Specialized footwear designed for use on ice surfaces, these provide the necessary support and stability for gliding and performing maneuvers. These items are typically constructed with a rigid outer shell, a supportive inner liner, and a blade attached to the sole. Figure skaters, hockey players, and recreational skaters all utilize this type of equipment.

The equipment’s construction and design are critical for performance and safety. Proper ankle support minimizes the risk of injury, while blade quality influences glide efficiency and control. Historically, these items have evolved from simple leather boots with attached bone or metal blades to technologically advanced models incorporating lightweight materials and custom fitting options. This evolution has greatly enhanced both athletic performance and the overall experience of skating.

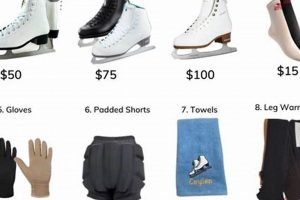

The subsequent sections will delve into the various types of this equipment available, the key features to consider when selecting a pair, and essential maintenance practices to ensure longevity and optimal performance. The materials used, the fitting process, and the proper care routines significantly impact the user’s experience.

Essential Guidelines for Selection and Maintenance

The following guidelines offer crucial advice for individuals seeking to optimize their experience with specialized footwear for ice surfaces. Proper selection and maintenance are paramount for both performance and longevity.

Tip 1: Prioritize Proper Fit: Ill-fitting specialized footwear can lead to discomfort, blisters, and compromised performance. Seek professional fitting services to ensure adequate support and prevent excessive movement within the boot.

Tip 2: Assess Ankle Support: Adequate ankle support is vital for stability and injury prevention. Evaluate the stiffness of the boot’s upper portion and choose a level of support appropriate for the intended skating discipline and skill level.

Tip 3: Consider Blade Quality: The blade’s material and design significantly impact glide efficiency and control. Higher-quality blades, often made of hardened steel, maintain their edge longer and provide superior performance.

Tip 4: Inspect Blades Regularly: Blades should be inspected regularly for nicks, burrs, and rust. Address any imperfections promptly to maintain optimal edge quality and prevent damage.

Tip 5: Dry Blades After Each Use: Moisture can cause rust and corrosion. After each use, thoroughly dry blades with a clean cloth and consider applying a rust inhibitor to prolong their lifespan.

Tip 6: Utilize Blade Guards: When not in use, protect blades with appropriate guards. Hard guards are suitable for walking off the ice, while soft guards absorb moisture and prevent rust during storage.

Tip 7: Store Appropriately: Store specialized footwear in a dry, well-ventilated area away from direct sunlight and extreme temperatures. This prevents the deterioration of materials and minimizes odor buildup.

Adhering to these guidelines enhances performance, extends the lifespan of the equipment, and contributes to a safer and more enjoyable skating experience.

The subsequent section will address common issues encountered with specialized footwear, providing troubleshooting advice and potential solutions.

1. Ankle Support

Ankle support constitutes a critical element within the design and functionality of specialized footwear intended for use on ice surfaces. Its presence and effectiveness directly influence the wearer’s stability, control, and susceptibility to injury. The boot’s structure, particularly in the ankle region, provides external stabilization, limiting excessive lateral movement. This stabilization is essential for maintaining balance and executing precise maneuvers inherent in activities such as figure skating and hockey. A deficiency in ankle support can lead to sprains, strains, and compromised performance. For instance, a hockey player lacking sufficient support might be more prone to ankle injuries during rapid turns and collisions, while a figure skater may struggle to maintain proper form during jumps and spins.

The level of desired ankle support varies depending on the skating discipline and the skater’s skill level. Beginner skaters often benefit from stiffer, more rigid support to facilitate learning and build confidence. Advanced skaters, particularly in figure skating, may prefer boots with a degree of flexibility to allow for greater range of motion and artistic expression. However, even with flexible boots, adequate support remains paramount to prevent injury during demanding routines. The construction materials, such as reinforced polymers and leather, significantly contribute to the boot’s ability to provide effective ankle support. Furthermore, the lacing system and any additional strapping mechanisms work in concert to secure the foot and ankle, further enhancing stability.

In summary, the relationship between ankle support and specialized ice footwear is integral to the skater’s safety and performance. Understanding the nuances of ankle support, including its impact on stability, control, and injury prevention, is crucial for selecting appropriate equipment and optimizing the skating experience. Neglecting this aspect can lead to compromised performance and an increased risk of injury. Selection should reflect the skater’s experience level and skating style.

