Protective coverings designed to shield the blades of ice skates during off-ice use are commonly employed. These coverings, often constructed from materials like hard plastic or durable rubber, prevent damage to the sharpened edges of the blades when walking on surfaces such as concrete, tile, or wood. This protection is critical for maintaining the blade’s integrity and performance. For example, a skater walking from the ice rink to the changing room would use these coverings to avoid dulling or chipping the blades.

The utilization of these protective accessories offers several key advantages. Firstly, they significantly extend the lifespan of the skate blades by minimizing wear and tear. Secondly, they enhance safety by preventing accidental slips or falls that can occur when walking on hard surfaces with exposed blades. Historically, skaters would use makeshift solutions like rags or cardboard to protect their blades, but modern engineered versions provide a more reliable and convenient solution. The evolution of these protective devices reflects a greater understanding of blade maintenance and skater safety.

The following discussion will elaborate on the materials, design variations, appropriate usage techniques, and maintenance best practices associated with these vital skate accessories, ensuring optimal performance and longevity of ice skate blades.

Essential Usage Guidance

The following recommendations ensure optimal performance and extended longevity when utilizing blade protectors.

Tip 1: Always ensure a secure and snug fit. Loose-fitting blade protectors can slide off, negating their protective function and posing a safety hazard. Verify proper alignment before each use.

Tip 2: Regularly inspect for wear and tear. Cracks, splits, or significant abrasions indicate a need for replacement. Compromised blade protectors offer diminished protection.

Tip 3: Clean blade protectors after each use, especially after exposure to moisture or debris. Accumulated dirt and moisture can accelerate blade corrosion or damage the protector itself. A simple wipe-down is often sufficient.

Tip 4: When not in use, store blade protectors in a dry environment. Prolonged exposure to humidity can degrade certain materials and shorten the lifespan of the protector.

Tip 5: Select the appropriate type of blade protector for the specific blade profile and skating discipline. Different blade designs may require variations in protector design to ensure a secure and effective fit.

Tip 6: Prioritize blade protector usage whenever skates are off the ice, regardless of the walking surface. Inconsistent use compromises blade integrity over time, even if surfaces appear relatively smooth.

Following these guidelines will significantly enhance the protective capability and durability of blade protectors, ultimately contributing to the prolonged lifespan and optimal performance of ice skate blades.

The ensuing sections will cover the various material compositions, design choices, and purchasing considerations associated with blade protection devices.

1. Material Durability

The relationship between material durability and the effectiveness of protective blade coverings is fundamental. The ability of these coverings to withstand abrasive forces directly determines their capacity to shield the delicate edges of ice skate blades from damage during off-ice use. Inadequate material durability results in premature wear, rendering the covering less effective and exposing the blades to potential harm. For example, coverings constructed from low-grade plastics may quickly develop scratches and gouges, compromising their protective barrier. Therefore, the selection of durable materials is paramount to the longevity and performance of the skate blades.

Real-world examples underscore the practical significance of material durability. A skater frequently traversing rough surfaces, such as concrete or gravel, requires coverings fabricated from robust materials like high-density polyethylene (HDPE) or reinforced rubber. These materials offer superior resistance to abrasion and impact, ensuring sustained protection. Conversely, coverings made from less durable materials may be suitable for occasional use on smoother surfaces, but are unlikely to withstand the rigors of frequent, heavy-duty applications. The frequency and intensity of usage should therefore dictate the material composition chosen.

In summary, material durability is a critical determinant of protective coverings’ efficacy. Selecting coverings constructed from high-quality, durable materials is essential for maximizing blade protection and extending the lifespan of ice skate blades. Challenges remain in balancing durability with factors such as weight and flexibility, but prioritizing material strength is paramount to ensuring long-term performance and preventing costly blade damage.

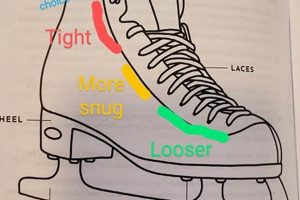

2. Fit Security

Fit security represents a critical attribute in the selection and utilization of blade protection accessories. Inadequate fit compromises the protective function, potentially leading to blade damage and creating safety hazards for the skater. The following aspects delineate the importance of a secure and stable fit.

