Specialized footwear designed for ice skating at the highest levels of competition and performance distinguishes itself through construction, materials, and customization options. These instruments are crafted to meet the demands of professional athletes, prioritizing responsiveness and durability. For example, a figure skater executing complex jumps or a hockey player requiring rapid acceleration depends on this specialized equipment.

The utilization of high-grade materials, such as heat-moldable carbon fiber, allows for enhanced support and a personalized fit. A tailored fit maximizes energy transfer, providing the skater with improved control and agility. Historically, advancements in blade technology and boot design have continuously pushed the boundaries of athletic achievement in ice sports, reducing injury risk and elevating performance ceilings.

The ensuing sections will delve into the specific characteristics, fitting procedures, and maintenance requirements associated with this elite category of ice skating equipment, examining various brands, models, and features that distinguish them from recreational alternatives. Furthermore, the article will discuss considerations for selecting the appropriate type based on the intended discipline, skill level, and individual biomechanics.

Guidance on Selection and Maintenance

The following recommendations offer insight into optimizing the selection, fit, and upkeep of high-performance ice skating equipment to maximize performance and longevity.

Tip 1: Professional Fitting: Seek assessment from a trained professional who can evaluate foot morphology and skating style to determine the correct boot size, shape, and stiffness index. Optimal fit minimizes discomfort and enhances energy transfer.

Tip 2: Heat Molding: Utilize the heat-moldable properties of select boots. The process should be conducted by a qualified technician to ensure proper customization, creating a contoured fit specific to the skater’s foot.

Tip 3: Blade Alignment: Ensure proper blade alignment by a qualified skate technician. Correct alignment optimizes glide efficiency, edge control, and minimizes stress on joints.

Tip 4: Blade Sharpening: Regular sharpening is essential for maintaining optimal edge quality. The frequency depends on usage intensity, ice conditions, and skating style. Employ a reputable sharpener experienced in the skaters discipline.

Tip 5: Boot Maintenance: After each use, thoroughly dry the boots, both inside and out, to prevent bacterial growth and material degradation. Remove the insoles to promote air circulation.

Tip 6: Blade Protection: Always use blade guards when walking on surfaces other than ice. This prevents damage to the edges and extends the life of the sharpening.

Tip 7: Screw Tightness: Regularly inspect the screws securing the blade to the boot, ensuring they are properly tightened. Loose screws can compromise stability and control.

Adhering to these guidelines helps extend the lifespan of this specialized equipment, while simultaneously improving performance and reducing the risk of injury.

The subsequent segment will consolidate the information presented, drawing definitive conclusions based on the key points discussed throughout this exploration.

1. Stiffness

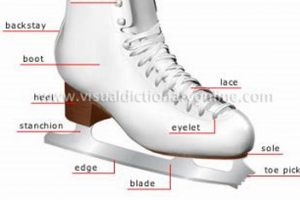

The stiffness of a ice skate boot is a critical determinant of performance at the elite level. It refers to the boot’s resistance to flexion, particularly around the ankle joint. Higher stiffness translates to increased energy transfer from the skater’s leg muscles to the blade, resulting in greater propulsion and control. This characteristic is paramount for disciplines such as hockey, where explosive acceleration and rapid changes in direction are essential, and figure skating where jumping, landing, and other technical elements require solid ankle support.

The selection of an appropriate stiffness level must consider skater weight, skill level, and skating style. A heavier skater or one executing more forceful movements typically benefits from a stiffer boot. Conversely, a skater who prioritizes agility and finesse may prefer a slightly more flexible boot. An overly stiff boot can restrict movement and increase fatigue, while a boot that is too flexible fails to provide adequate support, potentially leading to injury. For example, high-level hockey defensemen often select the highest stiffness ratings for maximum power during slapshots and cross-ice skating, while artistic skaters choose a somewhat less rigid boot to facilitate deeper knee bends and more fluid movements in their programs.

In conclusion, stiffness plays a critical role in determining the suitability of ice skating equipment for high-performance use. Appropriate stiffness balances power transfer and maneuverability, helping skaters of all skill levels optimize their potential. Misjudging the ideal stiffness can negatively impact performance and increase risk of injury. Therefore, professional assessment and fitting are vital steps to find the correct boots.

2. Blade Material

The performance of professional-grade ice skates hinges significantly on the composition of the blade. Blade material dictates the edge quality, glide efficiency, and overall durability experienced by the skater. Employing substandard materials invariably results in diminished control, reduced speed, and increased frequency of sharpening, ultimately impacting competitive performance. For instance, a figure skater executing intricate footwork sequences demands blades fabricated from high-carbon steel to maintain precise edge control throughout complex routines. Similarly, a hockey player relying on rapid acceleration and sharp turns requires blades engineered for maximum grip and responsiveness on the ice.