2. Blade attachment

The interface between blade and boot is fundamental to the performance characteristics of specialized footwear designed for ice surfaces. The secure and precise connection dictates the transfer of force from the skater’s body to the ice, influencing maneuverability, stability, and overall control. Methods of attachment vary, ranging from traditional riveting techniques to more modern approaches utilizing screws and specialized adhesives. Each method presents distinct advantages and disadvantages with respect to durability, adjustability, and shock absorption. Inadequate blade attachment can result in instability, reduced responsiveness, and, in extreme cases, catastrophic failure leading to injury. For example, a loose or improperly aligned blade can impair a hockey player’s ability to execute sharp turns or prevent a figure skater from landing jumps accurately.

The selection of an appropriate attachment method often depends on the intended use of the specialized footwear. Figure skating boots, for example, may benefit from a more precise and adjustable attachment system to allow for fine-tuning of blade alignment. Hockey boots, on the other hand, typically require a more robust and durable attachment method to withstand the high-impact forces associated with the sport. Furthermore, the materials used in both the blade and boot construction must be compatible to ensure a strong and lasting bond. Corrosion, differential thermal expansion, and galvanic corrosion are all potential concerns that must be addressed during the design and manufacturing processes. The correct installation and maintenance of the blade attachment are also critical, requiring specialized tools and expertise.

In summary, blade attachment is a critical determinant of the efficacy and safety of specialized footwear for ice surfaces. Proper selection, installation, and maintenance of the attachment mechanism are paramount for maximizing performance and minimizing the risk of injury. Understanding the intricacies of blade attachment enables informed decision-making regarding equipment selection and maintenance practices, contributing to an enhanced and safer skating experience. Further research and development in this area continue to drive improvements in blade attachment technology, promising even greater performance and safety in the future.

3. Internal padding

The presence and characteristics of internal padding significantly influence the functionality and user experience of specialized footwear designed for ice surfaces. This padding serves multiple crucial roles, extending beyond mere comfort to encompass performance enhancement and injury mitigation.

- Impact Absorption

Internal padding materials, such as foams and gels, possess inherent shock-absorbing properties. These properties are vital in reducing the transmission of impact forces from the ice to the skater’s foot and ankle, particularly during landings from jumps or collisions. Insufficient impact absorption can lead to discomfort, bruising, and even stress fractures over prolonged use.

- Customization and Fit

Many modern designs incorporate heat-moldable padding that conforms to the unique contours of the wearer’s foot. This customization ensures a snug and secure fit, minimizing slippage within the boot and maximizing energy transfer during skating. A poorly fitted interior can result in blisters, chafing, and compromised performance.

- Thermal Regulation

Internal padding materials can contribute to thermal regulation within the boot. Certain foams possess insulating properties, helping to maintain a comfortable temperature and prevent excessive heat loss in cold environments. Conversely, breathable padding materials can wick away moisture, preventing sweat buildup and reducing the risk of frostbite or discomfort.

- Support and Stability

Strategically placed padding can provide additional support to the ankle and foot, enhancing stability and control. High-density foams are often used in the ankle area to limit excessive movement and prevent sprains. Furthermore, arch support padding can improve foot alignment and reduce fatigue during extended skating sessions.

These various facets underscore the importance of carefully considering the internal padding characteristics when selecting specialized footwear for use on ice surfaces. The interplay between impact absorption, customization, thermal regulation, and support dictates the overall comfort, performance, and safety of the equipment. Neglecting the intricacies of internal padding can lead to compromised performance and an increased risk of injury.

4. Material composition

The performance and durability of specialized footwear for ice surfaces are inextricably linked to their material composition. The materials used in construction directly affect a boot’s weight, flexibility, support, thermal properties, and resistance to wear and tear. Understanding these relationships is crucial for selecting equipment that meets the demands of a particular skating discipline and the skater’s skill level. For example, the outer shell frequently incorporates layered materials such as leather, synthetic polymers, and reinforced composites. Leather offers traditional durability and moldability, while synthetic polymers provide water resistance and reduced weight. Composite materials, such as carbon fiber, offer exceptional stiffness and support, often favored in high-performance models.

The inner lining, responsible for comfort and thermal regulation, typically consists of moisture-wicking fabrics and insulating foams. These materials are chosen to manage perspiration, prevent frostbite, and provide cushioning. The blade attachment system also relies on specific material properties to ensure a secure and lasting bond. The blade itself is typically constructed from hardened steel, selected for its ability to maintain a sharp edge and resist corrosion. The rivets or screws used to attach the blade must also be resistant to corrosion and capable of withstanding repeated stress. Furthermore, the sole of the boot, which connects the upper portion to the blade, requires a material with high impact resistance and structural integrity.

In summary, material composition is a defining characteristic influencing the overall quality and functionality of specialized footwear for ice surfaces. The careful selection of materials, based on their specific properties and intended application, is essential for optimizing performance, ensuring durability, and maximizing safety. Ongoing research and development in materials science continue to drive innovation in this field, leading to lighter, stronger, and more comfortable equipment for skaters of all levels. The understanding of materials will help in selecting suitable “ice skate boots”.

