The braided or woven cords employed to fasten ice skates to the feet are critical components of the equipment. These fasteners, typically made of synthetic materials like nylon or polyester, are threaded through eyelets or hooks along the boot to provide a secure and adjustable fit. The tightness and configuration significantly impact the skater’s control and comfort on the ice.

Properly secured footwear is essential for optimal performance and injury prevention. A snug fit enhances ankle support, allowing for precise movements and edge control during skating. Historically, the materials and construction of these cords have evolved from natural fibers to more durable and water-resistant synthetics, reflecting advancements in materials science and the demands of competitive skating.

The subsequent discussion will delve into various aspects of these crucial fasteners, including types of materials, lacing techniques, maintenance procedures, and selection considerations for different skating disciplines and skill levels. This comprehensive exploration aims to provide a deeper understanding of this fundamental, yet often overlooked, element of ice skating equipment.

Ice Skate Laces

Optimizing the use of these fasteners is crucial for performance and safety on the ice. The following tips provide guidance on proper selection, maintenance, and lacing techniques.

Tip 1: Material Selection: Opt for laces made from high-tenacity polyester or nylon. These materials offer superior durability and resistance to abrasion compared to cotton or other natural fibers, which can degrade quickly when exposed to moisture.

Tip 2: Correct Length Determination: Ensure laces are of an appropriate length. Excessively long laces present a tripping hazard, while those that are too short may hinder proper tightening. Refer to skate manufacturer guidelines for recommended lengths based on boot size.

Tip 3: Consistent Tightening: Tighten laces incrementally from the toe to the ankle. This distributes pressure evenly across the foot and provides balanced support. Avoid overtightening, which can restrict circulation and cause discomfort.

Tip 4: Knot Security: Employ a secure knot, such as a surgeon’s knot or a double knot, to prevent slippage during skating. Regularly inspect the knot for wear or loosening and re-tie as needed.

Tip 5: Regular Inspection and Replacement: Examine laces regularly for signs of fraying, cuts, or weakening. Replace them immediately if any damage is detected to prevent failure during use.

Tip 6: Proper Drying Techniques: After each use, remove laces from the skates and allow them to air dry thoroughly. This prevents the growth of mold and bacteria, which can compromise the integrity of the material.

Tip 7: Lacing Techniques for Support: Utilize different lacing patterns to customize support. For example, skipping an eyelet near the ankle can alleviate pressure on the instep, while a “lace lock” technique above the ankle provides enhanced stability.

Adhering to these recommendations ensures the reliable performance of these essential components, contributing to both the skater’s comfort and safety.

The next section will explore the impact of different fastening methods on specific skating disciplines, such as figure skating, hockey, and recreational skating.

1. Material Durability in Ice Skate Laces

Material durability is a paramount consideration in the context of ice skate laces. The operational demands placed upon these components necessitate robust materials capable of withstanding significant stress, environmental factors, and repetitive use. The longevity and reliability of the laces directly influence the skater’s safety and performance.

- Tensile Strength and Load Bearing

Tensile strength, the ability to resist breaking under tension, is critical. Laces must withstand the forces exerted during tightening and the dynamic loads experienced during skating maneuvers. High-performance synthetic materials, like high-tenacity polyester, are chosen for their superior tensile properties. A failure can lead to instability and potential injury.

- Abrasion Resistance on Laces

Contact with the skate’s eyelets and the external environment causes abrasion. Laces with low abrasion resistance will fray and weaken over time. Manufacturers often employ tightly woven constructions and surface treatments to enhance abrasion resistance. Regular inspection is necessary to identify signs of wear and prevent breakage.

- Resistance to Environmental Degradation

Ice and snow expose laces to moisture, freeze-thaw cycles, and potential chemical exposure from ice-treating agents. Materials must resist degradation from these environmental factors. Hydrolytic stability, the ability to resist breakdown in the presence of water, is crucial. Some synthetic materials offer superior hydrolytic stability compared to natural fibers.

- Fatigue Resistance

Repetitive tightening and loosening cycles induce fatigue in the lace material. Fatigue resistance refers to the material’s ability to withstand these repeated stress cycles without failure. Materials with good elasticity and flexibility generally exhibit higher fatigue resistance. Proper lacing techniques, avoiding overtightening, can also extend the lifespan.

