Specialized footwear constitutes an essential component of the sport of roller derby. This equipment facilitates the rapid acceleration, precise maneuvering, and physical demands inherent in the game. Constructed for durability and performance, these items often incorporate features such as low-cut boots for enhanced agility and specialized wheels optimized for various track surfaces.

The specific design of this gear is pivotal for player safety and efficacy. The equipment’s robust structure withstands the high-impact collisions common in the sport. Historically, modifications and advancements in design have significantly contributed to the evolution of roller derby, allowing for greater speed, control, and ultimately, a more dynamic and competitive environment.

The subsequent discussion will delve into the specific components and considerations involved in selecting suitable equipment, including boot types, wheel durometer, and bearing quality, all of which significantly impact a player’s performance and safety on the track.

Equipment Selection and Maintenance Tips

Proper selection and consistent maintenance of specialized footwear are critical for optimal performance and safety in roller derby. Adherence to these guidelines will maximize equipment lifespan and enhance on-track capabilities.

Tip 1: Boot Selection. Choose boots that provide a snug, secure fit, offering adequate ankle support without restricting movement. Leather or synthetic materials with reinforced stitching are recommended for durability.

Tip 2: Plate Material. Aluminum plates offer a balance of strength and weight, contributing to responsiveness. Nylon plates are lighter but may lack the rigidity required for advanced maneuvers.

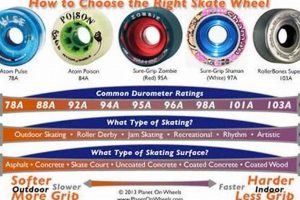

Tip 3: Wheel Durometer. Select wheels with a durometer rating appropriate for the skating surface. Harder wheels (higher durometer) are suitable for smooth surfaces, while softer wheels (lower durometer) provide better grip on slick or uneven tracks.

Tip 4: Bearing Maintenance. Regularly clean and lubricate bearings to ensure smooth wheel rotation. Contaminants can significantly reduce bearing efficiency and increase friction.

Tip 5: Toe Stop Adjustment. Properly adjust toe stops for stability and controlled stops. Worn toe stops should be replaced promptly to prevent accidents.

Tip 6: Hardware Inspection. Routinely inspect all mounting hardware (nuts, bolts, and screws) for looseness. Tighten components as needed to maintain structural integrity.

Tip 7: Professional Fitting. Consider a professional fitting at a reputable roller derby shop. Experts can provide personalized recommendations based on skating style and experience level.

By implementing these recommendations, skaters can optimize their gear’s performance and longevity, ultimately contributing to a safer and more effective skating experience.

The following sections will explore the advanced techniques and strategic considerations necessary to further enhance performance in the competitive arena.

1. Boot Construction

Boot construction is a critical element in the functionality and performance of roller derby equipment. The design and materials directly impact a skater’s agility, stability, and overall comfort, ultimately affecting their ability to effectively participate in the sport.

- Material Composition

The materials used in boot construction significantly influence durability, weight, and flexibility. Leather provides a traditional option, offering a balance of support and moldability. Synthetic materials, often lighter and more resistant to wear, are increasingly common. The choice depends on individual preferences and playing style.

- Ankle Support Design

Ankle support is paramount for preventing injuries and facilitating quick maneuvers. High-cut boots offer maximum support, limiting ankle movement. Conversely, low-cut boots provide greater flexibility, enabling sharper turns and quicker transitions. The appropriate level of support depends on skater experience and position played.

- Closure Systems

Closure systems, such as laces, straps, or a combination thereof, secure the boot to the foot. Laces allow for precise adjustments, ensuring a snug and customizable fit. Straps provide additional security and support, particularly around the ankle. The effectiveness of the closure system is crucial for transmitting power from the skater to the equipment.

- Internal Padding and Lining

Internal padding and lining contribute to comfort and shock absorption. Adequate padding reduces pressure points and minimizes the risk of blisters. Moisture-wicking lining materials help keep feet dry and comfortable during intense periods of skating. The quality of the internal components directly impacts the skater’s ability to maintain focus and performance.