- Dimensional Compatibility

Dimensional compatibility refers to the precise matching of blade guard dimensions to the length and curvature of the skate blade. Guards that are too large may slip or rotate, leaving portions of the blade exposed. Conversely, guards that are too small may not provide adequate coverage. Proper dimensional compatibility ensures complete and consistent protection. For example, a guard designed for a figure skate blade will likely be incompatible with a hockey skate blade due to differences in blade length and profile.

- Retention Mechanism Effectiveness

The retention mechanism, typically involving elastic straps, springs, or adjustable fasteners, is responsible for maintaining the guard’s position on the blade. A weak or ineffective retention mechanism can result in the guard dislodging during use, particularly when walking on uneven surfaces. A properly functioning retention mechanism should provide sufficient tension to hold the guard securely without causing excessive pressure that could damage the blade or guard. An example of ineffective retention is a stretched-out elastic strap that no longer provides adequate grip.

- Material Friction Coefficient

The friction coefficient between the inner surface of the guard and the skate blade influences the guard’s resistance to slippage. A higher friction coefficient, achieved through the use of textured materials or specialized coatings, enhances grip and reduces the likelihood of the guard rotating or sliding along the blade. Insufficient friction can lead to the guard shifting during use, compromising protection. For example, a guard with a smooth, polished inner surface may be more prone to slippage than one with a textured rubber lining.

- Structural Integrity Under Load

The structural integrity of the guard, particularly under load, ensures that it maintains its shape and position when subjected to weight or pressure. Guards constructed from flimsy or easily deformable materials may buckle or collapse under the skater’s weight, exposing the blade to potential damage. A structurally sound guard should be able to withstand the forces encountered during normal walking and turning movements without compromising its protective function. For instance, a guard made from brittle plastic may crack or shatter under pressure, rendering it ineffective.

The aspects described above, highlighting dimensional compatibility, mechanism effectiveness, material friction, and structural integrity, underscore the multifaceted nature of fit security. Prioritizing these characteristics when selecting blade guards is essential for ensuring adequate protection and preventing damage to expensive ice skate blades.

3. Edge Protection

Edge protection is the primary function facilitated by blade coverings. These accessories mitigate damage to the sharpened edges of ice skate blades during off-ice ambulation, preserving performance and extending the lifespan of the blades.

- Material Composition & Impact Absorption

Material composition directly influences the impact absorption capacity of these protective devices. Materials such as high-density polyethylene (HDPE) and vulcanized rubber possess superior shock-absorbing properties compared to softer, less resilient alternatives. The capacity to absorb impact prevents the transmission of force to the blade edge when encountering hard or uneven surfaces. For instance, a skater traversing a cobbled surface with inadequate edge protection risks chipping or dulling the blade; however, a covering constructed from a high-impact material disperses the force, minimizing potential damage. The selection of appropriate materials, therefore, is critical for effective edge protection.

- Coverage Area & Blade Profile Conformity

The extent of coverage provided by a blade covering is directly correlated with the level of edge protection afforded. Complete coverage of the blade edge, from toe to heel, is essential for preventing contact with abrasive surfaces. Furthermore, the covering must conform precisely to the blade profile to eliminate gaps or areas of exposure. An ill-fitting guard may leave portions of the blade vulnerable to damage, negating the protective benefits. For example, a covering designed for a figure skate blade may not adequately protect the longer, more curved blade of a hockey skate. Proper coverage area and profile conformity are paramount for comprehensive edge safeguarding.

- Surface Hardness & Abrasion Resistance

The surface hardness and abrasion resistance of the protective covering material determine its ability to withstand friction against various surfaces. Materials with a high surface hardness, such as hardened polymers, resist scratching and wear, maintaining a smooth, protective barrier between the blade edge and the ground. Low abrasion resistance leads to rapid degradation of the covering, compromising its protective capacity. A skater repeatedly walking on concrete with a covering constructed from a soft, easily abraded material will quickly wear through the guard, exposing the blade edge. Superior surface hardness and abrasion resistance are critical for long-term edge protection.