5. Closure system

The closure system of specialized footwear for ice surfaces plays a crucial role in ensuring a secure and customized fit, directly influencing performance, comfort, and safety. This system, encompassing laces, buckles, straps, or a combination thereof, is responsible for maintaining foot stability within the boot, preventing excessive movement that can lead to blisters, reduced control, or potential injury. Effective closure distributes pressure evenly across the foot, providing support and promoting optimal energy transfer during skating. For instance, a well-designed lacing system on a figure skating boot allows for precise adjustments to achieve the desired level of ankle support, while a secure buckle system on a hockey boot ensures a snug fit even during high-impact collisions. Without a reliable closure mechanism, the boot’s intended design characteristics are significantly compromised.

Different skating disciplines necessitate different closure system configurations. Figure skates often feature intricate lacing patterns that allow for customized tension zones, catering to the specific needs of complex maneuvers. Hockey skates, prioritizing impact resistance and rapid adjustments, frequently incorporate a combination of traditional laces and supplementary straps. Recreational skates may opt for simpler, more user-friendly systems such as buckles or hook-and-loop fasteners. The choice of materials used in the closure system, such as durable laces, reinforced buckles, and high-strength straps, is also critical for longevity and reliability. Furthermore, the placement and design of these components directly impact the ease of use and the ability to make quick adjustments while on the ice. The proper tension of the closure system can affect blood circulation, as too tight system can result in discomfort and even numbness due to restricted blood flow, whilst too loosely tied skating boots, or any of their components, increase the risk of ankles injuries.

In summary, the closure system represents an integral component of specialized footwear for ice surfaces, directly affecting fit, support, and overall performance. Understanding the nuances of different closure mechanisms, their specific applications, and their impact on the skating experience is essential for selecting appropriate equipment and ensuring a safe and enjoyable skating experience. Innovation in closure system design continues to focus on enhancing adjustability, durability, and ease of use, reflecting the ongoing pursuit of optimal performance and safety in ice sports.

6. Heat moldability

Heat moldability, as a feature in specialized footwear for ice surfaces, presents a significant advancement in achieving optimal fit and performance. The process involves utilizing heat to soften the boot’s internal structure, allowing it to conform precisely to the unique contours of the wearer’s foot. This customization is critical for eliminating pressure points, maximizing comfort, and enhancing energy transfer. A direct consequence of heat moldability is improved stability and control, particularly beneficial in disciplines such as figure skating where precise movements are paramount. For example, skaters with anatomical irregularities can benefit from the boot adapting specifically to their foot shape, mitigating discomfort and enhancing their ability to perform complex maneuvers. The practical significance of this lies in the reduction of break-in time, minimizing the risk of blisters and promoting a more enjoyable and efficient skating experience.

The implementation of heat moldability typically involves specialized ovens or heat guns, carefully applying controlled heat to the boot’s shell and internal padding. Manufacturers often provide specific instructions regarding temperature and duration to prevent damage to the materials. The success of the molding process depends on the quality and composition of the materials used in the boot’s construction. High-quality thermoplastic polymers and specialized foams are frequently employed to facilitate effective and repeatable molding. Furthermore, the design of the boot’s internal structure plays a crucial role in ensuring uniform heat distribution and preventing localized hot spots. Proper execution of the heat molding procedure can significantly enhance the skater’s connection with the ice, providing a more responsive and comfortable skating experience, translating to more efficiency in motion.

In conclusion, heat moldability represents a valuable feature in specialized footwear for ice surfaces, offering significant benefits in terms of fit customization, comfort, and performance. While challenges may exist in ensuring proper execution of the molding process and maintaining material integrity, the advantages outweigh the drawbacks for many skaters. This technology underscores the ongoing evolution of ice skating equipment, driven by the pursuit of enhanced performance and a more comfortable and enjoyable experience. Understanding the principles and practical applications of heat moldability contributes to informed decision-making when selecting and maintaining specialized footwear.

7. Blade sharpness

Blade sharpness is a critical determinant of the functionality of ice skate boots, directly affecting a skater’s ability to maneuver, control, and maintain balance on the ice surface. A properly sharpened blade allows for efficient energy transfer and precise edge control, essential for both recreational skating and competitive disciplines. The absence of adequate sharpness compromises these factors, increasing the risk of falls and hindering performance.

- Edge Control

Sharp blades provide distinct edges that grip the ice, enabling skaters to execute turns, stops, and intricate maneuvers with precision. Dull blades, conversely, slide uncontrollably, reducing edge control and making it difficult to maintain a stable position. For figure skaters, sharp edges are paramount for executing jumps and spins, while hockey players rely on sharp edges for quick turns and acceleration.

