The query addresses whether freshly purchased ice skates possess an adequate edge for immediate use. New blades, while appearing sharp, typically feature a factory finish that is not optimized for ice contact. This initial state often results in a dull, slippery feeling on the ice surface, hindering control and maneuverability.

Addressing this initial dullness is crucial for both safety and performance. Sharp blades enhance grip, enabling controlled turns, stops, and acceleration. Historically, skaters have understood the necessity of customized sharpening to match individual skating styles and skill levels. Failure to prepare the blades can lead to instability, falls, and a diminished skating experience.

Therefore, considering professional blade preparation is a fundamental step before the initial use of new ice skates. Factors to consider include the skater’s weight, experience, and preferred skating discipline. Consulting with a qualified skate technician ensures the blades are properly hollowed and edged for optimal performance.

Guidance on Initial Ice Skate Blade Preparation

The following points outline essential considerations for newly acquired ice skates, specifically regarding the preparation of their blades for optimal performance and safety.

Tip 1: Evaluate the Factory Finish: Understand that the factory finish on new blades is primarily for protection during shipping and storage, not for immediate use. The blade’s edge will likely feel dull to the touch and will not provide sufficient grip on the ice.

Tip 2: Seek Professional Assessment: Consult a qualified skate technician or sharpener before using new skates. The professional can assess the existing blade profile and recommend the appropriate hollow and edge based on skating ability and discipline.

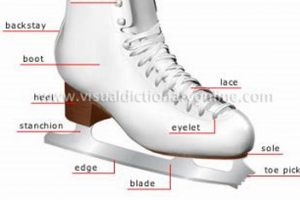

Tip 3: Understand Blade Hollow: The hollow refers to the concave curve ground into the blade between the inside and outside edges. A deeper hollow provides more bite but can reduce glide. The optimal hollow depth depends on the skater’s weight, skill, and preferred style.

Tip 4: Customize Blade Sharpening: Blade sharpening is not a one-size-fits-all process. A figure skater, hockey player, and recreational skater will each require a different blade profile and hollow depth to maximize performance.

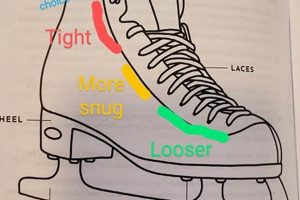

Tip 5: Check Blade Alignment: Ensure the blades are properly aligned with the boot. Misaligned blades can cause instability and make it difficult to maintain a straight line. A skate technician can adjust the blade alignment as needed.

Tip 6: Consider Blade Radius: The blade radius, or rocker, affects maneuverability and glide. A more pronounced rocker allows for quicker turns, while a flatter rocker provides greater stability. Adjustment to the rocker is a specialized service that should be performed by an experienced technician.

Initial preparation of ice skate blades is essential for safety, performance, and enjoyment. Properly sharpened and aligned blades will enhance control, prevent falls, and allow the skater to progress more effectively.

The next section will address maintenance and ongoing care of ice skate blades to prolong their life and maintain optimal performance.

1. Initial Blade Condition

The condition of blades on newly purchased ice skates is paramount in determining if professional sharpening is required. The initial state significantly influences performance, safety, and the overall skating experience.

- Factory Edge Quality

New skates often possess a factory-applied edge intended for protection during shipping and storage. This edge is rarely optimized for ice contact and typically feels dull or slippery when tested. Its primary function is preservation, not performance.

- Blade Profile Uniformity

The consistency of the blade profile is crucial. While new blades should theoretically be uniform, manufacturing tolerances can lead to slight variations. These inconsistencies can affect balance and control, underscoring the need for professional assessment and potential correction through sharpening.

- Potential for Surface Imperfections

Despite quality control measures, surface imperfections such as burrs or minor scratches can exist on new blades. These imperfections, though often microscopic, can impede glide and reduce edge control. Sharpening removes these imperfections, creating a smooth, consistent surface.

- Absence of Customized Hollow

The “hollow” refers to the concave curvature ground into the blade between the inside and outside edges. New skates lack a customized hollow that corresponds to the skater’s weight, skill level, and skating style. Professional sharpening establishes the appropriate hollow depth to optimize grip and glide.

In summary, the initial blade condition of new ice skates is typically unsuitable for immediate use. The factory edge, potential profile variations, surface imperfections, and absence of a customized hollow all contribute to the necessity of professional sharpening. This initial preparation ensures safe and optimal performance on the ice.

2. Professional Sharpening Necessity

The question of whether freshly purchased ice skates require sharpening is directly linked to the necessity of professional blade preparation. Factory-provided edges, while present, are designed for blade protection during transit and storage, not for performance. Consequently, they lack the precision and customization required for safe and effective skating. Professional sharpening addresses this deficiency by establishing the correct hollow depth and edge sharpness, customized to the skater’s individual needs and skating discipline. The absence of this professional intervention can lead to diminished control, increased risk of falls, and suboptimal performance.

