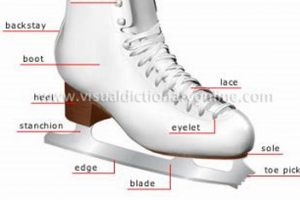

Footwear designed for gliding across ice surfaces, typically featuring a supportive boot attached to a metal blade, allows individuals to participate in activities such as ice hockey, figure skating, and recreational skating. The construction of these items prioritizes stability, comfort, and performance on ice.

These specialized boots offer a unique combination of support and flexibility, essential for both novice and experienced skaters. The rigid structure of the boot provides ankle stability, reducing the risk of injury, while the blade’s design enables efficient gliding and precise movements. Historically, improvements in materials and manufacturing techniques have significantly enhanced the performance and durability of these skates.

The following sections will explore specific design features, optimal maintenance practices, and considerations for selecting the appropriate equipment for various ice skating activities.

Guidance on Ice Skate Maintenance and Selection

Proper care and informed selection are crucial for maximizing the lifespan and performance of ice skating equipment. Adhering to the following guidelines will ensure both safety and optimal functionality.

Tip 1: Blade Protection: Utilize blade guards when off the ice. These shields prevent nicks and damage to the blade’s sharp edge, which is critical for maintaining glide and control.

Tip 2: Drying After Use: Thoroughly dry blades and boots after each use. Moisture promotes rust and deteriorates the materials, reducing the lifespan and performance of the equipment.

Tip 3: Blade Sharpening: Regularly sharpen the blades. The frequency depends on usage, but maintaining a sharp edge ensures proper grip and maneuverability on the ice.

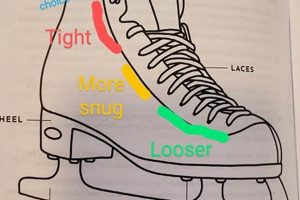

Tip 4: Boot Support: Ensure proper ankle support. A snug fit in the boot is essential for stability and control. Consider professional fitting services to guarantee optimal comfort and performance.

Tip 5: Material Considerations: Select equipment based on intended use. Different materials offer varying levels of support and performance characteristics. For instance, hockey players may require stiffer boots than recreational skaters.

Tip 6: Inspect Regularly: Conduct routine inspections for signs of wear and tear. Examine stitching, laces, and blade attachments for any potential issues that may compromise safety or performance.

Following these guidelines enhances the longevity and efficiency of ice skating equipment, contributing to an improved and safer skating experience.

The concluding section will summarize the key aspects discussed and provide resources for further research and information.

1. Blade Steel Quality

The composition and treatment of blade steel significantly influence the performance and longevity of ice skates. The materials used determine the blade’s ability to maintain an edge, resist corrosion, and withstand the stresses of repeated use on ice. High-quality steel is essential for optimal skating performance.

- Edge Retention and Hardness

Blade steel with superior hardness retains its edge longer, requiring less frequent sharpening. Materials with increased carbon content contribute to this hardness. However, excessive hardness can lead to brittleness and chipping. The ideal balance is achieved through specific tempering processes. For example, some blades utilize specialized coatings to further enhance edge retention and durability.

- Corrosion Resistance

Exposure to moisture during and after skating sessions can cause rust and corrosion, which degrades the blade’s surface and dulls the edge. Certain steel alloys, such as those with added chromium, offer increased resistance to corrosion. Proper drying and storage practices remain essential to mitigate corrosion risks.

- Flexural Strength and Impact Resistance

Blades are subjected to bending and impact forces during skating maneuvers. The steel must possess sufficient flexural strength to withstand these forces without permanent deformation or breakage. Alloying elements like nickel and molybdenum enhance the steel’s ability to absorb impact energy and resist cracking.

- Manufacturing Precision and Finishing

The quality of the steel is only one factor; the precision of the manufacturing process and the surface finish are equally important. Uniform blade thickness and a smooth, polished surface minimize friction with the ice and contribute to a cleaner, more efficient glide. Advanced machining techniques are employed to achieve these critical tolerances.

The steel quality of ice skate blades directly affects a skater’s ability to perform maneuvers, maintain speed, and control their movements on the ice. The skater’s experience and success is contingent on the choice of steel blade.

2. Boot Ankle Support

Ankle support within the boot structure is a critical determinant of performance and safety in ice skates. The design and materials employed directly influence the skater’s stability, control, and risk of injury. Effective ankle support allows for efficient power transfer and precise execution of skating maneuvers.

