An implement designed to hone the blades of ice skates to a desired edge for optimal performance on ice surfaces is available for acquisition. These devices range from manual hand-held models to automated machines, each offering varying degrees of precision and control over the sharpening process. The availability of such equipment allows individuals or organizations to maintain skate blades, ensuring they grip the ice effectively.

Maintaining sharp skate blades is crucial for ice skaters of all levels, enhancing maneuverability, speed, and overall safety. Historically, sharpening was often performed by skilled technicians. However, the proliferation of personal sharpening tools has made blade maintenance more accessible. This accessibility leads to cost savings over time and ensures skates are always performance-ready, maximizing enjoyment and minimizing risk of injury.

The subsequent sections will detail the types of sharpening devices, factors to consider when selecting one, and best practices for using and maintaining said device.

Essential Guidance

The following suggestions are designed to provide guidance on acquiring and utilizing equipment to refine ice skate blades effectively. Prioritizing safety and precision during all operations is strongly advised.

Tip 1: Research Available Options: A comprehensive understanding of diverse devices is essential. Investigate manual sharpeners, electric models, and professional-grade machines. Compare features, capabilities, and user reviews to determine the most suitable option.

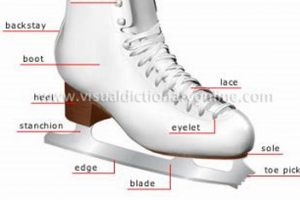

Tip 2: Evaluate Blade Compatibility: Ensure the chosen apparatus is compatible with the specific type of skate blades. Hockey skates, figure skates, and recreational skates may require different sharpening techniques or attachments.

Tip 3: Assess Skill Level: Consider experience level when choosing an implement. Manual sharpeners require a steady hand and practice, while automated machines offer greater consistency but may have a steeper learning curve.

Tip 4: Prioritize Safety Features: Safety should be paramount. Look for features such as blade guards, non-slip surfaces, and clear operating instructions to minimize the risk of accidents.

Tip 5: Understand Grit Ratings: Different grit levels are used for various stages of blade maintenance. Coarser grits are suitable for removing imperfections, while finer grits are ideal for polishing and refining the edge.

Tip 6: Practice Proper Technique: Mastering the correct sharpening technique is critical for achieving optimal results. Consult instructional videos or seek guidance from experienced skaters or technicians.

Tip 7: Maintain Equipment Regularly: Routine maintenance prolongs the lifespan of the tool and ensures consistent performance. Clean blades of metal filings and inspect components for wear and tear.

These tips are vital for those seeking an ice skate sharpener for sale, as proper selection and utilization contribute significantly to skate performance and user safety.

The subsequent section will address common questions and concerns related to these products.

1. Blade Edge Quality

Blade edge quality is fundamentally linked to the selection and utilization of sharpening devices. A well-maintained edge enhances a skater’s performance, control, and safety on the ice. Conversely, a poorly sharpened blade can lead to instability and increased risk of falls.

- Sharpness Consistency

A consistent edge across the blade’s length ensures predictable grip and glide. Inconsistent sharpness can cause uneven pressure distribution, leading to erratic movements. For example, an inconsistently sharpened hockey skate can reduce turning agility, while an inconsistently sharpened figure skate can affect jump landings.

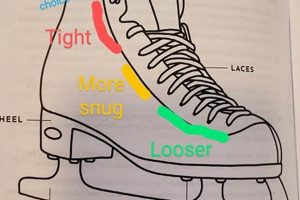

- Edge Angle Precision

The angle of the blade’s edge influences its bite into the ice. A shallower angle provides more glide but less grip, while a steeper angle offers increased grip at the expense of speed. Precision is critical to ensure each blade has a balanced edge angle, thereby optimizing performance characteristics.

- Surface Finish Smoothness

The surface finish of the sharpened edge impacts friction between the blade and the ice. A rough surface can create excessive friction, reducing glide efficiency. A smooth, polished surface minimizes friction, enhancing speed and flow. The correct selection of grit within the sharpener is important to ensure this.

- Burr Removal

Sharpening can leave microscopic burrs on the blade’s edge, which can catch on the ice and reduce glide. Proper deburring techniques or tools integrated into the sharpening process are essential to remove these imperfections and achieve a clean, smooth edge.

