

- Masking

Precise masking of areas that are not intended to be painted, such as the blade, rivets, or specific logos, is essential for maintaining the integrity of the skate’s original design and function. High-quality painter’s tape, carefully applied, prevents overspray and ensures clean lines. Improper masking results in an unprofessional appearance and potential damage to functional components.

- Priming

The application of a primer designed for the skate’s specific material (e.g., leather, synthetic composite) provides a uniform base for the winter blue coating. Primers improve paint adhesion, prevent the underlying color from bleeding through, and can enhance the overall durability of the finish. Selecting the correct primer formulation is crucial for achieving optimal results.

These preparatory steps, when executed meticulously, establish a solid foundation for the subsequent stages of the modification process. Inadequate preparation invariably leads to compromised aesthetic outcomes and reduced coating lifespan, ultimately detracting from the value and appearance of the customized ice skates.

2. Adhesion

The adherence of an aerosolized winter blue coating to the surface of ice skates is a primary determinant of the customization’s success. Robust adhesion ensures the color remains intact under the stresses of use, preventing chipping, peeling, or premature degradation of the finish. Factors influencing adhesion range from surface characteristics to the chemical properties of the paint itself.

- Surface Energy and Wettability

The surface energy of the skate material and the wettability of the winter blue paint formulation are critical. Higher surface energy and improved wettability promote closer contact between the paint and the surface, enhancing intermolecular forces responsible for adhesion. A surface with low energy, such as untreated plastic, may require surface treatment to improve wettability. A practical example is the use of flame treatment on polypropylene skate boots before coating.

- Mechanical Interlocking

Microscopic surface irregularities, created through sanding or abrasion, allow the paint to mechanically interlock with the surface. This interlocking provides a physical resistance to detachment. The depth and density of these irregularities are crucial; excessive abrasion can weaken the substrate, while insufficient abrasion provides inadequate adhesion points. The effect can be seen when coatings on smooth, untreated metal surfaces peel easily because of lack of interlocking sites.

- Chemical Bonding

Chemical bonding between the paint and the skate material, such as covalent or ionic bonds, represents the strongest form of adhesion. Primers containing reactive functional groups can facilitate chemical bonding. An example includes using an epoxy primer on composite skate components to increase bonding with the winter blue topcoat. Chemical bonding provides resistance to environmental degradation.

- Cohesive Strength of the Coating

The internal strength of the winter blue paint layer itself influences its ability to resist cohesive failure. A brittle or poorly formulated paint is more prone to cracking and delamination, even with adequate surface adhesion. This is often observed when using low-quality spray paints that lack flexibility, resulting in cracking when the skate flexes during use. Improving the coating’s formulation can help it resist such failures.

The interplay of surface energy, mechanical interlocking, chemical bonding, and cohesive strength collectively determines the adhesion of the aerosolized winter blue coating to ice skates. Ensuring optimal conditions for each of these factors is essential for achieving a durable and aesthetically pleasing custom finish. A comprehensive approach that considers surface preparation, material compatibility, and coating formulation is necessary for success.

3. Application Technique

The method by which the winter blue paint is applied directly impacts the final aesthetic and durability of the ice skate customization. Improper technique can result in uneven color distribution, drips, runs, or a textured surface, thereby compromising the visual appeal. For instance, holding the aerosol can too close to the skate during application results in concentrated paint deposition, leading to drips. Conversely, holding the can too far away may cause the paint to partially dry before contacting the surface, resulting in a rough, textured finish, and uneven color coverage

Several factors contribute to successful application. Consistent distance between the spray nozzle and the skate surface, typically six to ten inches, ensures uniform paint distribution. A sweeping motion, rather than a stationary spray, prevents localized over-application and subsequent drips. Multiple thin coats, rather than one thick coat, allow each layer to dry evenly, minimizing the risk of runs and ensuring proper adhesion between coats. Consider the contrasting example: an experienced painter who applies thin, even coats achieves a smooth, uniform color, while a novice who applies a single thick coat often faces issues with drips and inconsistent color. Also, temperature and humidity affect paint drying time and finish quality.

