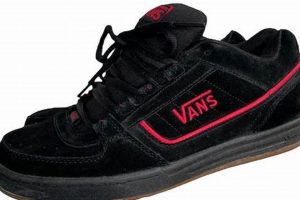

Footwear designed for skateboarding, often rendered in a dark, achromatic color, serves as a critical piece of equipment for both amateur and professional skaters. These specialized shoes typically feature durable construction, reinforced stitching, and a flat, grippy sole to provide optimal board feel and protection during skateboarding maneuvers. A practical example includes low-profile sneakers crafted with suede or canvas uppers and vulcanized rubber soles, commonly favored for their resilience and adherence to the skateboard deck.

The utility of this particular footwear stems from its capacity to withstand the abrasive nature of skateboarding. Features like padded collars and tongues enhance comfort and impact absorption, while robust materials resist tearing and wear from repeated contact with grip tape. Historically, these shoes have evolved from repurposed athletic footwear to purpose-built designs, reflecting the growing popularity and demands of skateboarding culture. Their prevalence signifies not only a practical choice for skaters but also a recognizable element of skateboard fashion and identity.

The following discussion will delve deeper into the specific characteristics that define high-quality skateboarding footwear, examining the significance of sole construction, upper materials, and design innovations that cater to the unique demands of skateboarding. Subsequent sections will further explore the impact of these features on performance, durability, and overall user experience.

Skate Shoe Selection Considerations

Proper selection of skateboarding footwear significantly impacts both performance and safety. The following guidelines offer valuable insights for choosing appropriate skate shoes.

Tip 1: Material Durability: Opt for materials such as suede or reinforced canvas for the upper portion. These materials exhibit superior resistance to abrasion from grip tape, extending the lifespan of the shoe. Examples include models with double-stitched ollie pads for increased durability in high-wear areas.

Tip 2: Sole Construction: Prioritize vulcanized rubber or cupsole constructions. Vulcanized soles provide enhanced board feel and flexibility, while cupsole designs offer superior impact protection and support. A flat, grippy tread pattern is essential for optimal traction on the skateboard.

Tip 3: Padding and Support: Evaluate the level of padding in the collar, tongue, and insole. Adequate padding reduces impact and enhances comfort during landings and tricks. Supportive insoles can minimize foot fatigue and prevent injuries.

Tip 4: Fit and Sizing: Ensure a snug, secure fit that allows for comfortable movement. Properly fitted shoes prevent slippage and maximize board control. Consider trying on different sizes and styles to determine the optimal fit for individual foot shape and preferences.

Tip 5: Stitching Reinforcement: Examine the stitching quality, particularly in areas prone to wear, such as the toe cap and side panels. Reinforced stitching minimizes tearing and prolongs the shoe’s overall durability. Look for double or triple stitching in high-stress zones.

Tip 6: Brand Reputation: Research established brands with a proven track record of producing high-quality skateboarding footwear. Reputable brands often invest in research and development to create shoes specifically designed for the demands of skateboarding.

Tip 7: Design Aesthetics: While functionality is paramount, consider the aesthetic appeal of the shoe. Choose a style and color that aligns with personal preferences. However, prioritize performance and durability over purely cosmetic considerations.

Selecting skateboarding footwear based on these guidelines enhances performance, reduces the risk of injury, and maximizes the lifespan of the shoe. These considerations are crucial for both novice and experienced skateboarders.

The subsequent sections will address the long-term care and maintenance of skateboarding footwear to further extend its usability and performance.

1. Material Abrasion Resistance

Material abrasion resistance is a paramount characteristic in footwear designed for skateboarding, especially those rendered in black, as it directly correlates to the product’s lifespan and sustained performance under the harsh conditions inherent in the sport.

- Surface Coating Integrity

The application of surface coatings or treatments, particularly on black-dyed materials, can significantly impact abrasion resistance. For instance, certain polyurethane coatings, while providing aesthetic appeal, may lack the flexibility required to withstand repeated friction against grip tape, leading to premature cracking and peeling. Conversely, impregnating agents that penetrate the material fibers can enhance resistance to both abrasion and fading without compromising flexibility.

