Equipment specifically designed for the sport of roller derby, procured within the United Kingdom, forms a critical element for participants. These specialized boots, mounted on a plate with four wheels, enable the agility, speed, and stability required for gameplay on a flat, indoor track. Examples include models prioritizing ankle support, durable wheel compounds optimized for various floor surfaces, and adjustable plates to customize handling.

The availability of quality equipment within the UK significantly impacts accessibility and the development of roller derby leagues. Locally sourced or easily obtainable skates reduce import costs and delivery times, fostering greater participation. Furthermore, access to a variety of models allows skaters to select equipment tailored to their specific skill level, playing style, and physical needs, potentially improving performance and reducing the risk of injury. Historically, the sport’s growth in the UK has been linked to the increasing availability of suitable, affordable gear.

The subsequent sections will delve into the specific features to consider when selecting appropriate equipment, the range of suppliers operating within the UK market, and maintenance strategies to prolong the lifespan of specialized roller derby skates.

Selection and Maintenance Guidance

Considerations for acquiring and preserving specialized equipment are outlined below. Proper attention to these details can enhance performance and extend the lifespan of the investment.

Tip 1: Assess Skill Level. Beginners should prioritize stability and comfort, opting for models with enhanced ankle support and forgiving wheel compounds. Advanced skaters might seek more responsive plates and specialized wheel durometers for optimal speed and maneuverability.

Tip 2: Evaluate Playing Style. Jammers may require equipment that facilitates rapid acceleration and agility, whereas blockers might benefit from skates providing enhanced stability and power transfer.

Tip 3: Determine Track Surface. Different surfaces require different wheel durometers. Harder wheels perform better on smooth surfaces, while softer wheels provide more grip on rougher tracks.

Tip 4: Ensure Proper Fit. Ill-fitting boots can lead to discomfort and injury. Consult sizing charts and, if possible, try on skates before purchase. Consider heat molding for a customized fit.

Tip 5: Inspect Equipment Regularly. Check wheels, bearings, and plates for wear and tear. Replace worn components promptly to maintain optimal performance and safety.

Tip 6: Clean and Lubricate Bearings. Proper bearing maintenance is crucial for smooth rolling. Clean bearings regularly and apply appropriate lubricant to minimize friction and extend their lifespan.

Tip 7: Tighten Hardware Periodically. Loose hardware can compromise stability and performance. Regularly check and tighten all nuts and bolts on the plates, wheels, and toe stops.

Adhering to these guidelines will promote a safer and more effective roller derby experience. Proper equipment selection and diligent maintenance are essential components of responsible participation.

The following section will provide an overview of prevalent issues encountered with specialized equipment and recommend troubleshooting strategies.

1. Equipment Regulations

The regulatory environment governing sports equipment impacts the availability and characteristics of roller derby skates within the United Kingdom. These regulations aim to ensure participant safety and establish minimum performance standards for equipment used in competitive contexts.

- Safety Standards Compliance

British Standards Institution (BSI) standards, and potentially European Norms (EN), may apply to certain components of the skates, such as the helmet, padding, or even the boot construction. Retailers importing or manufacturing equipment for sale within the UK must demonstrate compliance with these standards, often through certification and labeling. Failure to comply can result in fines and product recalls.

- Material Restrictions

Regulations may restrict the use of specific materials deemed hazardous to health or the environment in the manufacturing of equipment. For example, restrictions on certain phthalates in plastics could impact the types of wheel compounds or boot materials available. Manufacturers must adhere to these restrictions and provide documentation verifying compliance.

- Liability and Insurance

Equipment regulations can influence liability considerations for manufacturers and retailers. Compliance with safety standards can serve as a defense against liability claims in the event of injury. Furthermore, insurance providers may require adherence to specific equipment standards as a condition of coverage for roller derby leagues and events.

