Equipment designed for gliding across ice surfaces, primarily for recreational or competitive purposes, facilitates movement and maneuverability. This type of equipment generally consists of a boot attached to a blade, allowing the wearer to propel themselves across the ice. The construction and design features often vary depending on the intended use, such as figure skating, hockey, or recreational skating.

The utilization of this equipment offers several advantages, including physical exercise, recreational enjoyment, and competitive opportunities. Historically, its development has been marked by continuous refinement in blade materials, boot construction, and overall design to improve performance, comfort, and safety. The availability of this equipment has significantly contributed to the popularity of ice sports and recreational activities.

The subsequent sections will delve into specific types of such gliding equipment, including variations tailored for different disciplines and skill levels. Furthermore, considerations for selecting appropriate equipment and maintenance practices will be discussed to ensure optimal performance and longevity.

Essential Considerations for Optimal Performance

The following guidance addresses crucial aspects relating to bladed footwear, aiming to enhance the user experience and ensure both safety and peak functionality.

Tip 1: Blade Alignment Verification: Precise blade alignment is paramount for stability and efficient gliding. Routine inspections by a qualified technician are recommended to identify and correct any misalignment issues.

Tip 2: Boot Fit Assessment: A secure and comfortable boot fit is essential. Ill-fitting boots can lead to discomfort, blisters, and compromised performance. Professional fitting services are advised.

Tip 3: Blade Sharpening Regularity: Consistent blade sharpness is crucial for maintaining edge control. The frequency of sharpening depends on usage and ice conditions; however, regular maintenance schedules should be established.

Tip 4: Proper Lacing Technique: Correct lacing techniques provide optimal support and ankle stability. Variations in lacing patterns can be employed to address specific comfort or performance needs.

Tip 5: Protective Gear Utilization: The use of appropriate protective equipment, such as helmets and padding, mitigates the risk of injury, particularly for beginners or those attempting challenging maneuvers.

Tip 6: Edge Control Development: Mastery of edge control is fundamental for executing advanced techniques and maintaining balance. Dedicated practice and instruction are essential for skill development.

Tip 7: Moisture Management Protocol: Thoroughly drying the blades and boots after each use prevents rust and material degradation. Protective covers should be employed during storage to minimize environmental exposure.

Adhering to these recommendations contributes to a safer and more rewarding experience, promoting longevity of the equipment and enhancing overall performance.

The subsequent section will examine advanced techniques and strategies for skill enhancement, building upon the foundational principles outlined above.

1. Blade Material

Blade material significantly influences the performance characteristics of ice skates. The choice of material affects factors such as edge retention, gliding speed, and overall durability. Carbon steel, stainless steel, and various alloys are common choices, each presenting a different balance of these properties. For example, carbon steel blades offer superior edge sharpness initially but are more prone to rust, necessitating diligent maintenance. Stainless steel blades, conversely, exhibit greater corrosion resistance but may require more frequent sharpening to maintain optimal edge quality.

The effect of blade material selection extends to specific skating disciplines. Figure skates often utilize specialized alloys designed for precise edge control and intricate movements. Hockey skates prioritize durability and impact resistance, frequently incorporating materials capable of withstanding high-speed collisions. Recreational skates may compromise between cost-effectiveness and moderate performance, using materials that offer a balance of durability and affordability. The proper selection, therefore, is crucial for maximizing performance and safety within the intended skating context.

Understanding the relationship between blade material and performance is paramount for both skaters and equipment manufacturers. Correct material selection can lead to improved skating proficiency, enhanced safety, and extended equipment lifespan. Challenges remain in developing materials that simultaneously offer exceptional edge retention, corrosion resistance, and impact durability at a reasonable cost. Ongoing research and development efforts aim to address these challenges, pushing the boundaries of ice skate technology and providing skaters with improved equipment options.