The interplay of these factors underscores the importance of material selection in ice skate laces. Choosing laces constructed from durable, high-performance materials ensures reliable performance, enhances skater safety, and extends the lifespan of the skating equipment. Regular maintenance and timely replacement are also essential for preserving the integrity of these critical components.

2. Knot Security and Ice Skate Laces

The integrity of a knot tied in ice skate laces directly impacts the skater’s stability, control, and overall safety. Insufficient knot security can lead to loosening during use, resulting in compromised ankle support and increased risk of falls. Therefore, understanding the factors contributing to knot security is essential for both recreational and competitive skaters.

- Knot Type and Complexity

Different knot types offer varying degrees of security. Simple overhand knots are generally inadequate for ice skate laces due to their propensity to slip under tension. More complex knots, such as the surgeon’s knot or variations of the reef knot, provide enhanced holding power by increasing friction and interlocking the lace strands. The choice of knot should consider both security and ease of untying.

- Material Properties of the Laces

The material composition of the laces influences knot security. Smooth, synthetic materials like nylon, while offering durability and water resistance, can be more prone to slippage than textured natural fibers. The surface texture of the lace affects the friction generated within the knot, a critical factor in maintaining its integrity. Laces with a higher coefficient of friction are more likely to hold a knot securely.

- Tension and Lacing Technique

Consistent tension during the tying process is crucial for creating a secure knot. Uneven tension can lead to stress concentrations and premature loosening. Moreover, the lacing technique employed can indirectly affect knot security. Lacing patterns that distribute pressure evenly along the boot can reduce the strain on the knot, contributing to its longevity.

- Environmental Factors and Wear

Exposure to moisture, ice, and abrasive surfaces can degrade both the laces and the knot itself. Repeated wetting and drying cycles can weaken the fibers, reducing their ability to hold the knot securely. Regular inspection of the knot and laces for signs of wear, such as fraying or thinning, is essential. Worn or damaged laces should be replaced promptly to maintain optimal knot security.

In summary, maintaining adequate knot security in ice skate laces is a multifaceted consideration. It encompasses the selection of an appropriate knot type, the material properties of the laces, the consistency of the lacing technique, and vigilance against environmental factors and wear. Addressing each of these factors contributes to a more secure and reliable skating experience.

3. Lace Length and Ice Skate Laces

Lace length is a critical, yet often overlooked, parameter in the proper fitting and performance of ice skates. The correct length ensures secure fastening, adequate support, and optimal comfort, all of which directly influence a skater’s control and safety on the ice. Selecting an appropriate length is not merely a matter of aesthetics, but a functional necessity for effective skating.

- Impact on Ankle Support and Stability

Insufficient length can restrict the skater’s ability to properly tighten the laces around the ankle, leading to inadequate support and increased risk of instability. Conversely, excessive length presents a tripping hazard and can interfere with skating movements. Optimal length allows for secure tightening without excessive slack, promoting ankle stability and reducing the likelihood of injury. Skaters who participate in activities such as figure skating and hockey place significant demands on their ankles; therefore, sufficient lace length is critical.

- Influence on Tightening Precision and Comfort

The correct lace length allows for precise control over the tightness of the boot across the foot and ankle. This is essential for achieving a customized fit that maximizes comfort and minimizes pressure points. A lace that is too short may prevent uniform tightening, leading to discomfort and potential circulation issues. A lace that is too long can be difficult to manage and may require excessive looping or knotting, creating bulk and potential discomfort. Precise tightening allows skaters to adjust the fit based on their individual needs and preferences, contributing to enhanced comfort and performance.

- Relationship with Boot Size and Lacing Style

The required length is directly related to the size of the ice skate boot. Larger boots necessitate longer laces to adequately reach all eyelets and allow for secure fastening. Moreover, the lacing style employed can influence the required length. More elaborate lacing patterns, such as those used to provide additional ankle support, may require longer laces than simpler, more traditional methods. Manufacturers typically provide guidelines for lace length based on boot size, but skaters should also consider their preferred lacing style when selecting laces.

