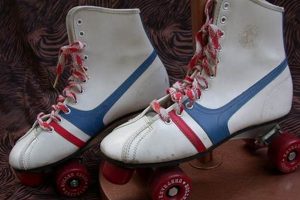

The term identifies a type of wheeled boot designed for recreational or competitive movement across surfaces. This equipment allows individuals to glide and maneuver, utilizing a frame affixed to the sole that holds a series of wheels. Users propel themselves through a combination of balance, coordination, and controlled leg movements.

These devices offer a low-impact cardiovascular workout, promoting physical fitness and coordination. Historically, these wheeled contraptions have evolved from simple inline configurations to variations with multiple wheels, impacting both speed and stability. Their adoption spans various disciplines, from artistic expression to competitive racing, offering a dynamic outlet for individuals of all ages and skill levels.

Understanding the mechanics and construction of such equipment is essential before considering their use. Factors such as wheel type, boot support, and brake systems play a critical role in safety and performance. The subsequent sections will detail these aspects, exploring the range of models available and their suitability for different environments.

Guidance on Wheeled Boot Selection and Usage

The following recommendations are provided to ensure responsible selection and effective use of this specialized footwear. Prioritizing safety and proper technique will maximize enjoyment and minimize the risk of injury.

Tip 1: Prioritize Proper Fit: Ensure the boot fits snugly but comfortably. Excess movement within the boot can lead to instability and blisters. A well-fitted boot enhances control and reduces the likelihood of ankle strain.

Tip 2: Evaluate Wheel Hardness: Wheel durometer impacts grip and speed. Softer wheels offer superior grip on slick surfaces, while harder wheels provide faster rolling speeds on smoother terrains. Select wheel hardness appropriate for the intended environment.

Tip 3: Regularly Inspect Equipment: Before each use, meticulously inspect the wheels, bearings, and frame for wear or damage. Loose components or compromised integrity can compromise safety. Replace worn parts promptly.

Tip 4: Master Fundamental Skills: Prioritize learning basic skills such as balancing, braking, and turning before attempting advanced maneuvers. Controlled movements are crucial for maintaining stability and preventing falls.

Tip 5: Utilize Protective Gear: Always wear appropriate protective gear, including a helmet, knee pads, elbow pads, and wrist guards. Impact protection is essential, particularly for beginners and when navigating challenging environments.

Tip 6: Practice in Safe Environments: Begin practicing in controlled, obstacle-free environments such as smooth pavement or designated skating areas. Gradually introduce more challenging terrains as proficiency increases.

Tip 7: Maintain Awareness of Surroundings: Remain vigilant and aware of surrounding obstacles, pedestrians, and traffic. Predictable movements and clear communication enhance safety in shared spaces.

Following these recommendations promotes a safer and more enjoyable experience. Consistent adherence to these principles minimizes risk and maximizes the potential for successful skill development.

The subsequent sections will delve into specific techniques and maintenance procedures, providing a comprehensive understanding of this recreational activity.

1. Boot Stability

Boot stability is a foundational element in the design and functionality of wheeled boots. It dictates the user’s ability to maintain balance, control movements, and minimize the risk of ankle injuries during operation. The structural integrity of the boot, particularly around the ankle area, directly influences the overall performance and safety of the equipment.

- Ankle Support Mechanisms

Ankle support mechanisms within the boot restrict excessive lateral and medial movement of the ankle joint. This can be achieved through rigid or semi-rigid shells, reinforced padding, and adjustable straps or buckles. Inadequate ankle support can lead to sprains, strains, and a reduced ability to execute precise maneuvers.

- Boot Height and Cuff Design

The height of the boot and the design of the cuff contribute significantly to ankle stability. Higher boot designs and cuffs provide greater support, limiting ankle flexion and extension. Conversely, lower-cut boots offer increased range of motion but may compromise stability, especially during high-impact activities.

- Material Properties and Construction

The materials used in the boot’s construction impact its ability to provide stable support. Stiffer materials, such as reinforced polymers or carbon fiber, offer greater rigidity and resistance to deformation. The method of construction, including stitching and bonding techniques, also contributes to the overall structural integrity of the boot.

- Lacing Systems and Closure Mechanisms

Effective lacing systems and closure mechanisms are critical for achieving a secure and customized fit. Properly tightened laces and straps help to minimize foot movement within the boot, maximizing energy transfer and reducing the risk of slippage or instability. Different lacing patterns and closure designs offer varying degrees of adjustability and support.

The integration of these stability-enhancing features directly impacts the usability and safety of wheeled boots across diverse applications. A well-engineered boot, prioritizing stability, enables users to confidently engage in various activities while minimizing the potential for injury.