The nuances of blade edge quality underscore the importance of selecting appropriate implements. The investment in quality devices, coupled with proper technique, directly influences the final edge characteristics. The implications for the skater, whether recreational or professional, demonstrate a clear connection between the device and performance.

2. Sharpening Device Type

The type of apparatus used to hone ice skate blades significantly affects the outcome of the sharpening process. The variety available directly impacts the suitability for individual users and the quality of the resultant edge. An informed selection requires careful consideration of operational methods, precision capabilities, and maintenance requirements.

- Manual Sharpeners

These hand-held implements rely on user skill and dexterity to achieve a desired edge. While generally more affordable, they demand a consistent hand and significant practice to ensure uniformity. Manual sharpeners provide limited control over edge angle and surface finish, making them suitable for minor touch-ups or skaters with extensive sharpening experience. An example is a handheld stone that requires the user to manually grind the skate blade, often resulting in inconsistent sharpness levels.

- Electric Sharpeners

Electric models utilize a motor-driven grinding wheel to sharpen the blade. They offer greater consistency and precision compared to manual sharpeners, reducing the reliance on user skill. These devices typically feature adjustable settings for edge angle and grinding pressure, allowing for customization. Electric sharpeners are suitable for skaters seeking a balance between convenience and quality. For example, a small electric sharpener may provide a more even edge than a handheld stone but requires careful operation to avoid over-sharpening.

- Automated Sharpening Machines

These machines represent the highest level of sophistication, employing computer-controlled systems to automate the sharpening process. Automated sharpeners offer unparalleled precision, consistency, and speed. They are capable of producing complex edge profiles and are ideal for professional skate shops or ice rinks requiring high-volume sharpening. An automated machine can quickly and consistently sharpen multiple pairs of skates, adjusting parameters to suit different blade types and skater preferences.

- Hollow Grinders

Designed for creating a concave groove along the length of the blade, hollow grinders are common in hockey skate maintenance. This groove enhances the skater’s ability to grip the ice and execute sharp turns. Different wheel radii allow for varying depths of the hollow, tailoring the edge to individual preferences and skating styles. Precise control is vital to ensure uniform hollowing along the length of the blade. An example is using a smaller radius grinding wheel that creates a deeper hollow, preferred by hockey players seeking maximum grip.

The selection of an appropriate instrument, as it relates to “ice skate sharpener for sale,” is intrinsically linked to the desired outcome and the user’s skill level. Manual devices provide basic functionality at a lower cost, while automated systems offer advanced capabilities at a premium. Hollow grinders cater to specific performance requirements. Understanding these distinctions is essential for making informed decisions when purchasing a sharpening tool.

3. Maintenance Frequency

The frequency with which ice skate blades require sharpening is directly related to the ownership of blade sharpening equipment. This periodicity is influenced by a range of factors, including the intensity of use, ice conditions, and skater skill level. The decision to acquire sharpening equipment is often contingent upon the required maintenance schedule.

- Skate Usage Intensity

Skaters who engage in frequent or high-impact activities, such as competitive hockey or figure skating, necessitate more frequent sharpening compared to recreational skaters. Higher usage accelerates blade wear, resulting in a loss of edge sharpness. This increased demand makes the acquisition of personal sharpening devices more economically viable and logistically convenient. For instance, a competitive skater might sharpen their blades weekly, while a recreational skater may only require sharpening every few months.

- Ice Surface Conditions

The condition of the ice significantly affects blade wear. Abrasive ice surfaces, characterized by impurities or excessive hardness, dull blade edges more rapidly. Skaters who frequent rinks with sub-optimal ice conditions benefit from having in-house sharpening capabilities, allowing for immediate correction of edge degradation. For example, outdoor rinks are often more abrasive than indoor rinks due to environmental factors.

- Skater Skill Level

Novice skaters tend to exert more lateral force on their blades, leading to increased edge wear. As skaters develop proficiency, their technique becomes more refined, reducing the stress on the blades. Consequently, less experienced skaters may require more frequent sharpening. This disparity in maintenance requirements influences the cost-benefit analysis of owning sharpening equipment.

- Blade Steel Quality

The quality of steel used in skate blade construction affects its durability and edge retention. Higher-grade steel alloys resist wear and maintain sharpness for longer periods. Skates equipped with superior steel require less frequent sharpening, potentially reducing the urgency to acquire sharpening tools. Conversely, blades made from lower-quality steel may necessitate more frequent attention.

