Protective coverings designed to shield the sharp edges of figure or hockey skate blades constitute essential equipment. These coverings, typically made of plastic or rubber, prevent damage to the blades when walking off the ice surface. For example, skaters use them to traverse from the locker room to the rink without dulling or chipping the finely honed edges.

The employment of such protective measures is paramount in maintaining the longevity and performance of the blades. Preserving the blade’s sharpness enhances a skater’s control and maneuverability on the ice. Historically, makeshift solutions were employed before specialized products became readily available, highlighting a continuous need to safeguard this crucial piece of sporting equipment.

The subsequent sections will elaborate on the different types of these coverings, their proper usage, maintenance tips, and factors to consider when selecting the most suitable option for specific skating needs.

Essential Practices for Optimal Blade Protection

This section provides key recommendations for ensuring the longevity and efficacy of blade protection devices, preserving skate performance and preventing unnecessary damage.

Tip 1: Proper Sizing is Critical: Ensure the protective covers fit snugly. Oversized or loose-fitting covers can slide off, leaving the blades vulnerable. Consult sizing charts provided by manufacturers.

Tip 2: Thorough Drying Post-Use: Always wipe down the blades with a dry cloth before inserting them into the protective covers. Moisture trapped inside can lead to rust and corrosion, diminishing blade sharpness and performance.

Tip 3: Regularly Inspect for Damage: Examine the covers for cracks, splits, or wear. Damaged covers offer inadequate protection and should be replaced immediately.

Tip 4: Use Soft Cloths for Cleaning: Avoid abrasive cleaners or scouring pads when cleaning the interior of the protective covers. These can scratch the material and compromise its protective capabilities. Use a mild detergent and a soft cloth.

Tip 5: Separate Storage When Not in Use: Do not store skates inside the covers for extended periods. The covers are primarily for short-term protection when transporting or walking off the ice. Allow blades to air dry fully in a well-ventilated area.

Tip 6: Replace Worn Covers Promptly: The lifespan of protective coverings is dependent on frequency of use and conditions. Replace them at the first signs of significant wear or damage to maintain optimal blade safeguarding.

Adhering to these guidelines will contribute significantly to the preservation of skate blades, ensuring consistent performance and extending the lifespan of expensive skating equipment.

The next section will provide guidance on selecting the most appropriate blade protection based on skating discipline and individual requirements.

1. Protection

Protection, in the context of ice skate blade guards, refers to the devices’ primary function: shielding the delicate and precisely sharpened edges of ice skate blades from damage during off-ice activities. This protection is crucial for maintaining performance and extending the lifespan of the blades.

- Abrasion Resistance

Blade guards are designed to withstand the abrasive forces encountered when walking on various surfaces, such as concrete, rubber flooring, or tile. Without this resistance, the blades would rapidly dull, requiring frequent and costly sharpening. Examples include skaters walking from the locker room to the ice surface, where the guards prevent contact with the abrasive surfaces. The implications are reduced blade maintenance costs and consistent skate performance.

- Impact Dampening

The protective covers help to absorb and distribute impact forces. Accidental bumps against hard objects can chip or damage the blade edges. The dampening effect minimizes the risk of such damage. An example is a skater inadvertently bumping their skates against a bench; the guards absorb some of the impact. The result is preserving the blade’s integrity, reducing the likelihood of damage requiring repair.

- Corrosion Prevention

Blade guards also indirectly contribute to corrosion prevention. By encouraging skaters to wipe down their blades before inserting them, the covers help minimize moisture retention, a key factor in rust formation. For instance, a skater consistently wiping down blades before using blade guards prevents the prolonged contact of moisture with the steel. This practice effectively slows corrosion.

- Edge Alignment Maintenance

The structure of certain blade guard designs can contribute to maintaining the alignment of the blade edge. While not their primary function, guards that fit snugly and securely can help prevent minor warping or misalignment during storage or transport. Skaters can benefit from this function if their blades are well fit and tight in the guards to prevent it from moving around.

