The maintenance activity that ensures optimal blade performance on ice skates involves refining the edges of the blade to a desired level of sharpness and contour. This process, typically performed by skilled technicians, is crucial for skaters of all levels, from recreational users to competitive athletes. A properly executed procedure enhances the skater’s ability to grip the ice, facilitating controlled movements, turns, and stops.

Optimal blade condition is paramount for safety and performance on the ice. Sharp edges provide the necessary bite for efficient skating, reducing the risk of slips and falls. Historically, this was achieved with manual tools; however, modern methods often incorporate specialized machinery to ensure precision and consistency. The benefits extend beyond improved safety; they also include enhanced agility, speed, and overall skating enjoyment.

The subsequent sections will delve into the various aspects of achieving and maintaining superior blade quality, including the methods employed, the factors influencing frequency of service, and selecting a qualified provider. Understanding these elements will empower skaters to make informed decisions regarding the care of their equipment.

Blade Maintenance Insights

Ensuring properly maintained blades contributes significantly to a skater’s performance and safety. The following guidelines offer insight into best practices regarding this essential aspect of skate care.

Tip 1: Assess Blade Condition Regularly: Perform visual inspections prior to each skating session. Look for nicks, burrs, or dull spots along the blade’s edges. Early detection of damage allows for timely intervention.

Tip 2: Understand Steel Hardness: Different blade steels exhibit varying degrees of hardness, impacting edge retention. Softer steels may require more frequent attention compared to harder alloys.

Tip 3: Avoid Non-Ice Surfaces: Minimize contact between skate blades and abrasive surfaces such as concrete or asphalt. Walking on these surfaces will dull the edges rapidly.

Tip 4: Properly Store Skates: After each use, thoroughly dry blades with a clean, absorbent cloth. Store skates in a well-ventilated area to prevent rust formation. Blade guards should only be used when walking on surfaces other than ice, and removed immediately after skating.

Tip 5: Consider Blade Hollow: The depth of the blade hollow influences the amount of bite on the ice. Experiment with different hollow depths to determine what best suits individual skating style and preferences.

Tip 6: Seek Professional Expertise: Entrust blade maintenance to qualified technicians possessing the appropriate tools and expertise. Attempting to sharpen blades without proper training can result in irreversible damage.

Tip 7: Document Sharpening History: Maintain a record of when and where skates were last sharpened. This data provides valuable insight into blade wear patterns and helps to optimize maintenance schedules.

Consistent adherence to these guidelines will help prolong blade life, enhance skating performance, and minimize the risk of injury. Prioritizing routine maintenance demonstrates a commitment to both safety and skill development on the ice.

The subsequent section will outline the criteria for selecting a qualified professional, further emphasizing the importance of informed decision-making in ensuring optimal blade performance.

1. Precision Edge Grinding

Precision edge grinding is a critical component of effective maintenance, directly influencing the quality and performance of the blade on the ice. The process involves the careful and controlled removal of material from the blade to establish sharp, consistent edges.

- Optimal Edge Angle

The achievement of the correct edge angle is paramount. This angle dictates the blade’s bite into the ice, influencing grip and control. Deviation from the optimal angle can result in slippage or excessive drag, hindering a skater’s ability to execute maneuvers. Specialized equipment and trained technicians are essential for consistently achieving the correct angle.

- Symmetry and Balance

Symmetrical edge grinding ensures balanced performance on both edges of the blade. Asymmetrical edges can lead to uneven pressure distribution, resulting in instability and difficulty in executing turns. Precision grinding techniques guarantee that both edges are sharpened to the same degree, fostering consistent and predictable performance.

- Surface Finish Quality

The surface finish of the sharpened edge affects ice interaction. A rough or uneven finish can create excessive friction, slowing the skater and reducing efficiency. Precision grinding techniques produce a smooth, polished edge that minimizes friction and maximizes glide. Microscopic imperfections are minimized to enhance performance.