- Material Type and Stretch Considerations

The material composition can influence the effective length of a lace over time. Some materials, particularly natural fibers, may exhibit stretching after repeated use, effectively shortening the lace and potentially compromising its ability to provide adequate support. Synthetic materials, such as nylon and polyester, generally offer greater resistance to stretching and maintain their length more consistently. Skaters should consider the material properties of the laces when selecting a length, opting for materials that minimize stretch and maintain their integrity over time.

In conclusion, lace length is a vital factor that should not be overlooked. The optimal length depends on several variables, including boot size, lacing style, and material properties. Careful consideration of these factors ensures that the laces provide adequate support, promote comfort, and enhance the overall skating experience. Selecting the correct length contributes to both performance and safety on the ice.

4. Tightness control

Tightness control, achieved through the manipulation of ice skate laces, is a critical determinant of skater performance and safety. The laces function as the primary mechanism for securing the foot and ankle within the boot, thereby directly influencing stability, responsiveness, and comfort. Inadequate tightness results in diminished ankle support, increasing the risk of injury and hindering the skater’s ability to execute precise movements. Conversely, excessive tightness can restrict circulation, leading to discomfort, numbness, and reduced performance.

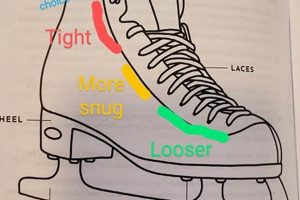

The ability to modulate lace tightness along different sections of the boot enables a customized fit that caters to individual anatomical variations and skating styles. For example, figure skaters often require a snug fit around the ankle for optimal support during jumps and spins, while hockey players may prefer a slightly looser fit to facilitate greater forward flexion and maneuverability. The specific lacing pattern employed, combined with the skater’s dexterity in tightening and loosening the laces, allows for fine-tuned adjustments that maximize performance and minimize discomfort. The skill is therefore integral to effective lace use.

Mastering tightness control with ice skate laces necessitates a thorough understanding of anatomical considerations, material properties, and lacing techniques. Challenges include maintaining consistent tension throughout the laces, preventing slippage during use, and adapting the lacing configuration to changing conditions. Ultimately, effective management promotes a balanced combination of support, comfort, and responsiveness, thereby contributing to a safer and more enjoyable skating experience.

5. Water Resistance and Ice Skate Laces

Water resistance is a critical property of ice skate laces due to the inherent exposure to moisture during skating activities. The composition of the material used in lace construction directly impacts its water resistance and, consequently, its longevity and performance. Laces that readily absorb water become heavier, less pliable, and more susceptible to freezing, which can impede tightening and loosening. Furthermore, absorbed water can accelerate the degradation of the lace fibers, reducing tensile strength and overall lifespan. For example, cotton laces, highly absorbent, are unsuitable for ice skates because they become brittle and prone to breakage when wet and frozen.

Synthetic materials, such as nylon and polyester, are commonly employed in the manufacture of ice skate laces due to their inherent water resistance. These materials exhibit minimal water absorption, maintaining their flexibility and strength even in wet conditions. However, even with synthetic laces, water resistance can be further enhanced through specialized coatings or treatments that create a hydrophobic barrier, preventing water from penetrating the fibers. This is particularly important for skaters who frequently encounter wet ice conditions or participate in prolonged skating sessions, where repeated exposure to moisture can gradually compromise the integrity of even water-resistant materials. Regular maintenance, including drying laces after each use, helps preserve water resistance and extend the functional lifespan.

In summary, water resistance is a non-negotiable attribute of quality ice skate laces. The use of water-resistant materials and proper maintenance practices are essential for ensuring optimal performance, durability, and safety. The selection of laces with appropriate water resistance characteristics should align with the skater’s intended use and the typical environmental conditions encountered. Failure to address water resistance can lead to premature lace failure, compromised ankle support, and an increased risk of injury, underscoring the practical significance of this often-overlooked aspect of ice skating equipment.