The correlation between maintenance frequency and the acquisition of sharpening devices underscores the importance of assessing individual skating habits and environmental factors. While high-volume users benefit most from personal tools, infrequent skaters might find it more economical to utilize professional services. Ultimately, the maintenance schedule informs the decision-making process concerning “ice skate sharpener for sale.”

4. User Skill Level

The proficiency of the user represents a critical determinant in the effective utilization of an ice skate sharpening device. Skill level influences both the selection of the appropriate sharpening tool and the ability to consistently achieve desired edge characteristics. A mismatch between user expertise and the complexity of the device can result in suboptimal sharpening or, potentially, damage to the skate blades. For example, a novice attempting to use a high-speed automated sharpener without proper training could easily create an uneven edge or overheat the blade, compromising its integrity.

Furthermore, advanced sharpening techniques, such as altering the radius of hollow or creating specific edge profiles, demand a high degree of skill and understanding of blade geometry. A seasoned skate technician, possessing an intricate knowledge of edge angles and grinding wheel characteristics, can leverage sophisticated equipment to fine-tune skate performance to a skater’s specific needs. Conversely, a less experienced individual may struggle to replicate these results, even with access to the same high-end equipment. The practical significance of skill is apparent in competitive skating, where subtle edge adjustments can impact a skater’s ability to execute complex maneuvers.

In conclusion, user skill level constitutes a significant factor in the successful application of tools. The complexities of sharpening ice skate blades require a balance between equipment capabilities and user expertise. Addressing the skill gap through training and education becomes essential to unlocking the full potential of sharpening tools and ensuring the longevity and optimal performance of ice skate blades. Understanding this connection is fundamental when considering the purchase of sharpening tools.

5. Cost Considerations

The acquisition of implements for refining ice skate blades involves a spectrum of cost factors that directly influence the accessibility and long-term financial implications for potential purchasers. The initial outlay represents only one facet of the economic equation, as recurring expenses, maintenance, and the potential for damage necessitate a comprehensive cost-benefit analysis. These economic factors are inextricably linked to the suitability of these products for individual users, skating rinks, and equipment retailers. For instance, a high-volume skating facility may find that a significant initial investment in a commercial-grade automated sharpening system is justified by reduced labor costs and the ability to offer a higher quality service, whereas a recreational skater might be better served by a less expensive, manual sharpener that meets infrequent needs.

Furthermore, the long-term operational costs associated with sharpening tools merit careful consideration. Grinding wheels, honing stones, and other consumable components require periodic replacement, adding to the total cost of ownership. Electric-powered implements incur ongoing energy expenses. The potential for equipment malfunction and subsequent repair further compounds the financial burden. Conversely, outsourcing sharpening services eliminates the need for capital investment and minimizes operational complexities, but it introduces recurring fees and reduces control over the sharpening process. An example includes a hockey player who must sharpen their skates weekly or twice a week where there are long-term benefits to owning a personal tool. These factors must be weighed against the initial expense when assessing the affordability of these products.

In summary, the decision to acquire ice skate sharpening devices is fundamentally driven by cost considerations. The purchase price, operating expenses, maintenance costs, and the potential for long-term savings must be carefully evaluated to determine the most economically viable solution. While professional grade equipment presents the potential for enhanced precision and efficiency, the initial cost can be prohibitive for many users. A realistic assessment of individual needs, skating frequency, and the total cost of ownership is paramount for making an informed purchasing decision.

6. Safety Measures

The safe operation of implements for refining ice skate blades is paramount. Potential hazards associated with these devices necessitate the implementation of comprehensive safety protocols and the utilization of appropriate protective equipment. The absence of adequate measures can result in physical injury, equipment damage, and compromised sharpening quality. Therefore, a thorough understanding of safety requirements is integral to the responsible utilization of this type of equipment.

- Eye Protection

The generation of metal filings and debris during the sharpening process poses a significant risk to ocular health. Eye protection, such as safety glasses or goggles, serves as a critical barrier against these projectiles. The failure to wear appropriate eye protection can result in corneal abrasions, embedded foreign bodies, and, in severe cases, vision impairment. For instance, during high-speed grinding operations, particles ejected from the grinding wheel can travel at considerable velocity, posing a direct threat to unprotected eyes.

