This equipment, vital for ice hockey and recreational skating, comprises specialized footwear with blades attached to the soles. These implements facilitate movement across frozen surfaces, enabling users to glide and maneuver with precision. A specific brand known for manufacturing high-quality versions of this essential gear has been a prominent figure in the sporting goods industry for decades.

The brand’s significance stems from its long-standing commitment to innovation and performance. Over the years, the company has introduced numerous advancements in design and materials, contributing significantly to the evolution of the sport. These enhancements have resulted in improved comfort, support, and ultimately, enhanced athletic performance for skaters at all levels. Its reputation is built upon a history of delivering reliable and durable products, earning the trust of both amateur and professional athletes.

The following sections will delve into specific aspects of ice skate construction, technological advancements within the industry, and considerations for selecting the appropriate equipment based on individual needs and skill levels.

Selecting and Maintaining Performance Ice Skates

Optimizing performance requires careful consideration of both selection and maintenance. The following tips provide essential guidance for ensuring longevity and maximizing effectiveness.

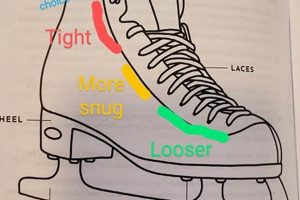

Tip 1: Proper Fit is Paramount. Ill-fitting equipment can hinder performance and increase the risk of injury. A professional fitting is highly recommended to ensure correct sizing and contouring to the individual’s foot.

Tip 2: Understand Blade Profiles. Different blade profiles cater to distinct skating styles. A deeper rocker facilitates tighter turns, while a flatter profile provides enhanced stability and speed. Consult with a skate technician to determine the appropriate profile.

Tip 3: Heat Molding for Customization. Many high-performance models feature heat-moldable materials. This process allows the skate to conform to the unique shape of the foot, providing a more secure and comfortable fit. Follow the manufacturer’s instructions carefully during the heat molding process.

Tip 4: Regular Blade Sharpening. Sharp blades are crucial for maintaining edge control and maximizing skating efficiency. The frequency of sharpening depends on usage and ice conditions. A professional sharpening is recommended to ensure consistent and accurate results.

Tip 5: Drying After Each Use. Moisture can corrode blades and degrade boot materials. After each use, thoroughly dry the equipment with a clean cloth and allow them to air dry completely before storing.

Tip 6: Blade Guards for Protection. Always use blade guards when walking on surfaces other than ice. This prevents damage to the blades and prolongs their lifespan. Hard guards should be used for walking, and soft guards are suitable for storage to absorb residual moisture.

Tip 7: Inspect Equipment Regularly. Periodically examine the boots, blades, and rivets for signs of wear or damage. Promptly address any issues to prevent further deterioration and maintain safety.

By adhering to these guidelines, users can significantly enhance the performance and longevity of their equipment, ensuring optimal comfort and control on the ice.

The subsequent sections will explore advanced customization options and troubleshooting common equipment-related issues.

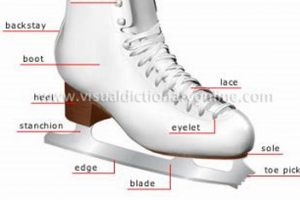

1. Precision Blade Design

Precision blade design is a cornerstone of high-performance ice skates, significantly impacting a skater’s agility, speed, and overall control. A specific brand has invested heavily in research and development to optimize blade characteristics for various skating styles and skill levels.

- Blade Profile and Radius

The curvature of the blade, both in terms of the rocker (front to back) and the radius of hollow (edge sharpness), directly influences turning ability and glide efficiency. A more pronounced rocker facilitates tighter turns, crucial for hockey players, while a flatter profile enhances straight-line speed, beneficial for speed skaters. The company offers various blade profiles tailored to specific skating disciplines.

- Steel Quality and Hardness

The type of steel used determines the blade’s ability to hold an edge and resist wear. Higher-quality steel, often with increased hardness ratings, requires less frequent sharpening and provides more consistent performance over time. The brand utilizes different steel alloys in its blade construction to achieve optimal balance between durability and performance.

- Blade Holder Integration

The connection between the blade and the boot, known as the blade holder, plays a vital role in energy transfer and responsiveness. A stiff and well-integrated blade holder minimizes energy loss during skating, allowing for more efficient strides and quicker reactions. The company employs advanced composite materials and innovative designs in its blade holders to maximize performance.

