Bladed footwear designed for gliding across frozen surfaces, primarily ice, facilitates movement and recreation. Examples include figure skating models for intricate maneuvers, hockey versions built for speed and protection, and recreational types designed for comfort and ease of use on public rinks.

Such equipment allows individuals to engage in a variety of winter activities, offering both physical exercise and enjoyment. Historically, these devices have evolved from rudimentary bone skates to technologically advanced designs incorporating lightweight materials and specialized blade configurations, expanding accessibility and enhancing performance.

The following sections will explore different aspects of this type of equipment, including their construction, proper maintenance, and selection criteria for various skill levels and intended purposes. Safety considerations and the impact of modern manufacturing techniques will also be addressed.

Equipment Usage and Maintenance Guidance

The following guidelines provide crucial information for maximizing the lifespan and performance of your bladed footwear. Adherence to these recommendations will enhance safety and optimize the skating experience.

Tip 1: Blade Protection. Employ blade guards when walking off-ice. Hard surfaces can damage the blade’s edges, negatively impacting glide and maneuverability. Always use soft guards for storage to absorb moisture.

Tip 2: Proper Drying. Thoroughly dry blades after each use. Moisture promotes rust formation, which degrades the metal and reduces performance. A clean, absorbent cloth is recommended.

Tip 3: Sharpening Schedule. Regular sharpening maintains optimal edge control. The frequency depends on usage and ice conditions; however, professional sharpening is generally recommended every 20-40 hours of skating time.

Tip 4: Boot Care. Wipe down the boot’s exterior after use to remove dirt and moisture. Leather boots should be conditioned periodically to prevent cracking and maintain flexibility.

Tip 5: Lacing Technique. Proper lacing provides crucial ankle support and comfort. Avoid over-tightening, which can restrict circulation. Ensure the laces are securely fastened before each session.

Tip 6: Storage Practices. Store in a dry, well-ventilated area to prevent mold and mildew growth. Avoid direct sunlight and extreme temperatures, which can damage the materials.

Tip 7: Professional Inspection. Schedule periodic inspections by a qualified technician. They can identify potential issues, such as loose rivets or blade misalignment, before they escalate.

Following these guidelines contributes significantly to the longevity and safe operation of the equipment, enhancing both recreational and competitive skating experiences.

The subsequent section will address safety protocols and essential gear to further minimize the risk of injury during skating activities.

1. Blade Material

Blade material constitutes a foundational component of ice skates, directly influencing performance characteristics and longevity. The type of steel utilized, its hardness, and its tempering process dictate edge retention, glide efficiency, and resistance to corrosion. For instance, high-carbon steel, frequently employed in professional-grade figure skating blades, offers superior edge sharpness and durability compared to softer alloys found in recreational models. Consequently, the choice of blade material directly impacts a skater’s ability to execute precise maneuvers and maintain speed on the ice. Ineffective blade material selection can lead to frequent sharpening requirements, compromised control, and increased susceptibility to damage from ice debris.

The practical significance of understanding blade material properties extends to maintenance and sharpening techniques. Different steel compositions require specialized sharpening methods to preserve the optimal edge geometry. Improper sharpening can negate the benefits of a high-quality blade material. Furthermore, knowledge of blade material corrosion resistance informs cleaning and storage protocols. For example, stainless steel blades require less diligent drying compared to carbon steel variants to prevent rust formation. Therefore, manufacturers often specify recommended maintenance procedures based on the blade material’s specific characteristics.

In summary, blade material is a critical determinant of skate performance, durability, and maintenance requirements. Understanding the properties of different blade materials enables informed equipment selection and proper care, ultimately influencing a skater’s overall experience and safety. While technological advancements continue to introduce new materials, the fundamental principle remains: the choice of blade material is inextricably linked to the effectiveness and longevity of the equipment.

2. Boot Support

Boot support within bladed footwear dictates stability, control, and injury prevention. The degree of rigidity offered by the boot directly influences the skater’s ability to transfer force to the blade and maintain balance. Insufficient support leads to ankle instability, increasing the risk of sprains and hindering precise movements. Conversely, excessive rigidity restricts range of motion and reduces sensitivity, potentially impeding performance in disciplines requiring nuanced footwork. For instance, figure skating boots necessitate a high degree of stiffness to facilitate jumps and spins, while recreational models prioritize comfort and flexibility.

The choice of boot support should align with the skater’s skill level, intended use, and physical characteristics. Beginners benefit from moderate support, which aids in developing proper technique and balance. Advanced skaters often require custom-fitted boots with reinforced ankle support to withstand the demands of complex routines. Furthermore, individual biomechanics play a crucial role; skaters with pronation or supination issues may require orthotic inserts or customized boot modifications to achieve optimal alignment and prevent discomfort. The type of lacing system further contributes to support, allowing for adjustable tension and personalized fit.