- Blade Life Extension

Controlled material removal during precision grinding extends the life of the blades. Aggressive or haphazard methods can remove excessive material, shortening blade life and potentially altering its structural integrity. Precise techniques minimize material loss while achieving optimal sharpness, maximizing the usable lifespan of the blades.

These facets highlight the importance of precision in blade maintenance. Substandard grinding techniques can negate any potential benefits, leading to compromised performance and premature blade wear. The selection of a provider with expertise in precision techniques is therefore essential for skaters seeking optimal blade condition and performance enhancement.

2. Consistent Blade Radius

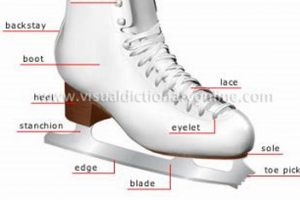

The maintenance procedure encompasses not only edge acuity but also the uniformity of the blade’s curvature, known as the blade radius. This radius, extending from the heel to the toe of the blade, plays a crucial role in a skater’s agility and control. The consistency of this radius is intrinsically linked to quality of maintenance.

- Turning Precision

A consistent radius enables predictable and controlled turns. When the radius varies along the length of the blade, the skater experiences inconsistent contact with the ice during turns, leading to instability and reduced control. Precise maintenance ensures a uniform radius, allowing for smooth and reliable turning performance.

- Edge Engagement

Uniformity of the radius ensures that the blade engages the ice evenly along its length. This uniform engagement is essential for generating power and maintaining balance. Inconsistencies in the radius can result in uneven pressure distribution, compromising edge control and reducing skating efficiency.

- Glide Efficiency

The radius influences the surface area of the blade in contact with the ice. A consistent radius optimizes this contact, promoting efficient glide and reducing friction. Variations in the radius can disrupt the smooth flow of movement, increasing drag and requiring additional effort to maintain speed.

- Blade Longevity

Maintaining a consistent radius through skilled maintenance minimizes localized stress points on the blade. Uneven wear patterns, caused by an inconsistent radius, can accelerate blade degradation and shorten the lifespan of the blades. Proper radius maintenance contributes to even wear, maximizing the longevity of the skater’s equipment.

These aspects underscore the significance of radius maintenance as a component of comprehensive maintenance. Technicians employ specialized tools and techniques to ensure that the blade radius remains consistent throughout its length, optimizing performance characteristics and extending the usable life of the equipment. Skilled execution contributes directly to skater’s performance and overall skating experience.

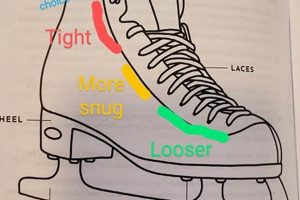

3. Appropriate Hollow Depth

The hollow depth ground into a skate blade directly influences the skater’s grip on the ice. Selection of an appropriate hollow depth is a critical element within the procedure, tailored to individual skating style, skill level, and ice conditions. Precise execution during the service is essential for optimizing performance and safety.

- Grip and Glide Balance

A deeper hollow provides increased grip due to the sharper edges digging further into the ice, beneficial for beginners or those requiring more control. Conversely, a shallower hollow offers more glide and speed, preferred by experienced skaters who prioritize agility. Achieving the right balance between grip and glide is essential, and the technicians role is to execute the depth selected by the user.

- Ice Condition Adaptation

The hardness of the ice surface impacts the optimal hollow depth. Softer ice requires a shallower hollow to prevent the edges from digging in excessively, causing drag. Harder ice benefits from a deeper hollow to provide adequate grip. A skilled technician will consider the typical ice conditions encountered by the skater when advising on hollow depth.

- Skating Discipline Considerations

Different skating disciplines necessitate varying hollow depths. Figure skaters generally prefer a deeper hollow for enhanced edge control required for jumps and spins. Hockey players often opt for a shallower hollow to maximize speed and maneuverability. Understanding the demands of each discipline is crucial for selecting an appropriate hollow depth.