- Blade Finish and Coating

The surface finish and any applied coatings can affect blade glide and corrosion resistance. A smooth, polished finish reduces friction against the ice, enhancing speed and efficiency. Protective coatings can prevent rust and corrosion, extending the blade’s lifespan. The brand often incorporates specialized coatings to optimize blade performance and durability.

The precise engineering of these elements within this equipment demonstrates the brand’s commitment to delivering superior skating experiences. Through continuous innovation and attention to detail, they strive to optimize blade performance for skaters of all levels.

2. Boot Stiffness Levels

Boot stiffness levels are a critical determinant of performance characteristics in ice skates. Different levels of stiffness cater to varying skating styles and skill requirements. Equipment from the specified manufacturer exemplifies this principle through distinct product lines designed for specific applications.

A stiffer boot offers enhanced support and energy transfer, enabling more powerful strides and quicker responses, particularly beneficial for advanced skaters executing complex maneuvers. Conversely, a more flexible boot provides greater comfort and range of motion, facilitating skill development for beginners and recreational skaters. Models within the manufacturer’s “Vapor” line often feature a lower stiffness profile to maximize agility, while “Supreme” models prioritize stiffness for enhanced power and stability. The choice of stiffness level directly impacts skating efficiency and control, influencing a skater’s ability to perform technical elements.

Understanding the relationship between boot stiffness and skating performance is essential for selecting the appropriate equipment. Factors such as skill level, skating style, and intended use should be carefully considered. Furthermore, the manufacturer’s consistent implementation of varying stiffness profiles across its product lines highlights its commitment to meeting the diverse needs of the skating community. Selecting the correct stiffness level optimizes performance and minimizes the risk of injury, thus enhancing the overall skating experience.

3. Ankle Support Systems

Ankle support systems within ice skates are paramount for skater stability, control, and injury prevention. These systems, integral components of models from various manufacturers, including the specified brand, directly affect the skater’s ability to execute complex maneuvers and maintain balance. Insufficient ankle support can lead to instability, increasing the risk of sprains and other lower extremity injuries. Conversely, a well-designed support system enhances energy transfer, enabling more efficient strides and quicker responses. The effectiveness of the ankle support is inextricably linked to the overall performance and safety of the ice skate.

The specific materials, construction techniques, and design elements used in creating ankle support systems vary across different skate models and manufacturers. Some systems employ rigid exoskeletal structures to provide maximum support, while others utilize strategically placed padding and flexible materials to allow for a greater range of motion without sacrificing stability. The correct implementation depends on the intended use of the skate, with hockey skates generally requiring more robust support than recreational skates. Skates often incorporate thermoformable materials in the ankle area, enabling a customized fit that conforms to the individual skater’s anatomy, further enhancing support and comfort. The continuous refinement of these systems reflects a commitment to optimizing skater performance and minimizing injury risk.

In summary, effective ankle support systems are indispensable to optimal skating performance and injury prevention. The design and materials employed in their construction directly influence a skater’s stability, control, and energy transfer. Recognizing the significance of this component allows skaters and coaches to make informed decisions when selecting equipment, ultimately enhancing the skating experience and minimizing the risk of injury. The manufacturer’s ongoing innovations in ankle support technology underscore its commitment to providing skaters with the highest levels of performance and protection.

4. Thermoformable Customization

Thermoformable customization represents a significant advancement in ice skate technology, enabling a more personalized fit and enhanced performance. Its application within a specific brand’s ice skate models allows skaters to achieve a level of comfort and responsiveness previously unattainable.

- Heat-Activated Shells

Specific ice skate models utilize heat-activated polymers in their boot construction. This allows the skate’s shell to mold to the unique contours of the skater’s foot when subjected to controlled heating. This process ensures a snug, comfortable fit that minimizes pressure points and maximizes energy transfer.

- Ankle Pocket Molding

The ankle area is particularly susceptible to discomfort and pressure. Thermoformable customization allows the ankle pocket to conform precisely to the skater’s ankle bone structure. This improves stability, reduces slippage, and minimizes the risk of blisters or chafing. The refined fit enhances responsiveness and control during skating maneuvers.

- Customizable Footbeds

Complementing the shell molding, some models offer thermoformable footbeds. These footbeds can be heated and molded to match the arch and shape of the skater’s foot. This provides enhanced arch support, improves weight distribution, and reduces foot fatigue during prolonged skating sessions.