In summary, boot support serves as a critical determinant of performance, safety, and comfort in bladed footwear. Careful consideration of the skater’s skill level, intended use, and individual biomechanics is essential when selecting boots. Proper boot support minimizes the risk of injury, enhances control, and ultimately contributes to a more enjoyable and effective skating experience.

3. Sharpening Frequency

The maintenance of bladed footwear, specifically concerning sharpening frequency, represents a critical aspect of performance and safety. The interval between sharpenings significantly influences the skater’s ability to maintain control and execute maneuvers effectively. Deviations from an optimal sharpening schedule can negatively impact both recreational and competitive skating experiences.

- Ice Hardness and Blade Wear

The hardness of the ice surface directly correlates with the rate of blade wear. Softer ice leads to more rapid dulling of the blade edge due to increased friction and abrasion. Indoor rinks, often maintained at a softer consistency, necessitate more frequent sharpening compared to outdoor rinks with naturally harder ice. The implication is a need for diligent assessment of ice conditions to determine the appropriate sharpening schedule.

- Skating Discipline and Blade Loading

Different skating disciplines impose varying levels of stress on the blade edge. Figure skating, characterized by intricate jumps and spins, places significant demands on edge control, requiring more frequent sharpening to maintain precision. Conversely, recreational skating, involving less strenuous activity, allows for longer intervals between sharpenings. This demonstrates that blade loading and discipline influence the degradation of the blade’s edge.

- Skater Skill Level and Technique

A skater’s skill level and technique influence blade wear patterns. Beginners, often applying inconsistent pressure and exhibiting less refined edge control, tend to dull blades more quickly. Advanced skaters, possessing efficient technique and precise edge control, can sustain sharper edges for longer periods. This highlights the crucial role of skill and technique in determining optimal sharpening frequency.

- Blade Material and Hardness

The inherent hardness and composition of the blade material determine its resistance to wear. Blades constructed from high-carbon steel, known for its superior hardness, retain sharpness for longer compared to blades made from softer alloys. This property of blade material directly influences the rate at which the blade loses its edge and, consequently, the required sharpening frequency.

In conclusion, optimal sharpening frequency for bladed footwear is a multifaceted consideration involving ice conditions, skating discipline, skater skill, and blade material. Consistent evaluation of these factors ensures peak performance, enhanced safety, and prolonged equipment lifespan. Ignoring the interdependence of these aspects can lead to compromised control and increased risk of injury.

4. Fit Precision

Fit precision constitutes a fundamental parameter governing the performance and safety of ice skates. Mismatched sizing, whether characterized by excessive looseness or undue constriction, directly impairs control, elevates the risk of injury, and compromises comfort. The interface between the skater’s foot and the boot must facilitate efficient force transmission to the blade, enabling precise execution of maneuvers. Example: A boot that is too large allows the foot to move independently, diminishing edge control and increasing the likelihood of ankle instability. Conversely, a boot that is excessively tight restricts circulation, leading to discomfort and potential long-term foot problems. The practical significance of precise fit extends beyond performance, encompassing injury prevention and long-term foot health. Therefore, meticulous attention to fit is non-negotiable for both recreational and competitive skaters.

Achieving optimal fit necessitates a comprehensive assessment, considering foot length, width, and arch height. Manufacturers often provide detailed sizing charts and fitting guidelines, but professional fitting by experienced skate technicians is highly recommended, particularly for serious skaters. The fitting process should account for sock thickness, potential foot swelling during activity, and individual foot morphology. Heat molding, a common technique, allows for customized boot shaping to conform precisely to the skater’s foot. Furthermore, the lacing system plays a crucial role in fine-tuning the fit, enabling targeted pressure distribution and secure ankle support. Real-world application example: A figure skater requiring precise control for complex jumps relies on a custom-fitted boot with reinforced ankle support, ensuring optimal force transmission and minimizing the risk of ankle injury. Regular adjustments and maintenance of the lacing system are essential to preserve fit precision over time.

In summary, fit precision represents a crucial element in the selection and utilization of ice skates. Its impact extends from performance enhancement to injury prevention and long-term foot health. While manufacturers provide guidelines, professional fitting services offer the most reliable pathway to achieving optimal fit. The challenge lies in maintaining fit precision over time, necessitating regular adjustments and attentive monitoring of boot condition. Ultimately, a properly fitted skate serves as a direct interface between the skater’s intent and the ice surface, enabling precise control and maximizing the enjoyment of the activity.