2. Boot Construction

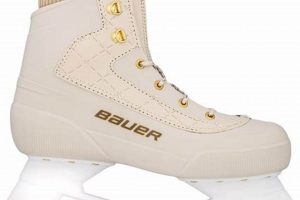

Boot construction is integral to the performance and safety characteristics of specialized footwear used for gliding on ice. The boot serves as the primary interface between the skater and the blade, dictating energy transfer, stability, and control. Variations in materials, design, and manufacturing techniques directly impact the skaters ability to execute maneuvers and maintain balance. For instance, a rigid boot shell, commonly found in hockey models, provides enhanced ankle support and power transfer, facilitating quick acceleration and sharp turns. Conversely, figure skating models often incorporate a more flexible construction, allowing for greater range of motion and artistry in movements.

The materials used in boot construction range from natural leather to advanced synthetic composites. Leather offers breathability and can mold to the skaters foot over time, providing a customized fit. Synthetic materials, such as molded polymers and carbon fiber, offer superior durability, water resistance, and reduced weight. The choice of material influences the boots stiffness, responsiveness, and thermal properties. Precise stitching, padding, and lacing systems contribute to the overall fit and comfort of the boot, reducing the risk of blisters and pressure points. The height and shape of the boot collar also play a critical role in ankle support and mobility.

Ultimately, effective boot construction contributes to a synergistic relationship between the skater, the boot, and the blade, resulting in enhanced performance, reduced risk of injury, and increased enjoyment. Improper boot construction, conversely, can lead to instability, discomfort, and compromised skating technique. Ongoing research and development efforts continue to refine boot designs and materials, striving to optimize the skater’s experience and push the boundaries of performance.

3. Ankle Support

Ankle support in ice skating equipment is a critical design element directly influencing performance, stability, and injury prevention. Insufficient ankle support can lead to instability, hindering the skater’s ability to maintain balance and execute precise movements. Conversely, excessive rigidity can restrict range of motion, limiting agility and finesse. Therefore, the level and type of support must align with the skater’s skill level, skating discipline, and individual anatomical needs.

The provision of adequate ankle support is often achieved through a combination of structural design features, material selection, and lacing systems. High-cut boot designs, reinforced with stiff materials like molded polymers or layered leather, provide greater lateral stability. Integrated padding and contoured shaping conform to the ankle’s anatomy, distributing pressure and preventing chafing. Lacing systems, when properly implemented, allow for customized adjustments, enabling skaters to fine-tune the level of support based on their preference and activity requirements. In hockey, for instance, rapid directional changes necessitate robust ankle support to prevent sprains and maintain control during aggressive maneuvers. Similarly, figure skating demands both stability and flexibility to facilitate intricate jumps and spins, requiring a more nuanced approach to ankle support design.

Therefore, optimized ankle support is an essential component of a well-designed ice skating product. Careful consideration of biomechanical principles and user-specific needs is crucial in achieving a balance between stability, flexibility, and comfort. Neglecting this aspect can compromise performance, increase the risk of injury, and detract from the overall skating experience. Ongoing advancements in materials and construction techniques continue to refine ankle support designs, offering skaters enhanced comfort, stability, and control on the ice.

4. Blade Sharpening

The efficacy of bladed footwear designed for traversing ice surfaces hinges significantly on the condition of the blade’s edge. Blade sharpening directly influences the skater’s ability to maintain control, execute maneuvers, and achieve desired speed. A dull blade compromises the skater’s grip on the ice, increasing the risk of slippage and reducing overall performance. Conversely, a properly sharpened blade creates a clean, precise edge that allows for controlled gliding and efficient energy transfer. The frequency of sharpening depends on factors such as ice conditions, the skater’s skill level, and the type of skating performed. For example, figure skaters, who rely on precise edge work for jumps and spins, typically require more frequent sharpening than recreational skaters. Neglecting blade maintenance inevitably leads to diminished performance and increased risk of injury.

The sharpening process itself involves carefully grinding the blade to create a hollow, which is a concave shape running along the length of the blade. This hollow creates two distinct edges that bite into the ice, providing the skater with grip and control. The depth of the hollow, often referred to as the “radius of hollow,” can be adjusted to suit the skater’s preferences and the prevailing ice conditions. A deeper hollow provides more grip, but it can also slow the skater down. A shallower hollow allows for faster gliding, but it may reduce edge control. Improper sharpening techniques can damage the blade, rendering it unusable or compromising its structural integrity. Therefore, professional sharpening services are often recommended to ensure that the blade is sharpened correctly and safely.

