The duration required for honing blades to the proper edge for ice skating varies significantly based on several factors. These factors include the skate’s condition, the equipment utilized, and the skill of the individual performing the sharpening. An estimate can range from a few minutes for a minor touch-up to upwards of twenty minutes for a more extensive grinding.

Proper blade maintenance is crucial for optimal performance and safety on the ice. Sharp blades offer better control, increased speed, and reduced risk of falls. The practice of maintaining skate blades has evolved alongside the sport itself, with advancements in sharpening technology contributing to increased precision and efficiency.

The following sections will delve into the key aspects influencing the time required for this maintenance, examining the preparation involved, the sharpening process itself, and post-sharpening procedures to achieve optimal results. Considerations also include frequency and the type of skater/skates.

Tips for Efficient Skate Sharpening

Optimizing the skate sharpening process necessitates a strategic approach. Adhering to specific guidelines can minimize the time required and maximize the quality of the resulting edge.

Tip 1: Pre-Sharpening Inspection: Always thoroughly inspect the skate blades prior to sharpening. Identifying existing damage, such as deep nicks or burrs, allows for appropriate preparation and prevents unnecessary time spent on blades that require significant repair.

Tip 2: Equipment Calibration: Verify the calibration of sharpening equipment before each use. A properly calibrated machine ensures consistent and accurate grinding, reducing the need for repeated passes and minimizing overall duration.

Tip 3: Consistent Pressure Application: Maintain consistent and even pressure during the sharpening process. Erratic pressure can lead to uneven edges and necessitate additional corrective passes, extending the total time involved.

Tip 4: Proper Wheel Selection: Utilize the appropriate grinding wheel for the type of skate and desired edge. Selecting the correct wheel minimizes material removal and optimizes the sharpening efficiency.

Tip 5: Regular Wheel Maintenance: Ensure grinding wheels are regularly cleaned and dressed. A clean and well-maintained wheel performs more efficiently, reducing the time required to achieve the desired edge.

Tip 6: Hone After Sharpening: After the sharpening process, employ a honing stone to remove any remaining burrs. This post-sharpening refinement contributes to a smoother, more consistent edge, eliminating the need for additional sharpening passes later on.

These tips, when implemented consistently, can contribute to a reduction in the duration spent sharpening skates while simultaneously enhancing the quality and longevity of the blade edge.

The subsequent sections will explore the factors that may influence the frequency needed, plus skater level consideration that can affect the duration of the sharpening procedure.

1. Blade Condition

The state of a skate blade prior to sharpening is a primary determinant of the time required for the procedure. A blade with minimal wear, requiring only a slight touch-up to restore a sharp edge, naturally demands less time than one exhibiting significant damage such as deep gouges, rust, or substantial dulling. In cases of severe damage, more extensive grinding is necessary to remove the imperfections and re-establish a proper edge profile.

For example, consider two scenarios: a figure skater who diligently maintains their blades by drying them after each use and regularly using blade guards will likely only need a quick honing to maintain optimal performance. Conversely, a hockey player who frequently encounters impacts with the boards and other players, resulting in nicks and edge damage, will require a more involved sharpening process, potentially including multiple passes on the grinding wheel to restore a smooth, even edge. Neglecting the condition of skate blades not only increases the sharpening duration but can also compromise the integrity of the blade over time, leading to premature replacement.

Therefore, understanding the initial condition of the blade is critical in accurately estimating the necessary sharpening duration. Regular blade maintenance and careful handling contribute significantly to reducing the time and effort required for sharpening, while also extending the lifespan of the skates themselves. This proactive approach ensures consistent performance and minimizes the risk of blade-related issues on the ice.

2. Equipment Calibration

The precise adjustment of skate sharpening machinery plays a crucial role in determining the efficiency of the blade maintenance process. When equipment is properly calibrated, the time required to achieve a consistently sharp and accurate edge is minimized. Conversely, miscalibration can significantly extend the sharpening duration and compromise the quality of the final result.

- Wheel Trueness and Dressing

A true and properly dressed grinding wheel is essential for uniform material removal. An out-of-round wheel, or one with embedded debris, will produce uneven contact with the blade, necessitating repeated passes and prolonging the sharpening time. Consistent dressing ensures the wheel’s abrasive surface remains clean and effective.

- Alignment of Blade Holder

Precise alignment of the blade holder is critical for maintaining the correct edge geometry. Misalignment can cause the blade to be ground at an incorrect angle, requiring additional adjustments and increasing the overall time. Furthermore, an improperly aligned holder can lead to uneven wear on the grinding wheel.

