Footwear designed for gliding across ice surfaces, frequently seen in a bright, unadulterated hue, represents a significant component of various winter sports and recreational activities. As a prime example, consider the figure skating discipline, where the visual aesthetic of the equipment often complements the athlete’s performance and attire. The specific shade in question can contribute to the overall presentation, aligning with themes and enhancing the artistic impression conveyed to the audience and judges.

The selection of this particular coloration provides benefits beyond mere aesthetics. Historically, the visibility of equipment on the ice surface has been crucial for safety and coordination, particularly in team sports like ice hockey. Furthermore, the visual appeal of gear can significantly impact consumer preference and drive market trends. These factors highlight the nuanced role of coloration in the context of sporting equipment, balancing functionality with cultural and commercial considerations.

The subsequent sections will delve deeper into the manufacturing processes of such equipment, examining the materials used, the technological advancements that have improved their performance, and the proper maintenance procedures essential for longevity and safety. Specific attention will be given to the considerations involved in selecting the appropriate equipment for different skill levels and skating disciplines.

Essential Considerations for Maintaining Pristine Ice Skates

Maintaining the visual appeal and optimal performance of ice skates requires diligent care and attention to detail. Addressing the challenges of ice conditions and the inevitable wear and tear is paramount for both aesthetic satisfaction and functional longevity.

Tip 1: Regular Cleaning is Crucial: Immediately following each use, meticulously wipe down the entire boot surface. This removes moisture, salt, and other debris accumulated during skating, which can lead to discoloration and material degradation. Employ a clean, soft cloth for this purpose.

Tip 2: Protect Blades from Rust: Moisture is a primary catalyst for rust formation on the blades. After cleaning the blades, thoroughly dry them. Consider applying a thin layer of lubricant, such as silicone-based spray, to provide a protective barrier against oxidation.

Tip 3: Proper Storage is Essential: Store the skates in a well-ventilated environment. Avoid enclosing them in airtight bags or containers, as this can trap moisture and promote mold growth. Use skate guards when transporting or storing the skates to protect the blades from damage.

Tip 4: Consider Protective Coatings: For particularly harsh skating environments or frequent use, explore applying a protective coating to the boot’s surface. This can shield against scuffs, stains, and UV damage, preserving the original finish.

Tip 5: Prompt Stain Removal: Address any stains or discolorations immediately. Use a mild cleaning solution specifically designed for the boot material. Avoid harsh chemicals or abrasive cleaners, which can damage the finish.

Tip 6: Professional Maintenance: Schedule regular professional maintenance for the skates. This includes blade sharpening, boot adjustments, and thorough cleaning. A qualified technician can identify and address potential issues before they escalate.

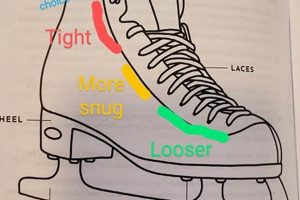

Tip 7: Inspect Laces Regularly: Laces contribute to the overall aesthetic and functional integrity of the skates. Regularly inspect laces for wear and tear, replacing them as needed. Consider using laces that are specifically designed to resist discoloration and maintain their visual appeal.

Adhering to these guidelines will significantly extend the lifespan of ice skates, preserving their visual appeal and ensuring optimal performance. Consistent maintenance practices minimize the risk of damage and maintain the desired pristine appearance.

The following section will address advanced techniques for restoring damaged or heavily soiled equipment, providing a comprehensive guide to maintaining ice skates in optimal condition.

1. Visual Appeal

Visual appeal, in the context of ice skates, significantly influences perceived performance and aesthetic value. The color of the equipment directly impacts its visibility, its role in artistic performances, and its marketability.

- Aesthetic Harmony and Impression Management

The pristine coloration of ice skates contributes to the overall aesthetic harmony of figure skating performances. It complements costumes and routines, enhancing the artistic impression conveyed to judges and audiences. The choice of color can be strategically employed to project an image of purity, precision, or elegance, all of which are desirable qualities in competitive skating.

- Brand Identity and Consumer Preference

The visual presentation of equipment is a key factor in brand recognition and consumer purchasing decisions. The association of a particular shade with a brand can create a strong visual identity, fostering customer loyalty. A bright, untarnished finish is often perceived as indicative of quality and craftsmanship, thereby influencing consumer preference.

