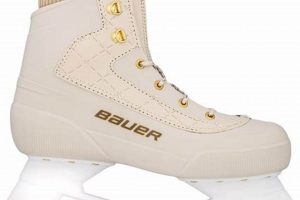

Italian-engineered footwear designed for ice skating, particularly figure skating, provides a crucial interface between the skater and the ice. The specialized boots and blades are crafted to facilitate precise movements and offer a high degree of control. These implements are essential tools for athletes pursuing excellence in various ice skating disciplines.

These specialized skates offer superior support and responsiveness, enabling skaters to execute complex jumps, spins, and footwork with greater confidence and precision. The emphasis on lightweight construction and advanced materials contributes to enhanced performance capabilities. The design philosophy prioritizes both comfort and performance, influencing the evolution of skating techniques and competitive standards.

The following sections will delve into specific models, technological innovations, fitting considerations, and maintenance practices associated with this specialized equipment, offering a comprehensive understanding of their impact on the sport of ice skating.

Tips for Optimal Use

Achieving peak performance and ensuring longevity requires adherence to specific guidelines for selection, maintenance, and use.

Tip 1: Ensure Proper Fit: Accurate sizing is paramount. Ill-fitting footwear can impede performance and increase the risk of injury. Professional fitting services are recommended to achieve optimal comfort and support.

Tip 2: Blade Alignment Verification: The alignment of the blades relative to the boot is critical for balance and edge control. Regular checks and adjustments by a qualified technician are advised.

Tip 3: Regular Drying and Storage: Moisture can degrade the boot’s structure and promote rust on the blades. Always thoroughly dry the boots after each use and store them in a well-ventilated environment with blade protectors.

Tip 4: Blade Sharpening Schedule: Maintain sharp blade edges for precise grip and control on the ice. The frequency of sharpening depends on skating frequency and ice conditions; consult with a professional sharpener for personalized recommendations.

Tip 5: Lacing Technique: Employ consistent lacing techniques to provide adequate ankle support without restricting circulation. Uneven lacing can compromise stability and comfort.

Tip 6: Boot Maintenance: Regularly clean the outer surface of the boots with a damp cloth to remove dirt and grime. Use appropriate leather care products as needed to maintain suppleness and prevent cracking.

Tip 7: Gradual Break-In: New boots require a gradual break-in period to conform to the skater’s foot. Short skating sessions followed by increasing duration are recommended to minimize discomfort and prevent blisters.

Adhering to these guidelines will contribute significantly to enhancing performance, extending the lifespan, and maximizing the overall skating experience.

The subsequent section will explore common issues encountered during usage and provide practical solutions to address them effectively.

1. Lightweight Boot Design

The incorporation of a lightweight boot design is a defining characteristic of Edea ice skates, directly influencing a skater’s agility, endurance, and overall performance. This design philosophy distinguishes these skates within the competitive landscape, demanding a thorough examination of its components and implications.

- Reduced Material Mass

Edea achieves lightweighting through the strategic selection of advanced composite materials and minimalist structural designs. By reducing the overall mass of the boot, skaters experience less fatigue during extended training sessions and competitions. The reduced weight allows for quicker transitions and more effortless execution of complex jumps and spins.

- Enhanced Agility and Responsiveness

Lighter boots translate directly into enhanced agility on the ice. Skaters can react more quickly to changing conditions and execute intricate footwork with greater precision. The reduced inertia allows for faster rotational speeds during spins and quicker acceleration during jumps, ultimately contributing to improved technical scores.

- Improved Energy Efficiency

The energy expenditure required to move and control a skate is directly proportional to its weight. Lightweight boots reduce the energy demands on the skater, allowing them to maintain a higher level of performance for a longer duration. This is particularly crucial in endurance-based disciplines such as long programs and theatrical ice skating.

- Advanced Polymer Usage

Edea implements the use of advanced polymers as opposed to the leather in traditional boots. By utilizing materials such as carbon fiber and advanced thermoplastic resins, the brand achieves the optimal balance between weight reduction, support, and durability. The benefits are seen in overall performance through reduced burden to the skater.

In conclusion, the lightweight boot design inherent in Edea ice skates represents a deliberate engineering choice, directly impacting the skater’s performance by enhancing agility, reducing fatigue, and improving energy efficiency. This focus on lightweight construction demonstrates a commitment to optimizing the skater’s experience and maximizing their competitive potential.

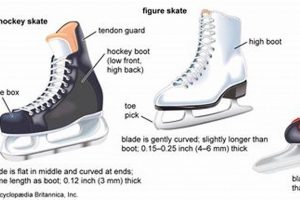

2. Blade Mounting Precision

Blade mounting precision represents a critical factor in the performance and safety of Edea ice skates. The accurate alignment and secure attachment of the blade to the boot directly influence a skater’s balance, control, and ability to execute complex maneuvers. Deviations from precise mounting specifications can compromise performance and elevate the risk of injury.

