These accessories are designed to safeguard the blades of ice skates when not in use or when traversing surfaces other than ice. Often crafted from materials like hard plastic or durable rubber, they encase the delicate edges of the blades, preventing nicks, scratches, and dulling. For instance, after a skating session, these covers are placed over the blades to protect them during transport and storage.

The employment of blade guards is critical for maintaining the longevity and performance of ice skates. By shielding the blades from abrasive surfaces like concrete or tile, these implements prevent premature wear and tear. Historically, skaters relied on makeshift solutions, but the development of specialized protectors has significantly improved blade care and has consequently extended the lifespan of skating equipment. This ultimately translates to reduced replacement costs and sustained optimal skating performance.

The following sections will delve into the various types available, material considerations, proper usage techniques, and maintenance best practices, all of which contribute to maximizing the benefits afforded by blade safety equipment. These considerations aid users in ensuring their valuable skating assets remain in prime condition for extended periods.

Essential Guidance for Preserving Ice Skate Blades

The following recommendations offer practical advice for maximizing the protective capabilities and extending the lifespan of blade safeguarding accessories.

Tip 1: Select Appropriate Materials. Blade protection comes in various materials. Hard plastic is suitable for off-ice walking but may crack under extreme stress. Rubber varieties offer better shock absorption and durability. Evaluate the typical usage environment to determine the optimal material.

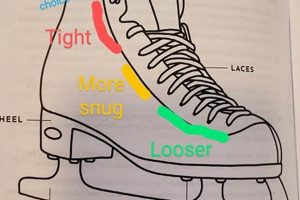

Tip 2: Ensure Proper Fit. A snug fit is crucial. Oversized protectors can slip off, leaving the blades exposed. Undersized protectors may not provide complete coverage. Measure the blade length and consult sizing charts to guarantee a secure fit.

Tip 3: Clean Blades Before Application. Moisture accelerates rust formation. Always wipe down ice skate blades with a dry cloth before placing blade coverings to prevent corrosion.

Tip 4: Store Separately When Not in Use. Confined spaces can trap moisture. When storing ice skates for extended periods, remove them from the coverings to allow for proper ventilation and prevent moisture buildup.

Tip 5: Inspect Regularly for Damage. Examine coverings periodically for cracks, tears, or other signs of wear. Damaged coverings compromise protection and should be replaced promptly.

Tip 6: Use Terry Cloth Soakers. Terry cloth soakers are ideal for absorbing moisture after skating. They act as a barrier between the blade and the protective covering, mitigating the risk of rust.

Adhering to these guidelines will contribute significantly to the sustained performance and longevity of ice skating equipment. Prioritizing preventative measures ensures a continued optimal skating experience.

The subsequent sections will provide further insights into advanced blade maintenance and storage techniques.

1. Material Composition

The selection of materials used in the construction of blade safety equipment profoundly influences its protective capabilities, durability, and suitability for various environments. Understanding the properties of these materials is essential for making informed choices regarding blade protection.

- Hardness and Abrasion Resistance

The hardness of the material dictates its ability to withstand abrasion from surfaces such as concrete, tile, or rubber flooring. Materials like hard plastic offer superior abrasion resistance, preventing the blades from coming into direct contact with damaging surfaces during off-ice transit.

- Impact Absorption and Flexibility

Impact absorption is crucial for mitigating shocks and vibrations that can damage blade edges. Flexible materials like rubber provide superior impact absorption, reducing the risk of chipping or cracking during accidental impacts. This is particularly important in environments where skates are frequently handled or transported.

- Moisture Permeability and Corrosion Resistance

Materials with low moisture permeability are essential to prevent corrosion. While no material is entirely impervious to moisture, non-porous materials like certain synthetic rubbers minimize the ingress of water, reducing the risk of rust formation on the blade surface. Some protectors incorporate ventilation to further minimize moisture retention.

