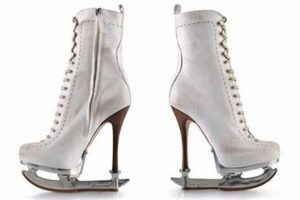

This specialized footwear is designed for figure skating, offering a combination of support and flexibility that aids athletes in performing complex jumps and maneuvers. The construction typically involves a reinforced boot with a blade attached to the sole, engineered to withstand the rigors of high-impact landings and intricate footwork. These skates often incorporate lightweight materials to enhance agility and responsiveness on the ice.

The development of these skates has significantly impacted the evolution of figure skating techniques. Their design facilitates increased jump height, improved landing stability, and enhanced overall performance. Historically, advancements in materials and construction methods have led to constant refinements, resulting in ever-more sophisticated models that meet the demands of elite skaters. The availability of customizable options allows for precise fitting, crucial for injury prevention and optimized athletic performance.

Further discussion will delve into the specific design features, technological innovations, and considerations for selecting appropriate models. Analysis of the materials used, the blade configurations available, and the fitting process will provide a comprehensive understanding of these essential pieces of equipment.

Guidance on Selection and Maintenance

The following recommendations are intended to assist individuals in choosing and caring for high-performance figure skating equipment to maximize performance and longevity.

Tip 1: Proper Sizing is Paramount: Accurate foot measurement is essential. Seek professional fitting services from a qualified retailer to ensure the correct size and width. Ill-fitting footwear can lead to discomfort, blisters, and compromised performance.

Tip 2: Consider Skill Level: Different models cater to varying skill levels. Beginners may benefit from boots with increased ankle support, while advanced skaters may require greater flexibility for complex maneuvers. Consult with a coach to determine the appropriate stiffness and features.

Tip 3: Blade Selection is Crucial: The blade profile and radius impact edge control and maneuverability. Research different blade types and consult with a skating professional to select a blade that complements skating style and technical abilities.

Tip 4: Regular Blade Sharpening: Dull blades compromise grip and control. Schedule professional sharpening regularly, based on skating frequency and ice conditions. A sharp blade ensures clean edges and optimal performance.

Tip 5: Boot Maintenance is Essential: After each use, thoroughly dry the boots inside and out to prevent moisture buildup. Consider using boot dryers or stuffing boots with absorbent materials. Regular cleaning and conditioning of leather components will prolong the lifespan of the equipment.

Tip 6: Proper Storage is Important: Store the equipment in a dry, well-ventilated area away from direct sunlight and extreme temperatures. Avoid storing equipment in skate bags for extended periods, as this can trap moisture and promote mildew growth.

Tip 7: Inspect Equipment Regularly: Before each use, inspect the boots and blades for signs of wear and tear, such as loose screws, cracked soles, or damaged blades. Address any issues promptly to prevent further damage or potential injury.

Adhering to these guidelines can significantly enhance performance, extend equipment lifespan, and contribute to a safer and more enjoyable skating experience.

The subsequent section will delve into advanced customization options and address common troubleshooting issues.

1. Lightweight construction

Lightweight construction is a critical design element within specialized figure skating equipment. This characteristic directly influences the skater’s agility, speed, and overall performance. The use of lighter materials reduces the energy required for jumps, spins, and other complex maneuvers. As a result, skaters experience less fatigue, allowing them to maintain performance quality throughout training sessions and competitions. A reduction in weight also translates to a quicker response time to changes in balance and direction, contributing to improved control and precision on the ice.

The implementation of lightweight construction involves employing advanced composite materials and innovative structural designs. For example, manufacturers often utilize carbon fiber and specialized polymers to minimize weight while maintaining the necessary support and durability. Furthermore, the internal components are engineered to reduce bulk without compromising stability. Consider the comparison between earlier skate models and contemporary designs; the reduction in overall weight is substantial, resulting in a noticeable improvement in skaters’ ability to execute challenging routines. This advancement allows skaters to focus more on technique and artistry, and less on overcoming the limitations of heavy equipment.

In summary, the lightweight construction significantly enhances performance capabilities, reduces fatigue, and improves responsiveness. This design consideration directly contributes to the competitiveness of skaters. The strategic use of advanced materials and refined engineering elevates the athlete’s potential on the ice. It’s crucial in high-performance skating, influencing jump height, rotation speed, and overall agility. Continued innovation in materials science will likely lead to further refinements in the lightweight construction of figure skating equipment, pushing the boundaries of what is physically possible on the ice.