- Lateral Alignment and Edge Control

The lateral alignment of the blade dictates the skater’s ability to maintain a stable edge. Precise mounting ensures that the blade’s center of pressure aligns with the skater’s center of gravity, providing optimal control during turns and edge work. Misalignment can lead to instability, difficulty in holding edges, and reduced maneuverability. Professional technicians use specialized jigs and measurement tools to ensure accurate lateral alignment during the mounting process.

- Longitudinal Positioning and Balance

The longitudinal positioning of the blade affects the skater’s overall balance and posture. Correct placement ensures that the blade’s sweet spot aligns with the skater’s natural stance, promoting efficient energy transfer and reducing strain on the joints. Improper longitudinal positioning can lead to forward or backward imbalances, affecting the skater’s ability to execute jumps and spins effectively. Expert fitters consider individual skater biomechanics when determining optimal longitudinal placement.

- Secure Attachment and Energy Transfer

The secure attachment of the blade to the boot is essential for efficient energy transfer. A loose or improperly mounted blade can dissipate energy, reducing the skater’s power and responsiveness. Secure attachment ensures that all the skater’s force is directed into the ice, maximizing propulsion and control. Edea utilizes high-quality mounting hardware and precision drilling techniques to achieve a robust and reliable connection between the blade and the boot.

- Influence on Jump Landings and Stability

Precisely mounted blades are critical for stability during jump landings. The accurate alignment and secure attachment provide a stable platform for absorbing impact forces, reducing the risk of ankle injuries. Furthermore, properly mounted blades promote even distribution of pressure, contributing to a more controlled and balanced landing. Skaters often report improved confidence and consistency in their jump landings after receiving professional blade mounting services.

The preceding points underscore the integral role blade mounting precision plays in the functionality of Edea ice skates. The alignment process facilitates optimized balance, control, and energy transfer. Professional fitters and technicians are essential to this process, ensuring the skates meet the unique needs of each skater.

3. Thermo-formable Customization

Thermo-formable customization is a pivotal feature integrated into the design of Edea ice skates, enabling a degree of personalization crucial for both performance enhancement and injury prevention. This process allows the boot’s materials to be molded to the unique contours of the skater’s foot through the application of heat. The result is a fit that minimizes pressure points, maximizes support, and optimizes the transfer of energy between the skater and the ice. Without this capability, achieving a truly individualized fit would be significantly more challenging, often necessitating compromises in comfort and performance.

The benefits of thermo-formable customization extend beyond mere comfort. By conforming precisely to the skater’s foot, the boot provides enhanced proprioception, allowing for more accurate feedback and control. This is particularly important for advanced skaters executing complex maneuvers. For instance, a skater experiencing persistent ankle pain due to ill-fitting boots might find significant relief and improved stability following a professional thermo-forming session. Similarly, skaters seeking incremental gains in performance often leverage this feature to refine their boot fit, maximizing responsiveness and minimizing energy loss. Proper customization also reduces the incidence of blisters and other foot-related ailments, facilitating longer and more productive training sessions.

In summary, thermo-formable customization is not merely an optional feature of Edea ice skates but an integral component that directly impacts the skater’s comfort, performance, and overall well-being. This design element underscores the brand’s commitment to providing athletes with equipment tailored to their individual needs, thereby maximizing their potential and minimizing the risks associated with the sport. While challenges remain in achieving perfect customization for every skater, ongoing advancements in materials and fitting techniques continue to improve the efficacy and accessibility of this vital feature.

4. Ankle Support System

The ankle support system within Edea ice skates represents a critical engineering consideration, directly impacting skater performance and injury prevention. Edea’s design philosophy emphasizes both flexibility and stability, acknowledging that unrestricted movement is as vital as safeguarding against excessive ankle strain. The structure of the boot, particularly around the ankle area, is meticulously designed to provide a balance between range of motion and controlled restriction, thus enabling skaters to execute demanding maneuvers while minimizing the risk of sprains or other injuries. For example, the higher boot height, reinforced heel counter, and strategic padding are all contributing factors to the system’s overall effectiveness. A skater performing a triple jump, for instance, relies heavily on the ankle support to maintain balance upon landing, preventing the ankle from collapsing inward or outward. The absence of adequate support could lead to significant instability and a higher likelihood of injury.