- Fiber Density and Weave Pattern

The density and weave pattern of the textile used in the upper construction play a crucial role. Tightly woven, high-density materials, such as ballistic nylon or tightly knit canvas, offer greater resistance to abrasion compared to loosely woven fabrics. Examples include the utilization of ripstop patterns, which prevent small tears from propagating and weakening the overall structure of the shoe.

- Material Composition and Treatment

The inherent properties of the materials chosen, such as suede versus canvas, significantly affect abrasion resistance. Suede, due to its napped surface, can initially exhibit higher abrasion resistance but may degrade more rapidly with prolonged use if not properly treated. Canvas, especially when reinforced with synthetic fibers like Kevlar, offers a robust and cost-effective alternative. Chemical treatments, such as silicone impregnation, can further enhance the water and abrasion resistance of either material.

- Stitching and Reinforcement Techniques

The method and density of stitching, particularly in high-wear areas like the toe cap and ollie patch, directly influence abrasion resistance. Reinforced stitching techniques, such as double or triple stitching, distribute stress and prevent seam failure under abrasive forces. Examples include the use of heavy-duty nylon thread and strategic placement of reinforcement panels to minimize wear and tear.

The interplay of these factors determines the overall abrasion resistance of skateboarding footwear. Choosing materials and construction methods that prioritize this characteristic ensures the longevity and performance of the shoes, ultimately contributing to a more sustainable and cost-effective solution for skateboarders. The black color exacerbates the visibility of abrasion damage, making the quality of these features even more crucial.

2. Sole grip consistency

Sole grip consistency represents a critical performance attribute of skateboarding footwear, inextricably linked to safety and maneuverability. In the context of dark-colored skate shoes, variations in rubber compound, tread pattern design, and manufacturing processes can directly influence the coefficient of friction between the sole and the skateboard deck’s grip tape. Diminished grip consistency results in reduced board control, increasing the potential for slips and falls during complex tricks or high-speed maneuvers. Real-world examples include vulcanized soles formulated with low-quality rubber exhibiting premature hardening and reduced tackiness after minimal use, thereby compromising grip. Conversely, specialized rubber compounds engineered for sustained grip performance maintain a consistent level of friction across a broader range of temperature and usage conditions.

The practical significance of understanding sole grip consistency manifests in the selection and maintenance of skateboarding shoes. Skaters prioritizing performance often opt for footwear featuring directional tread patterns, which channel away debris and water, maximizing contact area with the grip tape. Furthermore, regular cleaning of the sole, employing appropriate solvents to remove embedded dirt and grime, preserves the rubber’s inherent grip properties. The color, specifically black, does not directly impact grip consistency; however, it can influence heat absorption, potentially affecting rubber durometer and, consequently, grip. A higher sole durometer will often lead to less grip than a lower one, all other factors being equal.

In summary, sole grip consistency serves as a cornerstone of safe and effective skateboarding. While color is primarily an aesthetic consideration, material composition, tread design, and maintenance practices exert a direct and measurable influence on the contact friction. Challenges in consistently achieving optimal grip across diverse shoe models and manufacturing batches necessitate ongoing research and development into novel rubber compounds and sole construction techniques. Continued refinement in these areas contributes to enhanced skater performance and reduced risk of injury, affirming the importance of grip consistency in skateboarding shoe design.

3. Impact force distribution

Impact force distribution is a critical engineering consideration in the design of skateboarding footwear, and it directly influences the functionality and safety, regardless of the shoe’s coloration. In the context of black skate shoes, this attribute specifically refers to the shoe’s capacity to mitigate and evenly spread the forces generated during landings, jumps, and other high-impact maneuvers. The footwear’s structure, material composition, and internal cushioning systems are engineered to absorb energy and reduce the localized stress on the skater’s feet, ankles, and knees. A lack of effective impact force distribution can result in acute injuries, such as sprains and fractures, or chronic conditions stemming from repetitive stress. Consider, for instance, a skater executing a jump from a raised platform; the forces generated upon landing can be several times the skater’s body weight. A well-designed skate shoe, irrespective of its black color, redirects and attenuates this force across a wider area, minimizing concentrated pressure points.