These multifaceted protective aspects of blade guards are essential for skaters of all levels. By addressing abrasion, impact, corrosion, and edge alignment, these accessories contribute significantly to the upkeep of ice skates, guaranteeing that skaters can keep their performance.

2. Material

The composition of an ice skate blade guard fundamentally dictates its protective capabilities, durability, and overall effectiveness. The selection of material directly impacts the guard’s ability to withstand abrasion, absorb impact, and resist environmental degradation. Inadequate material choice can lead to premature wear, insufficient blade protection, and potential damage to the skates. For example, a guard made from brittle plastic may crack upon impact, rendering it unable to shield the blade from sharp edges or rough surfaces encountered during off-ice transit. The causal relationship between material and performance is thus undeniable: superior materials beget superior protection, while inferior materials compromise the integrity of the skate blades.

Various materials are employed in the manufacture of these guards, each offering a distinct set of advantages and disadvantages. Hard plastics, such as polypropylene, provide excellent abrasion resistance and structural integrity, suitable for walking on concrete or asphalt. However, these materials may lack sufficient impact absorption, potentially transmitting force to the blade upon impact. Softer materials, such as rubber or thermoplastic elastomers (TPEs), offer enhanced impact dampening and flexibility, making them ideal for use in locker rooms or on softer surfaces. Nonetheless, these materials may exhibit lower abrasion resistance, wearing down more rapidly with frequent use on abrasive surfaces. Hybrid designs, incorporating both hard and soft materials, seek to balance these competing properties, providing a compromise between abrasion resistance and impact absorption.

Therefore, material selection is a crucial consideration when choosing blade guards. Understanding the properties of different materials and their suitability for specific skating environments and usage patterns is essential for ensuring optimal blade protection and maximizing the lifespan of expensive skating equipment. A well-informed choice contributes directly to both cost savings through reduced maintenance and enhanced skating performance by preserving blade sharpness and integrity. A durable and well-chosen guard can safeguard the blades from the risks of damage, while an inadequate choice leaves the skater vulnerable to damage.

3. Size

The dimension of ice skate blade guards is a critical factor influencing their protective efficacy and usability. Proper sizing ensures secure blade coverage, prevents slippage, and optimizes overall performance of the guard.

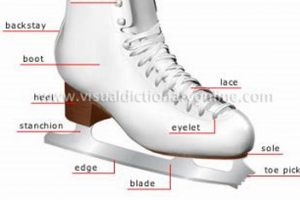

- Length Accommodation

This dimension must correspond accurately to the length of the skate blade. Insufficient length leaves portions of the blade exposed, rendering them vulnerable to damage. Conversely, excessive length can cause the guard to become unwieldy and prone to dislodging. For example, a figure skater with 9-inch blades requires guards of a corresponding length to ensure complete protection from heel to toe. Improperly sized guards result in compromised protection and potential blade damage.

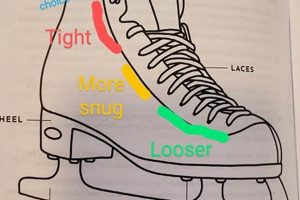

- Width Fit

The internal width of the guard must accommodate the blade’s thickness and profile. An overly tight fit can cause friction and accelerated wear on both the blade and the guard. An excessively loose fit allows the blade to move within the guard, increasing the risk of impact damage. An example includes a hockey skate blade, typically thicker than a figure skate blade, requiring a wider guard channel. An unsuitable width compromises blade security and potentially reduces guard lifespan.

- Rocker Profile Compatibility

Certain skate blades, particularly those used in figure skating, possess a pronounced rocker profile (curvature). Blade guards must be designed to accommodate this curvature to ensure proper fit and secure retention. Incompatible guard designs can exert undue pressure on the blade, potentially causing warping or damage. For instance, a guard designed for a flat blade may not properly fit a heavily rockered figure skating blade. Incorrect curvature compatibility causes damage or improper guarding.

- Adjustability Mechanisms

Some guards feature adjustable components, such as screws or elastic bands, to accommodate slight variations in blade size and profile. These mechanisms can enhance the versatility of the guard and provide a more customized fit. However, the effectiveness of these adjustments depends on the quality of the design and materials. For example, an adjustable guard with a weak elastic band may loosen over time, compromising blade security. Unreliable adjustability reduces long-term effectiveness.