The practical application of a well-designed ankle support system extends beyond injury prevention. A properly supported ankle allows skaters to exert more force through their blades, enhancing power and control. By minimizing energy loss due to ankle instability, the system optimizes the skater’s ability to execute intricate footwork, maintain clean edges, and achieve greater speed. Moreover, the integration of thermo-formable materials enables a customized fit around the ankle, further enhancing support and comfort. A skater spending hours on the ice can attest to the difference a properly fitted and supportive boot makes in terms of reducing fatigue and maximizing training effectiveness. The evolution of skating boot technology has led to significant advancements in ankle support systems, with manufacturers like Edea constantly innovating to improve both safety and performance.

In conclusion, the ankle support system in Edea ice skates serves as a critical link between skater and ice, enabling dynamic movement while mitigating injury risks. The intricate design, materials, and customization options all contribute to the system’s effectiveness. Understanding the nuances of this system is essential for skaters, coaches, and equipment specialists alike, as it informs decisions regarding boot selection, fitting, and maintenance. As skating continues to evolve, the demands placed on ankle support systems will only increase, driving further innovation and refinement in this crucial area of skate technology.

5. Blade Material Quality

Blade material quality directly influences the performance characteristics of Edea ice skates. The type of steel used in the blade’s construction determines edge retention, resistance to corrosion, and the overall lifespan of the equipment. High-quality steel alloys, often containing chromium and other elements, provide a harder, more durable edge that requires less frequent sharpening. This is crucial for figure skaters who rely on precise edges for executing intricate jumps, spins, and footwork. Inferior materials are prone to chipping, bending, and rapid dulling, compromising control and potentially leading to falls. The selection of premium materials is therefore a primary factor differentiating high-performance skates from entry-level models.

The metallurgical properties of the blade material also affect its interaction with the ice surface. Superior steel alloys exhibit a lower coefficient of friction, allowing for smoother gliding and enhanced speed. The ability of the blade to efficiently channel away meltwater generated by friction is also a function of the material’s composition and surface finish. Elite skaters often cite the superior glide characteristics of high-quality blades as a significant factor in their ability to achieve peak performance. For example, a skater executing a Biellmann spin requires a blade that maintains a consistent edge and minimizes friction to sustain the spin’s speed and stability. The choice of blade material, therefore, becomes a critical determinant of success at the highest levels of competition.

Ultimately, blade material quality represents a fundamental aspect of Edea ice skate design and performance. The use of premium steel alloys translates directly into enhanced edge control, improved glide characteristics, and increased durability. While higher-quality materials often entail a greater initial investment, the long-term benefits in terms of performance, safety, and equipment longevity justify the expense. Ongoing research and development in materials science continue to drive advancements in blade technology, pushing the boundaries of what is possible on the ice.

6. Heat Moldable Structure

The integration of heat-moldable technology in Edea ice skates represents a significant advancement in personalized fit and performance enhancement. This structural characteristic allows skaters to achieve a customized boot shape, addressing individual anatomical variations and optimizing comfort and control. The heat-moldable aspect interacts directly with the boot’s composite materials, enabling a conforming fit unattainable through traditional methods.

- Custom Contouring for Enhanced Comfort

The heat-moldable structure enables the boot to conform precisely to the skater’s foot contours, eliminating pressure points and potential sources of discomfort. This personalized fit is particularly beneficial for skaters with unique foot shapes or pre-existing foot conditions. The ability to mold the boot around bony prominences or areas prone to rubbing reduces the likelihood of blisters and other foot-related injuries, allowing for extended periods of comfortable skating. For example, a skater with bunions can achieve a customized fit that accommodates the deformity, preventing pain and allowing for unrestricted movement.

- Optimized Energy Transfer and Control

A snug, conforming fit maximizes the transfer of energy from the skater’s foot to the blade. This is achieved by minimizing internal slippage and ensuring that the skater’s movements are directly translated into blade control. The heat-moldable structure eliminates dead space within the boot, creating a more responsive and efficient connection between the skater and the ice. As an example, a skater performing a difficult jump will experience enhanced stability and control during takeoff and landing due to the optimized energy transfer facilitated by the customized fit.

- Improved Ankle Support and Stability

The heat-moldable structure extends to the ankle region, providing enhanced support and stability. The customized fit around the ankle helps to prevent excessive pronation or supination, reducing the risk of ankle sprains and other injuries. This is especially important for skaters performing demanding jumps and spins that place significant stress on the ankle joint. A well-molded ankle region provides a secure and stable platform, allowing the skater to maintain balance and control during complex maneuvers.

- Long-Term Durability and Fit Retention

While the heat molding process initially shapes the boot to the foot, the materials used are selected for their ability to retain their shape over time. This ensures that the customized fit remains consistent, even after repeated use. The long-term durability of the heat-moldable structure contributes to the overall lifespan of the skates, providing skaters with a reliable and comfortable performance platform for years to come. Properly maintaining the skates and following the manufacturer’s instructions for heat molding will maximize the longevity of the customized fit.