These facets of boot construction demonstrate the intricate relationship between design and functionality in roller derby equipment. By carefully considering these elements, skaters can optimize their gear for enhanced performance and reduced risk of injury, illustrating the importance of boot selection in this demanding sport.

2. Plate Material

The plate, a fundamental component of specialized footwear, connects the boot to the wheels and axles, profoundly impacting the equipment’s responsiveness and handling characteristics. The selection of plate material is therefore critical to achieving optimal performance in the demanding environment of roller derby.

- Aluminum Alloys

Aluminum alloys offer a high strength-to-weight ratio, providing durability without excessive bulk. These plates are typically CNC-machined for precision and often feature adjustable pivot arms and kingpin angles, enabling skaters to fine-tune their equipment for specific skating styles and track conditions. Examples include 7075 aluminum, known for its exceptional strength, and 6061 aluminum, prized for its weldability and corrosion resistance. These alloys deliver responsiveness favored by advanced skaters.

- Nylon and Composite Polymers

Nylon or composite polymer plates are lighter and more cost-effective than aluminum. These materials absorb vibrations effectively, providing a more comfortable ride, particularly on rougher surfaces. While less rigid than aluminum, these plates are suitable for beginner skaters and recreational use where immediate responsiveness is less critical. An example is glass-reinforced nylon, which offers enhanced stiffness compared to standard nylon.

- Titanium

Titanium plates represent a premium option, combining exceptional strength with minimal weight. Titanium exhibits superior fatigue resistance and vibration damping properties, making it a favored choice for elite-level skaters seeking a competitive edge. The high cost of titanium, however, limits its widespread adoption.

- Plate Length and Mounting

Plate length influences the skater’s turning radius and stability. Shorter plates enhance maneuverability, while longer plates provide increased stability at higher speeds. Proper mounting is crucial for ensuring balance and preventing stress fractures in the boot or plate. Incorrectly mounted plates can lead to uneven weight distribution and increased risk of injury.

The interplay between plate material, length, and mounting configuration underscores the intricate engineering considerations involved in roller derby equipment. The optimal choice depends on a skater’s skill level, skating style, and the specific demands of the track surface, necessitating careful evaluation to maximize performance and minimize the risk of equipment-related issues.

3. Wheel Durometer

Wheel durometer is a critical specification that dictates the hardness of the wheels utilized in roller derby equipment. This measurement, quantified using the Shore A scale, directly influences grip, roll speed, and overall performance on the track.

- Grip and Surface Interaction

Lower durometer wheels (e.g., 88A-92A) provide increased grip on smooth, polished surfaces. The softer compound conforms to minor imperfections, maximizing contact area and enhancing traction. This is particularly advantageous in environments where sudden stops and rapid directional changes are frequent, providing skaters with greater control. However, increased grip translates to reduced roll speed.

- Roll Speed and Efficiency

Higher durometer wheels (e.g., 97A-101A) prioritize roll speed over grip. The harder compound minimizes deformation under load, reducing rolling resistance and allowing for faster acceleration and sustained speed. These wheels are often favored on tracks with consistent, smooth surfaces where maintaining momentum is paramount. The trade-off is a reduction in grip, requiring skaters to execute maneuvers with greater precision.

- Track Surface Variability

The optimal wheel durometer is heavily dependent on the characteristics of the skating surface. Indoor tracks often feature polished concrete or coated surfaces that benefit from softer wheels. Conversely, outdoor tracks or arenas with rougher surfaces may necessitate harder wheels to mitigate excessive wear and maintain roll speed. Skaters must adapt their wheel selection based on the specific venue to optimize performance.

- Skater Weight and Style

Skater weight and skating style also influence durometer selection. Heavier skaters may benefit from harder wheels to prevent excessive compression and maintain roll speed. Skaters who prioritize agility and precise footwork may prefer softer wheels for enhanced grip. The interplay between these factors underscores the need for individual experimentation to determine the most suitable wheel durometer.