- Durability and Longevity

The durability of the material determines the protector’s lifespan and its ability to withstand repeated use. High-quality, durable materials resist cracking, tearing, and deformation, ensuring continued protection over an extended period. The choice of material must align with the anticipated frequency and intensity of use.

The interplay of hardness, impact absorption, moisture resistance, and durability dictates the overall effectiveness of blade safety equipment. By carefully considering the material composition, skaters can ensure their blades are adequately protected against the rigors of transport, storage, and off-ice environments, ultimately prolonging the life and performance of their equipment.

2. Blade Coverage

Blade coverage refers to the extent to which an ice skate protector shields the skate blade from external elements and potential damage. Adequate blade coverage is paramount in maintaining the integrity and longevity of the blade; insufficient coverage negates the intended protective function.

- Lateral Blade Protection

Lateral blade protection involves shielding the sides of the blade from impacts and abrasions. Protectors designed with raised side walls or reinforced edges provide this lateral protection, preventing damage that can alter the blade’s profile and affect skating performance. For example, striking a hard object from the side could nick the blade edge, which is best prevented by adequate lateral coverage.

- Tip and Heel Enclosure

Complete enclosure of the blade tip and heel is critical for preventing damage to these vulnerable areas. Many designs feature extended material that encapsulates these extremities, safeguarding against impacts and preventing the blade from snagging on surfaces. Unprotected blade tips are prone to chipping or bending, impacting stride efficiency.

- Cutting Edge Guarding

Effective protectors must shield the cutting edge from contact with abrasive surfaces. This is often achieved through a combination of durable materials and precise design, ensuring that the blade’s sharp edge remains protected during off-ice transport and storage. Contact with rough surfaces can quickly dull the cutting edge, reducing glide and control.

- Adjustability and Secure Fit

Even with complete coverage, a poorly fitted protector can compromise its effectiveness. Adjustable straps or secure locking mechanisms ensure that the protector remains firmly in place, preventing slippage that could expose the blade to damage. A loose protector is essentially useless, as it fails to maintain the intended barrier.

Therefore, optimizing blade coverage is a crucial factor in selecting effective blade safety equipment. Protectors that offer comprehensive coverage, combined with a secure and adjustable fit, provide the best defense against damage, preserving the blade’s integrity and extending its lifespan.

3. Fit Security

Fit security, in the context of blade safety equipment, refers to the degree to which an ice skate protector remains firmly and reliably attached to the skate blade during use and transport. A secure fit is not merely a convenience; it is a fundamental requirement for the protector to fulfill its primary function: preventing damage to the blade. A protector that readily detaches or shifts position provides inadequate protection, rendering the investment and intention ineffective. For example, if traversing a concrete surface with blade protectors that lack fit security, the blades may inadvertently come into contact with the abrasive material, negating the protective benefit.

The achievement of fit security depends on several factors, including the dimensional compatibility between the protector and the blade, the design of the fastening mechanism (if present), and the material properties that promote frictional resistance. Protectors designed with adjustable straps, tension springs, or form-fitting contours typically offer superior fit security compared to those relying solely on friction or loose tolerances. Furthermore, environmental conditions, such as temperature and humidity, can influence the fit security of certain materials; some plastics may become brittle and lose their grip in cold temperatures, whereas rubber can become slippery in high humidity. Ensuring correct sizing also is important: a protector too large or too small is unlikely to fit securely.

In summary, fit security is a critical, non-negotiable attribute of effective blade safety equipment. It directly influences the protector’s ability to shield the blade from damage during off-ice activities. Selection of protectors should prioritize designs and materials that guarantee a reliable and consistent fit across a range of environmental conditions and usage scenarios. Neglecting fit security exposes the blade to preventable damage, reducing its lifespan and compromising skating performance. Securing fit is not merely a supplementary feature; it is a foundational component of effective blade protection.