- Visibility and On-Ice Presence

The distinct visual characteristic of skates enhances visibility on the ice surface, especially during group performances or fast-paced hockey games. Enhanced visibility aids in player coordination, reduces the risk of collisions, and contributes to a more engaging spectator experience. The high contrast between the equipment and the ice improves the on-ice presence of the athlete or team.

- Perceived Cleanliness and Maintenance

A clean, unblemished finish conveys a sense of meticulous maintenance and care. It suggests that the equipment is well-maintained and in optimal condition, even if it has been used extensively. This perception can enhance confidence in the equipment’s performance and longevity. Conversely, soiled or discolored skates may detract from the perceived quality and overall visual appeal.

These interconnected facets demonstrate the crucial role of visual appeal in the context of ice skates. The aesthetic considerations extend beyond mere decoration, influencing performance, consumer perception, and overall satisfaction with the equipment. A deliberate emphasis on visual elements, from color selection to meticulous maintenance, elevates the overall value and impact of ice skates in both competitive and recreational settings.

2. Material durability

Material durability is a paramount consideration in the manufacture and usage of ice skates. The selection of materials and their resistance to wear, tear, and environmental factors directly impact the lifespan, performance, and safety of the equipment. This is especially pertinent for ice skates, where the pristine appearance often desired by users is intrinsically linked to the robustness of the materials used.

- Polymer Integrity and Color Retention

The polymeric materials commonly used in the construction of ice skate boots are susceptible to degradation from UV exposure, ice abrasion, and repeated flexing. This degradation can manifest as cracking, discoloration, and a general loss of structural integrity. Therefore, the choice of polymers with inherent UV resistance and high flexural strength is crucial for maintaining the desired color and overall durability. For example, thermoplastic polyurethanes (TPUs) are often preferred for their abrasion resistance and ability to retain color even under harsh conditions.

- Blade Hardness and Corrosion Resistance

The blades of ice skates are subjected to continuous friction against the ice surface, necessitating the use of high-carbon steel alloys. These alloys must be heat-treated to achieve the appropriate hardness for edge retention while simultaneously possessing sufficient corrosion resistance to withstand exposure to moisture and de-icing chemicals. Regular maintenance, such as drying and lubricating the blades, is essential to mitigate corrosion and preserve the blade’s structural integrity.

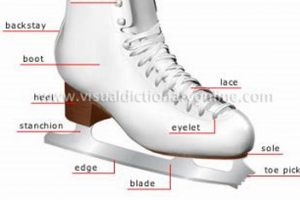

- Fastener Security and Environmental Resistance

Fasteners, such as rivets, screws, and eyelets, play a critical role in securing the various components of the ice skate. These fasteners must be constructed from materials that resist corrosion and maintain their structural integrity under stress and exposure to moisture. Stainless steel or other corrosion-resistant alloys are commonly employed to prevent loosening or failure of the fasteners, which could compromise the safety and performance of the skate.

- Liner and Padding Degradation

The liners and padding inside ice skate boots provide cushioning, support, and insulation. Over time, these materials can degrade due to compression, moisture absorption, and the growth of microorganisms. The selection of materials with inherent antimicrobial properties and resistance to compression set is essential for maintaining comfort, hygiene, and structural integrity. Regularly airing out and cleaning the liners can also prolong their lifespan and prevent the build-up of odors.

The long-term maintenance of ice skates’ appearance and functionality directly hinges on material durability. The interplay between the materials used in construction and the environmental challenges encountered on the ice dictates the need for quality components and proper care. Attention to these material aspects ultimately leads to a longer lifespan, improved safety, and sustained visual appeal.

3. Performance visibility

The characteristic of equipment on ice influences its visibility to athletes, officials, and spectators. Enhanced performance visibility translates to improved situational awareness, reduced risk of collisions, and increased opportunities for strategic play. Equipment featuring a pristine finish, specifically, optimizes visibility due to its high reflectivity and contrast against the ice surface. This increased visibility supports safety protocols and contributes to competitive advantage by allowing for quicker recognition and reaction to movement.

In team sports such as ice hockey, performance visibility is crucial. For instance, players need to rapidly identify teammates’ positions and movements. Utilizing equipment with enhanced visual characteristics, such as bright protective padding, can assist in this identification process. Similarly, officials rely on clear visibility of equipment to adjudicate plays accurately. A easily distinguishable surface aids in determining infractions and maintaining the integrity of the game.

The relationship between performance visibility and equipment is significant. Equipment with specific reflective qualities optimizes visual clarity, enhancing safety and competitive opportunities. Understanding this dynamic is essential for athletes, coaches, and manufacturers aiming to optimize on-ice performance. Prioritizing clear equipment choices contributes to a safer and more engaging sporting environment, supporting the overall quality of the athletic endeavor.