- League-Specific Rules

While not strictly “equipment regulations” in the legal sense, individual roller derby leagues within the UK often establish their own rules regarding permissible equipment modifications or restrictions. These rules are designed to ensure fair play and maintain a consistent level of safety across all participants. Examples include restrictions on certain types of toe stops or plate configurations.

In summary, equipment regulations, encompassing safety standards, material restrictions, liability considerations, and league-specific rules, directly shape the landscape of roller derby skates accessible within the UK. Adherence to these regulations contributes to participant safety, promotes fair play, and influences the types of equipment available to skaters.

2. UK Retailers

The availability, quality, and diversity of roller derby equipment within the United Kingdom are fundamentally determined by the retailers operating in this market. These entities serve as the primary conduit through which skaters access specialized boots, plates, wheels, and protective gear, directly impacting participation levels and the overall development of the sport. Their sourcing strategies, product offerings, and customer service capabilities represent integral components of the UK roller derby ecosystem. For example, a retailer specializing in high-performance skates might stock models from Riedell, Sure-Grip, or Antik, catering to experienced skaters, while another might focus on more affordable options for beginners.

The presence of knowledgeable retailers provides skaters with the opportunity to receive expert advice on equipment selection, fitting, and maintenance. This guidance is particularly crucial for novice skaters who may lack the technical expertise to make informed decisions. Furthermore, retailers often facilitate access to repair services and replacement parts, extending the lifespan of equipment and reducing the overall cost of participation. Real-world instances include retailers hosting skate maintenance workshops or offering custom skate building services, empowering skaters to personalize their equipment and optimize performance.

Ultimately, UK retailers constitute a vital link in the chain connecting manufacturers with skaters. Their role extends beyond mere product distribution to encompass education, support, and community building. The challenges they face, such as navigating import regulations or maintaining sufficient inventory levels, directly influence the accessibility and affordability of roller derby equipment. Recognizing the significance of these retailers is essential for fostering a thriving and sustainable roller derby community within the United Kingdom.

3. Boot Construction

Boot construction represents a critical determinant of performance, comfort, and safety in roller derby skates used within the UK. The materials, design, and manufacturing processes employed in boot construction directly influence a skater’s ability to maneuver, accelerate, and withstand the physical demands of the sport. The selection of an appropriate boot construction is therefore a crucial consideration for all participants.

- Material Composition

The materials used in boot construction, such as leather, synthetic fabrics, or composites, significantly impact weight, durability, and support. Leather boots, while offering a traditional feel and potentially greater longevity, may require a longer break-in period and demand more intensive maintenance. Synthetic boots often offer lighter weight and improved breathability, but may not provide the same level of support or durability. Composites can offer a balance of these characteristics, providing lightweight support and resilience. UK skaters’ choices often reflect the availability and price points of these different material types.

- Ankle Support and Padding

The level of ankle support and padding integrated into the boot construction directly affects stability and impact absorption. Insufficient ankle support can increase the risk of injury, particularly during lateral movements and collisions. Adequate padding can mitigate the impact of falls and collisions, reducing the risk of bruising and other injuries. UK skaters’ preferences often align with boot designs that prioritize protection without sacrificing maneuverability, given the physical nature of the sport.

- Closure Systems

The closure system employed, encompassing laces, straps, or buckles, plays a vital role in securing the boot to the foot and ensuring a snug, responsive fit. Laces offer a high degree of adjustability, allowing skaters to customize the fit to their individual foot shape. Straps and buckles can provide additional security and support, particularly around the ankle. The choice of closure system often depends on individual preference and the specific demands of the skater’s role within the team. UK retailers often stock a range of skates with differing closure systems to cater to these varying preferences.

- Boot Height and Cut

Boot height and cut influence the range of motion and overall support provided. Lower-cut boots allow for greater ankle flexibility, which may be preferred by jammers or skaters prioritizing agility. Higher-cut boots offer increased ankle support, which may be advantageous for blockers or skaters requiring greater stability. The optimal boot height and cut are highly dependent on individual skating style and physical characteristics. Within the UK market, a range of boot heights are typically available to accommodate different player positions and skating styles, which are closely tied to skate handling and performance.