Various design elements contribute to effective impact force distribution. These include the incorporation of specialized cushioning materials, such as polyurethane or ethylene-vinyl acetate (EVA) foams, which exhibit shock-absorbing properties. Additionally, structural features, like cupsole constructions, provide greater rigidity and stability, enabling the shoe to distribute forces more evenly across the plantar surface. Airbag or gel-based cushioning systems further enhance impact absorption by creating a dynamic buffer between the foot and the ground. As an example, the internal construction of the shoe might incorporate a multi-density foam insole, with denser foam in areas that receive the most impact, such as the heel and forefoot. Conversely, a shoe with inadequate cushioning and a poorly designed sole transmits the impact force directly to the foot, increasing the risk of injury. In practical terms, this understanding dictates the selection criteria for skateboarders, emphasizing the importance of internal shoe structure rather than solely relying on aesthetic appearance or external branding.

In summary, impact force distribution represents a fundamental biomechanical principle in the design of skate shoes. The effectiveness of impact force distribution is independent of shoe color, including black skate shoes, and depends instead on design and materials. The consistent and reliable attenuation of impact stresses directly correlates with reduced injury risk and improved skater performance. Continued research and development into novel cushioning technologies and structural designs are paramount for enhancing the safety and longevity of skateboarders’ feet. The challenge lies in balancing optimal impact protection with board feel and flexibility, requiring careful engineering and material selection.

4. Ankle support effectiveness

Ankle support effectiveness in footwear designed for skateboarding directly influences skater stability and injury prevention. The degree to which “skate shoes black,” or any skate shoe, mitigates ankle instability during high-impact maneuvers and landings serves as a critical determinant of its overall utility.

- Collar Height and Padding

The height of the shoe collar, coupled with the density and composition of its padding, significantly affects ankle support. Higher collars provide increased surface area for contact with the ankle, restricting excessive inversion or eversion. Stiffer padding materials resist compression under load, maintaining support during high-impact events. Examples include molded polyurethane collars that offer rigid support compared to traditional foam padding, which may compress over time, diminishing support effectiveness. The correlation to black skate shoes resides in material choices: dark materials may absorb more heat, potentially affecting padding density.

- Internal Heel Counter

The internal heel counter, typically constructed from reinforced plastic or composite materials, provides structural integrity to the heel cup, stabilizing the rearfoot. A robust heel counter resists deformation, preventing the ankle from rolling inward or outward. A weak or absent heel counter offers minimal support, increasing the risk of ankle sprains. Black skate shoes utilizing dark-colored plastics might be more susceptible to UV degradation, potentially weakening the heel counter over extended exposure to sunlight.

- Lacing System Integration

The lacing system, when properly integrated with the shoe’s upper construction, contributes to ankle support by securing the foot within the shoe. Lacing patterns that extend higher up the ankle, combined with reinforced eyelets, allow for a more customized and secure fit. Loose or poorly designed lacing systems fail to adequately stabilize the ankle, compromising support. Black skate shoes can feature contrasting colored laces and eyelets that accentuate the lacing system’s design and functionality.

- Midsole Stability Features

Certain skate shoes incorporate midsole features designed to enhance stability and support. These features may include medial posts, which resist overpronation, or torsional rigidity elements that prevent excessive twisting of the shoe. While less directly related to the ankle itself, these features contribute to overall foot and ankle stability, reducing the likelihood of ankle injuries. Midsole construction using dark-colored materials in black skate shoes is often shielded from direct sunlight, minimizing potential degradation.

The combined effectiveness of these features dictates the level of ankle support provided by “skate shoes black.” While the color itself does not inherently influence ankle support, it can affect material degradation and heat absorption, indirectly impacting performance. Skaters should prioritize shoes with robust ankle support features to minimize injury risk and enhance overall stability during skateboarding activities.

5. Stitching seam integrity

Stitching seam integrity, pertaining to footwear, particularly “skate shoes black,” denotes the robustness and durability of the stitched connections that bind different components of the shoe. This attribute is paramount for withstanding the rigorous demands of skateboarding, where shoes endure significant stress and abrasion. Compromised seam integrity leads to premature failure, necessitating frequent replacements and potentially increasing the risk of injury.

