Protective equipment designed for use with wheeled boots offering mobility is essential for participant safety. This encompasses items such as helmets, wrist guards, elbow pads, and knee pads, intended to mitigate potential injuries sustained during falls or collisions. A complete set ensures comprehensive protection of vulnerable joints and the head.

The employment of such safety provisions offers multiple advantages, including reduced risk of fractures, abrasions, and head trauma. Historically, a lack of these precautions led to a higher incidence of severe injuries among users. Modern iterations incorporate advanced materials and ergonomic designs, enhancing both comfort and impact resistance, thereby promoting a safer recreational or competitive experience.

The following sections will delve into the specific types of protective elements available, criteria for selecting appropriate sizes and styles, and maintenance practices to ensure their longevity and effectiveness in safeguarding against potential harm.

Essential Safety Guidelines

The following guidelines address crucial considerations for selecting and utilizing protective components designed for wheeled boot activities. Prioritizing these recommendations will contribute to a safer and more enjoyable experience.

Tip 1: Prioritize Certified Equipment: Verify that all protective items meet recognized safety standards, such as those established by ASTM International or similar organizations. Certification indicates rigorous testing and compliance with minimum safety requirements.

Tip 2: Ensure Proper Fit: A snug and secure fit is paramount for optimal protection. Loose or ill-fitting items may shift during impact, compromising their effectiveness. Carefully consult size charts and try on equipment whenever possible.

Tip 3: Replace Damaged Components: Regularly inspect gear for signs of wear, such as cracks, tears, or weakened straps. Compromised integrity diminishes protective capabilities. Promptly replace any damaged or worn items.

Tip 4: Focus on Head Protection: A helmet specifically designed for skating is non-negotiable. Head injuries are among the most severe and preventable. Replace a helmet after any significant impact, even if damage is not immediately apparent.

Tip 5: Maintain Wrist Stability: Wrist guards are essential for preventing fractures and sprains. Choose guards with rigid splints that extend along the palm and forearm to provide adequate support.

Tip 6: Knee and Elbow Coverage: Knee and elbow pads should offer full coverage of the joint. Select pads with durable shells and ample padding to absorb impact forces.

Tip 7: Consider Environmental Factors: Adjust protective measures according to the environment. For example, skating in low-light conditions may necessitate reflective elements on gear.

Adhering to these guidelines significantly reduces the potential for injury. The consistent application of these practices ensures enhanced safety and promotes responsible participation in activities involving wheeled boots.

The following sections will provide more detail about product maintenance, storage, and additional safety considerations.

1. Protection

The element of “Protection” is fundamentally linked to equipment used with wheeled boots, establishing a direct correlation between safety measures and user well-being. Protective gear is not merely an accessory but an integral component that minimizes the potential for injury during activity. Its significance lies in its capacity to absorb impact, distribute force, and safeguard vulnerable body parts.

- Impact Resistance

Impact resistance refers to the capacity of protective equipment to withstand forces generated during falls or collisions. Helmets, for example, are constructed with impact-absorbing materials designed to dissipate energy and reduce the risk of head trauma. Wrist guards incorporate rigid splints to prevent fractures from sudden impacts on outstretched hands. The effectiveness of these components is directly related to the materials used, the design, and the conformity to recognized safety standards. Failure to adequately resist impact can result in serious injuries.

- Abrasion Resistance

Abrasion resistance relates to the ability of protective gear to prevent skin abrasions and road rash caused by sliding on rough surfaces. Knee and elbow pads typically incorporate durable outer shells constructed from materials like high-density plastic. These shells protect against direct contact with the ground and minimize friction. The effectiveness of abrasion resistance is linked to the quality and thickness of the shell material, as well as the presence of padding to cushion the underlying skin. Insufficient abrasion resistance can lead to painful and potentially infected wounds.

- Joint Stabilization

Joint stabilization involves providing support and limiting the range of motion of joints, such as wrists, elbows, and knees, to prevent sprains and dislocations. Wrist guards and knee pads often incorporate straps and adjustable closures to secure the joint and restrict excessive movement. The effectiveness of joint stabilization is contingent upon the proper fit and secure fastening of the protective gear. Inadequate joint stabilization can increase the risk of ligament damage and joint instability.

- Visibility Enhancement

Visibility enhancement contributes to protection by increasing the user’s conspicuity to other individuals and vehicles, particularly in low-light conditions. Reflective materials and bright colors are commonly incorporated into protective gear to improve visibility. The effectiveness of visibility enhancement is directly related to the amount of reflective material used and the ambient lighting conditions. Low visibility increases the risk of collisions and related injuries.