- Calibration of Depth Control

The depth control mechanism regulates the amount of material removed with each pass. A properly calibrated depth control allows for precise adjustments, preventing excessive material removal and minimizing the risk of damaging the blade. Inaccurate depth control can lead to over-grinding, extending the sharpening process and potentially shortening the blade’s lifespan.

- Verification of Speed Settings

Grinding wheel rotational speed is important to the sharpen time. Higher speeds remove material quickly, but generates more friction/heat. Lower speeds may be necessary to prevent damage to the blade. However, the lower speeds increases the processing time.

In conclusion, the state of calibration of sharpening equipment directly influences the duration of the sharpening procedure. Properly maintained and calibrated machinery ensures efficient material removal, accurate edge geometry, and minimized risk of blade damage, ultimately reducing the time required to achieve a high-quality, sharp edge. Regular calibration checks are an essential aspect of responsible skate maintenance.

3. Skater Level

The skill level of an ice skater significantly influences the requirements for blade sharpening, thereby impacting the time invested in the process. The demands placed on the skates by different skill levels necessitate variations in the sharpening approach and desired edge characteristics.

- Beginner Skaters

Novice skaters generally require a shallower hollow, which offers enhanced stability and easier control. This shallower cut requires less material removal, shortening the sharpening time. The primary goal is to provide a forgiving edge that minimizes the risk of falls and promotes confidence on the ice. Sharpening for beginners focuses on a safe and manageable experience.

- Intermediate Skaters

As skaters progress, they often seek a slightly deeper hollow to improve their ability to execute turns and edges. This deeper cut necessitates more material removal, increasing the sharpening time compared to beginner skates. The sharpening process begins to prioritize enhanced maneuverability while still maintaining a degree of stability. The balance shifts toward performance rather than solely focusing on safety.

- Advanced Skaters (Competitive)

Elite skaters, including figure skaters and hockey players, demand precise edge control and maximum responsiveness. This often translates to a deeper hollow or specialized edge profiles that require meticulous sharpening techniques and increased time investment. These skaters may also have specific preferences or requirements tailored to their individual skating styles, adding further complexity to the sharpening process. Consistent performance and precision are very critical.

- Recreational Skaters

Recreational skaters’ needs are more flexible. Their requirement of a blade is usually to maintain a good time without needing the blades to be optimized for professional or advanced maneuvers. Therefore, a moderate sharpening is required that does not take long to accomplish.

In summary, skater proficiency directly correlates with the intricacy of the sharpening required. Beginners benefit from simple, quick sharpenings focused on stability, while advanced skaters necessitate more time-consuming, precise honing to achieve optimal performance characteristics. The demands of each skill level shape the sharpening approach and ultimately dictate the time needed to complete the process effectively.

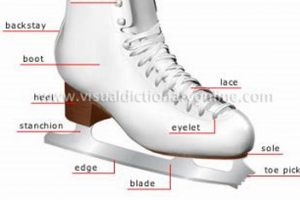

4. Desired ROH (Radius of Hollow)

The radius of hollow (ROH) refers to the concavity ground into the blade’s running surface, creating two distinct edges. This parameter exerts a direct influence on the duration required for skate blade sharpening. A deeper ROH, characterized by a smaller radius value (e.g., 3/8″), necessitates more material removal from the blade to achieve the desired concavity. Conversely, a shallower ROH, signified by a larger radius value (e.g., 1″), requires less material removal. Thus, the time spent grinding the blade is proportional to the depth of the hollow being created. For instance, transitioning from a 1/2″ ROH to a 3/8″ ROH on a pair of skates will inherently demand a longer sharpening time than simply refreshing an existing 1/2″ ROH. Selecting the correct ROH is not only important to the duration of the sharpening process, but crucial to performance in skating.

The relationship between desired ROH and sharpening time is further complicated by the skater’s discipline and skill level. Hockey players often prefer a deeper ROH for enhanced edge control and tighter turns, while figure skaters may opt for a shallower ROH to facilitate gliding and smoother transitions. Therefore, a hockey skate requiring a 3/8″ ROH will typically take longer to sharpen than a figure skate aiming for a 5/8″ ROH, assuming all other factors remain constant. Additionally, the initial condition of the blade influences the sharpening time; a badly worn blade requiring significant reshaping will take longer to sharpen regardless of the desired ROH. Technicians must always communicate with their customers to identify the use case for the skates, so that they can grind the skate blades to meet the customer’s needs. A failure to communicate with the customer may result in disappointment.

