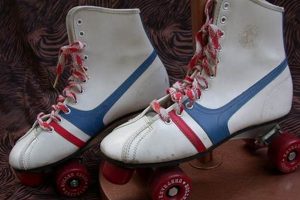

Modified or personalized skating footwear, tailored to individual preferences, constitutes a specialized sector within recreational equipment. These adapted items may feature variations in boot style, wheel type, bearing quality, plate material, and toe stop configuration. For example, an individual might select a high-top boot for increased ankle support, combine it with high-rebound wheels for enhanced speed, and incorporate a lightweight plate for improved maneuverability.

The value of such personal adaptation resides in optimized performance, enhanced comfort, and stylistic self-expression. Historically, modifications were limited to aftermarket components. Modern advancements include digitally designed and 3D-printed elements, allowing for unprecedented levels of customization. Benefits extend to improved skating technique, reduced risk of injury due to poor fit, and the satisfaction derived from owning a uniquely designed product.

Subsequent sections will delve into specific aspects of the adaptation process, examining available boot options, wheel characteristics, plate considerations, and the impact of bearing selection. Furthermore, it will explore the technological advances driving innovation in this specialized market, and the role of professional fitters and custom manufacturers in facilitating the creation of bespoke skating solutions.

Custom Roller Skates

The following outlines strategic recommendations for those seeking to optimize their skating experience through equipment modification.

Tip 1: Boot Selection: Evaluate ankle support requirements based on skating discipline. High-top boots offer superior stability for jam skating, while low-cut boots provide increased agility for dance or rhythm skating. Leather boots conform to the foot over time, offering a personalized fit. Synthetic materials provide consistent support and durability.

Tip 2: Wheel Hardness: Wheel durometer, measured on the A scale, affects grip and speed. Lower durometer wheels (e.g., 78A) provide increased grip for indoor surfaces. Higher durometer wheels (e.g., 97A) minimize rolling resistance on smooth surfaces such as polished concrete or wood. Surface conditions should dictate wheel selection.

Tip 3: Plate Material: Plate material impacts weight and responsiveness. Aluminum plates offer a balance of strength and weight, suitable for general skating. Composite plates are lightweight, reducing fatigue, but may not withstand high-impact maneuvers. Titanium plates provide maximum strength-to-weight ratio, ideal for competitive applications.

Tip 4: Bearing Quality: Bearing ABEC rating indicates manufacturing tolerances. Higher ABEC ratings (e.g., ABEC 7 or ABEC 9) signify tighter tolerances and reduced friction, resulting in increased speed. Lubrication is crucial. Periodically cleaning and lubricating bearings will maintain performance and extend lifespan.

Tip 5: Toe Stop Configuration: Adjustable toe stops allow for personalized brake positioning. Consider toe stop material; harder compounds offer increased durability, while softer compounds provide better grip. Angled toe stops facilitate quicker transitions and enhanced agility.

Tip 6: Professional Consultation: Seek guidance from experienced skate technicians. A qualified professional can assess skating style, foot morphology, and performance goals to recommend appropriate equipment modifications. This ensures optimal fit and performance.

Careful consideration of these optimization strategies will result in equipment that enhances performance, comfort, and overall skating enjoyment.

The subsequent section will address maintenance procedures and long-term care strategies for adapted skating equipment.

1. Boot construction

Boot construction is a foundational element in the creation of personalized roller skates, directly influencing performance, comfort, and safety. The materials, design, and structural integrity of the boot dictate the level of support provided to the ankle and foot, which in turn affects the skater’s ability to execute maneuvers and maintain balance. Consider, for example, the difference between a rigid, high-top boot constructed from reinforced leather and a flexible, low-cut boot made of synthetic materials. The former is suitable for activities requiring significant ankle stability, such as roller derby, where impacts and lateral movements are frequent. Conversely, the latter is better suited for artistic skating, where greater range of motion and responsiveness are prioritized.

The selection of materials further impacts the skater’s experience. Leather boots, known for their durability and ability to mold to the foot over time, offer a personalized fit that enhances comfort during extended use. However, they require regular maintenance to prevent cracking and stiffness. Synthetic boots, while generally less pliable, are often more resistant to moisture and abrasion, making them suitable for outdoor skating or environments where exposure to the elements is a concern. The stitching and reinforcement patterns employed in boot construction also contribute to its overall strength and resistance to wear and tear. A poorly constructed boot can lead to premature failure, resulting in discomfort, reduced performance, and an increased risk of injury.

Therefore, a comprehensive understanding of boot construction is essential when customizing roller skates. By carefully considering the materials, design, and intended use, skaters can select a boot that provides the optimal balance of support, comfort, and durability. This foundational element, when properly chosen, contributes significantly to a superior skating experience and minimizes the potential for injury. The challenges lie in balancing personal preference with objective performance requirements and in ensuring that the chosen boot is compatible with other components of the customized skate.