These facets of protection, when effectively implemented in the design and use of equipment, significantly mitigate the risks associated with wheeled boot activities. The selection of appropriate protective gear, coupled with adherence to safety guidelines, is paramount for minimizing the potential for injury and promoting a safer experience.

2. Comfort

Comfort, when associated with wheeled boot equipment, directly influences the duration and enjoyment of the activity. Ill-fitting or uncomfortable gear can lead to chafing, pressure points, and restricted movement, thus causing discomfort. This discomfort not only detracts from the experience but can also lead to fatigue and a higher risk of accidents. For example, improperly sized helmets may cause headaches or obstruct vision, while poorly designed wrist guards can chafe and limit hand dexterity. Therefore, prioritizing comfort is essential for safety and extended participation.

The selection of comfortable equipment necessitates consideration of materials, design, and adjustability. Breathable fabrics reduce perspiration and heat buildup. Ergonomic designs accommodate natural body contours, minimizing pressure points. Adjustable straps and closures enable a personalized fit, ensuring that gear remains secure without constricting movement. For instance, knee pads with articulated hinges allow for a greater range of motion, enhancing both comfort and performance. The integration of these features contributes to a more positive and secure experience.

Ultimately, comfort is a key element in ensuring regular and safe participation in activities involving wheeled boots. While protection remains the primary function of the equipment, comfort determines whether users will consistently wear the gear. Therefore, manufacturers must prioritize both safety and comfort to maximize user adherence and reduce the risk of injury. A balance between these aspects contributes to a safer and more enjoyable wheeled boot experience.

3. Durability

Durability, a critical attribute of equipment for wheeled boots, directly influences longevity, safety, and cost-effectiveness. The rigors of skating subject protective gear to significant stress, including impacts, abrasions, and exposure to environmental elements. Inadequate durability necessitates frequent replacements, increasing expenses and potentially compromising safety. Conversely, gear constructed from high-quality materials and engineered for resilience provides sustained protection and represents a sound long-term investment. For example, a helmet with a weak outer shell may crack upon impact, failing to provide adequate protection, while a more robust helmet absorbs the force, safeguarding the head.

The link between durability and safety extends beyond impact resistance. Straps, buckles, and fastening systems must withstand repeated use and stress to maintain a secure fit. Seams and stitching on pads should resist tearing or unraveling, preventing the pads from shifting during falls. Materials should resist degradation from sunlight, moisture, and chemicals, which can weaken their structural integrity over time. The incorporation of features such as reinforced stitching, corrosion-resistant hardware, and UV-resistant fabrics contributes significantly to the overall durability and reliability of protective equipment.

In summary, durability is not merely a desirable feature but a fundamental requirement for effective and reliable equipment for wheeled boots. Selecting gear constructed with durable materials and engineered for longevity ensures sustained protection, reduces replacement costs, and enhances the overall skating experience. Prioritizing durability is essential for both safety and economic considerations.

4. Fit

The concept of “fit” is inextricably linked to the effectiveness of equipment used with wheeled boots, impacting both safety and performance. An improper fit compromises the protective capabilities of the gear. For example, a helmet that is too large will not provide adequate impact protection, potentially shifting during a fall and exposing the head to injury. Similarly, wrist guards that are too loose may fail to provide sufficient support to the wrist joint, increasing the risk of sprains or fractures. A properly fitted piece of gear acts as a safeguard and enhances the overall experience. The appropriate dimensions ensure that the protective elements are positioned correctly to absorb impact and prevent injury.

Selecting correctly sized gear requires careful consideration of individual measurements and adherence to manufacturer sizing charts. Variations in body size and shape necessitate a personalized approach. Adjustable straps and closures are crucial for fine-tuning the fit and ensuring a secure and comfortable interface between the gear and the body. Furthermore, the type of activity also influences the ideal fit. For recreational skating, a slightly looser fit may be acceptable, prioritizing comfort. However, for more aggressive skating styles or competitive environments, a snugger, more secure fit is essential to maximize protection and minimize the risk of gear shifting during high-impact maneuvers.

In conclusion, the significance of fit cannot be overstated when selecting equipment for wheeled boot activities. Proper fit is not merely a matter of comfort; it is a fundamental aspect of safety and performance. By prioritizing accurate measurements, utilizing adjustable features, and considering the intended activity, users can ensure that their gear provides optimal protection and enhances their overall experience, with practical implications for injury prevention and performance enhancement.