5. Lacing System

The lacing system, an integral component of ice skates, directly influences boot fit, ankle support, and overall performance. Its design and implementation are critical for maximizing control and minimizing the risk of injury.

- Lace Material and Durability

The material composition of the laces dictates their tensile strength, resistance to abrasion, and longevity. High-strength synthetic materials, such as nylon or polyester, are commonly employed due to their durability and resistance to stretching. Waxed laces provide enhanced grip and prevent slippage, maintaining consistent tension throughout the skating session. Lace failure compromises boot integrity and necessitates immediate replacement to ensure skater safety.

- Lace Hook Configuration

The arrangement and design of lace hooks influence the distribution of tension across the boot. Strategically placed hooks allow for independent tightening of the lower and upper sections, enabling customized fit adjustments. Angled or recessed hooks minimize lace wear and prevent accidental snagging. Inadequate hook design can lead to uneven pressure distribution and discomfort.

- Lacing Techniques and Ankle Support

Various lacing techniques, such as power pulls or window lacing, can be employed to optimize ankle support and accommodate individual foot anatomy. Power pulls create targeted pressure zones for enhanced stability, while window lacing relieves pressure on sensitive areas. Improper lacing can restrict circulation or lead to ankle instability, underscoring the importance of proper technique.

- Impact on Performance and Control

A properly functioning lacing system enables efficient force transmission from the skater’s foot to the blade, enhancing control and agility. Consistent tension and secure ankle support allow for precise execution of maneuvers. Loose or improperly laced boots compromise stability and reduce skating efficiency. The lacing system is therefore a crucial link between the skater and the ice surface.

The interconnectedness of lace material, hook configuration, lacing technique, and performance demonstrates the crucial role of the lacing system in the overall functionality of ice skates. Regular inspection and maintenance of laces and hooks are essential for ensuring safety and maximizing skating potential. Failure to address deficiencies in the lacing system can significantly impair performance and increase the risk of injury, emphasizing its indispensable contribution to the sport.

6. Intended Use

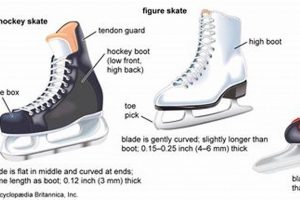

The intended application of bladed footwear exerts a significant influence on its design, construction, and selection. Different skating disciplines necessitate specific equipment features to optimize performance and ensure safety. This causal relationship between intended use and equipment characteristics is fundamental to understanding the diverse range of ice skates available. For example, hockey skates, designed for rapid acceleration, agility, and impact resistance, incorporate reinforced ankle support, a rigid boot structure, and a shorter, curved blade. Conversely, figure skates, optimized for jumps, spins, and intricate footwork, feature a longer, flatter blade with a toe pick, along with a more flexible boot to facilitate greater range of motion. The practical significance of this differentiation lies in the direct correlation between appropriate equipment selection and the ability to perform specific skating skills effectively and safely. The consequences of using equipment designed for an inappropriate purpose can range from impaired performance to increased risk of injury.

Further illustrating the impact of intended use, recreational skates prioritize comfort and ease of use. These models typically feature softer boots, less aggressive blade profiles, and simpler lacing systems, catering to individuals seeking casual skating experiences on public rinks. Speed skates, designed for competitive racing, minimize weight and maximize energy transfer. These models often incorporate long, straight blades and low-cut boots to enhance speed and efficiency. A real-world example would be a speed skater who would find the ankle support and blade design of a hockey skate restrictive and detrimental to performance, just as a hockey player would find the blade pick and flexible ankle of a figure skate ill-suited for the demands of their sport.

In conclusion, the intended use of bladed footwear is a critical determinant of its design and performance characteristics. Understanding the specific requirements of different skating disciplines enables informed equipment selection, optimizing both performance and safety. The challenge lies in accurately assessing individual needs and selecting equipment that aligns with those requirements. Failure to do so can result in compromised performance, increased risk of injury, and a diminished skating experience. The selection of this particular equipment is inextricably linked to the intended purpose, and this relationship should be the foremost consideration in the purchasing process.

7. Safety Standards

Adherence to established safety standards in the design and manufacture of ice skates directly mitigates the risk of injury associated with their use. These standards encompass material integrity, structural design, and performance testing, collectively aiming to ensure user safety across various skating disciplines.

- Material Integrity and Durability Standards

Safety standards mandate the use of materials capable of withstanding the stresses inherent in skating. This includes rigorous testing of blade steel for hardness and fracture resistance, as well as boot materials for impact absorption and structural integrity. Example: Standards may specify minimum tensile strength requirements for boot materials to prevent tearing during use. Non-compliance can result in equipment failure and subsequent injury.