In summary, the desired ROH is a key determinant of the time needed to sharpen ice skate blades. A deeper hollow equates to increased material removal and, consequently, a longer sharpening process. While skater discipline and blade condition also play significant roles, understanding the connection between ROH and sharpening time enables informed decisions regarding blade maintenance and allows for more accurate time estimates when seeking professional sharpening services. Ultimately, selecting the appropriate ROH ensures optimal performance and safety on the ice.

5. Technician Skill

The proficiency of the technician executing the sharpening procedure exerts a considerable influence on the duration of the service. Expertise in blade analysis, equipment operation, and fine-tuning directly correlates with efficiency. A seasoned technician can accurately assess the blade’s condition, select the appropriate grinding wheel and settings, and execute the sharpening process with minimal wasted effort. Conversely, an inexperienced technician may require more time to achieve comparable results, potentially due to uncertainty in blade assessment, suboptimal equipment handling, and iterative adjustments.

Consider a scenario involving two technicians tasked with sharpening identical pairs of hockey skates exhibiting similar wear. The first technician, possessing years of experience, quickly identifies minor imperfections, selects a precise grinding wheel, and completes the sharpening process in approximately fifteen minutes, achieving a consistent, high-quality edge. The second technician, relatively new to the craft, spends additional time analyzing the blade, experimenting with different wheel types, and making repeated passes to correct inconsistencies. This protracted process may extend the sharpening time to thirty minutes or more, and the resulting edge quality may not match that achieved by the experienced technician. Moreover, technician competence extends beyond speed to include blade preservation. Overzealous or incorrect grinding can prematurely wear down the blade, necessitating more frequent replacements.

In conclusion, technician expertise constitutes a critical determinant of the time required for skate sharpening. Skilled technicians streamline the process through efficient blade assessment, optimized equipment utilization, and precise execution, yielding consistent results in a reduced timeframe. This highlights the significance of seeking qualified professionals for skate maintenance, not only to ensure optimal blade performance but also to minimize the service duration and safeguard the longevity of the equipment. Choosing an experienced technician can lead to reduced waiting times and prolonged blade life, underlining the practical advantages of expertise in this specialized craft.

Frequently Asked Questions

The following questions address common concerns regarding the time required for ice skate blade sharpening. Answers are based on standard practices and considerations within the industry.

Question 1: What is the typical time range for sharpening a pair of ice skates?

The duration varies widely, typically falling between 10 and 30 minutes per pair. Factors influencing the time include blade condition, equipment calibration, and technician skill.

Question 2: Does the type of skating (hockey vs. figure skating) influence sharpening time?

Yes, the desired radius of hollow (ROH) often differs between disciplines. Hockey skates frequently require a deeper ROH, potentially increasing the time needed.

Question 3: Can a severely damaged blade significantly increase the sharpening duration?

Indeed, blades with deep gouges, rust, or significant dulling necessitate more extensive grinding, substantially extending the process.

Question 4: Does the skater’s skill level affect the time required for sharpening?

Yes, beginner skaters typically require a shallower ROH, which demands less material removal, thereby reducing the sharpening time.

Question 5: How does equipment calibration impact the duration of the sharpening process?

Properly calibrated machinery ensures consistent and accurate grinding, minimizing the need for repeated passes and reducing the overall duration. Miscalibration extends the time required.

Question 6: Is professional sharpening always faster than attempting to sharpen skates at home?

Generally, yes. Professional technicians possess the expertise and equipment necessary for efficient and precise sharpening. Home sharpening attempts, lacking proper tools and skills, are often slower and can potentially damage the blades.

Accurate time estimation necessitates considering the totality of factors outlined above. Seeking professional services from experienced technicians is recommended for efficient and reliable blade maintenance.

The subsequent section will examine the long-term consequences of neglecting blade maintenance and the potential benefits of establishing a regular sharpening schedule.

Determining the Duration of Ice Skate Sharpening

The question of “how long does it take to sharpen ice skates” is multifaceted, with no single definitive answer. As explored in this discussion, the duration is contingent upon a confluence of factors, encompassing blade condition, equipment calibration, skater level, desired radius of hollow, and the expertise of the technician. Neglecting any one of these elements can lead to inaccuracies in time estimation and potential compromises in blade quality.

Therefore, understanding these variables is crucial for both skaters and service providers. Prioritizing regular blade maintenance, seeking qualified technicians, and ensuring proper equipment calibration contribute to efficient sharpening processes and optimal performance on the ice. The investment in proper blade care is an investment in skater safety, performance, and the longevity of the skates themselves.