- Thread Material and Tensile Strength

The type of thread employed directly influences seam strength. High-tenacity nylon or polyester threads, chosen for their resistance to abrasion and high tensile strength, are preferable. Lower-quality threads are prone to fraying and breakage under stress. For instance, skate shoes black constructed with high-grade nylon thread in critical stress areas like the ollie patch exhibit superior resistance to seam failure compared to those using standard polyester thread. The thread’s color fastness is also relevant for aesthetics, ensuring the black stitching remains consistent over time.

- Stitch Density and Pattern

Stitch density, measured as stitches per inch (SPI), and stitch pattern contribute significantly to seam integrity. Higher SPI values create a more robust and durable seam by distributing stress across a greater number of stitches. Reinforced stitch patterns, such as double or triple stitching, further enhance seam strength in high-stress zones. Examples include skate shoes black featuring triple-stitched ollie patches, which offer enhanced resistance to tearing and abrasion compared to single-stitched designs. Backstitching at seam ends also prevents unraveling.

- Seam Construction Techniques

The method of seam construction plays a vital role in determining overall integrity. Flat-felled seams, where the edges of the fabric are folded over and stitched, provide superior strength and durability compared to serged or overlock seams, which are more prone to unraveling. Examples of black skate shoes incorporating flat-felled seams in high-stress areas, such as the heel and toe, exhibit enhanced resistance to seam failure. Internal taping of seams further reinforces them against stress and moisture.

- Needle Penetration and Material Damage

The needle penetration process itself can affect seam integrity. Improper needle selection or excessive needle speed can damage the material fibers, weakening the seam. Careful calibration of sewing machinery and selection of appropriate needle sizes minimize material damage and ensure seam strength. Black skate shoes crafted with meticulous attention to needle penetration techniques exhibit reduced material damage and enhanced seam longevity.

The interplay of thread material, stitch density, seam construction, and careful needle handling defines the overall seam integrity of skateboarding footwear. These factors are independent of color but directly affect shoe durability and longevity. When selecting “skate shoes black,” scrutiny of stitching details provides valuable insight into the shoe’s ability to withstand the rigors of skateboarding.

6. Thermal management properties

Thermal management properties in skate shoes, particularly those of a black hue, represent a critical, albeit often overlooked, aspect of footwear design. The ability of a skate shoe to regulate temperature and moisture directly impacts comfort, performance, and even hygiene. The following points explore the key facets of thermal management in this context.

- Material Breathability

The breathability of materials used in “skate shoes black” is crucial for dissipating heat and moisture generated during physical activity. Black absorbs more solar radiation than lighter colors, leading to higher internal shoe temperatures. Materials such as perforated suede or strategically placed mesh panels enhance airflow, facilitating evaporative cooling. Skate shoes lacking sufficient breathability can trap heat and moisture, creating an uncomfortable and potentially unhygienic environment, increasing the risk of fungal infections and blisters.

- Moisture-Wicking Linings

Moisture-wicking linings play a vital role in drawing sweat away from the foot. Synthetic fabrics, such as polyester blends, are often employed to wick moisture away from the foots surface. This is particularly important in “skate shoes black” where the darker color can lead to increased perspiration. Efficient moisture-wicking reduces friction, minimizing the likelihood of blisters and improving overall comfort. Examples include linings treated with antimicrobial agents to further inhibit bacterial growth and odor.

- Ventilation Systems

Integrated ventilation systems can significantly enhance thermal management. Strategically placed vents, often located in the sidewalls or toe box, allow for continuous airflow, promoting cooling and reducing moisture build-up. The effectiveness of ventilation systems in “skate shoes black” is particularly important to counteract the heat absorption characteristics of the dark color. Poorly designed ventilation can lead to localized hotspots or allow debris to enter the shoe, negating its benefits.

