The components that constitute footwear designed for gliding across ice surfaces are critical for performance, safety, and durability. These individual elements, when correctly assembled and maintained, directly impact the skater’s ability to execute maneuvers and maintain balance. Understanding these constituent pieces allows for informed equipment selection and proper upkeep.

The construction and quality of the various elements are paramount for optimizing the skating experience. Proper selection ensures comfort, stability, and responsiveness. Historically, innovations in materials and design have led to significant improvements in speed, control, and overall enjoyment of the activity. Knowledge of these aspects allows for tailored choices that align with individual needs and skill levels.

The following sections will provide detailed information on the blade, boot, and lacing systems, in addition to outlining routine maintenance procedures to ensure longevity and optimal functionality.

Essential Considerations for Optimal Ice Skate Performance

Selecting and maintaining the individual elements comprising skating footwear is crucial for both performance and safety. The following guidelines emphasize key considerations for ensuring a superior experience on the ice.

Tip 1: Blade Alignment: Precise blade alignment is essential for balance and edge control. Misalignment can lead to instability and inefficient skating. A professional fitting is recommended to ensure proper blade placement relative to the boot.

Tip 2: Boot Stiffness: The rigidity of the boot should correspond to the skater’s skill level. Beginners generally benefit from softer boots that allow for greater ankle flexibility, while advanced skaters require stiffer boots for enhanced support and power transfer.

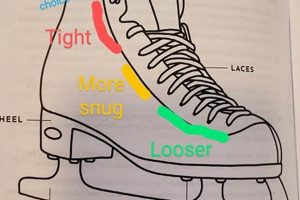

Tip 3: Lacing Technique: Proper lacing technique is crucial for secure and comfortable fit. Tightening the laces firmly around the ankle provides support, while allowing for more flexibility in the lower foot. Avoid over-tightening, which can restrict circulation.

Tip 4: Blade Sharpening: Regular blade sharpening is essential for maintaining edge quality and grip on the ice. The frequency of sharpening depends on the skater’s use and the hardness of the ice. A professional sharpener can ensure proper edge geometry.

Tip 5: Boot Maintenance: Regularly clean and dry the boots after each use to prevent the buildup of moisture and bacteria. Use a boot dryer or stuff the boots with newspaper to absorb excess moisture.

Tip 6: Blade Protection: Always use blade guards when walking off the ice to protect the blades from damage. Hard guards are suitable for walking, while soft guards are recommended for storage to absorb moisture and prevent rust.

Tip 7: Rivet and Screw Inspection: Periodically inspect rivets and screws that secure the blade to the boot. Loose fasteners can compromise stability and safety. Tighten or replace any loose or damaged hardware.

Adhering to these recommendations will contribute to improved performance, comfort, and safety while extending the lifespan of the equipment. Proper care and maintenance are integral to maximizing the investment in skating footwear.

The subsequent sections will delve into advanced customization options and troubleshooting techniques for common issues encountered with skating equipment.

1. Blade Edge

The blade edge, a critical attribute of ice skate blades, directly dictates a skater’s ability to grip and maneuver on the ice surface. It represents a primary point of interaction and is paramount to overall performance. The following facets explore its key characteristics and impact.

- Edge Angle and Sharpness

The angle at which the blade’s edges are sharpened, typically creating an “inside” and “outside” edge, determines the bite into the ice. Sharper edges provide greater grip, enabling tighter turns and more powerful acceleration. Conversely, dull edges result in slippage and reduced control. The correct angle is crucial for maximizing performance based on skating style and discipline.

- Hollow Ground

The hollow ground refers to the concave curvature running along the length of the blade between the inside and outside edges. This hollow enhances the edge bite by creating two distinct points of contact with the ice. The depth of the hollow influences the aggressiveness of the edge; a deeper hollow provides more grip, while a shallower hollow offers a smoother glide. The appropriate hollow depth depends on the skater’s weight, skill level, and ice conditions.

- Edge Consistency

Maintaining consistent sharpness and angle along the entire length of the blade is essential for predictable performance. Irregularities in the edge, such as nicks or dull spots, can lead to instability and difficulty in executing precise movements. Regular sharpening by a skilled technician is necessary to ensure consistent edge quality and optimal performance.

- Steel Composition

The type of steel used in the blade affects its hardness, durability, and ability to hold an edge. Higher-quality steel alloys generally maintain sharpness for longer periods and are more resistant to wear and tear. The steel composition directly influences the frequency of sharpening required and the overall lifespan of the blade.

These facets of the blade edge collectively underscore its critical role in ice skating. The careful selection, maintenance, and sharpening of the blade edge are essential for skaters of all levels seeking to optimize their performance, control, and safety. A well-maintained edge facilitates efficient skating, reduces the risk of falls, and enhances the overall enjoyment of the sport. In summary, the blade edge is an indispensable component of ice skates.