Consider the example of a figure skater attempting complex jumps and spins on factory-edged blades. The lack of a precisely sharpened edge could result in an inability to maintain control during landings, potentially leading to injury. Similarly, a hockey player requiring quick acceleration and sharp turns would find their performance significantly hampered by insufficiently sharpened blades. These scenarios illustrate the practical importance of professional sharpening as a critical component of preparing new ice skates for use. The customization provided by a skilled technician addresses specific requirements that a generic factory edge cannot.

In conclusion, the perceived need for sharpening new ice skates is not merely a matter of preference but a fundamental requirement for safety and performance. The professional sharpening process rectifies the shortcomings of factory-provided edges, tailoring the blade to the individual skater’s needs. This understanding is crucial for both recreational and competitive skaters, as it directly impacts their ability to control their movements and progress in their respective disciplines. Neglecting professional blade preparation introduces unnecessary risks and limits the potential benefits derived from the skating experience.

3. Performance Enhancement

The degree to which ice skate blades are properly sharpened directly influences a skater’s ability to execute maneuvers, maintain balance, and achieve optimal speed. Addressing the need for new ice skates to be sharpened is therefore integral to maximizing on-ice performance. The following points illustrate key facets of this connection.

- Edge Control and Precision

Sharpened blades provide the necessary edge control for precise turns, stops, and intricate footwork. Without a properly defined edge, skaters experience slippage, compromising their ability to execute maneuvers accurately. Examples include figure skaters requiring precise control for jumps and spins, and hockey players needing sharp turns for agility and puck handling. Sharpening, therefore, is not merely a preference but a prerequisite for precision skating.

- Acceleration and Speed

The sharpness of the blades directly impacts a skater’s ability to generate power and acceleration. A dull blade requires more effort to initiate movement and maintain speed, whereas a sharp blade grips the ice more effectively, translating force into forward motion. This is particularly critical for hockey players in sprints and power plays, where fractions of a second can determine success. Proper sharpening facilitates efficient energy transfer, resulting in increased speed and agility.

- Balance and Stability

Sharpened blades enhance balance and stability by providing a more secure contact point with the ice. This is particularly important for beginners and skaters learning new skills, as it reduces the likelihood of losing control and falling. Even experienced skaters benefit from the increased stability afforded by sharp blades, allowing them to maintain proper posture and execute complex maneuvers with confidence.

- Energy Efficiency

When blades are properly sharpened, less energy is required to propel and control movement on the ice. Dull blades require more muscle exertion to achieve the same level of performance, leading to fatigue and reduced endurance. Sharp blades, in contrast, allow skaters to glide more efficiently, conserving energy and enabling them to skate for longer periods without tiring. This is particularly advantageous for endurance-based skating disciplines, such as speed skating and long-distance recreational skating.

In summation, the benefits derived from sharpened ice skate blades extend beyond mere convenience, profoundly impacting performance across all skill levels and skating disciplines. The facets of edge control, acceleration, balance, and energy efficiency collectively demonstrate that addressing the requirement for new ice skates to undergo sharpening is essential for achieving optimal on-ice performance and maximizing the skater’s potential.

4. Safety Considerations

The proposition “do new ice skates need to be sharpened” is intrinsically linked to safety considerations on the ice. The absence of properly sharpened blades compromises a skater’s control, potentially leading to falls and injuries. New blades, possessing a factory finish optimized for protection rather than performance, often lack the necessary edge for secure grip. This deficiency can manifest in a variety of hazardous scenarios. For instance, a novice skater may struggle to maintain balance, increasing the risk of ankle sprains or fractures. Similarly, a hockey player attempting a sudden stop may find the unsharpened blades unable to provide sufficient traction, resulting in collisions with other players or the boards. These instances underscore the practical significance of blade sharpness as a critical safety component. The impact of dull blades is not limited to beginners; experienced skaters also face elevated risks when relying on inadequately prepared equipment.

Sharpening addresses these risks by creating a defined edge that allows the skater to “bite” into the ice, providing control and stability. The appropriate hollow depth, determined by a professional skate technician, further enhances grip and maneuverability. Consider the scenario of a figure skater executing a complex jump. The ability to land safely depends, in part, on the sharpness of the blades. Dull blades may cause the skater to slip upon landing, resulting in a fall and potential injury. Professional sharpening mitigates this risk by ensuring the blades are precisely honed to meet the demands of the skater’s discipline. Consistent blade maintenance is also crucial. Over time, even properly sharpened blades will lose their edge, necessitating regular re-sharpening to maintain optimal safety and performance.