4. Surface cleanliness

Surface cleanliness is a critical determinant of the visual appearance and functional lifespan of ice skates, particularly those with a pale finish. A clean surface on equipment minimizes the accumulation of dirt, ice debris, and residues from ice resurfacing chemicals, all of which can compromise the aesthetic quality of the equipment. The inherent brightness of surface renders it especially susceptible to visible staining and discoloration. Consequently, maintaining surface cleanliness is not merely an aesthetic consideration but a practical necessity for preserving the integrity and longevity of the materials used in ice skate construction.

The connection between surface cleanliness and the prolonged usability of is exemplified in the field of figure skating, where equipment often must retain a pristine appearance for competitive events. In these contexts, skaters and their support teams frequently employ specialized cleaning agents and maintenance protocols to remove scuff marks, water spots, and other surface imperfections. Neglecting routine cleaning can lead to the gradual buildup of contaminants that can degrade the surface finish. The accumulation can compromise the reflective properties of materials, thus diminishing the equipments visual appeal and potentially impacting its perceived value.

In summary, surface cleanliness directly influences both the aesthetic and functional characteristics. The proactive approach in maintaining cleanliness through regular cleaning routines, appropriate cleaning products, and protective measures can significantly extend the lifespan of equipment. Surface cleaning protects from material degradation and maintains visual appeal. The long-term benefits of this understanding range from preserving the investment in expensive equipment to improving the overall appearance and usability of essential ice sports gear.

5. Color Maintenance

The preservation of the specific hue in ice skates is a significant maintenance concern directly impacting their perceived value and aesthetic appeal. The intrinsic nature of materials used in the manufacturing process makes them susceptible to discoloration from multiple sources, including ultraviolet radiation, physical abrasion, and chemical exposure. Effective color maintenance practices are thus not merely cosmetic; they are integral to extending the usable life and maintaining the market value of the equipment. The selection of color-stable polymers, the application of protective coatings, and the implementation of proper cleaning protocols are all essential elements in mitigating the detrimental effects of these environmental factors.

Consider, for example, the common issue of yellowing observed in skate boots constructed from certain polymers. This phenomenon, primarily driven by UV exposure, can drastically alter the intended appearance and reduce the equipment’s desirability. To combat this, manufacturers often incorporate UV stabilizers into the polymer matrix or apply a UV-resistant coating to the surface. Furthermore, regular cleaning with pH-neutral solutions can prevent the accumulation of residues that exacerbate discoloration. The application of blade guards when skates are not in use also helps to prevent the chemical corrosion of the blade that could affect the boots’ color over time.

In conclusion, color maintenance represents a critical aspect of ice skate ownership. The challenges associated with preventing discoloration and preserving the intended color necessitate a comprehensive approach, encompassing material selection, protective measures, and conscientious maintenance practices. Failure to address these challenges results in a reduction in aesthetic value, which often translates directly to diminished market value and a shorter effective lifespan of the equipment. Successful color maintenance, conversely, ensures sustained visual appeal and prolongs the overall usability of equipment.

6. Contrast Enhancement

Contrast enhancement, in the context of equipment used on ice surfaces, directly influences visibility and visual acuity for athletes, officials, and spectators. The interplay between equipment and the ice background dictates the effectiveness of contrast enhancement strategies. The subsequent discussion outlines critical facets of contrast enhancement specific to equipment used in icy environments.

- Chromatic Adaptation and Perceptual Acuity

Chromatic adaptation refers to the human visual system’s ability to adjust to changes in illumination to maintain consistent color perception. However, under the uniform luminance conditions often present on ice rinks, chromatic adaptation can reduce the perceived contrast between equipment and the ice surface. Enhancing the equipment’s color saturation and luminance through targeted color selection mitigates this effect, thus promoting perceptual acuity and enabling faster recognition.

- Silhouette Definition and Edge Detection

The definition of an object’s silhouette is essential for rapid visual processing. Sharp, well-defined edges facilitate edge detection, a fundamental process in visual perception. Applying darker shades or strategically placed color bands along the edges of equipment creates a higher contrast ratio, improving silhouette definition and making the equipment more easily discernible against the reflective ice background. This is particularly critical in fast-paced sports where split-second decisions rely on accurate visual information.