In conclusion, boot construction is a multifaceted aspect of roller derby skates in the UK, influencing performance, comfort, and safety. Material composition, ankle support, closure systems, and boot height all contribute to the overall effectiveness of the skate. A careful consideration of these factors is essential for selecting equipment that meets the specific needs and preferences of individual skaters, considering their specific playing style and physical position and comfort.

4. Plate Materials

The plate, the component connecting the boot to the wheels, significantly affects the performance and handling characteristics of roller derby skates available in the UK. Its material composition dictates weight, strength, and responsiveness, all crucial for the demanding maneuvers of the sport. The selection of plate material is therefore a key decision for skaters.

- Aluminum Alloys

Aluminum alloy plates are common due to their strength-to-weight ratio. Different alloys offer varying levels of stiffness and durability. For example, 7075 aluminum provides higher strength than 6061, but may be more expensive. In the UK market, aluminum plates are popular among intermediate and advanced skaters seeking precise control and efficient power transfer. The higher cost can be a barrier for beginners.

- Nylon or Composite Polymers

Nylon or composite polymer plates offer a lighter and often more affordable alternative to aluminum. These materials provide good impact resistance and vibration dampening, which can enhance comfort. However, they generally lack the stiffness and responsiveness of aluminum. Within the UK, these plates are frequently found on entry-level skates targeted towards beginners or recreational skaters. The reduced cost makes them accessible, but the performance limitations may be a factor as skaters progress.

- Titanium

Titanium plates represent a high-end option, offering exceptional strength and lightness. This material provides superior responsiveness and durability compared to aluminum, but comes at a significant cost premium. While available in the UK through specialized retailers, titanium plates are relatively rare due to their expense, typically chosen by competitive skaters seeking a performance advantage. Examples of UK skaters using titanium would be rare to find, as cost is a factor.

- Forged vs. Cast Aluminum

Regardless of the aluminum alloy used, the manufacturing process also impacts plate characteristics. Forged aluminum plates are typically stronger and more durable than cast aluminum plates, due to the denser material structure achieved through forging. Forged plates are often preferred by skaters who engage in aggressive skating styles or require maximum durability. Although they generally cost more, these components have longer-lasting lifespans.

The choice of plate material for roller derby skates in the UK involves a trade-off between cost, weight, strength, and responsiveness. Aluminum alloys dominate the market due to their balance of properties, while nylon plates cater to entry-level skaters. Titanium represents a niche option for high-performance skaters willing to invest in top-tier equipment. The sourcing and manufacturing process is a significant factor when the final product is for sale.

5. Wheel Durometer

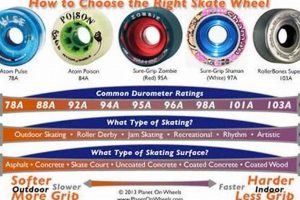

Wheel durometer, a measure of a wheel’s hardness, significantly affects performance and handling characteristics for roller derby skates used within the United Kingdom. The choice of durometer is a critical factor in optimizing grip, speed, and overall control on various skating surfaces. Understanding this measurement is essential for UK skaters to select appropriate equipment.

- Durometer Scale

Durometer is measured on the Shore A scale, ranging from softer (lower numbers) to harder (higher numbers). Softer wheels provide more grip but may roll slower and wear down faster. Harder wheels offer higher speeds but reduced grip, potentially leading to slippage. The UK skater must understand the scale to optimize for rink conditions.

- Surface Conditions

The ideal wheel durometer depends heavily on the skating surface. Smoother surfaces generally benefit from harder wheels (95A and above) for maximum speed. Rougher surfaces require softer wheels (88A-92A) to provide adequate grip. UK skaters must consider the specific surface characteristics of their local rinks when choosing wheels.