Proper application technique is not merely a procedural step but an integral element of the artistic and protective customization of ice skates. Mastering the technique reduces the likelihood of aesthetic imperfections and enhances the longevity of the modified color. The skill required transcends simple operation, embodying precision and an awareness of environmental factors. Achieving a professional result requires dedicated practice and attention to detail. It is the difference between a satisfactory finish and a truly exceptional transformation.

4. Paint Durability

Paint durability is a critical factor in the longevity and aesthetic appeal when using an aerosolized winter blue finish. The rigorous activity associated with ice skating subjects the paint to abrasion from skate guards, contact with ice surfaces, and repeated flexing of the skate boot. Therefore, the paint’s inherent resistance to these stresses directly impacts its ability to maintain its original color and finish over time. Using paints with poor durability properties leads to premature chipping, scratching, and fading. The choice of paint formulation, therefore, significantly determines the lifespan and appearance of the customization.

The selection of paints incorporating acrylic or polyurethane resins, known for their enhanced flexibility and abrasion resistance, is essential in this application. For instance, a two-part epoxy paint system, known for its high durability, could be applied to withstand the stresses of frequent skating activity. A clear coat sealant specifically designed to resist UV degradation protects against fading. The absence of such considerations will result in the need for frequent touch-ups or recoating, negating the benefits of the initial effort. Consider skaters applying a durable clear coat finish: their skate retains its color and finish longer than the skate left unprotected.

In summary, a focus on paint durability when applying a customized finish to ice skates is not simply an aesthetic concern but a practical imperative. Selecting appropriate materials and techniques guarantees the longevity of the customization. This reduces maintenance requirements and sustains the visual integrity of the skates over time, thereby ensuring long-term satisfaction with the applied color. A commitment to understanding the properties of different paint systems proves essential for achieving both visual appeal and functional resilience in ice skate color modification.

5. Color Uniformity

Achieving consistent color application during the aerosolized modification of ice skates with a winter blue finish is paramount for aesthetic quality and visual appeal. Color uniformity, in this context, refers to the absence of discernible variations in hue, saturation, and intensity across the entire painted surface. Deviations from uniform color application can result in a patchy, unprofessional appearance, detracting from the intended visual impact of the customized skates. The importance of uniform color stems from its direct contribution to the overall aesthetic harmony and perceived quality of the finished product. Example: If one area of the skate appears a lighter shade of winter blue than another, the unevenness becomes immediately noticeable, undermining the intended design.

Factors affecting color uniformity include but are not limited to: inconsistent spray technique, variations in surface preparation, environmental conditions during application, and inconsistencies in the paint formulation itself. Variations in spray distance and speed can lead to uneven paint distribution, causing some areas to receive more paint than others. Inadequate surface preparation, such as the presence of residual contaminants, can affect the paint’s ability to adhere evenly, resulting in color variations. Fluctuations in temperature and humidity can alter the paint’s drying characteristics, impacting color uniformity. Furthermore, batch-to-batch variations in paint manufacturing can introduce subtle differences in color that become apparent upon application. Understanding and controlling these variables are critical for achieving consistent color. Skates intended for professional competition, require high degree of uniformity.

In conclusion, color uniformity is an integral attribute of a successful skate customization. A uniform color contributes directly to the visual impact and perceived quality of the customized skates. Control over application technique, surface preparation, environmental factors, and material consistency contribute directly to this result. By recognizing the importance of color uniformity and implementing strategies to mitigate potential sources of variation, a more aesthetically pleasing final product can be achieved. The challenges associated with maintaining uniform color application highlight the need for diligence and precision in the skate painting process.