2. Wheel Durometer

Wheel durometer, a crucial specification of wheeled boot wheels, directly impacts the equipment’s performance characteristics. Measured on the Shore A scale, durometer indicates the wheel’s hardness and, consequently, its grip and rolling efficiency. Lower durometer values denote softer wheels, providing increased grip on varied surfaces. Conversely, higher values signify harder wheels, optimized for speed and minimal rolling resistance on smooth terrains. Selection of an appropriate durometer wheel is contingent upon the intended use and the environment where the boots will be employed. For instance, a softer wheel might be preferential for outdoor recreational use on asphalt, offering enhanced control. Conversely, a harder wheel would be suited for indoor rink skating, promoting higher speeds.

The interplay between wheel durometer and surface conditions significantly influences the user experience. A mismatch between wheel hardness and surface texture can compromise safety and performance. Using overly hard wheels on a slick surface reduces traction, increasing the risk of slippage and loss of control. Conversely, excessively soft wheels on smooth surfaces can result in increased rolling resistance, reducing speed and efficiency. Competitive disciplines, such as speed skating or roller derby, necessitate careful consideration of wheel durometer to optimize performance within the specific track or arena conditions. Manufacturers provide durometer ratings to assist users in selecting the most appropriate wheels for their needs and skill level.

Therefore, comprehending wheel durometer is essential for maximizing the usability and safety of wheeled boots. Ignoring this specification can lead to suboptimal performance and an elevated risk of injury. Proper selection of wheels, based on the intended application and environmental conditions, ensures a balanced blend of grip, speed, and control. This understanding extends beyond casual use, permeating into specialized disciplines where marginal gains in performance are highly valued. Ultimately, the wheel durometer is a critical component influencing the overall effectiveness of the equipment.

3. Frame Material

The selection of frame material in wheeled boots directly impacts their performance, durability, and overall suitability for different skating styles and environments. The frame, serving as the structural backbone, connects the boot to the wheels, influencing stability, energy transfer, and responsiveness. Materials ranging from polymers to aluminum alloys are employed, each exhibiting distinct properties that affect the boot’s handling characteristics.

Aluminum alloys, known for their strength-to-weight ratio, are frequently utilized in high-performance models. Their rigidity enhances energy transfer, allowing for more efficient power transmission from the skater’s leg to the wheels. This translates into increased speed and responsiveness, crucial for competitive skating. Conversely, frames constructed from composite materials, such as reinforced polymers, offer greater shock absorption and vibration dampening, making them suitable for recreational skating and rougher surfaces. The choice between these materials, and others, is a deliberate engineering decision, balancing the need for performance with considerations of comfort and cost.

Ultimately, understanding the properties of different frame materials is essential for informed selection and optimal use. The frame material influences the skating experience by affecting factors such as speed, stability, and vibration absorption. Recognizing the strengths and weaknesses of each material allows skaters to choose equipment that aligns with their skill level, skating style, and intended use environment, thereby optimizing both performance and enjoyment.

4. Bearing Precision

Bearing precision within wheeled boots directly correlates with rolling efficiency and overall performance. As an integral component, bearings facilitate smooth wheel rotation, directly influencing the speed and glide characteristics of the equipment. Higher precision bearings, manufactured to tighter tolerances, minimize friction and rotational resistance. This reduction in friction translates to a more efficient energy transfer, allowing the user to achieve higher speeds with less effort.

The ABEC (Annular Bearing Engineering Committee) scale, a common industry standard, quantifies bearing precision. Higher ABEC ratings indicate tighter tolerances and superior manufacturing quality. While higher ABEC ratings typically correlate with improved performance, factors such as lubrication, bearing material, and maintenance also play a significant role. For example, a competitive speed skater would prioritize high ABEC-rated bearings with specialized lubrication to minimize friction and maximize speed on a smooth track. Conversely, a recreational user may find that lower ABEC-rated bearings, properly maintained, provide adequate performance for casual skating.

In summary, bearing precision is a critical element determining the performance of wheeled boots. The selection of appropriate bearings, considering factors such as ABEC rating, lubrication, and maintenance, is essential for optimizing rolling efficiency and maximizing user satisfaction. Recognizing the importance of bearing precision enables users to make informed decisions, selecting equipment that aligns with their specific needs and performance goals.

5. Braking System

The braking system on wheeled boots constitutes a crucial safety component directly impacting user control and risk mitigation. Its effectiveness is intrinsically linked to the ability to decelerate or stop safely, particularly in dynamic environments or during unexpected situations. Without a reliable braking mechanism, the inherent momentum associated with wheeled movement poses a significant hazard, potentially leading to collisions and injuries. The most common implementation involves a heel brake, an abrasion-resistant pad positioned at the rear of one or both boots, engaged by tilting the foot. Alternative systems may employ toe stops or more sophisticated inline braking mechanisms, each designed to provide controlled deceleration across various surfaces and skill levels. The selection and proper maintenance of the braking system are therefore paramount to safe operation. For instance, worn brake pads must be replaced promptly to ensure adequate stopping power. Neglecting this aspect compromises the entire safety profile of the equipment.