These considerations underscore the importance of selecting ice skate blade guards with appropriate dimensions. Precise fitting assures that it guards the blade securely to maintain longevity and performance. An adequately sized guard effectively safeguards against damage and contributes to the skater’s overall safety and equipment maintenance. Mismatched size could defeat the purpose and damage blade.

4. Maintenance

The upkeep of ice skate blade guards is intrinsically linked to the longevity and performance of both the guards themselves and, crucially, the ice skate blades they are designed to protect. Neglecting maintenance can compromise the guard’s protective capabilities, leading to potential blade damage and premature replacement of equipment.

- Regular Cleaning

Accumulation of dirt, debris, and moisture within the guards can lead to corrosion of the blades and degradation of the guard material. Routine cleaning with a mild detergent and a soft cloth removes these contaminants, preserving the integrity of both components. For example, wiping down the interior of the guard after each use prevents the buildup of salt and grit that can accelerate rust formation on the blades. Regular cleaning prevents damage.

- Drying Procedures

Moisture trapped within the guards is a primary cause of blade corrosion. Establishing a consistent drying procedure, such as removing the blades from the guards immediately after use and allowing both to air dry, mitigates this risk. Failing to do so can result in rust spots and pitting on the blade surface, diminishing its sharpness and performance. Proper drying prevents rust.

- Inspection for Wear and Tear

Periodic inspection of the guards for cracks, splits, or worn areas is essential for identifying potential points of failure. Damaged guards offer inadequate protection and should be replaced promptly. Ignoring these signs can lead to unexpected blade damage during transport or off-ice activities. Regular inspection identifies points of failure.

- Proper Storage Practices

Storing blade guards and skates in a dry, well-ventilated environment prevents the growth of mold and mildew, further minimizing the risk of corrosion. Avoiding enclosed, damp spaces, such as skate bags, promotes air circulation and reduces moisture retention. Proper storage can lead to longer product lifespan.

In essence, a proactive maintenance regimen for ice skate blade guards is not merely a matter of hygiene but a critical investment in the long-term health and performance of skating equipment. Consistent cleaning, diligent drying, regular inspection, and proper storage collectively contribute to minimizing blade damage and maximizing the lifespan of both the guards and the blades they protect. A well-maintained guard can protect blade, or else it cannot.

5. Type

The category of ice skate blade guards significantly influences their suitability for specific skating disciplines and usage scenarios. Different skating styles necessitate different blade profiles and protection needs, leading to the development of specialized guard designs. Understanding these variations is crucial for selecting guards that effectively safeguard blades and enhance overall skating performance. For instance, figure skating blades often possess a pronounced rocker and toe picks, requiring guards with accommodating features, while hockey skate blades, with their relatively flat profile, may necessitate guards with greater abrasion resistance for frequent off-ice use.

Variations include hard plastic guards designed for walking on rough surfaces, often favored by hockey players traversing from locker rooms to the ice rink. These guards prioritize durability and abrasion resistance. In contrast, softer, pliable guards are more suitable for locker room use or temporary storage, minimizing the risk of scratching or damaging adjacent equipment. Some guard designs incorporate specialized features such as integrated rockers, which allow skaters to simulate skating motions off-ice, aiding in warm-up routines. The choice between these types hinges on the skater’s specific needs and the intended use of the guards.

In summation, the type of ice skate blade guard is not a trivial detail but a critical determinant of its effectiveness. Careful consideration of skating discipline, intended usage environment, and desired features is essential for selecting guards that provide optimal blade protection and contribute to a positive skating experience. Failure to account for type can result in inadequate protection, premature guard failure, or even damage to the skate blades themselves.