6. Protective Sealing

Protective sealing, in the context of applying an aerosolized winter blue finish, represents a critical final step that significantly influences the coating’s longevity and resistance to environmental factors. The application of a clear sealant over the winter blue paint layer serves as a barrier against abrasion, moisture, UV radiation, and chemical exposure, each of which can degrade the painted surface over time. Without protective sealing, the winter blue finish is inherently vulnerable to chipping, scratching, fading, and discoloration, compromising the aesthetic appeal and functional integrity of the customized ice skates. An example involves a clear coat containing UV inhibitors, which when applied, protects the winter blue finish from direct sunlight.

The selection of an appropriate sealant is paramount, considering factors such as its chemical compatibility with the underlying paint, its flexibility, and its abrasion resistance. Sealants formulated with acrylic, polyurethane, or epoxy resins offer varying degrees of protection, each suited to different environmental conditions and usage patterns. Sealants are often applied in multiple thin coats, allow proper curing to maximize effectiveness. Choosing a sealant designed for outdoor applications can further enhance UV and moisture resistance. Protective sealing provides a new shield preventing environmental damage, such as damage from handling the skates.

The integration of protective sealing into the workflow of custom skate finishing ensures that the aesthetic enhancement achieved through the paint application is preserved for an extended period. In its absence, the painted surface is exposed to potential damage. Protective sealing represents a necessary investment in the durability and longevity of the modification. The practice has evolved from merely applying paint, now involving protective sealing which increases lifetime. As a conclusion, protective sealing is an integral component and will protect the skate through the application.

Frequently Asked Questions

The following questions address common concerns regarding the modification of ice skates using an aerosolized winter blue coating. These answers aim to clarify best practices and potential challenges.

Question 1: Is surface preparation truly necessary before applying the aerosolized winter blue coating?

Surface preparation is essential for achieving adequate paint adhesion and a durable finish. Failure to properly clean, degrease, and abrade the surface can result in peeling, chipping, and premature coating failure.

Question 2: What type of primer should be used on ice skates prior to painting?

The primer should be specifically formulated for the skate’s material, whether it is leather, synthetic composite, or metal. A universal primer may not provide optimal adhesion or corrosion protection.

Question 3: How many coats of winter blue paint are recommended for optimal coverage and durability?

Multiple thin coats, typically two to three, are preferred over a single thick coat. Thin coats allow for even drying, minimize the risk of drips and runs, and promote better adhesion between layers.

Question 4: What environmental conditions are ideal for applying aerosolized paint to ice skates?

Optimal conditions include moderate temperatures (65-80F or 18-27C) and low humidity. Extreme temperatures or high humidity can affect the paint’s drying time, adhesion, and overall finish quality.

Question 5: Is a clear coat sealant necessary after painting ice skates?

A clear coat sealant is highly recommended to protect the winter blue paint from abrasion, UV radiation, and moisture. Sealants enhance the coating’s durability and prolong its aesthetic appeal.

Question 6: How long should the painted ice skates cure before being used?

The curing time varies depending on the paint and sealant formulations, but typically a minimum of 24-72 hours is required for the coating to fully harden and achieve optimal durability. Consult the product manufacturer’s instructions for specific curing times.

These answers provide a basis for making informed decisions regarding aerosolized winter blue finishes. Proper application and maintenance are critical for preserving the customized look of the ice skates.

The subsequent article section will explore the long-term maintenance considerations for customized skates.

Concluding Remarks

The preceding discussion has thoroughly examined the process of spray painting your ice skates winter blue ice blue. This endeavor extends beyond mere aesthetics, requiring meticulous attention to surface preparation, material compatibility, application technique, durability considerations, color uniformity, and protective sealing. Neglecting any of these factors can compromise the result. This systematic approach provides a framework for achieving a visually appealing and durable finish.

The successful execution of this process enhances the individual’s skating experience. The principles and techniques outlined herein empower individuals to make informed decisions. Continued adherence to quality control will refine the process and the long-term preservation of the skate’s custom finish. This ensures enduring performance on the ice.