2. Boot Stiffness

Boot stiffness, a critical attribute of ice skate parts, directly influences performance and support. The degree of rigidity within the boot structure determines the level of ankle stability and energy transfer during skating maneuvers. As a component of ice skates, boot stiffness must align with the skater’s skill level and intended use; selecting appropriate boot stiffness is essential for optimizing skating efficiency and minimizing injury risk.

The relationship between boot stiffness and ice skate parts is one of direct cause and effect. A stiffer boot, typically constructed with reinforced materials, provides enhanced ankle support, allowing for more precise control and powerful strides, particularly beneficial for advanced skaters executing complex jumps and spins. Conversely, a less rigid boot offers greater flexibility, facilitating more natural ankle movement, which is advantageous for beginners and those focused on recreational skating. For example, figure skates designed for triple and quadruple jumps necessitate exceptionally stiff boots to withstand extreme forces and maintain ankle alignment, while recreational skates often feature softer boots for increased comfort and ease of use. The mounting of blades onto boots of varying stiffness impacts overall stability and responsiveness.

Ultimately, the correct choice of boot stiffness, in conjunction with other ice skate parts, ensures a safe and effective skating experience. Understanding this connection enables skaters to make informed decisions about equipment selection, optimizing their performance and minimizing the potential for ankle strain or injury. The practical significance of this understanding lies in the ability to customize the boot-blade combination to suit individual needs and skating style. Failure to do so can lead to suboptimal performance, discomfort, and an increased risk of injury.

3. Lacing System

The lacing system is an integral component of ice skates, playing a crucial role in securing the foot, providing ankle support, and ultimately influencing performance. Its design and functionality directly impact the fit and feel of the skate, making it a key consideration within the broader context of ice skate parts.

- Lace Material and Durability

The material composition of the laces, typically nylon or synthetic fibers, dictates their strength, resistance to abrasion, and ability to maintain tension. Durable laces ensure a secure and consistent fit, preventing slippage and maintaining ankle support throughout skating sessions. Inadequate material can lead to premature wear and breakage, compromising the overall integrity of the skate.

- Eyelet Design and Placement

The eyelets, through which the laces pass, are strategically positioned to distribute pressure evenly across the foot and ankle. Reinforced eyelets prevent tearing and maintain the structural integrity of the lacing system. Poorly designed or misplaced eyelets can create pressure points, leading to discomfort and potential injury. The configuration of eyelets directly affects the skater’s ability to achieve a customized and secure fit.

- Lacing Technique and Customization

Varying lacing techniques allow skaters to customize the fit and support levels of their skates. Tightening certain sections of the laces provides targeted support in specific areas, such as the ankle or instep. Skaters often employ different lacing patterns to accommodate individual foot shapes and skating styles. Proper lacing technique is essential for maximizing performance and minimizing the risk of injury.

- Lace Hooks and Ankle Support

Lace hooks, commonly found in figure and hockey skates, provide additional leverage for tightening the laces around the ankle. They enable skaters to achieve a secure and supportive fit, enhancing ankle stability and control. The placement and design of lace hooks are crucial for optimizing ankle support and facilitating precise movements on the ice.

These facets of the lacing system underscore its significance within the ensemble of ice skate parts. From the selection of durable materials to the implementation of strategic eyelet placement and the application of personalized lacing techniques, each aspect contributes to the overall performance, comfort, and safety of the skater. A well-designed and properly utilized lacing system is indispensable for maximizing the potential of the ice skate and ensuring a positive skating experience.

4. Rocker Profile

The rocker profile, an element within ice skate parts, denotes the longitudinal curvature of the blade. This curvature significantly influences maneuverability and gliding characteristics. Variations in the rocker profile affect how much of the blade contacts the ice at any given moment, thus altering the skaters agility and speed. Different skating disciplines often require specific rocker profiles tailored to their unique demands. For example, figure skates typically exhibit a more pronounced rocker, enabling tighter turns and facilitating complex jumps. Conversely, hockey skates may feature a flatter profile, prioritizing speed and stability for rapid acceleration and quick stops. The rocker profile is not a static element; skilled technicians can adjust it to suit individual skating styles and preferences.

The interaction between the rocker profile and other ice skate parts is crucial for overall performance. A well-matched rocker profile, in conjunction with appropriate blade edge, boot stiffness, and lacing system, contributes to a balanced and responsive skating experience. Altering the rocker profile can compensate for deficiencies in other areas; however, a comprehensive approach to equipment selection and maintenance is essential for optimal results. A skater attempting advanced figure skating elements with a hockey skate blade, due to its flatter rocker, would likely experience difficulty in achieving the necessary control and precision. Similarly, a hockey player using a figure skate blade could struggle with maintaining speed and stability during high-speed maneuvers.

Understanding the impact of the rocker profile on ice skate performance allows skaters to make informed decisions about equipment selection and customization. While achieving an optimal rocker profile is essential, achieving this goal necessitates a comprehensive appreciation for the interplay of all relevant components. Furthermore, routine maintenance and periodic adjustments are necessary to retain the desired characteristics of this element and ensure its ongoing contribution to the skaters performance.