4. Moisture Management

The preservation of ice skate blades hinges significantly on effective moisture management. The presence of moisture, particularly after skating sessions, accelerates the corrosion process, leading to rust formation and subsequent blade degradation. Blade safety equipment, therefore, must address the issue of moisture retention to mitigate these detrimental effects. The failure to manage moisture effectively negates the protective function of blade guards, irrespective of their material composition or design.

Many blade safety implement designs incorporate features aimed at moisture reduction. Ventilation holes or breathable materials facilitate air circulation, promoting evaporation and preventing moisture buildup within the confined space between the blade and the protector. Furthermore, some skaters employ absorbent materials, such as terry cloth soakers, as an intermediate layer between the blade and the protector. These soakers wick away residual moisture, minimizing the risk of corrosion. However, it is essential that these soakers are themselves regularly dried to prevent them from becoming a source of moisture.

Effective moisture management in blade care is a multifaceted undertaking that encompasses both the design of the safety implement and the practices of the skater. The selection of blade guards with ventilation features, coupled with the diligent use of absorbent materials and consistent drying protocols, constitutes a comprehensive approach to minimizing corrosion and prolonging the life of ice skate blades. Ignoring this aspect renders the function of ice skate protection devices incomplete and, potentially, counterproductive.

5. Durability Rating

Durability rating, when applied to blade safety equipment, denotes the capacity of a protector to withstand wear, stress, and environmental factors without compromising its protective function. This rating serves as a critical indicator of the protector’s lifespan and its ability to consistently safeguard ice skate blades over an extended period. It informs purchasing decisions and influences the long-term cost-effectiveness of the equipment.

- Material Fatigue Resistance

Material fatigue resistance assesses the ability of the protector’s constituent materials to endure repeated stress cycles without cracking, tearing, or deforming. A high fatigue resistance ensures that the protector maintains its structural integrity and protective capability despite frequent use and exposure to varying temperatures. Low-quality plastics, for instance, may become brittle and crack after minimal usage, thus lowering the durability rating.

- Abrasion Threshold

The abrasion threshold quantifies the protector’s resistance to surface wear caused by friction against abrasive materials such as concrete, tile, or rubber flooring. A high abrasion threshold indicates that the protector can withstand prolonged contact with these surfaces without significant material loss or degradation, ensuring continued protection of the blade edges. Protectors used primarily on rough surfaces require higher abrasion thresholds.

- Impact Tolerance

Impact tolerance measures the protector’s capacity to absorb and dissipate kinetic energy from impacts without sustaining structural damage. A high impact tolerance is crucial for preventing blade damage caused by accidental drops, collisions, or other sudden forces. Materials like rubber and high-density polymers typically exhibit superior impact tolerance compared to brittle plastics. For example, protectors used during travel in equipment bags are more likely to require a high impact tolerance rating.

- Environmental Degradation Resistance

Environmental degradation resistance signifies the protector’s ability to withstand the effects of moisture, ultraviolet radiation, and temperature fluctuations without undergoing significant deterioration. This is particularly important for protectors used in humid environments or stored outdoors. Materials that are susceptible to UV degradation or corrosion will have a lower durability rating in these contexts.

In conclusion, the durability rating of blade safety equipment encompasses multiple factors that collectively determine its lifespan and protective effectiveness. A comprehensive assessment of these factors ensures that skaters select protectors that meet their specific needs and provide reliable, long-term protection for their valuable ice skate blades. Investing in protectors with a high durability rating minimizes replacement costs and ensures consistent performance over time.

6. Storage Practices

Proper storage practices directly influence the effectiveness and longevity of ice skate protectors. Inadequate storage can compromise the protective capabilities of these accessories, potentially leading to blade damage and equipment degradation. Adherence to established storage protocols is, therefore, crucial for maintaining the integrity of both protectors and skates.

- Ventilation and Drying

Enclosed storage without adequate ventilation traps moisture, fostering corrosion on skate blades. Ice skate protectors should be removed and allowed to air dry, or be stored in well-ventilated areas. Damp environments accelerate rust formation, negating the protective benefits of the covers. For instance, storing skates immediately after use in an enclosed bag with the protectors attached will promote corrosion.