In summary, the question of blade sharpness is not merely a matter of performance enhancement; it is fundamentally a safety concern. The inadequate edges of unsharpened new blades can lead to diminished control, increased risk of falls, and potential injuries across all skill levels. Professional blade preparation and consistent maintenance are therefore essential for mitigating these risks and ensuring a safe and enjoyable skating experience. The practical significance of this understanding should inform the decisions of all skaters, regardless of their experience or discipline.

5. Customization Requirement

The necessity for customizing ice skate blades directly influences the question of whether new skates require sharpening. Factory-produced blades, irrespective of their initial edge, lack the personalized attributes essential for optimal skating performance. The customization requirement stems from variations in skater weight, skill level, skating discipline (e.g., hockey, figure skating, recreational skating), and individual preferences. A factory edge cannot account for these variables. Consequently, even skates with seemingly sharp, new blades will likely underperform or pose a safety risk if used without tailored sharpening. For instance, a lightweight figure skater requires a shallower hollow than a heavyweight hockey player. Using skates with a generic edge would impede the figure skater’s glide and compromise the hockey player’s grip.

Professional sharpening facilitates this customization by allowing for the precise creation of a hollow depth that aligns with the skater’s specific needs. The hollow depth, the concave curve ground into the blade between the inside and outside edges, directly affects the blade’s grip on the ice. A deeper hollow provides more bite, enabling sharper turns and quicker stops, while a shallower hollow promotes glide and speed. Furthermore, skilled technicians can adjust the blade profile to optimize the rocker, affecting maneuverability and stability. A customized rocker can improve agility for figure skaters executing spins or enhance speed for hockey players accelerating across the ice. The lack of such adjustments in factory edges necessitates professional intervention.

In summary, the inherent need for customization renders the factory edge on new ice skates inadequate for most skaters. Professional sharpening allows for the creation of a blade profile tailored to individual requirements, enhancing both performance and safety. This customization, encompassing hollow depth and rocker adjustments, underscores that new ice skates invariably benefit from professional sharpening before initial use. The potential for improved control, stability, and efficiency justifies the investment in custom blade preparation.

Frequently Asked Questions

The following addresses common inquiries regarding the necessity of sharpening new ice skate blades.

Question 1: Are factory-fresh ice skate blades ready for immediate use?

Typically, no. The factory finish serves primarily for blade protection during shipping, not optimal on-ice performance. An assessment by a qualified technician is recommended before use.

Question 2: What are the risks associated with using unsharpened ice skate blades?

Unsharpened blades diminish control, increase the likelihood of falls, and hinder the execution of basic skating maneuvers. Safety is compromised when blades lack a proper edge.

Question 3: How does blade sharpening improve skating performance?

Sharpening enhances edge control, enabling precise turns and stops. The skater experiences improved balance, acceleration, and overall maneuverability.

Question 4: Why is professional sharpening recommended over self-sharpening methods?

Professional sharpening employs specialized equipment and expertise to achieve consistent and precise blade profiling. Self-sharpening methods often lack the necessary precision, potentially damaging the blades or producing an uneven edge.

Question 5: How often should ice skate blades be sharpened?

The frequency depends on usage, skating style, and ice conditions. Regular inspection of the blade edge will indicate when sharpening is necessary. As a general guideline, sharpening may be required after 20-40 hours of skating.

Question 6: Does the type of skating discipline influence sharpening requirements?

Yes. Hockey skates, figure skates, and recreational skates each require specific hollow depths and blade profiles to optimize performance for their respective disciplines. A qualified technician can advise on the appropriate specifications.

Proper blade preparation is paramount for a safe and enjoyable skating experience. Professional sharpening ensures optimal performance and minimizes the risk of injury.

The subsequent section will address maintenance practices to prolong the life of sharpened ice skate blades.

The Imperative of Blade Sharpening for New Ice Skates

The foregoing discussion has established that new ice skates invariably require professional sharpening prior to their initial use. The factory finish, designed primarily for protection during shipping and storage, does not provide the necessary edge for safe and effective skating. Professional sharpening addresses this deficiency by establishing the correct hollow depth and edge sharpness, tailored to the skater’s individual needs and skating discipline. This process enhances control, reduces the risk of falls, and optimizes performance.

Given the inherent inadequacies of factory-supplied edges and the significant implications for both safety and performance, skaters must recognize that professional blade preparation is not merely a matter of preference but a fundamental requirement. Prioritizing this crucial step ensures a safe and enjoyable skating experience, allowing skaters to realize their full potential while minimizing the risk of injury. The informed skater understands that blade maintenance is integral to both safety and performance, not an afterthought.