2. Ankle support system

The ankle support system is a critical component in “edea ice fly skates,” directly influencing performance and safety. Its primary function is to provide stability to the ankle joint, mitigating the risk of injury during demanding maneuvers. Without adequate support, skaters face an increased probability of sprains or more severe damage due to the high impact forces generated during jumps and landings. The design of this support system incorporates rigid or semi-rigid materials strategically positioned to restrict excessive lateral movement while still allowing the necessary range of motion for proper technique. This balance between stability and flexibility is paramount.

The effectiveness of the ankle support system can be observed in the execution of complex skating elements. A properly supported ankle enables the skater to maintain alignment during rotations, contributing to increased jump height and improved landing stability. Examples of this can be seen in professional skaters who are able to perform quad jumps with minimal wobble, a direct consequence of the stable platform provided by the support system. The design impacts the skater’s ability to land cleanly and transition smoothly between elements, impacting overall performance and scores. Furthermore, proper fit of the boot around the ankle is essential; even a well-designed support system will be ineffective if the boot is too loose or too tight.

In conclusion, the ankle support system in “edea ice fly skates” is fundamental for injury prevention and optimized performance. Its integration within the skate design has undergone continuous refinement. Further research and development in materials and engineering will likely continue to improve the effectiveness of this critical component, further improving outcomes for skaters at all levels. A clear understanding of its importance is therefore essential for skaters, coaches, and equipment specialists.

3. Blade attachment precision

Blade attachment precision represents a critical factor in the performance and safety of figure skates. This element ensures the proper alignment between the blade and the boot, directly influencing balance, stability, and edge control on the ice. Imperfections in this attachment can compromise the skater’s ability to execute maneuvers accurately and consistently, potentially leading to falls or injuries.

- Alignment with the Boot’s Centerline

The blade must be precisely aligned with the boot’s longitudinal axis. Deviations from this alignment can result in uneven weight distribution, causing the skater to compensate with improper technique. For example, a blade mounted slightly off-center may lead to a tendency to lean excessively on one edge, hindering the execution of clean turns and jumps. Skilled technicians use specialized tools to ensure this alignment, measuring the distance from key points on the boot to the blade’s edges. This meticulous process minimizes the risk of imbalances that could negatively impact performance.

- Consistent Blade Angle

The angle at which the blade is mounted relative to the sole of the boot significantly impacts the skater’s edge control. Variations in this angle can alter the depth of the edges and affect the skater’s ability to grip the ice effectively. Adjustments to the blade angle are often made to accommodate individual skating styles and preferences. Achieving and maintaining a consistent blade angle requires careful calibration and precise mounting techniques.

- Secure Mounting

The blade must be securely attached to the boot to prevent movement or slippage during use. Loose or improperly tightened screws can compromise the stability of the blade, increasing the risk of accidents and hindering performance. Regular inspection and maintenance of the mounting hardware are essential to ensure a secure connection. High-quality mounting hardware, such as stainless steel screws and reinforced plates, contribute to the overall reliability and longevity of the blade attachment.

- Impact on Biomechanics

Precision in blade attachment directly influences the skater’s biomechanics. A correctly mounted blade promotes a more natural and efficient skating posture, reducing stress on joints and muscles. Conversely, an improperly mounted blade can force the skater to adopt compensatory movements that lead to fatigue and increased risk of injury. Proper alignment allows for optimal power transfer from the skater’s body to the ice, maximizing performance and minimizing the risk of strain.

These elements collectively underscore the importance of blade attachment precision. The accuracy of these components significantly impacts skating performance, safety, and the longevity of the equipment. It’s essential for skaters, coaches, and technicians to recognize and address this aspect to ensure the best possible outcomes on the ice.

4. Heat-moldable structure

The integration of heat-moldable technology within skating equipment represents a significant advancement in achieving a personalized fit. This innovation directly addresses the unique anatomical variations of individual skaters, enhancing both comfort and performance capabilities.

- Customized Fit and Comfort

The heat-moldable structure allows the skate boot to conform precisely to the contours of the skater’s foot. By applying heat, the materials soften, enabling the boot to mold to the foot’s shape. This process eliminates pressure points, reduces the risk of blisters, and ensures a snug, supportive fit. For example, skaters with bunions or other foot deformities can benefit from this technology, as the boot can be molded to accommodate these specific needs, providing a level of comfort that traditional, non-moldable boots cannot offer.

- Enhanced Performance Capabilities

A customized fit directly translates to improved performance. A secure and supportive fit enhances the skater’s ability to control the skates, allowing for more precise movements and greater agility on the ice. With less internal slippage, the skater’s energy is more efficiently transferred to the blade, resulting in increased power and responsiveness. In competitive skating, even slight improvements in edge control and maneuverability can make a significant difference in overall performance.