- Skater Style and Position

Skater style and position also influence optimal wheel durometer. Jammers often prefer harder wheels for maximizing speed and acceleration, while blockers may favor softer wheels for enhanced grip and stability during blocking maneuvers. UK leagues often have a mix of surfaces and skater styles requiring a diversified range of durometers.

- Wheel Wear and Replacement

Wheel durometer impacts wear rate. Softer wheels wear down more quickly, particularly on abrasive surfaces. Harder wheels offer greater durability but may still require replacement due to wear or damage. UK skaters should regularly inspect their wheels and replace them as needed to maintain optimal performance and safety.

In summary, wheel durometer is a crucial consideration for roller derby skaters in the UK. The optimal choice depends on surface conditions, skater style, and position, and also impacts wheel wear and replacement frequency. Selection involves a tradeoff between grip and speed. Regular inspection is vital for safety.

6. Bearing Precision

Bearing precision directly impacts the performance of roller derby skates within the United Kingdom. Bearings, small components housed within the wheels, facilitate smooth rotation and contribute significantly to speed and glide. Higher precision bearings minimize friction, allowing for faster speeds and more efficient energy transfer. Conversely, lower precision bearings introduce more friction, hindering performance and requiring greater exertion from the skater. UK skaters seeking competitive advantage often invest in higher precision bearings. The choice reflects the cause-and-effect relationship between bearing quality and skating performance.

The ABEC (Annular Bearing Engineers’ Committee) rating system, though not the sole determinant of quality, is commonly used to classify bearing precision. Higher ABEC ratings (e.g., ABEC 7, ABEC 9) indicate tighter tolerances and smoother operation. However, other factors, such as material quality and lubrication, also influence bearing performance. Some UK retailers stock bearings from Bones Bearings, known for their Skate Rated system instead of ABEC. The practical significance of understanding bearing precision lies in the ability to optimize skate performance for specific needs and budgets. A beginner may find ABEC 3 bearings sufficient, while a competitive skater may prefer higher-rated options.

Bearing maintenance, including cleaning and lubrication, is crucial for preserving precision and extending lifespan. Dirt and debris can degrade bearing performance, regardless of the initial precision rating. Regular maintenance minimizes friction and ensures smooth rolling. Challenges include the subjective nature of performance evaluation and the initial cost of higher precision bearings. However, the benefits of improved speed and glide, coupled with proper maintenance, contribute to a more enjoyable and efficient roller derby experience. The key insight remains: bearing precision is a critical component affecting performance within the context of roller derby skates used in the UK.

7. Maintenance Protocols

Maintenance protocols are integral to ensuring the longevity, safety, and optimal performance of roller derby skates utilized within the UK. Consistent adherence to established maintenance procedures prolongs the lifespan of equipment, minimizes the risk of injury, and maximizes the skater’s performance capabilities.

- Bearing Cleaning and Lubrication

Bearings, critical components within the wheels, require regular cleaning to remove accumulated dirt and debris that impede smooth rotation. Subsequently, lubrication with appropriate bearing oil or grease minimizes friction and protects against corrosion. Neglecting this protocol results in reduced speed and increased exertion for the skater. UK skaters should adhere to schedules that account for practice frequency and rink conditions.

- Wheel Inspection and Rotation

Wheels should undergo routine inspection for signs of wear, such as flat spots or chipping. Uneven wear patterns indicate the need for wheel rotation, which involves repositioning the wheels on the skate to distribute wear evenly. Failure to address wheel wear compromises grip and stability, potentially leading to falls. UK skaters should also verify the integrity of the wheel’s core and urethane bond to detect any signs of separation.

- Plate and Truck Maintenance

The plate and trucks, the structural components connecting the boot to the wheels, require periodic inspection for loose hardware or signs of damage. Nuts and bolts should be tightened to specified torque levels to ensure stability and responsiveness. Damaged or cracked plates or trucks must be replaced immediately to prevent catastrophic failure and potential injury. Furthermore, cushions and pivot cups, which influence the skate’s turning response, should be inspected and replaced as needed to maintain desired handling characteristics.