5. Mounting Hardware

Mounting hardware, a seemingly minor, yet fundamentally vital aspect of ice skate parts, serves to securely affix the blade to the boot. Its integrity directly impacts stability, control, and safety. Compromised mounting hardware can lead to blade detachment, resulting in potential injury and performance degradation.

- Rivet Material and Construction

Rivets, commonly used in skate construction, are subject to considerable stress during skating. The material composition, often steel or aluminum alloys, must possess sufficient strength and corrosion resistance. Poorly constructed or corroded rivets can shear or loosen, compromising the blade’s secure attachment to the boot. Regular inspection and replacement of compromised rivets are critical for maintaining structural integrity.

- Screw Thread Design and Locking Mechanisms

Screws, employed in more advanced skate designs, offer adjustable blade positioning. The thread design must provide secure engagement with both the blade and boot mounting plates. Locking mechanisms, such as thread-locking compounds or locking washers, prevent loosening due to vibration. Failure of these mechanisms can result in blade misalignment or detachment, jeopardizing skater safety and performance.

- Mounting Plate Material and Interface

The mounting plate, situated between the blade and boot, distributes force and provides a stable platform. The material, typically a rigid polymer or metal, must withstand substantial loads without deformation. A properly designed interface between the mounting plate and both the blade and boot ensures optimal force transfer and minimizes stress concentrations. Cracks or deformation in the mounting plate can compromise blade stability and responsiveness.

- Hardware Corrosion and Environmental Factors

Exposure to moisture, ice, and cleaning agents can accelerate corrosion of mounting hardware. Corrosion weakens the hardware, reducing its load-bearing capacity and increasing the risk of failure. Regular cleaning, drying, and application of corrosion inhibitors can prolong the lifespan of mounting hardware and maintain its structural integrity. Ignoring environmental factors can lead to premature hardware degradation and potential skating hazards.

The selection, maintenance, and inspection of mounting hardware are paramount for ensuring the safe and effective operation of ice skates. Although often overlooked, these small components play a critical role in maintaining the connection between skater and ice, directly influencing performance and mitigating the risk of injury. A proactive approach to hardware maintenance is an essential aspect of responsible skating equipment management.

Frequently Asked Questions

The following section addresses common inquiries regarding the components of ice skates. Understanding these aspects promotes informed equipment selection and maintenance.

Question 1: How frequently should ice skate blades be sharpened?

The sharpening frequency depends on usage intensity, ice hardness, and skater proficiency. Professional skaters may require sharpening after each session, while recreational skaters may find monthly sharpening adequate. Indications of dull blades include decreased grip and increased slippage.

Question 2: What constitutes appropriate boot stiffness for a beginner skater?

Beginner skaters generally benefit from softer boot models. These provide greater ankle flexibility, facilitating the development of proper skating technique and balance. Progressing to stiffer boots is appropriate as skill levels advance and greater ankle support becomes necessary.

Question 3: How should ice skate boots be properly dried after use?

Excess moisture should be removed immediately after skating. Boot dryers are an effective option. Alternatively, stuffing the boots with absorbent material, such as newspaper, can mitigate moisture buildup. Adequate drying prevents bacterial growth and extends the boot’s lifespan.

Question 4: What is the significance of the rocker profile of an ice skate blade?

The rocker profile refers to the curvature of the blade along its longitudinal axis. This curvature influences the blade’s contact with the ice, affecting maneuverability and glide. Different skating disciplines require specific rocker profiles tailored to their respective demands.

Question 5: What are the key considerations when selecting lacing for ice skates?

Lace material should prioritize durability and resistance to abrasion. Eyelets must be securely fastened and properly spaced to distribute pressure evenly. Lacing technique should be tailored to provide adequate ankle support without restricting circulation. Regular inspection for wear is essential.

Question 6: How can corrosion of ice skate mounting hardware be prevented?

Routine cleaning and drying after each use are crucial. Application of corrosion inhibitors to the hardware provides an additional layer of protection. Regular inspection for signs of rust or degradation allows for timely replacement of compromised components.

Proper maintenance and informed selection of these elements are essential for optimizing performance, ensuring safety, and extending the longevity of ice skating equipment.

The subsequent section will address advanced customization options for ice skate components.

Ice Skate Parts

This exploration has highlighted the intricate relationship between the individual elements composing ice skates and their collective impact on performance and safety. The correct selection, meticulous maintenance, and precise adjustment of blade edges, boot stiffness, lacing systems, rocker profiles, and mounting hardware are non-negotiable for optimal functionality. Neglecting any single aspect of these individual parts can compromise the entire system.

Continued vigilance in monitoring the condition of skating equipment is paramount. Regular inspections, professional assessments, and timely replacements are essential investments, not only in performance enhancement, but also in injury prevention. Prioritizing a thorough understanding of ice skate parts and adhering to stringent maintenance protocols are critical for ensuring a safe and productive skating experience.