- Structural Design and Ankle Support Standards

Design standards dictate the level of ankle support provided by the boot. Ankle support must be sufficient to prevent excessive lateral movement and reduce the risk of sprains. Standards may specify minimum height and rigidity requirements for the boot cuff. Improper design can compromise stability and increase the likelihood of ankle injuries.

- Blade Attachment and Security Standards

Standards address the method of blade attachment to the boot, ensuring a secure and reliable connection. Rigorous testing protocols are implemented to verify the integrity of the attachment mechanism under various load conditions. Example: Standards may require the use of specific rivet types and quantities to prevent blade detachment during use. Failure to meet these standards can result in catastrophic equipment failure and severe injury.

- Performance Testing and Certification Standards

Equipment performance must be validated through standardized testing procedures. These tests simulate real-world skating conditions and assess the skate’s ability to withstand stress and maintain functionality. Certification from recognized organizations provides assurance that the equipment meets established safety criteria. Lack of certification may indicate substandard quality and increased risk of injury.

The integration of these safety standards into the manufacturing process represents a crucial component of responsible equipment design. Regular review and updates to these standards are essential to address evolving technologies and identified safety concerns. Consistent enforcement of these standards contributes significantly to minimizing the risk of injury and promoting a safer skating environment.

Frequently Asked Questions Regarding Bladed Footwear

This section addresses common inquiries and misconceptions pertaining to this specific type of sporting equipment. The information provided aims to clarify pertinent aspects of selection, maintenance, and safety.

Question 1: What factors should be considered when selecting the correct size of such equipment?

Accurate sizing requires consideration of foot length, width, and instep height. It is recommended to consult manufacturer sizing charts and, ideally, seek professional fitting services to ensure optimal comfort and performance. Allowance for sock thickness should also be considered.

Question 2: How often should the blades be sharpened to maintain optimal performance?

Sharpening frequency depends on usage intensity, ice conditions, and blade material. Generally, professional sharpening is advised after 20-40 hours of skating time. However, more frequent sharpening may be necessary for softer ice conditions or advanced skating techniques.

Question 3: What are the primary differences between figure and hockey designs?

Figure versions feature longer, flatter blades with toe picks for jumps and spins, along with more flexible boots to allow for a greater range of motion. Hockey versions incorporate shorter, more curved blades for enhanced agility and acceleration, as well as stiffer boots for increased ankle support and impact protection.

Question 4: How should these items be properly stored to prevent damage and prolong their lifespan?

Proper storage entails drying the blades thoroughly after each use to prevent rust, storing them in a well-ventilated area, and using blade guards to protect the edges when walking off-ice. Avoid direct sunlight and extreme temperatures.

Question 5: What safety precautions should be observed while using this type of sporting equipment?

Safety precautions include wearing appropriate protective gear, such as a helmet, gloves, and potentially padded clothing. It is also crucial to ensure that the equipment fits properly and that the blades are sharp and in good condition. Awareness of surroundings and adherence to rink rules are also essential.

Question 6: What are the potential consequences of using ill-fitting or poorly maintained equipment?

Using ill-fitting or poorly maintained equipment can lead to decreased performance, increased risk of injury (including ankle sprains, cuts, and fractures), and accelerated equipment deterioration. Proper fit and regular maintenance are therefore crucial for safety and longevity.

In summary, selecting the appropriate size, maintaining the blades, understanding the differences between disciplines, storing the equipment correctly, and observing safety precautions are all critical factors in ensuring a safe and enjoyable skating experience.

The next section will delve into the history and evolution of this particular footwear.

Conclusion

This exploration has examined bladed footwear from various perspectives, including construction materials, maintenance procedures, safety standards, and the significance of selecting equipment appropriate for the intended use. A thorough understanding of these factors is crucial for maximizing performance and mitigating potential risks associated with their use.

Continued adherence to established safety protocols, coupled with ongoing advancements in materials and design, is essential for fostering a secure and enjoyable skating experience. Prioritizing informed decision-making and diligent maintenance contributes to the longevity of the equipment and the well-being of the skater.

![Find Your Pair: Most Comfortable Ice Skates Review [2024] Learn to Surf & Skate: A Beginner's Step-by-Step Guide Find Your Pair: Most Comfortable Ice Skates Review [2024] | Learn to Surf & Skate: A Beginner's Step-by-Step Guide](https://universitysurfandskate.com/wp-content/uploads/2026/03/th-84-300x200.jpg)