6. Abrasion Resistance

Abrasion resistance is a critical performance characteristic of ice skate laces due to the constant frictional forces they endure. During use, laces repeatedly rub against the eyelets of the skate boot, a process that causes gradual wear and material degradation. This abrasive action, if unchecked, can lead to fraying, thinning, and ultimately, breakage of the lace. The selection of materials with inherent abrasion resistance is therefore paramount in ensuring the longevity and reliability of ice skate laces. Low abrasion resistance can cause lace failure during critical moments on the ice, potentially leading to falls and injuries. The impact of this property on safety and performance warrants careful attention.

The choice of materials directly impacts abrasion resistance. Synthetic fibers such as high-tenacity polyester and nylon are commonly employed due to their superior resistance compared to natural fibers like cotton. Moreover, the construction of the lace influences its ability to withstand abrasion. Tightly woven structures minimize the surface area exposed to frictional forces, reducing the rate of wear. Some manufacturers apply specialized coatings to further enhance resistance, creating a protective layer that shields the underlying fibers from abrasion. Examining the materials and construction processes offers insights into understanding the impact of abrasion resistance.

The practical significance of abrasion resistance extends beyond preventing unexpected lace failure. Durable laces retain their structural integrity for a longer period, reducing the need for frequent replacements and saving costs. Further, consistent performance over time translates to enhanced control and confidence on the ice, particularly for demanding activities like figure skating and hockey. Abrasion resistance in ice skate laces is therefore not merely a desirable attribute but a fundamental requirement for safety, performance, and economic efficiency.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, maintenance, and proper use of these essential components of ice skating equipment.

Question 1: What constitutes an acceptable material for ice skate laces?

Synthetic materials, specifically high-tenacity polyester and nylon, are recommended due to their superior durability, water resistance, and abrasion resistance compared to natural fibers. Cotton laces are unsuitable due to their propensity to absorb moisture and weaken when frozen.

Question 2: How does one determine the appropriate length?

The appropriate length is dependent upon the boot size and the lacing pattern employed. Consult the skate manufacturer’s guidelines for recommended lengths based on boot size. Additional length may be required for elaborate lacing patterns that provide enhanced ankle support.

Question 3: What knot type is most secure for ice skate laces?

A surgeon’s knot or a double knot is recommended to prevent slippage during skating. These knots provide enhanced holding power by increasing friction and interlocking the lace strands. Regularly inspect the knot for wear or loosening and re-tie as needed.

Question 4: How frequently should ice skate laces be replaced?

laces should be replaced immediately if any signs of damage, such as fraying, cuts, or weakening, are detected. Regular inspection is essential to prevent failure during use. The frequency of replacement depends on the intensity of use and the environmental conditions encountered.

Question 5: What are the implications of overtightening the laces?

Overtightening can restrict circulation, leading to discomfort, numbness, and reduced performance. It can also contribute to premature wear of the laces and the skate boot. Incremental tightening from the toe to the ankle is recommended to distribute pressure evenly.

Question 6: How does moisture affect ice skate laces, and what preventive measures are recommended?

Exposure to moisture can degrade lace fibers and reduce their tensile strength. It is recommended to remove the laces from the skates and allow them to air dry thoroughly after each use. This prevents the growth of mold and bacteria, which can compromise the integrity of the material.

Adhering to these recommendations ensures the reliable performance, contributing to the skater’s comfort and safety. Key takeaways include prioritizing synthetic materials, maintaining regular inspection, and employing secure knots.

The subsequent section will explore specific product recommendations and brands known for manufacturing high-quality laces.

Ice Skate Laces

This exploration has underscored the fundamental role of ice skate laces in both recreational and competitive skating. Key aspects, including material durability, knot security, and appropriate length, directly influence a skater’s performance, safety, and comfort. The transition from natural to synthetic materials represents a significant advancement, providing enhanced water resistance and abrasion resistance. Proper maintenance, inspection, and timely replacement are critical for preserving the integrity of these components.

The selection and care of ice skate laces should not be treated as an afterthought. These elements are critical. Continued advancements in materials and manufacturing processes offer the potential for further improvements in performance and durability. Skaters are encouraged to critically evaluate their laces and prioritize quality and maintenance to ensure a safe and rewarding experience on the ice. Neglecting this critical aspect of equipment increases the likelihood of injury and impairs optimal performance.