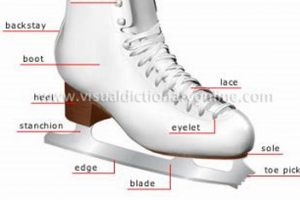

Footwear specifically designed for gliding across ice surfaces comprises a specialized boot affixed to a blade. This equipment enables individuals to participate in activities ranging from recreational skating to competitive figure skating, ice hockey, and speed skating. The construction typically involves a supportive boot, often made of leather or synthetic materials, securely fastened to a sharpened metal blade.

Properly engineered equipment of this nature offers crucial ankle support and stability, allowing for controlled movement and minimizing the risk of injury. Historically, this type of equipment evolved from rudimentary bone skates to sophisticated designs incorporating advanced materials and manufacturing techniques, reflecting ongoing efforts to enhance performance and comfort. The development has significantly broadened accessibility to ice sports and recreation for enthusiasts of all skill levels.

The following sections will delve into the diverse types of this specialized footwear, examining the specific features and considerations relevant to different disciplines and user needs. Further discussion will explore materials, fitting guidelines, maintenance, and emerging technologies shaping the future of this essential component of ice-based activities.

Essential Guidance for Optimal Performance

Selecting and maintaining appropriate footwear for ice activities is crucial for performance, safety, and longevity of the equipment. The following guidance offers insights to maximize the benefits derived from this specialized gear.

Tip 1: Prioritize Proper Fit: Ensure the footwear conforms closely to the foot’s contours without restricting circulation or causing pressure points. Ill-fitting footwear can lead to discomfort, blisters, and compromised control. Professional fitting services are recommended for initial purchase.

Tip 2: Select the Appropriate Style: Recognize the specific demands of the intended activity. Figure styles provide greater ankle support and blade articulation, while hockey variants offer increased protection and responsiveness. Speed styles prioritize minimal weight and maximum energy transfer. Choosing the correct style is paramount.

Tip 3: Maintain Blade Sharpness: Regular sharpening of the blade is essential for optimal grip and glide on the ice surface. The frequency of sharpening depends on usage and ice conditions. Dull blades significantly reduce control and increase the risk of falls.

Tip 4: Dry Thoroughly After Each Use: Moisture can corrode the blade and degrade the boot materials. After each session, thoroughly dry both the interior and exterior of the footwear with a clean cloth. Consider using boot dryers to accelerate the process and prevent bacterial growth.

Tip 5: Protect Blades During Storage and Transport: Use blade guards when not in use and during transport to prevent damage to the edges. Fabric or soft guards absorb moisture, while hard guards offer superior protection against impacts.

Tip 6: Inspect Regularly for Wear and Tear: Routinely examine the boot, blade, and laces for signs of damage or degradation. Replace worn components promptly to maintain performance and safety. Loose stitching, cracked blades, and frayed laces should be addressed immediately.

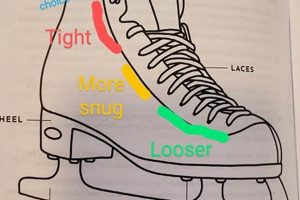

Tip 7: Use Appropriate Lacing Techniques: Proper lacing is vital for ankle support and secure fit. Experiment with different lacing patterns to find the configuration that provides the optimal balance of comfort and stability. Avoid over-tightening, which can restrict circulation.

Adhering to these guidelines will contribute to enhanced performance, improved comfort, and extended lifespan of the specialized footwear. Consistent attention to fit, maintenance, and proper usage is essential for a positive and safe experience on the ice.

The subsequent sections will delve into more advanced topics, including customization options and technological advancements in ice equipment design, to further optimize the user experience.

1. Ankle Support

Ankle support is a critical attribute of footwear designed for ice skating. Its influence extends to stability, control, and injury prevention, thereby impacting both performance and user safety. This feature is carefully engineered within the structure of the footwear.

- Boot Height and Rigidity

The height of the boot shaft, extending above the ankle joint, contributes significantly to lateral stability. Stiffer materials used in the boot’s construction, such as reinforced leather or synthetic composites, further restrict ankle movement. This rigidity minimizes the risk of ankle sprains and provides a stable platform for executing complex maneuvers.