Different alloys offer varying degrees of hardness, wear resistance, and corrosion resistance. High-carbon steel, often preferred in professional applications, provides a superior balance of these properties, allowing for sharper edges and prolonged use between sharpenings. The tempering process applied to the steel further influences its performance characteristics, impacting its ability to withstand the stresses of repeated impacts and rigorous use. Moreover, advanced coatings, such as chrome or titanium, may be applied to enhance blade hardness and reduce friction, thereby optimizing glide efficiency. To illustrate, a speed skater racing at high velocities benefits from blades treated with low-friction coatings, minimizing drag and maximizing speed potential.

Therefore, the selection of appropriate blade material represents a crucial element in the customization process for high-performance skating equipment. Understanding the nuances of different materials and their respective impact on skating characteristics enables informed decision-making, ultimately contributing to enhanced performance, reduced maintenance, and extended equipment lifespan. A failure to consider the qualities of the blade material often leads to a compromise in the overall capabilities, particularly in competitive settings where marginal performance differences can determine success.

3. Custom Fitting

The meticulous process of custom fitting constitutes a cornerstone in optimizing the performance and comfort derived from professional ice skates. Unlike off-the-shelf options, custom fitting addresses the unique biomechanical characteristics of each skater, ensuring a harmonious interface between the foot, boot, and blade. This tailored approach minimizes the risk of injury, enhances energy transfer, and maximizes responsiveness, enabling athletes to perform at their peak potential.

- Foot Morphology Assessment

Custom fitting begins with a comprehensive evaluation of the skater’s foot. This includes precise measurements of length, width, arch height, and any anatomical irregularities such as bunions or bone spurs. Specialized tools, such as 3D foot scanners, capture detailed data that informs the selection of the appropriate boot model and size. Accurate assessment of foot morphology ensures a snug yet comfortable fit, eliminating pressure points and promoting optimal blood circulation.

- Heat Molding and Customization

Many professional ice skate boots feature heat-moldable materials that allow for further customization. During the heat molding process, the boot is heated, making it pliable and adaptable to the unique contours of the skater’s foot. A trained technician carefully molds the boot, addressing specific areas of concern and creating a personalized fit that maximizes comfort and support. Customization may also involve adding padding, shims, or other modifications to fine-tune the fit and address individual biomechanical needs. An athlete with high arches, for instance, may require additional arch support to prevent pronation and maintain proper alignment.

- Blade Alignment and Positioning

Proper blade alignment is crucial for optimizing skating performance and minimizing the risk of injury. Custom fitting includes precise adjustment of the blade position relative to the boot and the skater’s ankle. This ensures that the blade is aligned with the skater’s natural center of gravity, promoting efficient glide, edge control, and balance. A misaligned blade can lead to instability, fatigue, and an increased risk of falls. Skilled technicians use specialized tools and techniques to fine-tune the blade position, ensuring optimal performance and biomechanical efficiency.

- Performance Optimization

Ultimately, the goal of custom fitting is to enhance skating performance. A well-fitted boot allows for greater energy transfer from the skater’s leg muscles to the blade, resulting in increased power and agility. It also provides improved responsiveness, enabling skaters to execute intricate maneuvers with greater precision and control. By addressing individual biomechanical needs and optimizing the interface between the foot, boot, and blade, custom fitting empowers athletes to reach their full potential on the ice. This process facilitates a symbiosis between skater and equipment, a crucial element in professional ice sports.

The integration of these custom fitting facets is fundamental in transforming standard skates into performance-enhancing instruments, highlighting the commitment to athlete-specific requirements within the domain of professional ice skating. This customization not only ensures a secure and comfortable fit but also directly contributes to optimized performance metrics and enhanced safety on the ice, thereby underscoring its paramount importance.

4. Ankle Support

In the realm of professional ice skates, ankle support emerges as a pivotal determinant of performance, injury prevention, and overall skating control. The structural integrity of the boot around the ankle directly impacts the skater’s ability to execute complex maneuvers, generate power, and maintain balance, highlighting its undeniable significance.

- Boot Stiffness and Stability

The inherent stiffness of the boot material surrounding the ankle provides a crucial foundation for stability. Stiffer materials, such as reinforced carbon fiber or advanced composites, resist lateral flexion and provide a more rigid structure, enabling greater control during edge work and intricate footwork. For instance, a figure skater executing a triple axel relies on the ankle support to maintain stability upon landing, preventing excessive ankle roll and minimizing the risk of injury. Conversely, insufficient ankle support can lead to instability, fatigue, and compromised performance.