The selection of appropriate wheel durometer is a nuanced process that demands careful consideration of track conditions, skater characteristics, and desired performance attributes. Effective wheel selection is a critical determinant of a skater’s success in roller derby, illustrating the importance of understanding the relationship between wheel durometer and performance optimization.

4. Bearing Precision

Bearing precision, measured by the ABEC (Annular Bearing Engineers’ Committee) scale or similar ISO standards, significantly affects the performance of specialized footwear. Higher precision bearings, characterized by tighter tolerances and smoother surfaces, minimize friction, resulting in increased roll speed and efficiency. The implementation of high-precision bearings translates directly to enhanced acceleration and the ability to maintain higher velocities on the track. Conversely, bearings with lower precision exhibit greater friction, hindering performance and requiring increased exertion from the skater to achieve comparable speeds. Consider a skater attempting to maintain position in a pack; high-precision bearings enable them to conserve energy, while lower precision bearings could lead to fatigue and reduced effectiveness.

Furthermore, bearing precision impacts the skater’s ability to execute precise maneuvers. Reduced friction allows for more responsive wheel rotation, facilitating quicker turns and more controlled stops. Skaters employing high-precision bearings often report improved agility and responsiveness, enabling them to navigate the track with greater confidence and precision. This advantage becomes particularly evident during gameplay scenarios involving rapid transitions and intricate blocking strategies. As an example, during a jammer’s attempt to navigate the pack, high-precision bearings can provide the incremental advantage needed to exploit a gap or evade a blocker. The improved responsiveness allows for subtle adjustments and quick reactions.

In summary, bearing precision constitutes a critical factor influencing the performance characteristics of specialized roller derby equipment. The selection of high-precision bearings enhances speed, responsiveness, and overall efficiency. While the initial investment may be greater, the long-term benefits in terms of performance and reduced physical strain make it a worthwhile consideration for serious roller derby participants. A consistent maintenance regime is required to ensure high precision bearings last long and remain at top quality. The understanding of bearing precision and its impact on skating performance is essential for optimizing equipment selection and achieving competitive success.

5. Toe Stop Design

The design of toe stops on specialized footwear constitutes a critical element in roller derby, influencing skater agility, control, and safety. Its configuration directly impacts braking efficiency, stability during starts and stops, and the ability to execute specific maneuvers intrinsic to the sport.

- Material Composition and Durability

The material from which toe stops are constructed dictates their durability and grip characteristics. Natural rubber provides excellent grip but may wear down more rapidly. Synthetic compounds, such as polyurethane, offer enhanced abrasion resistance and longevity. The selection of material is dependent on skating frequency, track surface, and skater weight, as these factors collectively influence the rate of wear and tear. Improper material selection can compromise braking performance and increase the risk of accidents.

- Shape and Surface Area

The shape and surface area of toe stops affect braking power and maneuverability. Larger, flatter toe stops provide greater surface contact, facilitating quicker and more stable stops. Smaller, rounded toe stops enhance agility, allowing for more precise footwork and transitions. Skaters must consider their skating style and the demands of their position when selecting toe stop shapes, as this choice influences their ability to execute specific skills effectively.

- Adjustability and Positioning

The adjustability of toe stops is essential for customizing equipment to individual preferences and skating techniques. Adjustable toe stops allow skaters to modify the height and angle of the stop, optimizing contact with the skating surface. Proper positioning ensures consistent braking performance and reduces the risk of instability during stops and starts. Incorrectly adjusted toe stops can negatively impact balance and control, potentially leading to injuries.

- Thread Type and Compatibility

The thread type of toe stops must be compatible with the plates on the specialized footwear. Standard thread types include metric and imperial sizes. Incorrect thread compatibility can result in insecure mounting, increasing the risk of toe stop failure during critical maneuvers. Skaters must verify thread compatibility before installation to ensure equipment integrity and prevent accidents. A secure and properly installed toe stop is essential for maintaining control and stability during gameplay.