In conclusion, blade sharpening is not merely a maintenance task but rather an integral component of maximizing the performance and safety. Consistent maintenance of edge sharpness preserves a skater’s ability to glide, turn, and maneuver effectively. The direct correlation between blade condition and skating ability underscores the practical significance of this knowledge, reinforcing the importance of regular professional attention to ensure longevity and safe usage.

5. Fit Accuracy

Accurate fit is paramount when selecting specialized footwear designed for ice surfaces. The interaction between the foot and the equipment directly influences performance, comfort, and safety. Compromised fit negates potential advantages offered by design and materials, increasing the risk of injury and hindering skill development.

- Length Matching

Proper length matching ensures the toes have adequate space without being cramped, preventing discomfort and potential injuries such as blisters or neuromas. Incorrect length can also impact balance and control, particularly during advanced maneuvers.

- Width Accommodation

Width accommodation is critical for maintaining circulation and preventing lateral foot movement within the boot. Insufficient width can cause pressure points and numbness, while excessive width reduces stability and responsiveness during turns and edges.

- Ankle Confinement

Secure ankle confinement stabilizes the joint, providing support during demanding movements and minimizing the risk of sprains. Inadequate ankle support compromises balance and increases vulnerability to injury, particularly for beginners or those attempting complex skills.

- Arch Support Conformity

Correct arch support conformity maintains proper foot alignment, reducing strain on the plantar fascia and preventing overpronation or supination. Inadequate arch support can lead to foot fatigue, pain, and potential long-term biomechanical issues.

Achieving precise fit accuracy requires careful measurement and assessment, often necessitating professional fitting services. Failure to prioritize fit negates the intended benefits of advanced designs and materials, compromising the user experience and increasing the risk of complications. The relationship between proper fit and user satisfaction underscores the importance of this consideration.

6. Rust Prevention

The materials used in the construction of bladed footwear designed for ice surfaces, particularly the blades themselves, are often susceptible to corrosion when exposed to moisture. The nature of the activity, which involves direct contact with ice and subsequent exposure to ambient humidity, creates an environment conducive to rust formation. Rust, or iron oxide, weakens the metal, degrades the blade’s edge, and ultimately diminishes the performance and lifespan of the equipment. Consequently, rust prevention is not merely a cosmetic concern but a critical aspect of maintaining the functionality and structural integrity of such equipment. The severity of rust formation varies depending on blade composition, with high-carbon steel being particularly vulnerable.

Effective rust prevention strategies include diligent drying of the blades after each use, application of protective coatings such as silicone sprays or blade oils, and storage in a dry environment. Blade covers, often made of terry cloth or absorbent materials, serve to wick away moisture and prevent condensation. Regular inspection of the blades for any signs of rust is also essential, allowing for prompt remediation with appropriate rust removal products. Neglecting these preventive measures leads to accelerated corrosion, necessitating costly repairs or replacements. Consider, for instance, the impact on competitive skaters, where even minor imperfections in the blade can significantly affect performance. In such cases, rust prevention becomes a matter of maintaining a competitive edge.

The importance of rust prevention extends beyond individual users to manufacturers and retailers. Product design incorporating corrosion-resistant materials, such as stainless steel or coated alloys, contributes to the overall durability and value of the equipment. Providing clear instructions on proper care and maintenance reinforces the user’s responsibility in rust prevention. While complete elimination of rust may be unattainable, proactive measures minimize its impact and extend the life of the blade. Rust prevention is thus an essential element in ensuring satisfactory performance and long-term usability.