- Lateral Stability and Injury Prevention

Adequate lateral support minimizes ankle roll and prevents sprains or other related injuries. Stiff materials and reinforced construction around the ankle joint provide a secure fit, reducing the likelihood of excessive movement during sharp turns or sudden stops. The degree of stiffness varies depending on the skater’s skill level and intended use, with advanced skaters often requiring stiffer boots for enhanced responsiveness.

- Power Transfer Efficiency

A supportive boot facilitates efficient transfer of energy from the skater’s leg to the blade. The boot acts as a rigid lever, allowing the skater to generate more force with each stride. Insufficient ankle support results in energy loss and reduced skating efficiency. Professional skaters often seek custom-fitted boots to maximize power transfer.

- Material Composition and Construction

The materials used in the boot’s construction significantly impact ankle support. Stiff synthetic materials, such as molded polymers or reinforced leather, provide greater support than softer, more flexible materials. Composite materials, combining multiple layers of varying stiffness, offer a balance of support and comfort. The boot’s design, including the height of the ankle cuff and the lacing system, also contributes to the overall level of support.

- Customization and Fit Considerations

Proper fit is essential for optimal ankle support. Ill-fitting boots can cause discomfort, blisters, and reduced performance. Custom fitting, including heat molding and padding adjustments, ensures a snug and supportive fit around the ankle. Many advanced skaters opt for custom-made boots to achieve the perfect balance of support, comfort, and performance.

The interplay between these elements shapes the skater’s experience. Therefore, selecting ice skates based on individual needs and prioritizing effective ankle support is critical for both recreational and competitive skating.

3. Thermal Comfort Liners

Thermal comfort liners, integrated within ice skate boots, play a crucial role in maintaining foot warmth and enhancing overall skating experience. These liners mitigate the impact of cold temperatures on the skater’s feet, thereby influencing comfort, performance, and duration of skating sessions.

- Insulation Material Properties

Liners often incorporate insulating materials like Thinsulate or synthetic fleece, which trap air to create a thermal barrier against the cold. The effectiveness of these materials depends on their density and fiber structure, with denser materials generally providing superior insulation. However, excessive density can compromise breathability, leading to moisture build-up. Considerations include insulation thickness and the material’s ability to retain warmth when damp.

- Moisture Management Capabilities

Perspiration during physical activity can lead to chilling and discomfort. Moisture-wicking liners facilitate the evaporation of sweat, maintaining a dry environment inside the boot. Materials such as microfiber or specialized synthetic fabrics are designed to draw moisture away from the skin. The liner’s construction should promote airflow to further enhance moisture evaporation and prevent the accumulation of condensation.

- Anatomical Fit and Comfort

The liner’s design conforms to the natural contours of the foot, providing cushioning and reducing pressure points. A well-fitted liner enhances blood circulation and minimizes friction, preventing blisters and discomfort. Some liners are heat-moldable, allowing for customization to individual foot shapes. The liner’s thickness and density must strike a balance between thermal insulation and sensitivity for feel on the ice.

- Odor Control Features

Prolonged use can lead to the development of unpleasant odors within the skate boot. Liners with antimicrobial treatments inhibit the growth of odor-causing bacteria. These treatments often involve the incorporation of silver ions or other antimicrobial agents into the fabric. Regular cleaning and ventilation of the liners are essential to maintain hygiene and odor control over time.

These elements contribute significantly to the comfort and performance attributes of ice skates. Selection of skates with appropriate thermal comfort liners is essential for optimal performance and comfort during prolonged ice exposure.

4. Size Precision Fitting

Accurate sizing is paramount when selecting ice skates, directly impacting performance, comfort, and injury prevention. The relationship between foot dimensions and skate size, often referred to as “size precision fitting,” demands careful consideration to ensure optimal functionality within ice skates.

- Foot Measurement Methodology

Precise foot measurement is foundational for accurate skate sizing. Utilizing calibrated Brannock devices or similar tools provides standardized length and width readings. Measurements should be taken while bearing weight, as foot dimensions can change under load. These measurements serve as a baseline for comparison against skate manufacturer sizing charts, acknowledging that sizes can vary between brands and models. The foot should be measured in stocking that usually use for ice skating.

- Last Shape Compatibility

Skate manufacturers employ “lasts,” which are foot-shaped models around which the boot is constructed. Different lasts accommodate varying foot shapes, including variations in width, arch height, and instep volume. A skater’s foot shape should be compatible with the last shape of the chosen skate. Mismatches can lead to pressure points, discomfort, and compromised performance. Some manufacturers offer multiple last options to cater to a wider range of foot morphologies. This is more effective if last shape is precise, so feet will be more comfortable.