2. Wheel durometer

Wheel durometer, a measure of a wheel’s hardness, is a crucial consideration in the customization of roller skates. Its selection directly impacts the skater’s experience, affecting grip, speed, and suitability for various surfaces. Tailoring wheel durometer to the intended use case allows for optimized performance and enhanced control.

- Grip and Surface Adhesion

Lower durometer wheels (e.g., 78A-85A) exhibit greater flexibility, conforming to surface irregularities and providing increased grip. This is particularly advantageous on uneven or slippery surfaces such as outdoor asphalt or polished indoor floors. However, this increased grip comes at the cost of reduced rolling speed and increased rolling resistance. Examples include recreational skaters seeking stability or those skating on rough terrain.

- Speed and Rolling Efficiency

Higher durometer wheels (e.g., 95A-101A) are more rigid and maintain their shape under load, minimizing rolling resistance and maximizing speed. These wheels are suitable for smooth, hard surfaces such as concrete skateparks or polished wood floors found in rinks. While they offer superior speed, they provide less grip, demanding greater skill and control from the skater. Examples include speed skaters and those performing advanced tricks requiring minimal friction.

- Durability and Wear Resistance

Wheel durometer also influences durability. Harder wheels, while faster, tend to wear down more slowly on smooth surfaces than softer wheels. However, on abrasive surfaces, softer wheels may exhibit greater resistance to chipping and cracking. The choice depends on the balance between desired performance characteristics and the expected lifespan of the wheels. For instance, a skater primarily using their skates outdoors on varied surfaces might prioritize a mid-range durometer for a balance of grip, speed, and durability.

- Impact Absorption and Vibration Dampening

Softer wheels absorb more vibrations from the skating surface, leading to a smoother and more comfortable ride, especially on rough terrain. Harder wheels transmit more vibrations, potentially causing fatigue and discomfort. This is an important consideration for skaters who prioritize comfort over speed, or those with joint sensitivities. Outdoor recreational skaters often benefit from the vibration dampening offered by softer wheels.

The selection of wheel durometer represents a trade-off between grip, speed, durability, and comfort. Customizing roller skates with appropriate wheel durometer allows skaters to optimize their performance based on their individual skating style, the intended use case, and the prevailing surface conditions. Furthermore, the selection contributes significantly to the overall comfort and enjoyment of the skating experience.

3. Plate material

The plate constitutes a critical structural component in customized roller skates, directly influencing responsiveness, stability, and overall performance. As the interface between the boot and the wheels, its material composition dictates its strength, weight, and ability to transfer energy efficiently. The selection of an appropriate plate material is therefore paramount to achieving the desired skating characteristics. Consider, for example, the impact of a lightweight composite plate versus a heavier steel plate. The composite plate, while reducing overall skate weight, may flex under high stress, diminishing energy transfer during aggressive maneuvers. Conversely, the steel plate offers superior rigidity and durability but adds significant weight, potentially reducing agility. Examples include aluminum alloy plates favored by roller derby skaters for their balance of strength and responsiveness, and nylon plates often found in recreational skates prioritizing affordability and lightness.

Furthermore, the material properties of the plate influence its vibration dampening characteristics and resistance to corrosion. Aluminum plates, while strong and relatively lightweight, may transmit more road vibrations than composite plates, potentially leading to fatigue during extended use. Anodizing aluminum plates enhances their corrosion resistance, crucial for skaters frequently exposed to moisture or outdoor elements. Steel plates, while inherently strong, are susceptible to rust; protective coatings are therefore necessary. The practical application of this understanding extends to maintenance procedures. Choosing appropriate cleaning agents and storage conditions based on the plate material preserves its integrity and prolongs the lifespan of the customized skates. This knowledge also informs modification strategies, such as upgrading to a higher-performance plate to improve responsiveness and control.

In summary, the choice of plate material is a fundamental decision in customizing roller skates, requiring careful consideration of performance objectives, environmental factors, and maintenance requirements. Understanding the cause-and-effect relationship between plate material and skating characteristics empowers individuals to optimize their equipment for specific disciplines and personal preferences. Challenges in this area include balancing cost considerations with performance demands and staying informed about emerging materials and manufacturing technologies. A well-informed decision regarding plate material ultimately contributes to a more enjoyable and efficient skating experience, aligning equipment characteristics with individual needs.