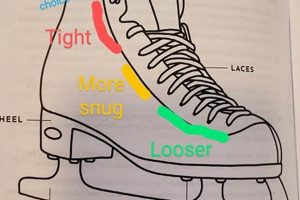

- Lacing Systems and Customization

Sophisticated lacing systems, often incorporating power straps and specialized closure mechanisms, allow skaters to fine-tune the degree of ankle support based on individual preferences and specific skating demands. Tightening the laces around the ankle enhances stability and responsiveness, while loosening them provides greater flexibility and range of motion. Elite hockey players, for example, may prefer a tighter lacing configuration for maximum ankle support during aggressive skating and rapid changes in direction, whereas figure skaters may opt for a slightly looser fit to facilitate more fluid movements and deeper knee bends.

- Padding and Internal Boot Design

Strategically placed padding within the boot’s ankle pocket provides cushioning, reduces friction, and enhances overall comfort. The internal boot design, including the shape and contours of the ankle area, further contributes to the level of support and stability. Some professional ice skates feature heat-moldable liners that conform to the skater’s unique ankle anatomy, creating a custom fit that minimizes pressure points and maximizes support. This personalized approach is invaluable for skaters with anatomical variations or previous ankle injuries.

- Blade Mounting and Alignment

The proper mounting and alignment of the blade relative to the boot and the skater’s ankle directly influences the effectiveness of ankle support. Misaligned blades can compromise stability, lead to uneven weight distribution, and increase the risk of ankle injuries. Skilled technicians ensure that the blade is positioned correctly, aligning it with the skater’s natural center of gravity and promoting efficient force transfer. This meticulous attention to detail is crucial for maximizing performance and minimizing strain on the ankle joint.

In conclusion, the multidimensional interplay of boot stiffness, lacing systems, internal boot design, and blade alignment collectively determines the efficacy of ankle support in professional ice skates. A well-engineered and properly fitted skate provides the necessary stability, responsiveness, and comfort to enable skaters to perform at their best, while simultaneously minimizing the risk of injury. The symbiotic relationship between ankle support and overall skate design underscores its paramount importance in the pursuit of excellence on the ice.

5. Heat Moldability

Heat moldability, as a feature in professional ice skates, directly affects the fit and performance capabilities of the equipment. The underlying principle involves the use of thermo-reactive materials within the skate’s boot construction. When exposed to controlled heat, these materials soften, allowing the boot to conform more precisely to the unique contours of the skater’s foot. Upon cooling, the boot retains its new shape, providing a customized fit that is unattainable with traditional, non-moldable skates. The effect of this customized fit is reduced pressure points, enhanced comfort, and optimized energy transfer. A figure skater, for example, may experience improved responsiveness and control during intricate footwork sequences due to the absence of slippage or discomfort caused by an ill-fitting boot. The practical significance lies in the potential for improved performance, minimized risk of blisters and other foot-related injuries, and extended periods of comfortable wear during training and competition.

The implementation of heat moldability in professional ice skates presents a complex interplay of material science, manufacturing precision, and fitting expertise. The specific type of thermo-reactive material, the distribution of this material within the boot, and the heating process itself all influence the effectiveness of the molding process. Furthermore, the expertise of the technician performing the molding procedure is crucial. Overheating or improper molding techniques can damage the boot’s structural integrity, compromising its performance and durability. A hockey player requiring maximum ankle support, for instance, might rely on a carefully molded boot to provide a secure and responsive fit, enabling rapid changes in direction and explosive acceleration. However, if the molding process is flawed, the boot may not provide adequate support, increasing the risk of ankle sprains or other injuries.

In conclusion, heat moldability represents a significant advancement in ice skate technology, offering a means to achieve a highly personalized and performance-enhancing fit. While the benefits are substantial, the effective utilization of this feature requires a thorough understanding of the underlying principles, meticulous attention to detail during the molding process, and access to qualified fitting professionals. The challenges associated with improper application underscore the importance of seeking expert guidance and prioritizing quality over cost when investing in heat-moldable professional ice skates. By addressing these challenges, skaters can unlock the full potential of heat moldability, realizing enhanced comfort, improved performance, and a reduced risk of injury.

6. Edge Precision

Edge precision in professional ice skates is paramount, serving as the critical interface between skater and ice. Its influence permeates every aspect of performance, determining agility, speed, and the successful execution of technical elements. Skates designed for elite athletes prioritize edge control through sophisticated blade geometry, materials, and construction techniques.