5. Maintenance

Maintenance constitutes a crucial element in prolonging the lifespan and optimizing the performance of equipment designed for wheeled boot activities. Neglecting routine upkeep leads to accelerated wear and tear, potentially compromising the structural integrity and protective capabilities of the gear. For instance, moisture accumulation can corrode metal components, while accumulated dirt and debris can degrade the performance of bearings and wheels. Scheduled maintenance serves to mitigate these detrimental effects, ensuring that the equipment functions as intended and continues to provide adequate protection.

Specific maintenance procedures vary depending on the type of equipment. Helmets require regular inspection for cracks or dents, coupled with cleaning to remove sweat and dirt. Padding should be washed periodically to maintain hygiene and prevent the buildup of bacteria. Wheel bearings demand lubrication to reduce friction and ensure smooth rotation. Wheels themselves should be rotated to promote even wear and prevent premature degradation. Straps and closures should be inspected for fraying or damage and replaced as needed. Failing to address these maintenance requirements can lead to decreased performance, increased risk of component failure, and potential safety hazards.

In summary, consistent and thorough maintenance is paramount for ensuring the longevity, reliability, and safety of equipment used in wheeled boot activities. Adhering to recommended maintenance schedules and performing routine inspections can significantly extend the lifespan of the gear, optimize its performance, and minimize the risk of accidents. This proactive approach represents a responsible investment in both the equipment and the user’s well-being.

6. Certification

Certification, in the context of equipment for wheeled boots, serves as a critical validation of safety standards and performance criteria. It provides assurance that the gear meets established benchmarks for impact resistance, durability, and overall reliability. This external verification process is crucial in distinguishing between substandard products and those offering verifiable protection, especially as it pertains to mitigating the risk of injuries associated with wheeled boot activities.

- Standard Compliance

Standard compliance refers to adherence to specific testing protocols and performance requirements established by recognized organizations such as ASTM International (ASTM), the Consumer Product Safety Commission (CPSC), or the European Committee for Standardization (CEN). Certification marks, such as ASTM F1447 for helmets, indicate that the gear has undergone rigorous testing to verify its ability to withstand specified impact forces. Non-compliance with these standards can result in serious injury or death, underscoring the importance of selecting certified products.

- Material Validation

Material validation involves verifying the composition and properties of materials used in the construction of equipment. Certified gear utilizes materials that meet minimum strength and durability requirements, ensuring that the equipment can withstand the stresses of regular use. For example, helmet shells are often made from polycarbonate or ABS plastic, materials known for their impact resistance. The certification process confirms that these materials meet specified standards, mitigating the risk of premature failure or degradation, thus providing a robust safety measure.

- Performance Verification

Performance verification involves evaluating the gear’s ability to perform its intended function under simulated real-world conditions. This may include impact testing, abrasion resistance testing, and stability testing. For example, knee and elbow pads are subjected to impact tests to assess their ability to absorb energy and protect the joints. Certification ensures that the equipment meets minimum performance standards, reducing the risk of injury in the event of a fall or collision. Performance metrics must meet or exceed accepted guidelines to meet qualification requirements.

- Traceability and Accountability

Traceability and accountability are essential aspects of the certification process. Certified gear is typically marked with unique identifiers that allow for tracking the product back to its manufacturer and production batch. This enables consumers and regulatory agencies to verify the authenticity of the certification and trace any defects or safety concerns back to their source. This accountability mechanism promotes product safety and provides recourse in the event of product failure, thereby ensuring that manufacturers adhere to established standards.

In conclusion, certification serves as a cornerstone of safety and reliability within the realm of equipment used with wheeled boots. By ensuring compliance with established standards, validating materials, verifying performance, and promoting traceability, certification provides consumers with a means to assess the quality and safety of equipment. Prioritizing certified gear is essential for mitigating the risks associated with wheeled boot activities and promoting a safer recreational or competitive experience. Non-certified equipment may not meet minimum safety standards, and may have structural failures.

7. Performance

Performance, in the context of wheeled boot activities, is significantly influenced by the quality and design of the related equipment. Equipment characteristics, such as wheel composition, bearing precision, boot construction, and protective gear fit, directly impact the user’s speed, agility, comfort, and safety.