4. Bearing precision

Bearing precision, typically indicated by the ABEC (Annular Bearing Engineers’ Committee) rating, directly impacts the rolling efficiency and speed of customized roller skates. The ABEC scale, ranging from 1 to 9 with odd numbers only (1, 3, 5, 7, 9), signifies the manufacturing tolerances of the bearing. Higher ABEC ratings denote tighter tolerances and consequently, reduced friction. This reduction in friction translates to increased speed and smoother rolling performance, crucial aspects for skaters seeking optimized performance in disciplines such as speed skating, roller derby, or freestyle skating. For example, a customized skate intended for speed skating would benefit significantly from high ABEC-rated bearings (e.g., ABEC 7 or 9), allowing the skater to achieve higher velocities with less physical exertion. The practical significance lies in the skater’s ability to maintain speed and momentum more efficiently, leading to improved performance and reduced fatigue.

The selection of bearing precision also affects the maintenance requirements and overall lifespan of the bearings. Higher ABEC-rated bearings, due to their tighter tolerances, are often more susceptible to contamination and require more frequent cleaning and lubrication. Conversely, lower ABEC-rated bearings are more robust and tolerant of less-than-ideal conditions but provide diminished performance in terms of speed and smoothness. A customized skate designed for recreational use or outdoor skating on varied surfaces may benefit from lower ABEC-rated bearings (e.g., ABEC 3 or 5), prioritizing durability over peak performance. For instance, a skater using customized skates for outdoor trails would prioritize bearings that can withstand dirt and debris, even at the expense of slightly reduced speed.

In summary, bearing precision is a critical parameter in the customization of roller skates, influencing speed, rolling efficiency, maintenance requirements, and overall longevity. The selection of an appropriate ABEC rating represents a trade-off between performance and durability, dependent on the skater’s specific needs and skating environment. Challenges lie in balancing the cost of higher ABEC-rated bearings with the perceived performance gains and in adhering to proper maintenance procedures to maximize the lifespan of these precision components. Understanding the implications of bearing precision allows for informed decisions that optimize the skating experience, ensuring that the customized roller skates meet the skater’s individual requirements.

5. Toe stop type

Toe stop type is a critical consideration within the realm of customized roller skates, directly influencing braking efficiency, maneuverability, and overall safety. As the primary braking mechanism, the toe stop enables skaters to decelerate rapidly, execute controlled stops, and perform specialized movements like pivots and spins. The selection of an appropriate toe stop type should align with the skater’s skill level, skating discipline, and desired performance characteristics. For instance, a jam skater requiring quick, precise stops might opt for a small, hard toe stop to minimize drag and maximize responsiveness. Conversely, a beginner skater may prioritize a larger, softer toe stop for enhanced stability and controlled braking.

The material composition and shape of the toe stop significantly impact its performance. Harder compounds, such as natural rubber, offer increased durability and responsiveness, making them suitable for aggressive skating styles and abrasive surfaces. Softer compounds, like polyurethane, provide greater grip and shock absorption, enhancing comfort and control on smoother surfaces. Furthermore, the toe stop’s shape influences its braking effectiveness and maneuverability. Round toe stops facilitate smooth transitions and controlled slides, while angled toe stops offer increased leverage for abrupt stops and directional changes. For example, a roller derby skater would benefit from an angled toe stop constructed from a durable compound, enabling rapid stops and agile maneuvering within the competitive environment.

In summary, toe stop type is an integral component of customized roller skates, affecting braking efficiency, maneuverability, and safety. The selection of an appropriate toe stop should consider the skater’s skill level, skating discipline, material preferences, and desired performance characteristics. Neglecting this critical component can compromise braking effectiveness, reduce maneuverability, and increase the risk of injury. Therefore, careful consideration of toe stop type is essential when customizing roller skates to ensure optimal performance and safety. Challenges include balancing durability with grip and responsiveness, and accurately assessing individual skating needs to select the most appropriate toe stop configuration.

6. Liner material

Liner material, an often-overlooked component in personalized roller skates, significantly impacts comfort, fit, and overall skating performance. As the interface between the skater’s foot and the rigid boot shell, the liner provides cushioning, support, and moisture management, directly influencing the skating experience. Variability in liner material properties results in a spectrum of performance characteristics, affecting factors such as heat moldability, breathability, and durability. For example, a heat-moldable liner composed of specialized foam can conform to the unique contours of an individual’s foot, providing a customized fit that enhances comfort and reduces pressure points. This is particularly beneficial for skaters with atypical foot shapes or those participating in prolonged skating sessions. Conversely, a liner constructed from a less breathable material, such as closed-cell foam, may trap moisture, leading to discomfort and potential skin irritation. The selection of an appropriate liner material, therefore, constitutes a critical step in optimizing customized skating equipment.