- Glide Efficiency

Sharp blades reduce friction between the blade and the ice surface, resulting in a smoother and more efficient glide. This minimizes energy expenditure and allows skaters to maintain speed with less effort. Dull blades create greater friction, requiring more force to maintain momentum and leading to premature fatigue. For long-distance skaters, glide efficiency is crucial for conserving energy and maximizing speed.

- Safety and Stability

Sharp blades enhance stability by providing a secure grip on the ice, reducing the likelihood of slips and falls. Dull blades offer minimal resistance, increasing the risk of losing balance and sustaining injuries. Proper blade sharpness is particularly important for beginner skaters, as it provides them with the necessary stability to learn basic skating techniques safely.

- Response and Precision

Sharp blades provide skaters with immediate and precise response to their movements. Slight adjustments in body position translate directly into changes in direction and speed. Dull blades, in contrast, exhibit a delayed and imprecise response, making it challenging to execute complex maneuvers with accuracy. Advanced skaters rely on this responsiveness for optimal performance.

The interplay between blade sharpness and the functionality of ice skate boots underscores the importance of regular blade maintenance. Consistent sharpening ensures that the blades retain their optimal edge, maximizing performance, safety, and the overall skating experience. Neglecting blade sharpness can negate the benefits of even the highest-quality ice skate boots. The skater would not get the expected benefits of “ice skate boots” if the “blade sharpness” is not optimal.

Frequently Asked Questions

The following section addresses common inquiries regarding specialized footwear designed for use on ice. The information provided aims to clarify misconceptions and offer practical guidance on selection, maintenance, and usage.

Question 1: How frequently should blades undergo sharpening?

The frequency of blade sharpening depends on several factors, including the quality of the ice, the skater’s skill level, and the amount of use. As a general guideline, blades should be sharpened when the edges feel dull or when the skater notices a decrease in grip and control. Professional assessment is recommended to determine the optimal sharpening schedule.

Question 2: What distinguishes figure skating boots from hockey boots?

Figure skating boots typically feature a higher cut for greater ankle support and a more flexible sole to facilitate jumps and spins. Hockey boots prioritize impact protection and stiffness, with a lower cut for increased mobility and a more rigid sole for power transfer. Blade configurations also differ significantly between the two disciplines.

Question 3: How should specialized footwear be properly stored?

Specialized footwear should be stored in a dry, well-ventilated area away from direct sunlight and extreme temperatures. Blades should be dried thoroughly after each use to prevent rust, and blade guards should be employed to protect the edges during storage and transport. Avoid storing the equipment in airtight containers, as this can promote moisture buildup.

Question 4: Can specialized footwear be used for activities other than skating?

Specialized footwear is designed specifically for use on ice surfaces and is not suitable for other activities. Walking on hard surfaces can damage the blades and compromise the structural integrity of the boot. Furthermore, using the equipment for non-skating activities may void the manufacturer’s warranty.

Question 5: What are the signs of a poorly fitted specialized boot?

Signs of a poorly fitted specialized boot include excessive movement of the foot within the boot, pressure points or discomfort in the ankle or foot, and blisters or chafing after skating. A professional fitting is essential to ensure proper size and support, minimizing the risk of injury and maximizing performance.

Question 6: How does the material composition of specialized footwear affect performance?

The material composition of specialized footwear significantly influences its weight, flexibility, support, and durability. High-quality materials, such as reinforced polymers, leather, and hardened steel, provide optimal performance and longevity. The selection of appropriate materials is crucial for meeting the demands of a particular skating discipline and the skater’s skill level.

Proper selection and maintenance are paramount for maximizing the lifespan and performance capabilities. Addressing these queries fosters a more informed understanding of the importance of this specialized equipment.

The subsequent section will delve into troubleshooting common issues encountered with specialized footwear, providing potential solutions and preventative measures.

Conclusion

The preceding exploration has illuminated the multifaceted nature of ice skate boots, emphasizing their crucial role in facilitating safe and effective movement on ice. Key considerations, ranging from ankle support and blade attachment to material composition and closure systems, directly influence the skater’s performance, comfort, and risk of injury. Understanding these aspects is paramount for making informed decisions regarding equipment selection and maintenance.

The ongoing evolution of ice skate boot technology underscores a commitment to enhancing both athletic capabilities and user experience. Continued adherence to best practices in fitting, maintenance, and blade care remains essential for maximizing the lifespan and performance capabilities of this equipment. Investing in quality and proper care ultimately translates to a safer, more enjoyable, and more productive time on the ice. The information provided should facilitate the selection of ice skate boots suited to individual needs and skill levels.