- Boot Care and Protection

The skate boot requires proper care to maintain its structural integrity and comfort. Leather boots should be cleaned and conditioned regularly to prevent cracking and drying. Synthetic boots can be cleaned with mild soap and water. In either case, allowing the boot to dry completely after use prevents the growth of mold and bacteria. Proper storage, away from direct sunlight and extreme temperatures, extends the boot’s lifespan. UK skaters should also consider using toe guards or other protective measures to minimize scuffing and wear on the boot’s exterior.

These maintenance protocols, when diligently implemented, preserve the investment in specialized equipment and contribute to a safer and more effective roller derby experience. Regular maintenance is not merely a matter of prolonging equipment lifespan; it is an integral aspect of responsible participation and risk mitigation within the context of roller derby skates in the UK.

Frequently Asked Questions

The following section addresses common inquiries concerning specialized equipment used for roller derby within the United Kingdom. These questions are intended to provide clarity and informed guidance to skaters and prospective participants.

Question 1: Are specific safety standards mandated for roller derby skates sold in the UK?

Yes, skates sold in the UK should adhere to relevant British Standards (BS) or European Norms (EN) pertaining to sports equipment. Compliance with these standards ensures minimum safety and performance criteria are met. Retailers are responsible for verifying and demonstrating adherence.

Question 2: Where can individuals purchase roller derby skates within the United Kingdom?

Specialized skates can be acquired through dedicated online retailers, brick-and-mortar skate shops, and sporting goods stores. The availability of specific brands and models varies across retailers. Assessing product offerings and customer service policies before purchase is advisable.

Question 3: How does wheel durometer affect performance on UK rinks?

Wheel durometer, a measure of hardness, significantly influences grip and speed. Softer wheels (lower durometer values) provide greater grip on rougher surfaces, while harder wheels (higher durometer values) offer increased speed on smoother surfaces. Skaters should select durometers appropriate for the specific rink conditions encountered.

Question 4: What are the key considerations when selecting a skate plate material?

Plate material influences weight, strength, and responsiveness. Aluminum plates offer a balance of these characteristics, while nylon plates are lighter and more affordable, albeit less responsive. Titanium plates provide maximum performance but at a higher cost. The skater must assess the appropriate plate for the intended skill level and budget.

Question 5: How frequently should bearings be cleaned and lubricated?

Bearing maintenance frequency depends on usage intensity and rink conditions. Regular cleaning and lubrication are essential for preserving bearing precision and lifespan. Inspection for debris and subsequent cleaning should occur after every few uses. Lubrication should follow cleaning procedures.

Question 6: What steps should be taken to maintain the boot’s integrity?

Boot maintenance varies depending on the material composition. Leather boots require regular cleaning and conditioning, while synthetic boots can be cleaned with mild soap and water. Allowing the boot to dry completely after each use is crucial. Additionally, protective measures such as toe guards can minimize wear and tear.

This FAQ section has provided insights into common queries regarding roller derby equipment in the UK. A thorough understanding of these factors promotes informed decision-making and contributes to a safer and more enjoyable experience.

The succeeding section will present information related to advanced topics or specialized equipment modifications for discerning skaters.

Conclusion

This exposition has thoroughly examined specialized equipment within the United Kingdom. From regulatory compliance and retail availability to the nuanced selection of components such as boot materials, plate composition, wheel durometer, and bearing precision, the analysis has underscored the multifaceted nature of selecting and maintaining appropriate gear. The effectiveness of these skates is fundamentally tied to understanding these variables.

Therefore, continued vigilance regarding equipment standards and ongoing engagement with reputable suppliers remain paramount for the safety and progression of roller derby within the UK. Skaters are encouraged to prioritize informed decision-making to ensure optimal performance and minimize the risk of injury. Further research and collaborative efforts within the community will undoubtedly contribute to the continued refinement and accessibility of roller derby skates within the UK.