- Lacing System and Closure Mechanisms

The lacing system, often incorporating strategically placed hooks and eyelets, allows for customized tightening around the ankle. This enables the user to adjust the level of support based on personal preference and the demands of the activity. Additional closure mechanisms, such as power straps or buckles, can further enhance ankle stabilization.

- Internal Padding and Contouring

Internal padding, typically composed of closed-cell foam or gel materials, conforms to the anatomical contours of the ankle. This padding not only enhances comfort but also provides additional support and shock absorption. The strategic placement of padding can help prevent pressure points and minimize the risk of blisters or chafing.

- Blade Integration and Heel Counter

The integration of the blade with the boot’s heel counter contributes to overall ankle stability. A well-designed heel counter, often reinforced with rigid materials, provides a secure connection between the foot and the blade. This connection is essential for efficient power transfer and precise control during skating maneuvers.

The interplay of these facets within the overall design of skating footwear is fundamental to providing the necessary support and protection for the ankle joint. Different skating disciplines, such as figure skating, hockey, and speed skating, necessitate varying degrees of ankle support, reflecting the specific demands of each activity. The optimization of ankle support remains a central focus in the ongoing development of ice skating equipment.

2. Blade Attachment

The manner in which a blade is affixed to a skating boot constitutes a critical engineering consideration that fundamentally affects the performance characteristics of the entire assembly. Blade attachment methodologies must ensure structural integrity under substantial forces generated during skating maneuvers, while simultaneously allowing for precise adjustments to optimize balance and responsiveness. The success or failure of this connection directly translates to the skater’s ability to execute controlled movements and efficiently transfer energy to the ice. For instance, improperly secured blades can lead to instability, reduced power output, and an increased risk of injury. The specific attachment method employed varies depending on the intended use, with figure styles demanding greater precision and adjustability compared to hockey or recreational styles. Examples of these methods include riveting, screwing, or bonding the blade to the sole of the boot, each offering distinct advantages and disadvantages in terms of durability, adjustability, and manufacturing complexity.

Further analysis reveals that the material properties of both the blade and the boot, as well as the interface between them, play a crucial role in the overall performance. Differences in thermal expansion coefficients between the materials can introduce stresses that compromise the bond over time, necessitating careful material selection and design considerations. Additionally, the ability to fine-tune the blade’s position relative to the boot, often through micro-adjustment mechanisms, allows skaters to personalize their equipment for optimal performance and comfort. A real-life example is the use of shims or plates to adjust the blade’s alignment, correcting for individual biomechanical variations or specific skating techniques. The practical application of this understanding is evident in the iterative design processes employed by manufacturers, where feedback from professional skaters and biomechanical analysis informs continuous improvements to blade attachment systems.

In summary, the blade attachment mechanism represents a fundamental aspect of skating equipment design. It directly impacts stability, control, and energy transfer, with implications for both recreational and competitive skating. Challenges remain in optimizing the interface between the blade and the boot to achieve a balance of durability, adjustability, and performance. Ongoing research and development efforts are focused on exploring new materials, attachment methods, and adjustment mechanisms to further enhance the functionality and reliability of this critical component, ultimately contributing to safer and more enjoyable experiences on the ice.

3. Boot Material

The selection of boot material in footwear designed for ice skating directly influences performance, protection, and longevity. The chosen material dictates the boot’s rigidity, thermal properties, weight, and resistance to wear, all of which are paramount considerations for skaters across various disciplines. Leather, a traditional material, provides a degree of natural insulation and molds to the wearer’s foot over time, offering a customized fit. Synthetic materials, on the other hand, often exhibit enhanced water resistance and durability, minimizing maintenance and prolonging the equipment’s lifespan. The cause-and-effect relationship is evident: choosing a more rigid material improves ankle support but potentially reduces comfort, while a more flexible material enhances comfort but compromises stability. The importance of boot material as a component is underscored by its direct impact on the skater’s ability to control their movements and avoid injuries. As an example, hockey styles typically incorporate reinforced synthetic materials for impact resistance, while figure styles prioritize leather or layered composites for precise ankle articulation.