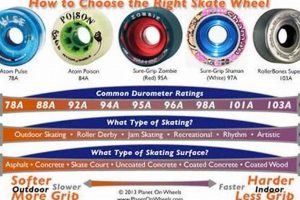

- Wheel Composition and Hardness

The material and durometer (hardness) of the wheels affect grip, roll speed, and durability. Softer wheels offer greater grip and are better suited for indoor surfaces or rough terrain, while harder wheels provide faster roll speeds on smooth surfaces. Wheel composition impacts energy transfer, vibration absorption, and overall efficiency. A wheel that is too soft may cause drag, reducing speed, while one too hard might lack sufficient grip, resulting in loss of control. Optimal wheel selection depends on the specific skating style and environment.

- Bearing Precision and Lubrication

Bearings facilitate wheel rotation and determine the smoothness and efficiency of the roll. ABEC (Annular Bearing Engineering Committee) ratings indicate the precision of the bearing components, with higher ratings generally signifying greater precision and lower friction. Proper lubrication is crucial for maintaining bearing performance and preventing wear. Clean, well-lubricated bearings enhance speed, reduce energy expenditure, and contribute to a smoother and more enjoyable skating experience. Neglecting bearing maintenance leads to increased friction, reduced speed, and premature bearing failure.

- Boot Construction and Support

The boot provides support, stability, and control. Boot construction materials, such as leather, synthetic fabrics, and composite materials, influence weight, breathability, and responsiveness. Proper ankle support is essential for preventing injuries and maintaining balance. A well-fitting boot transfers energy efficiently from the skater’s foot to the wheels, enabling precise movements and maximizing power output. Poorly constructed or ill-fitting boots compromise stability, reduce control, and increase the risk of discomfort and injury.

- Aerodynamics and Fit of Protective Gear

While primarily designed for safety, protective gear can also impact performance. Bulky or poorly fitted pads can restrict movement and increase drag, reducing speed and agility. Streamlined, aerodynamic designs and properly fitted gear minimize resistance and allow for a greater range of motion. A helmet that fits securely and does not obstruct vision is essential for maintaining awareness and control. The selection of protective gear that balances safety and performance considerations is critical for optimizing the skating experience.

In conclusion, the interplay between equipment and performance is undeniable in wheeled boot activities. Wheel properties, bearing precision, boot construction, and protective gear design collectively determine the user’s speed, agility, comfort, and safety. Selecting equipment tailored to the specific skating style and environment, coupled with diligent maintenance, is essential for maximizing performance and minimizing the risk of injury. The synergy between well-chosen equipment and skilled technique enables a safer and more rewarding skating experience.

Frequently Asked Questions

The following section addresses common inquiries regarding protective equipment for roller skating, providing essential information for safe participation in the activity.

Question 1: What constitutes essential protective equipment for roller skating?

A comprehensive set typically includes a certified helmet, wrist guards, elbow pads, and knee pads. These items mitigate the risk of head injuries, fractures, and abrasions.

Question 2: How does one determine the correct size for roller skating protective gear?

Manufacturers provide sizing charts based on body measurements. A snug but comfortable fit is crucial, allowing for freedom of movement while ensuring adequate protection upon impact.

Question 3: What safety standards should one look for when purchasing a roller skating helmet?

Ensure the helmet meets standards set by organizations such as ASTM International (ASTM) or the Consumer Product Safety Commission (CPSC). These certifications indicate the helmet has undergone rigorous testing.

Question 4: How frequently should roller skating protective gear be replaced?

Replace any item that sustains damage, such as cracks or tears. Helmets should be replaced after any significant impact, even if no visible damage is apparent. Otherwise, consider replacing every five years due to material degradation.

Question 5: What maintenance procedures are recommended for roller skating protective gear?

Regularly inspect gear for damage and clean with mild soap and water. Avoid harsh chemicals that can degrade materials. Allow gear to air dry completely before storing.

Question 6: Is it necessary to wear protective gear even when skating in controlled environments?

While the risk may be lower in controlled environments, falls can still occur. Wearing protective gear is always advisable to minimize the potential for injury, regardless of the skating location.

The information presented aims to clarify key considerations regarding roller skating protective equipment, contributing to safer participation.

The next section will explore advanced equipment options and specific recommendations for various skating styles.

Skate Gear Roller Skates

This exploration has emphasized the vital role of equipment in mitigating risks and optimizing performance in activities involving wheeled boots. Key aspects include impact protection, abrasion resistance, joint stabilization, comfort, fit, durability, maintenance, and certification. The confluence of these factors directly affects user safety and the longevity of the equipment itself.

The responsible selection and consistent utilization of appropriate safety measures constitute a fundamental responsibility. Prioritizing certified, well-maintained equipment not only minimizes the potential for injury but also fosters a safer and more sustainable environment for all participants, with real-world implications for emergency services workload and healthcare cost reduction.