The implementation of effective braking systems necessitates a nuanced understanding of material science, biomechanics, and user ergonomics. Brake pad materials must exhibit high frictional coefficients to maximize stopping force while demonstrating durability to withstand repeated abrasion. Ergonomic design considerations ensure ease of engagement and modulation of braking force, allowing users to maintain balance and control during deceleration. The location and angle of the brake pad relative to the wheel are critical, optimizing contact area and minimizing the risk of slippage. Real-world applications highlight the importance of robust braking systems in preventing accidents in urban environments, skate parks, and during downhill skating. Proper technique, including weight distribution and controlled application of pressure, further enhances the effectiveness of the braking system, minimizing stopping distance and maintaining stability.

In conclusion, the braking system represents a fundamental safety feature of wheeled boots, directly influencing user control and the potential for injury mitigation. Its effectiveness is contingent upon design parameters, material selection, and user proficiency. Regular inspection and maintenance are essential to ensure optimal functionality. Continued research and development in braking system technology aim to enhance safety and performance, addressing challenges such as improved stopping distances and enhanced modulation capabilities across diverse terrains. The integration of advanced braking mechanisms underscores a commitment to user safety and the promotion of responsible skating practices.

Frequently Asked Questions About Specialized Wheeled Boots

This section addresses common inquiries regarding wheeled boots, providing concise and informative answers to ensure a comprehensive understanding of their functionality and application.

Question 1: What constitutes the primary difference between inline and quad wheeled boot configurations?

Inline configurations feature wheels arranged in a single line, facilitating increased speed and maneuverability. Quad configurations utilize two pairs of wheels, offering enhanced stability, particularly for beginners.

Question 2: How does wheel durometer affect performance in wheeled boots?

Wheel durometer, measured on the Shore A scale, indicates hardness. Lower durometer values denote softer wheels with increased grip. Higher durometer values signify harder wheels designed for speed on smooth surfaces.

Question 3: What role does bearing precision play in wheeled boot functionality?

Bearing precision, often quantified by the ABEC rating, influences rolling efficiency. Higher ABEC ratings indicate tighter tolerances and reduced friction, contributing to smoother and faster wheel rotation.

Question 4: How frequently should wheeled boot components undergo inspection and maintenance?

Prior to each use, wheels, bearings, frames, and braking systems should undergo thorough inspection for wear or damage. Regular maintenance, including cleaning and lubrication, should be performed to ensure optimal performance and safety.

Question 5: What safety precautions are essential when using wheeled boots?

Appropriate protective gear, including helmets, knee pads, elbow pads, and wrist guards, is mandatory. Controlled environments and awareness of surroundings are crucial to minimize the risk of accidents and injuries.

Question 6: How does frame material impact the performance characteristics of wheeled boots?

Frame material, ranging from aluminum alloys to composite polymers, influences weight, rigidity, and vibration dampening. Aluminum frames enhance energy transfer and responsiveness. Composite frames offer increased shock absorption.

These FAQs provide a foundational understanding of crucial aspects related to wheeled boots. Addressing these concerns promotes informed decision-making and facilitates safe and efficient utilization of the equipment.

The following section will delve into specific models and their applications, providing a comprehensive overview of the market landscape.

Concluding Insights on Pigeon Roller Skate

The preceding exploration has dissected the core components and considerations surrounding the term pigeon roller skate, analyzing elements from boot stability and wheel durometer to frame materials, bearing precision, and braking systems. The analysis underscores the importance of understanding each element in relation to user safety, performance optimization, and intended application. Rigorous adherence to safety protocols and informed component selection are essential for a safe and rewarding experience.

The future of pigeon roller skate technology hinges on continuous innovation in material science and biomechanical design. Further research into advanced braking systems and customized ergonomic solutions remains crucial for enhancing user safety and performance across diverse skill levels and environmental conditions. Continued diligence in promoting responsible usage and advocating for stringent safety standards will be instrumental in shaping the evolution of this specialized equipment.

![Buy Roller Skate Wheels Near Me: [Shop Name] Offers! Learn to Surf & Skate: A Beginner's Step-by-Step Guide Buy Roller Skate Wheels Near Me: [Shop Name] Offers! | Learn to Surf & Skate: A Beginner's Step-by-Step Guide](https://universitysurfandskate.com/wp-content/uploads/2026/03/th-51-300x200.jpg)