- Design for Drainage & Debris Mitigation

The design of blade coverings can incorporate features that facilitate drainage and prevent the accumulation of debris. Grooves, channels, or perforations allow water and dirt to escape, minimizing corrosion and maintaining a clean interface between the blade and the guard. Accumulated debris can act as an abrasive agent, accelerating wear on both the blade and the covering. A covering with inadequate drainage may trap moisture, leading to rust and blade degradation. Therefore, design features that promote drainage and debris mitigation contribute significantly to overall edge protection.

Collectively, these considerations underscore the multifaceted nature of edge protection. Prioritizing material composition, coverage area, surface hardness, and design features ensures that blade coverings effectively safeguard ice skate blade edges, preserving performance characteristics and extending the lifespan of the equipment. Investing in high-quality, well-designed blade coverings is a prudent measure for maintaining the integrity of valuable ice skate blades.

4. Moisture Management

The effective removal or mitigation of moisture within blade protectors is inextricably linked to the longevity and performance of ice skate blades. Condensation, snow melt, and residual water from the ice surface can accumulate within the enclosed space of a blade guard. This trapped moisture creates an environment conducive to corrosion and rust formation on the blade surface. Protective coverings that lack adequate moisture management exacerbate this issue, accelerating blade degradation. Conversely, blade guards designed with ventilation, absorbent materials, or drainage channels actively combat moisture buildup, thereby prolonging blade life. For instance, a skater who routinely neglects to remove moisture from their blade guards may experience premature blade dulling and the development of rust spots, necessitating frequent sharpening or even blade replacement. Therefore, moisture management constitutes a critical element of effective blade protection.

The practical application of moisture management principles manifests in various design features of blade guards. Some models incorporate absorbent liners constructed from materials like microfiber or foam, which wick away moisture from the blade surface. Others feature strategically placed ventilation holes to promote airflow and evaporation. Advanced designs may integrate drainage channels to facilitate the expulsion of excess water. Skaters can further enhance moisture management by regularly removing and drying their blade guards after each use, ensuring that the interior remains free from accumulated moisture. In colder climates, where rapid temperature fluctuations can lead to increased condensation, diligent moisture management practices are particularly crucial. Neglecting these practices can result in significant and costly damage to the blades.

In conclusion, moisture management is an indispensable consideration in the design, selection, and utilization of blade protectors. The effective control of moisture levels within these accessories directly impacts the lifespan, performance, and maintenance requirements of ice skate blades. While challenges persist in balancing ventilation with protection from external elements, prioritizing moisture management through appropriate design features and user practices remains paramount to safeguarding the investment in high-quality ice skates.

5. Surface Compatibility

The performance and longevity of blade protectors are intrinsically linked to their compatibility with diverse surface textures. These accessories, designed to safeguard skate blades during off-ice transit, encounter a spectrum of flooring types, each presenting unique abrasive properties. Inadequate surface compatibility can lead to accelerated wear and tear on the blade protector itself, diminishing its protective capabilities and potentially exposing the blades to damage. For example, a protector designed primarily for smooth, indoor surfaces may quickly degrade when used frequently on rough asphalt or concrete. The interaction between the protector’s material and the surface texture dictates the degree of protection afforded to the blades. Therefore, the choice of protector material and design must align with the typical surfaces encountered by the skater.

Practical implications of surface compatibility extend to both material selection and protector design. Materials exhibiting high abrasion resistance, such as certain polymers or reinforced rubber compounds, offer enhanced protection against rough surfaces. Design considerations include tread patterns or surface textures that improve grip and reduce the likelihood of slippage, particularly on smooth or polished floors. A skater who routinely traverses varied terrains, from carpeted locker rooms to concrete sidewalks, requires a protector constructed from a robust material with a versatile tread pattern. Conversely, a skater who primarily skates indoors on specialized surfaces may opt for a lighter-duty protector with a smoother profile. The decision hinges on a careful assessment of the most common surfaces encountered and the corresponding demands placed on the protector.