- Blade Geometry and Profile

Blade geometry, encompassing the radius of hollow (ROH) and blade profile, dictates the depth and consistency of the edge. A smaller ROH creates a deeper bite into the ice, enhancing grip for powerful turns, as required by hockey players. The blade profile, or curvature along its length, influences glide and maneuverability, crucial for figure skaters executing jumps and spins. Precise manufacturing ensures uniformity and predictable edge behavior, essential for consistent performance in competition.

- Steel Hardness and Edge Retention

The hardness of the steel used in blade construction directly impacts edge retention, the ability to maintain a sharp, clean edge over time. High-carbon steel alloys, often heat-treated for increased hardness, offer superior edge retention, reducing the frequency of sharpening and ensuring consistent performance throughout a competition or practice session. A dull edge compromises control, increasing the risk of falls and diminishing skating efficiency.

- Sharpening Techniques and Customization

Professional skaters rely on skilled technicians employing specialized sharpening techniques to achieve optimal edge quality. Custom sharpening profiles can be tailored to individual skating styles and preferences. Some skaters prefer a deeper hollow for increased grip, while others opt for a shallower hollow for greater glide. Precise sharpening ensures symmetrical edges, promoting balanced skating and preventing uneven wear. A poorly sharpened blade undermines the skater’s ability to control their movements, negating the benefits of high-quality skates.

- Blade Mounting and Alignment

Precise blade mounting and alignment are critical for maximizing edge control. The blade must be securely and accurately positioned relative to the boot and the skater’s anatomy. Misaligned blades can cause uneven weight distribution, leading to instability and compromised edge control. Professional skate technicians meticulously align blades to ensure optimal balance and responsiveness, allowing skaters to fully exploit the capabilities of their equipment.

In conclusion, edge precision is an indispensable attribute of professional ice skates, directly influencing performance across all disciplines. The combination of sophisticated blade geometry, high-quality materials, precise sharpening, and accurate mounting enables skaters to achieve the control and responsiveness necessary to execute demanding maneuvers with confidence and consistency. Compromises in any of these areas can significantly impair skating ability and increase the risk of injury, underscoring the importance of investing in high-quality skates and skilled maintenance.

Frequently Asked Questions about Pro Ice Skates

This section addresses common inquiries concerning the selection, use, and maintenance of high-performance ice skates, designed for competitive and professional applications.

Question 1: What distinguishes high-performance ice skates from recreational models?

High-performance skates are characterized by superior materials, enhanced stiffness, customizable fit options, and optimized blade design, catering to the demands of professional athletes. Recreational skates typically prioritize comfort and affordability over performance characteristics.

Question 2: How critical is professional fitting for elite ice skates?

Professional fitting is paramount. An expert assessment ensures proper boot size, shape, and stiffness, optimizing energy transfer, minimizing discomfort, and reducing the risk of injuries associated with ill-fitting equipment.

Question 3: What role does blade material play in overall skate performance?

Blade material significantly affects edge quality, glide efficiency, and durability. High-carbon steel, frequently used in professional applications, provides a superior balance of hardness, wear resistance, and corrosion resistance for optimal control and longevity.

Question 4: What are the maintenance requirements for maintaining elite ice skates?

Routine maintenance involves drying the boots after each use, regularly sharpening the blades, protecting blades with guards when off the ice, and periodically checking and tightening screws to ensure stability and longevity of equipment.

Question 5: How often should ice skate blades be sharpened to maintain performance?

Sharpening frequency depends on usage intensity, ice conditions, and skating style. Regular sharpening, conducted by a skilled technician, is essential to maintaining optimal edge quality for control and performance.

Question 6: How does stiffness influence skating performance in different disciplines?

Stiffness affects energy transfer and control. Stiffer boots provide increased power transfer, crucial for disciplines such as hockey, while artistic skaters may opt for slightly less rigid boots to enable deeper knee bends and fluid movements.

Key takeaways include the necessity of professional fitting, the importance of high-quality blade materials, and the imperative for diligent maintenance to ensure peak performance and extend equipment lifespan.

The subsequent segment will delve into the potential future advancements and technological shifts expected to influence the evolution of high-performance ice skate design.

Pro Ice Skates

The preceding analysis has detailed the critical attributes of specialized footwear engineered for peak performance on ice. From material composition and boot stiffness to custom fitting and edge precision, each element contributes to the athlete’s capacity for control, agility, and power. Neglecting these specialized characteristics compromises performance and increases the risk of injury.

Therefore, selecting and maintaining professional-grade ice skates requires a commitment to precision and informed decision-making. The pursuit of excellence in ice sports demands careful attention to detail, ensuring that the equipment serves as an extension of the athlete’s skill and dedication. Continued innovation and adherence to best practices will undoubtedly shape the future of these critical instruments, enabling further advancements in athletic achievement.