6. Durability

Durability, in the context of ice skate blade guards, represents the capacity of the guards to withstand prolonged use and exposure to various environmental factors without significant degradation in their protective capabilities. The durability of blade guards directly influences their lifespan and, consequently, the degree of protection afforded to the delicate ice skate blades. The cause-and-effect relationship is clear: less durable guards degrade more rapidly, increasing the risk of blade damage, while durable guards maintain their protective function for an extended period, safeguarding the blades from nicks, scratches, and corrosion. For example, guards constructed from low-grade plastic may crack or split after only a few months of use, exposing the blades to potential harm. The importance of durability as a component of ice skate blade guards is therefore paramount, serving as a critical determinant of their long-term value and effectiveness.

The selection of materials and manufacturing processes significantly impacts durability. High-density polymers and reinforced construction techniques enhance a guard’s resistance to abrasion, impact, and environmental stressors. Skaters who frequently traverse rough surfaces, such as concrete or asphalt, demand guards with exceptional durability to withstand the abrasive forces. Similarly, skaters who subject their equipment to extreme temperatures or humidity require guards that resist degradation under these conditions. Manufacturers often employ rigorous testing procedures to assess the durability of their products, simulating real-world wear and tear to ensure they meet specified performance standards. The practical application of this understanding lies in enabling skaters to make informed purchasing decisions, selecting guards that align with their individual needs and skating environments.

Ultimately, the pursuit of durable ice skate blade guards is an investment in the long-term preservation of skating equipment. While initial cost may be a factor, the reduced frequency of replacement and the minimized risk of blade damage associated with durable guards often translate to significant cost savings over time. Challenges remain in accurately assessing durability prior to purchase, as subjective factors such as usage patterns and environmental conditions can influence a guard’s lifespan. Nevertheless, a focus on reputable brands, high-quality materials, and positive user reviews provides a reasonable basis for selecting durable blade guards that effectively protect valuable ice skate blades.

Frequently Asked Questions

This section addresses common inquiries regarding ice skate blade guards, providing clarity on their purpose, usage, and maintenance.

Question 1: Why are ice skate blade guards necessary?

Ice skate blade guards protect the finely sharpened edges of skate blades when walking off the ice. Contact with hard surfaces, such as concrete or tile, can quickly dull or damage the edges, impacting skating performance. Guards mitigate this risk.

Question 2: What materials are commonly used in ice skate blade guards?

Common materials include hard plastics (polypropylene), rubber, and thermoplastic elastomers (TPEs). Hard plastics offer abrasion resistance, while softer materials provide impact dampening. Hybrid designs incorporating both are also available.

Question 3: How should ice skate blade guards be sized?

Guards should correspond accurately to the length and width of the skate blade. Length should cover the entire blade from heel to toe. Width should accommodate the blade’s thickness without excessive tightness or looseness.

Question 4: What is the proper maintenance routine for ice skate blade guards?

Maintenance includes regular cleaning with a mild detergent, thorough drying of both the guards and blades after each use, and periodic inspection for cracks or wear. Avoid storing skates in guards for extended periods.

Question 5: Are there different types of ice skate blade guards for different skating disciplines?

Yes, different types exist. Hard plastic guards are common for hockey, prioritizing abrasion resistance. Softer guards are often used in figure skating. Some feature integrated rockers for off-ice warm-up exercises.

Question 6: How often should ice skate blade guards be replaced?

Replacement frequency depends on usage and wear. Guards should be replaced at the first signs of significant damage, such as cracks, splits, or worn areas, to maintain adequate blade protection.

Proper usage and maintenance of ice skate blade guards are critical for prolonging the life and performance of ice skate blades. Adhering to these guidelines will contribute to an enhanced skating experience.

The subsequent section offers a concluding summary encapsulating the key information.

Conclusion

Ice skate blade guards are critical components in preserving the condition and performance of ice skate blades. This exploration has underscored the significance of appropriate material selection, accurate sizing, consistent maintenance, and choosing a guard type suited to the specific skating discipline. Failure to address these factors can lead to premature blade wear, increased maintenance costs, and compromised skating performance.

The safeguarding of ice skate blades requires a diligent and informed approach. Prioritizing the appropriate protective measures outlined herein will contribute to the longevity of skating equipment and ensure consistent performance on the ice. Skaters, coaches, and equipment managers bear a shared responsibility in promoting best practices for blade maintenance and protection.