- Impact on Fatigue

An inappropriate hollow depth can contribute to increased fatigue. A hollow that is too deep requires more effort to maintain speed and execute turns, leading to quicker exhaustion. Conversely, a hollow that is too shallow can result in a loss of control, forcing the skater to exert more energy to stay balanced. Selecting the appropriate hollow depth minimizes unnecessary strain and optimizes skating efficiency.

The selection and proper execution of appropriate hollow depth demonstrates the direct relationship between maintenance and on-ice performance. A well-informed decision, implemented with precision, maximizes the benefits of the service, enhancing the skater’s experience and minimizing potential risks.

4. Burr Removal Process

The burr removal process is an indispensable stage in blade refinement, directly impacting both blade performance and skater safety. The presence of burrs, microscopic imperfections created during the sharpening process, can degrade the quality of the blade’s edge and impede smooth gliding on the ice. Therefore, meticulous burr removal is essential to realizing the full benefits of the service.

- Edge Refinement

Burrs, formed as a result of metal displacement during the sharpening process, compromise the precision of the newly established edge. These imperfections disrupt the blade’s contact with the ice, reducing grip and control. The burr removal process, through honing or polishing, eliminates these imperfections, resulting in a cleaner, more defined edge. This refined edge enhances the skater’s ability to execute precise movements and maintain balance, significantly improving performance.

- Friction Reduction

The presence of burrs on a skate blade increases friction between the blade and the ice. This increased friction translates to reduced glide efficiency and increased exertion for the skater. Burr removal techniques, such as polishing with specialized stones or compounds, smooth the blade surface, minimizing friction and allowing for a smoother, more efficient glide. Reduced friction contributes to improved speed and decreased fatigue during skating sessions.

- Blade Longevity

Burrs can weaken the blade edge, making it more susceptible to chipping and damage. These imperfections act as stress concentrators, accelerating wear and potentially shortening the blade’s lifespan. Effective burr removal strengthens the edge, making it more resistant to damage and prolonging the usability of the skates. By minimizing wear and tear, the burr removal process represents a cost-effective measure in the long-term maintenance of skate equipment.

- Safety Enhancement

Unremoved burrs can pose a safety hazard to skaters. These sharp imperfections can catch on the ice, causing unexpected stumbles or falls. Furthermore, loose burrs can detach from the blade and become embedded in the ice surface, creating a potential hazard for other skaters. A thorough burr removal process eliminates these risks, creating a safer skating environment for all.

The burr removal process represents a critical step in ensuring the quality and safety of skates. Skimping on or omitting this stage undermines the value of the sharpening process. A comprehensive service includes meticulous attention to burr removal, resulting in enhanced performance, increased blade longevity, and a safer skating experience.

5. Technician Skill Level

The proficiency of the technician executing the maintenance procedure is a foundational element determining the ultimate quality and effectiveness of the service. A technician’s expertise directly impacts blade performance, skater safety, and the longevity of the skating equipment. Inadequate skill leads to compromised outcomes, underscoring the necessity of entrusting this task to qualified professionals.

- Equipment Calibration Expertise

A skilled technician possesses in-depth knowledge of the sharpening equipment and its proper calibration. Miscalibrated equipment results in inconsistent edge angles, uneven hollow depths, and potential blade damage. Expertise in calibration ensures that the equipment operates within precise parameters, delivering consistent and predictable results. Accurate calibration necessitates ongoing training and a thorough understanding of the machinery’s operating principles, impacting the final product delivered to the skater.

- Blade Assessment Proficiency

Accurate assessment of blade condition is crucial for determining the appropriate sharpening approach. A skilled technician identifies subtle imperfections, assesses steel hardness, and determines the optimal hollow depth for the skater’s needs. This assessment requires experience and a keen eye for detail, ensuring that the sharpening process is tailored to the specific characteristics of the blade and the skater’s performance requirements. Failure to accurately assess blade condition leads to suboptimal sharpening and reduced performance on the ice.