- Orientation and Support

The orientation in which skates are stored can affect the shape and fit of protectors. Storing skates upright, with the blades resting on a hard surface, can cause the protectors to deform over time, compromising their ability to securely grip the blades. Horizontal storage, or the use of skate-specific bags with internal supports, maintains the protector’s shape and fit. Example: Storing skates in a manner that causes pressure against any part of the blade safety implement.

- Temperature and Humidity Control

Extreme temperature fluctuations and high humidity levels can degrade the materials from which protectors are made. Exposure to direct sunlight or prolonged storage in damp environments can cause plastics to become brittle and rubbers to lose elasticity. Controlled storage environments, such as temperature-regulated closets or dry storage rooms, are optimal for preserving protector integrity. If the protector’s material begin degrading the implement’s purpose is negated.

- Protection from Physical Stress

Protectors are susceptible to damage from physical stress, such as being crushed under heavy objects or subjected to repeated impacts. Proper storage involves placing skates in locations where they are shielded from external forces that could deform or break the protectors. For example, storing skates at the bottom of an equipment bag, beneath heavy pads or helmets, can damage the blade protecting item.

In summary, effective storage practices extend beyond simply placing skates in a bag or closet. It encompasses a holistic approach that considers ventilation, orientation, environmental conditions, and protection from physical stress. These practices, when consistently implemented, ensure that ice skate protectors maintain their integrity and provide reliable blade protection, thus prolonging the lifespan of both the protectors and the skates themselves. This approach optimizes protection of blades and enhances usability.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, usage, and maintenance of ice skate protectors to ensure optimal blade protection and longevity.

Question 1: Are protectors necessary for all ice skates?

Yes, blade safety equipment is recommended for all ice skates when traversing surfaces other than ice. Exposure to abrasive materials can damage the blades, regardless of the skate type or skill level of the skater.

Question 2: How frequently should protectors be replaced?

The replacement frequency depends on the material composition, usage intensity, and storage conditions. Regular inspection is advised; protectors exhibiting cracks, tears, or significant wear should be replaced immediately.

Question 3: Can protectors be used on wet blades?

While convenient, placing protectors on wet blades is not recommended. Moisture can lead to rust formation. Blades should be thoroughly dried before applying blade safety implements.

Question 4: Are all protectors universally compatible with all skate blade types?

No, compatibility depends on the dimensions of the blade and the protector. It is crucial to select protectors that are appropriately sized for the specific skate blade being used. Incorrectly sized items may not offer adequate protection.

Question 5: What is the best way to clean protectors?

Protectors can be cleaned with mild soap and water. Abrasive cleaners or solvents should be avoided as they can damage the material. Thoroughly drying the protectors after cleaning is essential to prevent moisture buildup.

Question 6: Can protectors be used for extended storage of ice skates?

While protectors shield the blades, they are not ideal for long-term storage. For extended periods, remove protectors to allow air circulation around the blades, which will prevent moisture accumulation and subsequent corrosion.

Proper use of these protective accessories maximizes protection and ensures a longer lifespan for valuable ice skating equipment.

The following sections will explore detailed case studies where implementing consistent blade maintenance improves the efficiency of skate usage.

Ice Skate Protectors

The preceding discussion has illuminated the diverse aspects of safeguarding implements for ice skate blades. Key factors include material composition, blade coverage, fit security, moisture management, durability rating, and storage practices. Optimal implementation of these considerations enhances blade longevity and maintains skating performance. Choosing suitable protection extends blade lifespan through the mitigation of wear, corrosion, and impact damage, ensuring reliability during use.

Recognizing that consistent blade care is an investment in skating equipment, adoption of rigorous maintenance standards ensures prolonged optimal functionality. These measures prevent preventable damage and extend the period before replacement needs arise. Continued diligence is essential for preserving equipment integrity, resulting in consistent performance of quality blades.