Further analysis reveals a growing trend towards hybrid constructions, combining the benefits of both traditional and modern materials. Manufacturers are experimenting with carbon fiber, thermoplastics, and specialized foams to optimize weight reduction, thermal management, and impact protection. These advancements allow for more responsive and energy-efficient performance. For instance, a speed skating boot may utilize a carbon fiber shell to maximize stiffness and minimize energy loss during each stride, while incorporating strategically placed foam padding for comfort and pressure relief. The practical application of this understanding is seen in the customized fitting processes employed by professional skaters, where the boot material is often heat-molded to conform precisely to the individual’s foot, enhancing both performance and reducing the risk of blisters or other discomfort.

In summary, the selection of boot material is a critical decision that significantly impacts the functionality and user experience. Trade-offs exist between different materials, necessitating careful consideration of the skater’s individual needs and skating style. Challenges remain in developing materials that offer the optimal balance of comfort, support, durability, and performance. Ongoing research and development efforts are focused on exploring novel materials and construction techniques to push the boundaries of ice skate footwear technology and further enhance the skater’s experience on the ice.

4. Proper Fit

The relationship between proper fit and ice skating footwear is foundational to performance, safety, and comfort. Ill-fitting equipment can directly lead to discomfort, blisters, reduced control, and increased risk of injury. A boot that is too large allows the foot to move excessively, hindering power transfer and precision. Conversely, a boot that is too small restricts circulation, causing numbness and pain, ultimately impeding performance. The importance of proper fit as a component of ice skating footwear cannot be overstated; it is a prerequisite for realizing the intended benefits of the equipment. Consider the example of a hockey player whose footwear is too loose, leading to instability during rapid turns, increasing the chance of a fall and potential injury. The practical significance of this understanding is evident in professional fittings, which employ specialized tools and techniques to ensure an optimal fit for each individual.

Further analysis reveals that proper fit is not merely a matter of size but also encompasses the boot’s shape and volume relative to the wearer’s foot. Variations in foot width, arch height, and ankle circumference necessitate careful consideration during the fitting process. Customization options, such as heat molding and padding adjustments, allow for fine-tuning the fit to accommodate individual anatomical differences. For instance, skaters with narrow heels often require specific padding to prevent slippage and maintain a secure fit. The practical application of this understanding is reflected in the growing availability of specialized fitting services that leverage biomechanical analysis and advanced measurement technologies to optimize footwear performance and comfort.

In summary, achieving proper fit is a critical aspect of selecting and utilizing ice skating footwear. Challenges remain in accommodating the wide range of individual foot shapes and sizes, as well as the varying demands of different skating disciplines. Continuous advancements in fitting technologies and customization options are aimed at addressing these challenges and maximizing the benefits derived from specialized equipment, ensuring both safe and enjoyable experiences on the ice.

5. Thermal Insulation

Maintaining foot warmth within ice skating footwear is critical due to the frigid environment inherent in ice-based activities. Effective thermal insulation mitigates heat loss, prevents discomfort, and safeguards against potential cold-related injuries, such as frostbite. The design and materials of skating boots play a central role in providing adequate thermal protection.

- Material Composition

The type and arrangement of materials directly influence the insulation properties of the footwear. Natural materials, such as wool felt, possess inherent insulating capabilities due to their fibrous structure, which traps air and reduces heat transfer. Synthetic materials, including closed-cell foams and Thinsulate, offer enhanced insulation per unit thickness and are often incorporated into modern designs. The layering of these materials creates a thermal barrier that minimizes heat loss from the foot to the surrounding cold environment. For example, high-performance figure styles often integrate multiple layers of insulating materials to maintain optimal foot temperature during extended practice sessions or competitions.

- Boot Construction and Sealing

The method of construction impacts the overall thermal efficiency of the footwear. Tightly sealed seams and closures minimize the ingress of cold air and moisture, which can significantly diminish the insulating properties of the boot. Water-resistant or waterproof outer layers further enhance thermal protection by preventing the absorption of moisture, which conducts heat away from the foot. For instance, hockey styles often feature reinforced seams and water-resistant coatings to withstand the rigors of gameplay and maintain foot warmth in icy conditions.