- Reduced Risk of Injury

A well-fitted skate minimizes the likelihood of injury. Heat-moldable technology contributes to injury prevention by providing enhanced stability and support to the ankle and foot. By eliminating gaps and pressure points, the risk of chafing, blisters, and other foot-related problems is significantly reduced. Skaters who spend long hours on the ice training can benefit from the improved comfort and support offered by heat-moldable boots, helping them to avoid overuse injuries.

- Process and Materials

The heat-molding process typically involves heating the boot in a specialized oven or using a heat gun. The specific temperature and duration of the heating process vary depending on the materials used in the boot’s construction. Once heated, the skater inserts their foot into the boot, and the materials are allowed to cool and harden, conforming to the shape of the foot. Materials commonly used in heat-moldable skate boots include specialized foams and thermoformable polymers, which offer the necessary flexibility and durability.

The incorporation of heat-moldable structure represents a fusion of technology and biomechanics, striving to meet the unique requirements of each skater. This custom fit enhances comfort, boosts performance, and minimizes injury risks. Further advancements in this area will likely lead to even more personalized and effective solutions for skaters of all levels.

5. Impact absorption technology

Impact absorption technology integrated within figure skates serves as a crucial mechanism for mitigating the physical stresses associated with the sport. The repetitive nature of jumps, landings, and intricate footwork places considerable force on the skater’s joints, particularly the ankles, knees, and hips. The inclusion of specialized materials and structural designs engineered to dissipate this energy is essential for both performance enhancement and injury prevention. Skates incorporating this technology effectively dampen the shock experienced upon landing, allowing skaters to maintain balance and control, while simultaneously reducing the risk of stress-related injuries. In practice, the reduction in impact force translates to less fatigue, enabling skaters to sustain higher performance levels over extended training sessions and competitive routines.

The composition of impact-absorbing elements varies, often involving strategically placed layers of viscoelastic polymers or foam composites within the boot’s construction. These materials possess the capacity to deform under pressure, absorbing a portion of the energy generated during impact. Furthermore, advancements in sole design, such as integrated cushioning systems or articulated structures, contribute to the overall effectiveness of impact absorption. For example, specific models incorporate gel-filled inserts within the heel and forefoot regions, providing targeted cushioning in areas subjected to the highest impact forces. Analysis of skater performance data reveals a correlation between the use of skates with effective impact absorption and a decrease in reported joint pain and fatigue. This highlights the direct impact of this technology on skater well-being and longevity within the sport.

In conclusion, impact absorption technology is a key feature influencing comfort, safety, and performance. The ongoing development of innovative materials and designs continues to refine this aspect of skate technology, promising even greater levels of protection and performance enhancement for figure skaters. The understanding of how it mitigates stress on joints is essential for skaters, coaches, and equipment specialists. As the sport evolves and demands greater physical feats, the continued advancement of impact absorption technology will play a vital role in safeguarding skaters’ physical well-being.

6. Customization availability

Customization options are integral to achieving optimal performance and comfort. This element addresses the unique needs of skaters, enabling precise adjustments to various aspects of the equipment.

- Boot Stiffness Options

Skaters can select boot stiffness levels to match skill levels and skating styles. Softer boots offer greater flexibility for beginners, while stiffer boots provide increased support for advanced skaters performing complex jumps and landings. Selecting the correct stiffness ensures proper ankle support and responsiveness. Incorrect boot stiffness can hinder performance and increase the risk of injury.

- Blade Mounting Adjustments

Blade placement is crucial for balance and edge control. Precision blade mounting allows technicians to fine-tune the blade’s position relative to the boot, optimizing the skater’s center of gravity and facilitating proper technique. Adjustments can be made to accommodate individual skating styles and address specific biomechanical needs. Inaccurate blade mounting can lead to instability and compromised performance.

- Liner Customization

The liner within the boot can be customized to enhance comfort and fit. Options include heat-moldable liners that conform to the skater’s foot shape, providing a snug and supportive fit. Custom liners can also address specific foot conditions, such as bunions or plantar fasciitis, by providing targeted cushioning and support. A properly fitted liner minimizes slippage and reduces the risk of blisters and other foot-related issues.

- Hardware Modifications

Minor hardware adjustments can further optimize the skate’s performance. This includes modifications to the lacing system, such as adding power straps or adjusting the tightness of specific laces to provide targeted support. Customizing the hardware allows skaters to fine-tune the fit and feel of the skates, enhancing comfort and control. Attention to detail helps the skater to achieve peak performance.

The range of customization options reflects the dedication to providing skaters with the tools necessary to perform at their best. Addressing individual needs through precise adjustments enhances comfort, support, and performance, ultimately contributing to a more successful and enjoyable skating experience.