The choice of liner material also influences the skate’s responsiveness and energy transfer. Thicker, more heavily padded liners offer increased cushioning and impact absorption, suitable for recreational skating or disciplines involving frequent jumps and landings. However, this increased cushioning can diminish responsiveness and reduce the skater’s feel for the skate. Conversely, thinner, less padded liners provide a more direct connection to the boot, enhancing responsiveness and control, but potentially sacrificing comfort during extended use. Liners constructed from materials with high rebound properties, such as certain types of memory foam, can improve energy transfer, allowing skaters to generate more power with each stride. This is particularly relevant for speed skating or roller derby, where maximizing efficiency is paramount. The practical application of this understanding extends to the selection of aftermarket liners. Skaters can replace stock liners with higher-performance alternatives to fine-tune the fit and feel of their customized skates, optimizing them for specific skating styles and preferences.

In summary, liner material is a crucial, though often underestimated, aspect of customized roller skates. Its properties dictate comfort, fit, moisture management, responsiveness, and energy transfer. The careful selection of liner material, based on individual needs and skating objectives, can significantly enhance the skating experience. Challenges include accurately assessing individual foot morphology and skating requirements, and navigating the vast array of liner materials and construction techniques available. By prioritizing liner material considerations, skaters can create customized equipment that not only performs optimally but also provides a comfortable and enjoyable skating experience.

Frequently Asked Questions Regarding Custom Roller Skates

The following addresses prevalent inquiries concerning the selection, configuration, and maintenance of modified skating equipment. This information is intended to provide clarity and guidance in navigating the complexities of personalized roller skate systems.

Question 1: What constitutes a “custom” roller skate, and how does it differ from a standard, off-the-shelf model?

A custom roller skate is assembled from individually selected components, tailored to specific anatomical requirements and performance objectives. Standard models typically offer limited adjustability and pre-determined component configurations, whereas custom skates allow for precise matching of boot style, plate material, wheel durometer, and bearing precision to individual needs.

Question 2: What are the primary benefits of investing in custom roller skates as opposed to using stock equipment?

Primary benefits include enhanced comfort due to improved fit, optimized performance resulting from component synergy, and reduced risk of injury stemming from improper support or biomechanical misalignment. Customized equipment can address specific anatomical variations and skating style preferences, leading to greater efficiency and control.

Question 3: How is the correct boot size and fit determined for a custom roller skate?

Accurate measurement of foot length and width is crucial. Ideally, a professional fitting, employing a Brannock device or similar measuring tool, should be conducted. Digital foot scanning and 3D modeling are emerging technologies providing increasingly precise fit assessments. Considerations include sock thickness and individual foot morphology.

Question 4: What factors should be considered when selecting wheel durometer for custom roller skates?

Surface type, skating style, and desired grip-to-speed ratio are paramount. Softer wheels (lower durometer) offer increased grip on slick surfaces, while harder wheels (higher durometer) minimize rolling resistance on smooth surfaces. The skater’s weight and skill level also influence optimal wheel durometer selection.

Question 5: How frequently should bearings be cleaned and lubricated on custom roller skates, and what are the recommended maintenance procedures?

Bearing maintenance frequency depends on usage and environmental conditions. Under normal use, cleaning and lubrication every 1-3 months is advisable. Procedures involve removing bearings, cleaning with a solvent, drying thoroughly, and applying a suitable lubricant. Ceramic bearings require specialized lubricants.

Question 6: Can custom roller skates be modified or upgraded after initial assembly, and what are the limitations?

Yes, components such as wheels, bearings, toe stops, and even plates can be replaced or upgraded. Boot replacement is more complex, potentially requiring re-mounting of the plate. Limitations depend on component compatibility and the structural integrity of the boot. Consultation with a skate technician is recommended before undertaking significant modifications.

In summary, the creation of personalized roller skates involves a multifaceted process requiring careful consideration of individual needs and equipment specifications. Informed decision-making and professional guidance are key to realizing the full potential of this specialized equipment.

Subsequent sections will explore the retail landscape of custom roller skates, including notable manufacturers and customization services.

Conclusion

The preceding analysis has explored the nuanced aspects of custom roller skates, detailing the significance of personalized component selection and its impact on performance, comfort, and safety. From boot construction and wheel durometer to plate material, bearing precision, toe stop type, and liner material, each element contributes to a tailored skating experience. The selection process necessitates a comprehensive understanding of individual needs and skating objectives.

The deliberate application of this knowledge enables the creation of equipment optimized for specific disciplines and anatomical requirements. Continued advancements in materials science and manufacturing techniques promise further innovation in this specialized market. Serious consideration of these factors will empower skaters to make informed decisions, ultimately enhancing their performance and enjoyment. The future of skating depends on respecting the technological changes for a better outcome.

![Buy Roller Skate Wheels Near Me: [Shop Name] Offers! Learn to Surf & Skate: A Beginner's Step-by-Step Guide Buy Roller Skate Wheels Near Me: [Shop Name] Offers! | Learn to Surf & Skate: A Beginner's Step-by-Step Guide](https://universitysurfandskate.com/wp-content/uploads/2026/03/th-51-300x200.jpg)