- Spectral Reflectance and Illumination Conditions

The spectral reflectance properties of equipment materials determine how effectively they reflect light under various illumination conditions. Materials with high reflectance values in spectral regions that are prevalent in indoor ice rinks or outdoor sunlight maximize contrast enhancement. Conversely, materials that absorb a significant portion of incident light will exhibit lower contrast, potentially reducing visibility. Therefore, selecting materials with tailored spectral reflectance profiles is essential for optimizing visual performance.

- Pattern Design and Visual Disruption

Strategic pattern design can disrupt the visual background and further enhance contrast. Utilizing geometric patterns or contrasting color blocks creates visual cues that improve the equipment’s conspicuity. However, it is essential to avoid patterns that induce visual illusions or interfere with the observer’s ability to accurately perceive the equipment’s form and movement. A balance between contrast enhancement and perceptual clarity is therefore paramount in effective pattern design.

The effective deployment of contrast enhancement techniques can substantially improve the visibility and recognition of equipment on ice surfaces. In the specific instance, strategically enhancing its contrast is vital for promoting safety, optimizing performance, and ensuring clear visual communication within the sporting environment.

Frequently Asked Questions

This section addresses common inquiries and concerns related to ice skates, particularly focusing on aspects relevant to equipment of that coloration. These answers provide clarity regarding maintenance, performance, and material considerations.

Question 1: What are the primary advantages of selecting an equipment with this coloration?

The principal advantage lies in enhanced visibility on the ice surface. The increased visibility promotes safer skating conditions and aids in visual tracking during team sports. Additionally, this distinct coloration can enhance the aesthetic appeal, aligning with figure skating aesthetics and performance presentation.

Question 2: How does one effectively prevent the discoloration or yellowing?

Preventive measures include regular cleaning with pH-neutral solutions, protection from prolonged ultraviolet radiation exposure, and the avoidance of abrasive cleaning agents. Storage in a dry, well-ventilated environment can also mitigate discoloration. Applying specific protectant sprays can also provide an extra layer of defense.

Question 3: What materials are best suited for maintaining the visual appeal over extended periods?

Polymeric materials with inherent ultraviolet resistance and high flexural strength are preferred. Thermoplastic polyurethanes (TPUs) are often selected due to their abrasion resistance and capacity to retain color under demanding conditions. High-quality, color-stable dyes are also crucial in the manufacturing process.

Question 4: Are there any specific cleaning products or techniques that should be avoided?

Avoid abrasive cleaners, solvents, and bleaching agents, as these can damage the surface finish and accelerate discoloration. Similarly, avoid harsh scrubbing or the use of hard-bristled brushes, which can scratch the material. Always test cleaning products on a small, inconspicuous area before applying them to the entire surface.

Question 5: How does the color impact performance visibility in different lighting conditions?

The high reflectivity enhances visibility in both indoor and outdoor environments, provided that the surface is clean and well-maintained. However, direct glare from intense lighting can, in some instances, reduce visibility. In such cases, strategic placement of contrasting elements can mitigate this effect.

Question 6: What is the typical lifespan of equipment of this type, and how does maintenance influence it?

The typical lifespan is contingent on usage frequency, intensity, and adherence to proper maintenance protocols. Consistent cleaning, diligent protection against environmental factors, and timely repairs can significantly extend the equipment’s lifespan. Neglecting maintenance can substantially reduce its usability and visual appeal.

Consistent maintenance, including regular cleaning and protection from the elements, is critical for preserving the visual appeal and prolonging the lifespan of equipment. Choosing the right cleaning products and storage methods is also essential.

The subsequent section will delve into the advanced techniques of ice skate customization, focusing on how alterations can enhance both performance and individual style.

Conclusion

The preceding analysis has thoroughly examined “ice skates white” through multiple lenses, encompassing aesthetic considerations, material durability, performance visibility, maintenance protocols, and contrast enhancement strategies. The significance of these factors, individually and collectively, contributes substantially to the equipment’s value proposition within both recreational and competitive ice sports contexts. The selection, maintenance, and utilization of equipment necessitate informed decision-making to optimize functionality, safety, and visual appeal.

Therefore, the continued pursuit of innovation in materials science, cleaning technologies, and design methodologies remains paramount to advancing the performance and longevity of ice skates. The synthesis of these considerations facilitates a superior skating experience and ensures the enduring relevance of essential equipment across a spectrum of ice-related activities. Further research into sustainable materials and advanced manufacturing techniques will undoubtedly shape the future of ice skate technology and aesthetic design.