- Sharpening Technique Mastery

The application of proper sharpening techniques is paramount for achieving optimal blade performance. A skilled technician employs controlled movements, precise pressure, and appropriate wheel selection to create sharp, consistent edges without removing excessive material. Mastery of these techniques minimizes the risk of blade damage, maximizes edge retention, and ensures a smooth, predictable feel on the ice. Improper technique leads to uneven edges, premature blade wear, and compromised skating performance.

- Burr Removal Expertise

The meticulous removal of burrs following sharpening is essential for realizing the full benefits of the maintenance procedure. A skilled technician employs specialized tools and techniques to eliminate microscopic imperfections, resulting in a clean, polished edge that minimizes friction and enhances glide. Expertise in burr removal ensures a smooth, safe skating experience and prolongs the life of the blade. Inadequate burr removal leads to increased friction, reduced glide, and potential safety hazards on the ice.

These facets emphasize the critical role of technician skill level in achieving optimal blade performance and ensuring skater safety. The selection of a qualified professional, possessing the necessary expertise and experience, represents a fundamental investment in the skater’s equipment and their overall skating experience. Ultimately, the technician’s proficiency dictates the quality of the service and its positive impact on the skater’s performance.

Frequently Asked Questions Regarding Ice Skate Sharpening Service

The following questions address common inquiries and misconceptions concerning the proper maintenance of ice skate blades. Understanding these points is crucial for maximizing performance and ensuring safety on the ice.

Question 1: How frequently should ice skates be sharpened?

The frequency of sharpening depends on several factors, including skating frequency, ice quality, and the skater’s skill level. Recreational skaters may only require sharpening once or twice per season, while competitive skaters may need it more frequently, even weekly. Blades should be inspected regularly for signs of dullness or damage.

Question 2: What are the indicators that ice skates require sharpening?

Key indicators include a loss of edge grip, difficulty executing turns, and a general feeling of instability on the ice. Visual inspection may reveal rounded or damaged edges. Skaters experiencing these issues should seek professional evaluation.

Question 3: Is it possible to over-sharpen ice skates?

Yes, excessive or improper sharpening can remove too much material from the blade, shortening its lifespan and altering its intended geometry. It is crucial to entrust sharpening to qualified technicians who understand proper techniques and material removal limits.

Question 4: What is the significance of the “hollow” on an ice skate blade?

The hollow refers to the concave groove ground into the bottom of the blade, creating two distinct edges. The depth of this hollow influences the grip and glide characteristics of the blade. Deeper hollows provide more grip, while shallower hollows offer more glide. The appropriate hollow depth depends on the skater’s style and preferences.

Question 5: Can ice skate blades be sharpened at home?

While DIY sharpening kits are available, attempting to sharpen blades without proper training and equipment can result in irreversible damage. Consistent and accurate sharpening requires specialized machinery and a skilled hand. It is generally advisable to seek professional services.

Question 6: How should ice skate blades be cared for between sharpenings?

Proper care includes drying the blades thoroughly after each use to prevent rust, storing them with blade guards to protect the edges, and avoiding walking on abrasive surfaces without guards. Regular maintenance can extend the time between sharpenings.

The information provided above is intended to offer general guidance on ice skate maintenance. Consulting with experienced technicians is recommended for personalized advice and services.

The next section will explore selecting a qualified sharpening service, emphasizing the importance of experience and proper equipment.

Concluding Remarks on Ice Skate Sharpening Service

This exploration has elucidated the multifaceted nature of ice skate sharpening service, emphasizing its pivotal role in optimizing performance and safety on the ice. Key points covered include the necessity of precision edge grinding, consistent blade radius, appropriate hollow depth, meticulous burr removal, and the critical influence of technician skill. Consistent adherence to best practices in blade maintenance, coupled with informed selection of a qualified service provider, is paramount for all skaters.

Prioritizing proper maintenance of skate blades, through a reputable ice skate sharpening service, represents a fundamental investment in both the longevity of equipment and the skater’s overall experience. Neglecting this essential aspect can compromise performance, increase the risk of injury, and ultimately detract from the enjoyment of skating. Therefore, diligent attention to blade condition and the selection of a skilled sharpening service should be viewed as integral components of responsible skating practice.