- Repeatable Molding Process

The thermoformable properties of the materials allow for a repeatable molding process. If the initial fit is not ideal, the skate can be re-heated and re-molded to achieve the desired level of customization. This adaptability ensures that skaters can fine-tune the fit over time as their feet change or skating preferences evolve.

The integration of thermoformable customization into specific ice skates exemplifies a commitment to providing skaters with a superior fit and enhanced performance capabilities. The ability to mold the skate to the unique contours of the foot minimizes discomfort, maximizes energy transfer, and ultimately improves the skating experience.

5. Impact Protection Technology

The integration of impact protection technology within ice skates is a critical design element, particularly evident in the product lines offered by a prominent manufacturer. This technology mitigates the forces generated during collisions, falls, and puck impacts, reducing the risk of injury. The effectiveness of impact protection directly correlates with skater safety and performance, enabling confident execution of maneuvers without undue concern for potential harm. For example, high-end hockey skates incorporate strategically placed foams and composite materials to absorb and dissipate energy, safeguarding vulnerable areas such as the ankles and metatarsals. The specific materials utilized, their density, and their placement are all critical factors in determining the overall level of protection offered. Without adequate impact protection, skaters are at a significantly elevated risk of fractures, contusions, and other debilitating injuries.

Advanced impact protection extends beyond basic padding. Some models incorporate multi-density foams that offer varying levels of protection based on the intensity of the impact. Others utilize specialized materials that harden upon impact, providing a responsive defense against sudden forces. The placement of these materials is also crucial, with particular attention given to areas prone to high-impact collisions, such as the sides of the foot and the tongue of the skate. Furthermore, the design of the boot itself contributes to impact protection. Stiffer boots provide greater overall support and stability, reducing the likelihood of ankle injuries. Examples of this include skates featuring Curv composite or similar rigid materials in their construction. This integration of materials and design ensures that the skate as a whole provides a comprehensive level of impact protection.

In conclusion, impact protection technology is an indispensable component of modern ice skates. Its presence significantly reduces the risk of injury, allowing skaters to perform at their best without undue fear. The commitment of manufacturers to incorporating advanced materials and innovative designs underscores the importance of skater safety. The efficacy of impact protection is continually being improved through research and development, further enhancing the safety and performance benefits of ice skates. Understanding the principles and applications of impact protection technology is essential for selecting the appropriate equipment and ensuring a safe and enjoyable skating experience.

6. Moisture Management Liners

The integration of moisture management liners within ice skates, particularly those manufactured by a prominent brand, represents a critical design consideration impacting user comfort and performance. Perspiration generated during skating accumulates within the boot, creating an environment conducive to bacterial growth, odor development, and reduced thermal insulation. The presence of moisture also compromises the structural integrity of the boot over time, potentially leading to premature degradation. Moisture management liners address these challenges by wicking moisture away from the foot, promoting evaporation, and maintaining a drier, more comfortable internal environment.

The effectiveness of moisture management liners hinges on the materials used and their construction. Synthetic fabrics such as microfiber and specialized polyester blends are commonly employed due to their superior wicking properties and ability to dry quickly. These materials are often treated with antimicrobial agents to inhibit bacterial growth and minimize odor. The design of the liner itself further enhances moisture management capabilities. Some liners incorporate strategically placed ventilation channels to promote airflow and accelerate evaporation. Others feature multi-layer construction, with an inner layer designed to wick moisture away from the foot and an outer layer designed to facilitate evaporation. The practical significance of this technology lies in its ability to enhance comfort during prolonged skating sessions, improve hygiene, and extend the lifespan of the ice skates. For instance, hockey players engaged in intense gameplay benefit significantly from moisture management liners, as they help maintain a dry and comfortable internal boot environment, reducing the risk of blisters and chafing, and improving overall performance.

In summary, moisture management liners are essential components of high-performance ice skates, contributing significantly to user comfort, hygiene, and equipment longevity. The materials used, their construction, and the overall design of the liner are all critical factors in determining its effectiveness. While the implementation of this technology adds to the cost of ice skates, the benefits in terms of improved comfort, hygiene, and equipment durability justify the investment. The specific brand’s commitment to incorporating advanced moisture management liners underscores its dedication to providing skaters with a superior and more comfortable skating experience.