7. Sport Specificity

Sport specificity dictates the design and functional characteristics of ice skates, directly influencing performance and safety. The demands of figure skating differ significantly from those of hockey or recreational skating, necessitating distinct equipment configurations. For instance, figure skates prioritize blade curvature and toe picks for jumps and spins, while hockey skates emphasize ankle support and blade length for speed and agility. Recreational skates often feature a more generalized design, balancing comfort and stability for casual use. The improper selection of skates based on sport specificity can compromise performance, increase the risk of injury, and detract from the overall skating experience. Therefore, understanding the specific requirements of each skating discipline is paramount for optimal equipment selection.

The cause-and-effect relationship between sport specificity and ice skate design is evident in the materials used, the blade geometry, and the boot construction. Hockey skates, for example, utilize reinforced materials to withstand high-impact collisions and provide robust ankle support for rapid directional changes. Figure skates, conversely, incorporate lightweight materials and flexible ankle designs to facilitate intricate movements and artistic expression. The blade curvature, known as the rocker, varies depending on the sport, influencing maneuverability and gliding efficiency. Moreover, the presence or absence of toe picks, a defining feature of figure skates, directly impacts the skater’s ability to perform jumps and spins. These design variations reflect the distinct biomechanical demands and performance objectives of each sport.

In conclusion, sport specificity is a fundamental consideration in ice skate selection. The distinct requirements of each skating discipline necessitate tailored equipment designs to optimize performance, ensure safety, and enhance the overall skating experience. A comprehensive understanding of these sport-specific demands, along with professional guidance, facilitates informed decision-making, enabling skaters to choose equipment that aligns with their individual needs and goals. This is significant for enhancing the experience in skating or avoiding possible injuries.

Frequently Asked Questions

This section addresses common inquiries regarding specialized footwear utilized on ice surfaces, providing clarity on various aspects of their selection, maintenance, and performance.

Question 1: What factors determine the appropriate bladed footwear size?

Foot length and width are primary determinants of size. Additionally, internal boot volume and sock thickness should be considered. Professional fitting services are recommended to ensure accurate sizing.

Question 2: How frequently should the blades be sharpened?

Sharpening frequency depends on usage, ice conditions, and skating discipline. Competitive skaters typically require more frequent sharpening than recreational users. A professional assessment of edge condition is advisable to determine the optimal sharpening schedule.

Question 3: What materials are commonly used in blade construction?

Carbon steel, stainless steel, and various alloy blends are prevalent. Carbon steel provides initial sharpness but is susceptible to rust. Stainless steel offers corrosion resistance but may require more frequent sharpening. Alloy blends aim to balance these properties.

Question 4: How can rust formation on blades be prevented?

Thorough drying after each use, application of protective coatings, and storage in a dry environment are essential. Blade covers made of absorbent materials further mitigate moisture exposure. Regular inspection for signs of rust allows for timely remediation.

Question 5: What distinguishes bladed footwear designed for different skating disciplines?

Figure skating models typically feature toe picks and a curved blade profile, facilitating jumps and spins. Hockey models emphasize ankle support and blade length for speed and agility. Recreational models offer a balance of comfort and stability for general use.

Question 6: How does boot construction influence performance and safety?

Rigid boot shells provide enhanced ankle support and power transfer, while flexible constructions allow for greater range of motion. Material selection impacts durability, water resistance, and thermal properties. Proper fit is crucial for comfort, stability, and injury prevention.

Adherence to these recommendations contributes to enhanced performance, prolonged equipment lifespan, and minimized risk of complications.

The following section will examine advanced techniques and strategies for skill enhancement, building upon the foundational principles outlined above.

Concluding Remarks on Bladed Footwear

The preceding exploration has detailed the multifaceted nature of bladed footwear designed for use on ice surfaces. From material composition and blade geometry to boot construction and maintenance protocols, each element contributes significantly to performance, safety, and longevity. A comprehensive understanding of these factors is essential for both users and manufacturers to ensure optimal utilization of this specialized equipment.

Continued advancements in materials science, biomechanical engineering, and manufacturing techniques hold the potential to further refine bladed footwear design, enhancing athletic performance and mitigating the risk of injury. Prioritizing research and development, coupled with adherence to established best practices, will solidify the role of bladed footwear in both recreational pursuits and competitive sports.