- Sock Selection and Management

The choice of socks worn in conjunction with ice skating footwear significantly affects thermal insulation. Moisture-wicking socks, made from materials such as merino wool or synthetic blends, help to draw perspiration away from the foot, preventing it from becoming chilled. Thick, insulating socks provide additional warmth but can also restrict circulation if the footwear is already tightly fitted. Effective moisture management is crucial for maintaining foot warmth and preventing discomfort during prolonged skating activities. Speed skaters, for example, often opt for thin, moisture-wicking socks to minimize bulk and maximize feel within their tightly fitting boots.

- Fit and Circulation

Proper fit is essential for optimal thermal insulation. Overly tight footwear can constrict blood flow to the feet, reducing warmth and increasing the risk of cold-related injuries. Conversely, excessively loose footwear allows for increased air circulation, which can also accelerate heat loss. Properly fitted equipment, with adequate room for toe movement and unimpeded circulation, promotes natural foot warmth and enhances the effectiveness of the insulating materials. Recreational skaters, who may spend extended periods on the ice, should prioritize properly fitted footwear to ensure both comfort and thermal protection.

The integration of these various factors material composition, boot construction, sock selection, and proper fit collectively determines the thermal performance of ice skating footwear. Addressing each aspect is crucial for maximizing foot warmth, preventing discomfort, and ensuring a safe and enjoyable experience on the ice.

Frequently Asked Questions

This section addresses common inquiries regarding ice skating footwear, providing concise and informative answers to enhance understanding and promote informed decision-making.

Question 1: What are the primary differences between ice skating footwear designed for figure skating versus hockey?

Figure skating styles typically feature higher, more rigid boots for enhanced ankle support and greater blade articulation, facilitating intricate movements and jumps. Hockey styles prioritize protection and responsiveness, employing reinforced materials and a more streamlined design for agility and puck control.

Question 2: How frequently should blades be sharpened?

The frequency of blade sharpening depends on usage and ice conditions. Regular sharpening maintains optimal grip and glide. Dull blades compromise control and increase the risk of falls. Professional assessment is recommended to determine the appropriate sharpening schedule.

Question 3: What materials are commonly used in the construction of ice skating footwear, and what are their respective advantages?

Leather provides a customized fit and natural insulation. Synthetic materials offer enhanced water resistance and durability. Hybrid constructions combine the benefits of both, optimizing weight reduction, thermal management, and impact protection.

Question 4: How should ice skating footwear be properly fitted?

Proper fit entails conformity to the foot’s contours without restricting circulation or causing pressure points. Professional fitting services are recommended to ensure optimal comfort, performance, and injury prevention. The boot’s shape and volume should align with individual foot characteristics.

Question 5: What measures can be taken to prevent moisture damage to ice skating footwear?

Thorough drying after each use is essential. Boot dryers accelerate the process and inhibit bacterial growth. Blade guards protect edges during storage and transport, preventing corrosion. Regular inspection identifies potential wear and tear.

Question 6: How does sock selection impact the performance and comfort of ice skating footwear?

Moisture-wicking socks prevent perspiration build-up, maintaining foot warmth and minimizing discomfort. Proper sock thickness avoids restricting circulation or compromising fit. Material selection and sock design influence thermal properties and overall foot health.

Key takeaways emphasize proper fit, regular maintenance, and appropriate style selection for optimal performance and longevity of ice skating footwear. Adherence to these principles promotes safety, comfort, and enjoyment of ice-based activities.

The following section will explore customization options and emerging technologies shaping the future of ice skating equipment design.

Conclusion

The preceding analysis has explored various facets of ice skate shoe construction, materials, fitting, and maintenance. Attention to these details is vital for optimizing performance, ensuring safety, and prolonging the lifespan of this specialized equipment. Specific considerations include the selection of appropriate styles tailored to individual needs, the importance of proper fit in promoting comfort and control, and the necessity of regular maintenance to prevent degradation.

Continued advancements in materials science and engineering will undoubtedly shape the future of ice skate shoe design, leading to enhanced performance, improved comfort, and greater accessibility for individuals of all skill levels. Understanding the fundamental principles outlined herein provides a solid foundation for navigating these advancements and making informed decisions regarding the selection and care of ice skate footwear.