The interplay between material composition, shape, adjustability, and thread compatibility underscores the importance of careful toe stop selection in roller derby. A properly chosen and maintained toe stop enhances braking efficiency, stability, and overall skater safety, contributing to improved performance on the track.

6. Truck Adjustability

Truck adjustability, a critical feature of specialized roller derby equipment, allows skaters to fine-tune the responsiveness and handling characteristics. This customization influences turning radius, stability, and overall maneuverability on the track. Proper adjustment enables skaters to optimize their equipment to suit their individual skating style and the demands of their position.

- Kingpin Angle and Its Effect

The kingpin angle, the angle at which the kingpin (the bolt connecting the plate to the trucks) is positioned, significantly affects turning responsiveness. A steeper kingpin angle generally results in quicker, more agile turns, while a shallower angle provides greater stability at higher speeds. Skaters can adjust the kingpin angle, if the plate design permits, to fine-tune the balance between agility and stability based on personal preference and track conditions. This adjustment directly influences a skater’s ability to navigate the pack and execute precise blocking maneuvers.

- Cushion (Bushing) Durometer

The durometer (hardness) of the cushions, also known as bushings, controls the resistance to turning. Softer cushions allow for easier turning and greater lean, enhancing agility at lower speeds. Harder cushions provide more resistance, increasing stability at higher speeds and minimizing unwanted wobble. By changing the cushions, skaters can tailor the equipment’s responsiveness to their skating style and the specific demands of the game. A jammer, for example, might prefer softer cushions for quick maneuvering through the pack, while a blocker might opt for harder cushions for enhanced stability when holding a line.

- Truck Tightness and Pivot Cup Condition

The tightness of the truck nuts affects the overall resistance to turning. Loosening the truck nuts increases agility, while tightening them enhances stability. However, excessive tightness can restrict movement and reduce responsiveness. The condition of the pivot cups, which house the pivot arms, also plays a crucial role. Worn or damaged pivot cups can lead to instability and reduced responsiveness. Regular inspection and maintenance of the pivot cups are essential for maintaining optimal truck performance. Over tightening can damage the pivot cup.

- Impact on Skating Style and Position

Truck adjustability directly influences a skater’s ability to execute specific skills and maneuvers. Jammers often benefit from more agile setups with softer cushions and looser trucks, allowing for quick directional changes and evasive maneuvers. Blockers may prefer more stable setups with harder cushions and tighter trucks, providing a solid foundation for holding a line and absorbing impacts. Ultimately, truck adjustability empowers skaters to personalize their equipment and optimize their performance based on their individual style and the demands of their position on the track. Finding the right combination often requires experimentation, but it improves effectiveness.

In conclusion, truck adjustability represents a fundamental aspect of specialized roller derby equipment, enabling skaters to fine-tune the handling characteristics and optimize their performance on the track. By carefully considering kingpin angle, cushion durometer, and truck tightness, skaters can personalize their equipment to suit their individual style and the demands of their position, illustrating the importance of truck adjustability in enhancing overall skating performance and maximizing effectiveness in the competitive arena.

7. Maintenance Regimen

A consistent maintenance regimen is inextricably linked to the performance and longevity of specialized footwear in roller derby. The rigorous demands of the sport place significant stress on the equipment, necessitating proactive measures to mitigate wear and ensure optimal functionality. Failure to adhere to a regular maintenance schedule directly impacts performance and safety, potentially leading to equipment failure during critical moments in competition. For example, neglected bearings can seize, significantly reducing roll speed and increasing the risk of falls. Similarly, worn toe stops compromise braking effectiveness, increasing the likelihood of collisions.