7. Durability expectations

These specialized figure skates represent a significant financial investment for skaters. Therefore, durability is a paramount consideration, influencing purchasing decisions and overall satisfaction. Purchasers anticipate that the skates will withstand the stresses of regular training and competition, maintaining their structural integrity and performance characteristics over an extended period. Failure to meet these expectations can result in financial losses, compromised performance, and potential injury. For instance, if the boot’s support system degrades prematurely, the skater may experience decreased ankle stability, increasing the risk of sprains or other injuries. Similarly, if the blade attachment weakens, it may lead to inconsistent edge control, impacting the execution of technical elements.

The achievement of durability depends on factors such as the quality of materials used, the precision of manufacturing processes, and the proper care and maintenance provided by the skater. Skates constructed from high-grade leather, reinforced with carbon fiber or other composite materials, generally exhibit greater resistance to wear and tear. Regular cleaning, drying, and blade sharpening can further extend the lifespan of the skates. Conversely, neglecting these maintenance practices or exposing the skates to harsh conditions, such as excessive moisture or extreme temperatures, can accelerate their deterioration. A practical example would be a skater who meticulously dries their skates after each use, thus preventing the breakdown of the boot’s materials and prolonging its overall lifespan, contrasted with another skater who leaves their skates damp, leading to premature degradation.

In conclusion, “edea ice fly skates” are intended to be durable enough to endure high level of performance in figure skating. Skaters invest considerable time and money into this type of equipment, so the investment should be able to withstand a series of elements. Manufacturers should be able to put the skate into a situation where the skate will last the person using it a long time and maintain the same quality.

Frequently Asked Questions

The following questions address common inquiries regarding the selection, use, and maintenance of “edea ice fly skates.” The information provided is intended to clarify key considerations and inform decision-making.

Question 1: What is the typical lifespan?

The lifespan is contingent upon usage frequency, skill level, and maintenance practices. Elite skaters training daily may require replacement more frequently than recreational skaters. Proper care, including regular drying and blade sharpening, significantly extends the lifespan. Typically, expect a lifespan of 1-3 years with consistent use.

Question 2: How does the heat-molding process work?

The heat-molding process involves applying heat to the boot to soften the materials, allowing them to conform to the skater’s foot. The boot is heated in a specialized oven or with a heat gun, then the skater inserts their foot. As the materials cool, they retain the shape of the foot, providing a custom fit. Consult a professional fitter for optimal results.

Question 3: What blade type is recommended for beginners?

Beginners typically benefit from blades with a flatter rocker and a larger radius of curvature. These blades provide increased stability and edge control, facilitating the development of fundamental skating skills. Consult with a qualified coach or skate technician for specific recommendations.

Question 4: How often should the blades be sharpened?

Blade sharpening frequency depends on skating frequency, ice conditions, and the skater’s technique. Inspect the blade edges regularly for signs of dullness. As a general guideline, blades should be sharpened every 20-40 hours of skating time. Professional sharpening is recommended to maintain proper edge alignment and prevent damage.

Question 5: What are the key considerations for fitting?

Proper fitting involves accurate foot measurement and assessment of individual foot characteristics. Ensure adequate toe room, heel lock, and ankle support. The boot should fit snugly without causing pressure points or discomfort. Professional fitting services are essential to ensure optimal fit and prevent injuries.

Question 6: How can odor be mitigated?

Odor is a common concern due to moisture accumulation. After each use, thoroughly dry the boots inside and out. Use boot dryers or stuff boots with absorbent materials, such as newspaper or silica gel packets. Regularly clean the liners with a mild soap and water solution. Avoid storing skates in closed bags, as this traps moisture and promotes bacterial growth.

These FAQs address common inquiries about key considerations, and will hopefully help you with any confusion you may have had. Understanding these points is essential for a successful and enjoyable skating experience.

The subsequent section will provide resources for further assistance and information.

Concluding Remarks

This exposition has detailed the critical aspects of specialized figure skating equipment, from design features and technological innovations to selection criteria and maintenance procedures. The analysis encompassed the lightweight construction, ankle support system, blade attachment precision, heat-moldable structure, impact absorption technology, customization availability, and durability expectations. Understanding these facets is paramount for skaters, coaches, and equipment specialists seeking to optimize performance and ensure longevity of equipment.

Continued advancements in materials science and biomechanical engineering hold the promise of further enhancements in skating equipment design. As the demands of the sport evolve, ongoing research and development will be crucial for pushing the boundaries of athletic performance while prioritizing skater safety and well-being. Those involved are encouraged to remain informed about emerging technologies and best practices to fully leverage the potential of this essential equipment.