In summary, surface compatibility is a critical determinant of blade protector effectiveness. Selecting protectors engineered to withstand the specific abrasive characteristics of frequently encountered surfaces is essential for maximizing blade protection and prolonging the lifespan of both the blades and the protectors themselves. Challenges remain in developing universally compatible materials that balance durability, grip, and weight. Nonetheless, prioritizing surface compatibility is a fundamental aspect of responsible skate maintenance, contributing directly to the preservation of valuable equipment and the safety of the skater.

6. Impact Resistance

Impact resistance is a critical performance characteristic directly influencing the protective capabilities of blade coverings. These accessories must effectively absorb and dissipate forces generated by impacts to prevent damage to the delicate edges of ice skate blades. The capacity to withstand such impacts is paramount to ensuring blade integrity and extending the lifespan of the equipment.

- Material Selection and Shock Absorption

The choice of material is fundamental to impact resistance. Polymers, rubber compounds, and composite materials exhibit varying degrees of shock absorption. Materials with higher damping coefficients effectively attenuate impact forces, minimizing transmission to the blade. For example, a blade guard constructed from high-density polyethylene (HDPE) will generally provide superior impact resistance compared to one made from a lower-density plastic. The material’s ability to deform and recover without permanent damage is also crucial for repeated impact protection.

- Structural Design and Load Distribution

Structural design plays a significant role in distributing impact forces across the blade guard. Ribs, ridges, and other reinforcing features can enhance the overall stiffness and strength of the structure. A well-designed guard will distribute the impact load over a larger area, reducing stress concentrations on the blade. For instance, a guard with internal reinforcement struts will exhibit greater resistance to deformation under impact than a guard with a simple, unreinforced shell.

- Energy Dissipation Mechanisms

Energy dissipation mechanisms refer to features designed to convert impact energy into other forms, such as heat or deformation. These mechanisms can include crumple zones, flexible hinges, or specialized damping elements. By absorbing energy during an impact, these features reduce the force transmitted to the blade. An example is a guard incorporating a layer of visco-elastic polymer that deforms under impact, absorbing a significant portion of the energy.

- Testing Protocols and Performance Standards

Testing protocols are essential for quantifying and validating the impact resistance of blade guards. Standardized tests, such as drop tests or impact tests using calibrated weights, provide objective measures of performance. Adherence to established performance standards ensures that guards meet minimum levels of impact protection. For example, a guard that conforms to a specific ASTM standard has been subjected to rigorous testing and meets defined criteria for impact resistance.

These interconnected factors demonstrate the complex relationship between impact resistance and blade protection. By carefully considering material properties, structural design, energy dissipation mechanisms, and adherence to testing protocols, manufacturers can develop blade guards that effectively safeguard ice skate blades from the damaging effects of impacts, thereby preserving performance and extending the lifespan of the equipment.

7. Blade Longevity

Ice skate blade longevity, the duration for which a blade maintains optimal performance characteristics, is intrinsically linked to the consistent use of protective coverings during off-ice transit and storage. The implementation of such protective measures directly mitigates damage accumulation, thereby extending the usable lifespan of the blade.

- Mitigation of Abrasive Wear

Abrasive wear, caused by contact with hard or irregular surfaces, constitutes a primary source of blade degradation. Protective coverings provide a sacrificial barrier, absorbing the frictional forces that would otherwise act directly upon the blade edges. For instance, walking on concrete without protection results in microscopic material loss from the blade, gradually dulling the edges. Consistent use of a protective covering significantly reduces this abrasive wear, preserving sharpness and extending the intervals between necessary sharpenings.

- Prevention of Edge Chipping and Notching

Impacts against hard objects can cause chipping or notching of the delicate blade edges. Even minor imperfections compromise performance, affecting the skater’s ability to execute precise movements. Protective coverings, particularly those constructed from impact-resistant materials, cushion the blade against accidental collisions, minimizing the risk of edge damage. An unprotected blade striking a metal object, such as a locker latch, is highly susceptible to chipping, whereas a protected blade experiences a significantly reduced impact force.