The implementation of a comprehensive maintenance schedule encompasses several key areas. Regular cleaning of bearings removes debris and contaminants, preserving their efficiency. Lubrication reduces friction and prevents corrosion, extending bearing lifespan. Inspection of mounting hardware ensures structural integrity, preventing component loosening or detachment. Wheel rotation promotes even wear, maximizing the lifespan of the wheels. Toe stop replacement ensures reliable braking performance. These practices, when consistently applied, contribute to the reliability and responsiveness of the equipment, enhancing the skater’s ability to perform at their peak. Consider a competitive skater diligently maintaining their gear; they are more likely to experience consistent performance compared to a skater neglecting their equipment, where performance degradation will likely occur.

In summary, a well-defined and consistently executed maintenance regimen is not merely an ancillary task but an integral component of maximizing the utility and safety of specialized roller derby footwear. It addresses the inherent challenges imposed by the sport’s physical demands and contributes directly to enhancing performance. Furthermore, adherence to a structured maintenance schedule mitigates the risk of equipment failure, protecting skaters from potential injuries. This connection underscores the practical significance of understanding and prioritizing equipment maintenance within the context of roller derby.

Frequently Asked Questions About Roller Derby Roller Skates

The following addresses common inquiries and clarifies misconceptions pertaining to the selection, maintenance, and utilization of specialized footwear used in roller derby.

Question 1: What distinguishes roller derby equipment from conventional items?

Roller derby equipment is specifically engineered to withstand the high-impact collisions and rapid maneuvers inherent in the sport. Construction incorporates reinforced boots, durable plates, and specialized wheels optimized for various track surfaces, differentiating it from recreational or artistic items.

Question 2: How does wheel durometer influence skating performance?

Wheel durometer, a measure of wheel hardness, impacts grip and roll speed. Softer wheels (lower durometer) provide increased grip on slick surfaces, while harder wheels (higher durometer) maximize speed on smoother tracks. Appropriate wheel selection is crucial for optimizing performance based on track conditions and skating style.

Question 3: What role does bearing precision play in skating efficiency?

Bearing precision, gauged by ABEC or similar ISO standards, affects friction within the wheel assembly. Higher precision bearings minimize friction, resulting in increased roll speed and reduced energy expenditure. Skaters employing high-precision bearings often experience enhanced acceleration and sustained velocity.

Question 4: Why is regular maintenance essential for roller derby equipment?

Consistent maintenance, including cleaning, lubrication, and hardware inspection, preserves the performance and extends the lifespan of specialized footwear. Neglecting maintenance can lead to equipment failure, compromising safety and reducing skating efficiency.

Question 5: How does truck adjustability impact handling characteristics?

Truck adjustability, encompassing kingpin angle and cushion durometer, allows skaters to fine-tune turning responsiveness and stability. Proper adjustment enables skaters to optimize their equipment to suit their individual skating style and the demands of their position, enhancing maneuverability and control.

Question 6: What are the key considerations when selecting specialized footwear?

Boot fit, plate material, wheel durometer, bearing precision, toe stop design, and truck adjustability are all critical considerations. A thorough evaluation of these factors, coupled with professional fitting assistance, ensures optimal equipment selection and enhances both performance and safety.

The preceding provides a foundational understanding of the key elements related to specialized footwear in roller derby. Informed equipment selection and consistent maintenance are paramount for maximizing performance and mitigating potential risks.

The subsequent discussion will shift to exploring strategies for advanced performance enhancement, including skill development and tactical considerations.

Conclusion

The preceding analysis has elucidated the multifaceted nature of roller derby roller skates, emphasizing their integral role in skater performance, safety, and competitive success. The discussion encompassed component selection, maintenance protocols, and the intricate relationship between equipment design and skating technique. Key aspects such as boot construction, plate material, wheel durometer, bearing precision, and truck adjustability have been examined, providing a comprehensive understanding of their influence on agility, stability, and overall efficiency.

A thorough comprehension of specialized footwear represents a foundational element for achieving proficiency and mitigating risks within the demanding sport of roller derby. Continuous refinement of equipment selection and consistent adherence to rigorous maintenance practices are essential to maximizing skater potential and ensuring long-term participation. Future advancements in materials science and engineering may further enhance the performance characteristics of this essential equipment, thereby contributing to the continued evolution of the sport.