- Fit Assessment Protocols

Evaluating the fit of ice skates requires adherence to standardized protocols. The skater should wear the appropriate socks and lace the skates securely. Assess heel lock to ensure minimal slippage during forward motion. Evaluate toe clearance; a small gap between the toes and the boot’s end is desirable, preventing toe jamming during skating. Identify any areas of pressure or discomfort, as these may indicate a sizing or last incompatibility. Skate fit should ideally be evaluated under skating conditions to fully assess performance and comfort.

- Heat Molding and Customization

Many modern ice skates feature heat-moldable boots, allowing for customized fit adjustments. Heat molding softens the boot’s materials, enabling it to conform more precisely to the skater’s foot shape. Customization options, such as padding adjustments or orthotic inserts, further refine the fit and address individual anatomical variations. Professional skate fitters can assist with heat molding and customization procedures to achieve optimal comfort and performance. Customization increases precise fit.

The four components outlined above underscore the importance of precise size determination when selecting ice skates. Adherence to established measurement techniques, consideration of last compatibility, diligent fit assessment, and utilization of customization options contribute to a safe, comfortable, and high-performing skating experience.

5. Blade Sharpening Frequency

Maintaining optimal blade sharpness is critical for the performance and safety of ice skates. The frequency with which the blades require sharpening is influenced by several factors, directly impacting the skater’s ability to execute maneuvers and maintain control. For recreational use, the sharpening frequency may be less important than competitive because the speed and force are generally lower.

- Ice Hardness and Quality

The hardness and quality of the ice surface significantly affect blade wear. Hard, abrasive ice accelerates the dulling of the blade’s edge, necessitating more frequent sharpening. Conversely, softer, smoother ice results in less wear and extends the time between sharpenings. The presence of debris, such as dirt or sand, embedded in the ice can also accelerate blade dulling.

- Skating Frequency and Intensity

Increased skating frequency and intensity correlate with increased blade wear. Regular skaters and those who engage in high-impact activities, such as hockey or figure skating, require more frequent sharpening than occasional recreational skaters. The forces exerted on the blade during jumps, turns, and stops contribute to edge degradation.

- Skate Blade Steel Composition

The type of steel used in the skate blade impacts edge retention. Higher-quality steel alloys, such as those with a higher carbon content, generally maintain their sharpness for a longer duration compared to less durable materials. The steel’s hardness and resistance to wear influence the frequency with which sharpening is required.

- Skater Weight and Skill Level

Skater weight and skill level influence the forces exerted on the blade. Heavier skaters place greater stress on the blade, leading to increased wear. Advanced skaters, who execute more complex maneuvers, also tend to require more frequent sharpening to maintain the precise edge needed for optimal performance. Sharpening should take into account skater weight and skill level to optimize blade wear.

The interplay of these factors determines the optimal blade sharpening frequency for ice skates. Regular inspection of the blade’s edge and adherence to a consistent sharpening schedule are crucial for maximizing performance, ensuring safety, and extending the lifespan of the skating equipment.

6. Lace Durability Design

The structural integrity of laces is a critical design element in ice skates. Lace failure compromises support and safety, potentially leading to injury and hindering performance. Robust lace design is therefore essential for reliable functionality.

- Material Composition and Tensile Strength

Lace materials, often synthetic fibers such as nylon or polyester, must exhibit high tensile strength to withstand repeated tension and abrasion. Weaving techniques and fiber treatments contribute to enhanced durability. Inferior materials are prone to fraying, stretching, and ultimately, breakage. Superior laces must retain their integrity throughout extended use. This includes resistance to wear and tear and external elements.

- Construction Techniques and Abrasion Resistance

The method of lace construction directly impacts its resistance to abrasion. Braided or woven structures provide greater durability compared to simple twisted cords. Tightly packed fibers minimize friction and prevent internal abrasion. Surface coatings or treatments further enhance abrasion resistance, prolonging the lace’s lifespan. These construction techniques result in a longer life of the product as well as less maintenance.

- Eyelet Interface and Friction Reduction

The design of the eyelets through which the laces pass influences lace wear. Smooth, rounded eyelets minimize friction and prevent fraying. Metal or reinforced eyelets offer increased durability compared to plastic alternatives. The spacing and alignment of eyelets also contribute to even tension distribution, reducing stress on specific sections of the lace.