- Reduction of Corrosion and Oxidation

Exposure to moisture and atmospheric elements promotes corrosion and oxidation, which weaken the blade material and degrade its surface finish. Protective coverings, especially those designed with moisture-wicking or ventilation features, help to maintain a dry environment around the blade, inhibiting the formation of rust and other corrosive byproducts. Storing unprotected blades in humid conditions accelerates corrosion, whereas the use of a well-maintained protective covering mitigates moisture exposure and slows the degradation process.

- Maintenance of Blade Profile and Geometry

The consistent application of protective measures helps to preserve the intended blade profile and geometry. Frequent sharpening to correct damage or wear alters the blade’s original shape, eventually impacting its performance characteristics. By minimizing the need for frequent sharpening, protective coverings contribute to the long-term maintenance of the blade’s optimal profile. A blade that is consistently protected requires less frequent sharpening, thereby retaining its intended geometry for a longer period.

The factors detailed above illustrate the direct influence of protective coverings on blade longevity. By mitigating abrasive wear, preventing edge damage, reducing corrosion, and maintaining blade profile, these accessories contribute significantly to extending the usable lifespan of ice skate blades. The consistent and appropriate application of protective measures represents a sound investment in preserving the performance and value of skating equipment.

Frequently Asked Questions Regarding Blade Protection

The following addresses commonly encountered inquiries regarding the proper utilization and maintenance of protective coverings designed for ice skate blades. Accurate information facilitates optimal blade preservation and prolongs equipment lifespan.

Question 1: What constitutes the primary function of blade coverings?

The principal objective of blade coverings is to shield the sharpened edges of ice skate blades from damage during off-ice transit. These coverings mitigate abrasive wear, prevent edge chipping, and protect against corrosion, thereby preserving blade performance and extending their usable lifespan.

Question 2: How frequently should blade coverings be replaced?

Replacement frequency is contingent upon usage intensity and environmental conditions. Coverings exhibiting significant wear, such as cracks, tears, or substantial material loss, should be replaced immediately to ensure adequate protection. Routine inspection is recommended.

Question 3: Are all blade coverings universally compatible with all ice skate blade types?

No. Blade coverings are often designed to accommodate specific blade profiles and dimensions. Using an incompatible covering may result in inadequate protection or even damage to the blade. Consult manufacturer specifications to ensure proper fit and compatibility.

Question 4: Is it necessary to dry blades before installing protective coverings?

Yes. Residual moisture trapped between the blade and the covering promotes corrosion and rust formation. Blades should be thoroughly dried before installing coverings to prevent such degradation. Allowing blades to air dry prior to covering is recommended.

Question 5: Can blade coverings be used for long-term storage of ice skates?

While coverings provide short-term protection, long-term storage requires specific considerations. For extended periods of inactivity, blades should be cleaned, dried, and treated with a corrosion inhibitor before being stored in a climate-controlled environment. Covering alone may not suffice for long-term preservation.

Question 6: What materials are best suited for blade coverings?

Optimal materials exhibit high abrasion resistance, impact absorption, and moisture-wicking properties. Common materials include high-density polyethylene (HDPE), vulcanized rubber, and specialized polymer blends. The selection of appropriate materials depends on the intended use and environmental conditions.

Proper utilization and maintenance of blade coverings are essential for preserving the performance and extending the lifespan of ice skate blades. Neglecting these practices can result in costly repairs or premature equipment replacement.

The following discussion will address advanced techniques for blade maintenance and preservation, focusing on sharpening protocols and storage best practices.

Conclusion

This exploration has detailed the crucial role of `rockerz ice skate guards` in safeguarding ice skate blades from damage incurred during off-ice activity. Key aspects such as material durability, fit security, edge protection, moisture management, surface compatibility, and impact resistance were examined, emphasizing their individual and collective contributions to blade longevity. Understanding these factors enables informed selection and utilization of these protective devices.

Proper implementation of preventative measures, including the consistent use of `rockerz ice skate guards` and adherence to recommended maintenance practices, is paramount to preserving the performance characteristics and extending the lifespan of ice skate blades. The investment in these protective accessories is a prudent strategy for minimizing equipment degradation and ensuring consistent on-ice performance.