In conclusion, the heat-moldable structure of Edea ice skates offers a significant advantage in terms of personalized fit, comfort, and performance. By allowing skaters to achieve a customized boot shape, this technology enhances energy transfer, improves ankle support, and reduces the risk of foot-related injuries. The integration of heat-moldable materials represents a commitment to optimizing the skating experience and maximizing the potential of each skater.

7. Performance Enhancing Features

Edea ice skates incorporate several performance-enhancing features engineered to optimize athletic capabilities on the ice. The integration of lightweight materials, such as carbon fiber and advanced polymers, reduces overall skate weight, leading to decreased skater fatigue and increased agility. This weight reduction allows for quicker acceleration and more efficient execution of complex maneuvers. Blade mounting precision, achieved through advanced manufacturing techniques, ensures optimal blade alignment, maximizing edge control and stability. The thermo-formable boot construction enables a customized fit, conforming to the skater’s foot and minimizing energy loss due to internal slippage. These features collectively contribute to improved balance, responsiveness, and overall skating proficiency.

The practical significance of these performance-enhancing features is evident in competitive skating. Athletes utilizing Edea ice skates often demonstrate improved jump height, spin speed, and edge quality, resulting in higher scores and greater competitive success. For instance, the lightweight construction can enable a skater to rotate more quickly during quadruple jumps, increasing the likelihood of successful completion. The precise blade alignment contributes to cleaner edge landings, reducing deductions and improving overall program scores. Furthermore, the customized fit minimizes discomfort and fatigue, allowing skaters to train for longer periods and maintain peak performance levels throughout competitions. These features, therefore, directly impact a skater’s ability to execute demanding routines with greater precision and consistency.

In summary, the performance-enhancing features integrated into Edea ice skates represent a deliberate engineering focus on optimizing athletic performance. Lightweight materials, precise blade mounting, and thermo-formable construction work synergistically to improve balance, responsiveness, and overall skating proficiency. These features have a tangible impact on competitive success, enabling skaters to execute complex maneuvers with greater precision and consistency. Continued innovation in materials and manufacturing techniques will likely lead to further advancements in skate technology, pushing the boundaries of athletic performance on the ice. These innovations do, however, present economic challenges related to accessibility for skaters who may be unable to afford higher end models.

Frequently Asked Questions

The following questions address common inquiries regarding the selection, maintenance, and usage of specialized skating equipment.

Question 1: What factors should be considered when selecting Edea ice skates?

Selection depends on the skater’s skill level, skating discipline, and foot characteristics. Professional fitting services are recommended to ensure optimal fit and performance. Considerations include boot stiffness, blade type, and thermo-formability.

Question 2: How often should Edea ice skate blades be sharpened?

Sharpening frequency depends on skating frequency, ice conditions, and the skater’s individual preferences. Regular inspections for edge dullness are advised. A qualified skate technician can provide personalized sharpening recommendations.

Question 3: What is the proper method for drying Edea ice skates after use?

Boots should be thoroughly dried inside and out after each use. Remove the insoles to facilitate air circulation. Blade protectors should be used during storage to prevent rust formation. Avoid direct heat sources, which can damage the boot’s materials.

Question 4: How does the thermo-formable feature of Edea ice skates work?

The thermo-formable materials within the boot can be molded to the skater’s foot shape using heat. This process requires specialized equipment and expertise. Professional fitting services are recommended to ensure proper molding and prevent damage to the boot.

Question 5: What is the expected lifespan of Edea ice skates?

Lifespan depends on usage frequency, maintenance practices, and the skater’s skill level. Proper care and regular maintenance can extend the lifespan of the skates. Signs of wear and tear, such as boot degradation or blade damage, may indicate the need for replacement.

Question 6: What are the recommended storage conditions for Edea ice skates?

Store in a cool, dry environment away from direct sunlight and extreme temperatures. Use blade protectors to prevent rust and damage. Avoid storing in airtight containers, which can trap moisture and promote mold growth.

Proper selection, maintenance, and storage are crucial for maximizing performance and extending the lifespan of the product.

The next section will explore common issues encountered during usage and provide practical solutions to address them effectively.

Conclusion

This exploration has highlighted various facets of Edea ice skates, encompassing their design, technological innovations, performance-enhancing features, and maintenance requirements. Key points include the significance of lightweight construction, blade mounting precision, thermo-formable customization, and ankle support systems, all of which contribute to enhanced skater performance and safety.

The continued pursuit of innovation in materials and manufacturing techniques will undoubtedly shape the future of skating equipment. Skaters, coaches, and equipment specialists should maintain a commitment to understanding and applying best practices in skate selection, fitting, and maintenance to maximize both athletic potential and equipment longevity. The evolution of skating hinges, in part, on the conscientious utilization of advanced equipment like Edea ice skates.