- Hand Protection

The handling of sharp blades and potentially abrasive surfaces requires the use of appropriate hand protection. Gloves constructed from cut-resistant materials mitigate the risk of lacerations and abrasions. Inadequate hand protection can lead to injuries that impede the user’s ability to maintain a secure grip on the blade or sharpening tool, increasing the likelihood of accidents. Example: Using gloves with grip can allow for a more secure process, which can help in preventing any cuts.

- Machine Guarding

Sharpening devices incorporating rotating components, such as grinding wheels, must be equipped with appropriate machine guards. These guards prevent accidental contact with moving parts, reducing the risk of entanglement and impact injuries. The removal or bypass of machine guards compromises user safety and increases the potential for severe trauma. For example, without a blade guard, the user may accidentally come in contact with the blade which may cause injuries.

- Ventilation

The inhalation of metal dust and airborne particles generated during sharpening can pose a respiratory health hazard. Adequate ventilation, either through natural airflow or mechanical exhaust systems, is essential to minimize exposure to these contaminants. The prolonged inhalation of metal dust can lead to respiratory irritation, allergic reactions, and, in some cases, more severe pulmonary conditions. Example: Proper ventilation is crucial to ensure the users health is not being impacted by particles floating around.

The effective implementation of these safety measures is crucial for mitigating the risks associated with the use of ice skate sharpening devices. Compliance with safety protocols, coupled with appropriate training and equipment maintenance, ensures a safe and productive sharpening environment. Furthermore, selecting equipment with integrated safety features, such as automatic shut-off mechanisms and ergonomic designs, contributes to a safer user experience.

Frequently Asked Questions

The following questions address common inquiries concerning instruments used for honing ice skate blades, and the associated considerations when evaluating potential purchase.

Question 1: What types of sharpeners are suitable for different skate blade types?

The suitability of a sharpener depends on the blade type. Hockey skates typically benefit from hollow grinding, while figure skates require more precise edge profiling. Recreational skates may be adequately maintained with simpler, less specialized devices. It is crucial to verify compatibility before purchase.

Question 2: How often should ice skate blades be sharpened?

Sharpening frequency varies depending on usage intensity, ice conditions, and skating style. Competitive skaters may require sharpening weekly, while recreational skaters can often extend this interval to several months. Inspection of the blade edge for wear or damage is a useful indicator.

Question 3: What safety precautions should be observed during sharpening?

Safety glasses, gloves, and adequate ventilation are essential. Ensure the sharpening device is properly grounded and that all safety guards are in place. Familiarization with the device’s operating instructions prior to use is critical to minimize risk.

Question 4: Can sharpening damage ice skate blades?

Improper sharpening techniques can compromise blade integrity. Excessive grinding can remove too much material, weakening the blade. Overheating can alter the steel’s temper, affecting its hardness and edge retention. Skilled operation is therefore paramount.

Question 5: What is the difference between manual and electric sharpeners?

Manual sharpeners rely on user skill and physical effort to achieve a desired edge. Electric sharpeners offer greater consistency and precision but require less manual dexterity. The choice depends on the user’s experience level and desired outcome.

Question 6: What are the ongoing maintenance requirements for sharpeners?

Sharpeners require routine maintenance, including cleaning, lubrication, and replacement of worn components. Grinding wheels and honing stones must be periodically replaced to maintain optimal performance. Failure to adhere to maintenance schedules can reduce device lifespan and compromise sharpening quality.

The answers above provide clarity on important aspects of ice skate blade sharpening, informing better-educated choices when acquisition equipment.

The next section will provide a comprehensive summary of topics discussed.

In Summary

This exploration of “ice skate sharpener for sale” has underscored the importance of careful consideration when acquiring such equipment. The choice of device, user skill level, safety measures, and cost implications are all significant factors that directly impact the effectiveness and economic viability of sharpening operations. Furthermore, the blade edge quality, the type of implement utilized, and maintenance frequency emerge as critical elements influencing the overall performance and longevity of ice skates.

The ability to maintain sharp ice skate blades is essential for both recreational enjoyment and competitive success. While the initial investment in sharpening tools may seem substantial, the long-term benefits of improved performance, enhanced safety, and cost savings from reduced professional sharpening services often outweigh the upfront expenses. Potential purchasers are advised to thoroughly evaluate their individual needs and circumstances before making a decision, ensuring that the selected equipment aligns with their skating style, budget, and skill level. The ultimate objective is to optimize the skating experience through consistent and effective blade maintenance.