- Knot Security and Slippage Prevention

Lace design should facilitate secure knotting to prevent slippage during use. Textured surfaces or specialized weaves enhance friction, ensuring that knots remain tied under stress. Elasticity in the lace material can also contribute to knot security by maintaining constant tension. A loose lace is not only unhelpful, it could be dangerous to the user.

Integrating durable laces contributes significantly to the overall quality and reliability of ice skates. Selecting skates with robust lace designs ensures secure closure, consistent support, and prolonged product lifespan.

7. Overall Build Strength

Overall build strength in ice skates refers to the composite resilience of all components boot, blade, and associated hardware to withstand the stresses of use. In the context of specific sporting goods, this attribute dictates the longevity and safety of equipment, and how it reacts to various weather conditions. Compromised build strength increases the probability of equipment failure, potentially resulting in injury. Build strength dictates a great deal about an ice skate, including how much a user can push their skates.

The build strength of skates, for instance, directly correlates with their performance capabilities. Skates used in competitive hockey necessitate enhanced durability due to the high-impact nature of the sport. Boots constructed from reinforced materials, coupled with blades securely fastened to the chassis, are crucial for withstanding the rigors of aggressive skating and frequent collisions. This robustness translates to increased power transfer, allowing players to generate higher speeds and execute sharper turns. Recreational skates, while not subjected to the same level of stress, must still possess adequate build strength to endure regular use and prevent premature wear. The build strength also affects the type of usage the skate can handle, and also the amount of time for which the skates can be used.

Considerations regarding build strength extend beyond material selection to encompass manufacturing processes and design features. Precision engineering, including robust stitching, secure riveting, and meticulous quality control, are essential for ensuring the integrity of the final product. Moreover, design features such as reinforced ankle supports and strategically placed padding contribute to overall durability and skater protection. Prioritizing build strength in equipment design and manufacturing translates to enhanced safety, improved performance, and extended product lifespan, ultimately benefiting both recreational and competitive users. Thus, build strength can greatly improve the product and the user’s experience with the product.

Frequently Asked Questions About Ice Skates

The following addresses common inquiries regarding ice skate selection, maintenance, and performance characteristics, providing guidance for both novice and experienced skaters.

Question 1: What factors determine the appropriate ice skate size?

Skate size is determined by foot length and width, measured accurately using a Brannock device. Fit should be snug but not constricting, allowing minimal toe movement. Consideration should be given to sock thickness, as this impacts overall fit.

Question 2: How often should ice skate blades be sharpened?

Sharpening frequency depends on usage intensity and ice conditions. Blades should be sharpened when the skater experiences reduced glide or difficulty executing turns. Regular inspection for nicks or dull spots is advisable.

Question 3: What constitutes proper ice skate maintenance?

Proper maintenance includes drying blades immediately after use to prevent rust, storing skates in a dry environment, and utilizing blade guards when walking on non-ice surfaces. Regular inspection for loose rivets or worn components is also essential.

Question 4: How does boot stiffness affect skating performance?

Boot stiffness dictates the level of ankle support and power transfer. Stiffer boots are preferred for advanced skaters requiring maximum control and responsiveness, while softer boots provide greater comfort for recreational use.

Question 5: What is the significance of blade rocker and radius?

Blade rocker refers to the curvature of the blade, influencing maneuverability. Radius denotes the depth of the hollow ground into the blade, affecting edge grip. These factors are critical for specific skating styles and skill levels.

Question 6: Are heat-moldable ice skates beneficial?

Heat-moldable skates offer customized fit, conforming to the individual’s foot shape for enhanced comfort and performance. This is particularly advantageous for skaters with unique foot contours or fit challenges.

In summary, selecting appropriate ice skates involves careful consideration of size, blade characteristics, boot stiffness, and maintenance practices. Understanding these factors contributes to a safer and more enjoyable skating experience.

The subsequent sections delve into advanced topics related to ice skate technology and performance optimization.

Reebok Ice Skates

This exploration has detailed various critical aspects of ice skates, encompassing blade materials, boot construction, and maintenance protocols. Each element contributes significantly to the performance, safety, and longevity of the equipment. Understanding these facets empowers informed purchasing decisions and optimized utilization, regardless of skill level.

The continued advancement of materials and manufacturing techniques promises further enhancements in ice skate design. Prioritizing proper maintenance and informed selection remains paramount for maximizing the benefits of this equipment. Continued adherence to best practices will foster safer and more efficient utilization of ice skates for all participants.