7. Blade Sharpening Frequency

Blade sharpening frequency is intrinsically linked to the performance and longevity of ice skates, particularly those manufactured by Bauer. The sharpness of the blade directly affects a skater’s ability to maintain edge control, execute turns, and generate speed. Reduced edge sharpness diminishes these capabilities, leading to compromised performance and increased risk of falls. Therefore, understanding the factors influencing blade sharpening frequency is crucial for optimizing the utility of equipment.

Several variables dictate how often blades require sharpening. The quality of the steel used in construction is a primary determinant; higher-quality steel retains its edge longer. The frequency and intensity of use are also significant. Skaters who train daily or compete regularly necessitate more frequent sharpening than recreational skaters. Ice conditions play a crucial role; abrasive ice dulls blades more quickly. Moreover, individual skating styles influence blade wear. Skaters with aggressive skating techniques or those who frequently perform sharp turns require more frequent sharpening. Failure to maintain adequate blade sharpness compromises performance and increases the risk of falls, directly negating the benefits of the equipment. For instance, a hockey player utilizing Bauer skates with dull blades would experience diminished agility and control, negatively impacting their gameplay and potentially leading to injuries. This underscores the need for skaters to develop a consistent sharpening schedule based on their individual circumstances.

In conclusion, blade sharpening frequency is not merely a routine maintenance task but a fundamental aspect of optimizing the performance and extending the lifespan of ice skates. The interplay of steel quality, usage intensity, ice conditions, and skating style dictates the ideal sharpening schedule. A proactive approach to blade maintenance ensures skaters can consistently leverage the full capabilities of their equipment, maximizing performance and minimizing the risk of injury. Neglecting this aspect compromises the investment in ice skates and diminishes the benefits of their advanced design and construction.

Frequently Asked Questions about Ice Skates Bauer

The following addresses common inquiries regarding the proper selection, maintenance, and performance characteristics of ice skates manufactured by Bauer.

Question 1: What is the significance of blade steel quality in Bauer ice skates?

The quality of blade steel directly impacts edge retention, corrosion resistance, and overall performance. Higher-grade steel alloys require less frequent sharpening and provide superior edge control. The specific steel utilized varies across different Bauer skate models to achieve an optimal balance between durability and performance.

Question 2: How does boot stiffness affect skating performance in Bauer ice skates?

Boot stiffness influences energy transfer and ankle support. Stiffer boots offer enhanced power and stability, while more flexible boots provide greater agility and comfort. Bauer utilizes varying stiffness profiles across its product lines, such as Vapor (agility) and Supreme (power), to cater to different skating styles and skill levels.

Question 3: What is the purpose of thermoformable customization in select Bauer ice skate models?

Thermoformable customization allows the skate boot to be molded to the unique contours of the skater’s foot through heat application. This process enhances comfort, reduces pressure points, and improves overall fit, leading to enhanced performance and reduced risk of blisters.

Question 4: How frequently should Bauer ice skate blades be sharpened?

Sharpening frequency depends on several factors, including steel quality, ice conditions, skating frequency, and individual skating style. Regular sharpening is essential for maintaining edge control and optimal performance. A professional sharpening is recommended to ensure consistent and accurate results.

Question 5: What impact protection technologies are incorporated into Bauer ice skates?

Bauer ice skates incorporate various impact protection technologies, including multi-density foams and composite materials, strategically placed to absorb and dissipate energy from collisions and impacts. These features mitigate the risk of injury to vulnerable areas such as the ankles and metatarsals.

Question 6: What is the function of moisture management liners in Bauer ice skates?

Moisture management liners wick moisture away from the foot, promoting evaporation and maintaining a drier, more comfortable internal environment. This reduces bacterial growth, minimizes odor, and prolongs the lifespan of the boot. The specific materials and construction techniques used in these liners vary across different models.

Proper selection and maintenance of ice skates manufactured by Bauer are crucial for optimizing performance, ensuring safety, and extending equipment longevity.

The subsequent sections will explore advanced customization options and common troubleshooting procedures for the equipment.

Conclusion

The preceding discussion has illuminated key facets of ice skates manufactured by Bauer. The analysis encompasses blade design, boot stiffness, ankle support, customization options, impact protection, moisture management, and blade maintenance. Understanding these elements allows for informed decision-making regarding selection and care, optimizing performance and extending equipment lifespan.

The continued pursuit of innovation in this equipment ensures its relevance in a dynamic sporting landscape. Consistent attention to detail in design and manufacturing will sustain its position as a critical component for athletes and recreational users alike. Proper maintenance and informed selection are crucial to realizing the full potential of this equipment.