- Sole Construction and Airflow

The construction of the sole also impacts thermal management. Sole designs incorporating channels or cavities can promote airflow around the foot, aiding in heat dissipation. Materials used in the midsole and outsole should ideally be breathable to allow moisture vapor to escape. Solid, non-breathable soles can trap heat, contributing to discomfort, especially in “skate shoes black” used in warm climates. For example, vulcanized soles, while durable, tend to be less breathable than cupsole constructions with integrated airflow channels.

In conclusion, effective thermal management is paramount for optimizing the comfort and performance of “skate shoes black.” While the color inherently contributes to increased heat absorption, strategic material selection, ventilation design, and moisture-wicking technologies can mitigate these effects. A holistic approach to thermal management ensures that these shoes provide a comfortable and hygienic environment for skateboarding, even under demanding conditions.

Frequently Asked Questions

The following addresses common inquiries regarding skateboarding footwear, specifically models predominantly black in color. These questions explore functional aspects, maintenance considerations, and related misconceptions.

Question 1: Do black skate shoes offer any performance advantage compared to lighter-colored alternatives?

The coloration of skateboarding footwear does not inherently influence performance attributes such as grip, durability, or impact absorption. Performance characteristics are primarily determined by material composition, construction techniques, and design features, irrespective of the shoe’s color.

Question 2: Are black skate shoes more prone to overheating than lighter-colored shoes?

Darker colors absorb more solar radiation than lighter colors, potentially leading to increased internal shoe temperatures. However, the extent of this effect is mitigated by factors such as material breathability, ventilation design, and the skater’s usage environment. Adequate ventilation and moisture-wicking linings can counteract the heat-absorbing properties of black footwear.

Question 3: How should black skate shoes be cleaned to maintain their appearance?

Cleaning protocols depend on the shoe’s primary material. Suede requires specialized suede brushes and cleaning solutions, while canvas can typically be cleaned with mild soap and water. Abrasive cleaners should be avoided to prevent damage to the shoe’s surface. Regular cleaning prevents the buildup of dirt and grime, preserving the shoe’s aesthetic appeal.

Question 4: Do black skate shoes require any special maintenance considerations?

While the color itself does not dictate specific maintenance requirements, regular inspection of stitching, sole adhesion, and material integrity is essential. Prompt repair of minor damage prevents escalation and extends the shoe’s lifespan. Darker materials may show wear and tear more prominently, necessitating more frequent cleaning or touch-up applications.

Question 5: Are black skate shoes suitable for all skateboarding styles and terrain?

The suitability of any skateboarding shoe, regardless of color, depends on its design and construction. Shoes designed for street skateboarding typically feature reinforced stitching and durable materials, while those intended for vert skating may prioritize impact absorption. Selection should be based on the intended use and individual skater preferences, independent of the shoe’s color.

Question 6: Is the price of black skate shoes generally different from that of other colors?

Price variations primarily reflect material costs, construction complexity, and brand reputation rather than color. Black skate shoes are typically priced similarly to other color variations within the same model line, assuming identical materials and construction. Limited edition or collaboration models may command higher prices, irrespective of color.

In conclusion, the selection and maintenance of black skateboarding footwear should prioritize functional attributes and material characteristics over purely aesthetic considerations. Understanding the interplay between design, construction, and intended use is paramount for optimizing performance and longevity.

The subsequent section will delve into the environmental considerations surrounding the production and disposal of skateboarding footwear.

In Conclusion

This exploration of skate shoes black has traversed the critical aspects of design, functionality, and maintenance pertinent to this specific category of skateboarding footwear. The analysis underscored the importance of material selection, construction techniques, and thermal management in optimizing performance and longevity. The analysis also clarified the common misconceptions, focusing on the importance of objective factors, and dismissing superficial attributes. Black color influences heat absorption and aesthetic visibility of wear, reinforcing the need for quality material and meticulous upkeep.

The sustained pursuit of enhanced material durability, improved impact force distribution, and efficient thermal regulation remains essential for the evolution of skateboarding footwear. Future development will inevitably necessitate integrating sustainable materials and ethical manufacturing practices, thereby minimizing the environmental impact associated with their production and disposal. Continued research and innovation in these areas will ensure skate shoes, irrespective of color, meet the evolving demands of skaters while upholding responsible environmental stewardship.