Footwear designed for gliding across ice surfaces, commonly used for recreational skating, figure skating, ice hockey, and other related activities, typically features a specialized blade attached to a supportive boot. Such equipment enables individuals to move efficiently and gracefully on frozen water.

The utilization of bladed boots offers numerous advantages, including promoting physical fitness, providing opportunities for social interaction, and enhancing balance and coordination. Historically, these implements have evolved from rudimentary bone attachments to sophisticated, engineered designs utilizing advanced materials and construction techniques. This development reflects a continuous effort to improve performance, safety, and user experience.

The subsequent sections will delve into specific aspects of ice skating equipment, including material science considerations, different blade types and their applications, and the crucial role of proper fit and maintenance for optimal performance and longevity. These elements are essential for both novice and experienced skaters seeking to maximize their enjoyment and skill development on the ice.

Essential Considerations for Ice Skating Equipment

Optimal performance and safety in ice skating necessitate careful attention to equipment selection and maintenance. These recommendations aim to guide individuals in making informed decisions regarding their ice skating apparatus.

Tip 1: Blade Material Selection: Evaluate blade materials based on intended use and skill level. Carbon steel blades offer enhanced edge control for advanced maneuvers, while stainless steel provides greater corrosion resistance for recreational use.

Tip 2: Boot Fit Assessment: Ensure a snug, supportive fit within the boot. Proper ankle support is paramount for stability and injury prevention. Ill-fitting boots can compromise performance and increase the risk of discomfort or injury.

Tip 3: Blade Sharpening Frequency: Establish a regular blade sharpening schedule. Sharp blades provide superior grip and control on the ice surface. The frequency of sharpening depends on usage intensity and ice conditions.

Tip 4: Lacing Technique Optimization: Employ a lacing technique that distributes pressure evenly across the foot and ankle. Over-tightening can restrict circulation, while loose lacing compromises support.

Tip 5: Protective Gear Implementation: Always utilize appropriate protective gear, including helmets, knee pads, and elbow pads. Safety should be prioritized regardless of skill level or skating environment.

Tip 6: Regular Equipment Inspection: Conduct routine inspections of the boots and blades for signs of wear or damage. Promptly address any issues to prevent potential hazards and maintain performance.

Tip 7: Consider Intended Skating Discipline: Select equipment tailored to the specific discipline of skating, such as figure skating, hockey, or recreational skating. Each discipline requires unique blade and boot characteristics.

Adherence to these guidelines will contribute to a safer and more enjoyable ice skating experience, enhancing performance and minimizing the risk of injury.

The following section will address advanced techniques and considerations for optimizing skating performance.

1. Blade Material Composition

The selection of blade material is a critical determinant of performance characteristics in ice skating implements. The interplay between material properties and ice friction directly impacts maneuverability, edge control, and overall durability. For instance, high-carbon steel blades, renowned for their hardness, offer superior edge retention and precision. This translates to enhanced responsiveness during intricate skating maneuvers, commonly observed in figure skating disciplines where minute adjustments are crucial for executing complex jumps and spins. Conversely, stainless steel blades provide increased corrosion resistance, which is advantageous for recreational skaters who may not adhere to rigorous maintenance protocols. Neglecting proper drying and storage with carbon steel blades can lead to rust formation, compromising their structural integrity and necessitating more frequent sharpening.

The specific grade and treatment processes applied to the steel further influence its mechanical properties. Cryogenic tempering, for example, can increase the hardness and wear resistance of blades, extending their lifespan and maintaining sharpness over prolonged use. This is particularly relevant in competitive hockey, where players demand consistent performance under high-stress conditions. Similarly, blade coatings, such as titanium nitride, reduce friction and enhance glide, contributing to increased speed and agility. The choice of coating, however, must be carefully considered, as some coatings can alter the blade’s inherent feel and responsiveness, potentially affecting a skater’s control.

In conclusion, blade material composition represents a fundamental design parameter directly influencing the performance, longevity, and maintenance requirements of ice skating equipment. A deliberate understanding of the material properties, manufacturing processes, and intended application is paramount for optimizing skating performance and ensuring the structural integrity of the blades. This understanding allows skaters to select equipment best suited to their skill level, skating style, and environmental conditions, thereby maximizing their on-ice experience.

2. Boot Stiffness Characteristics

Boot stiffness is a crucial characteristic directly influencing performance. Acting as a lever arm between the skater’s foot and the blade, boot stiffness dictates the efficiency of force transfer. A stiffer boot will, generally, transmit more energy directly to the blade, resulting in greater control and responsiveness. Conversely, a more flexible boot allows for greater range of motion but at the expense of precision. The selection of appropriate boot stiffness depends heavily on the intended use and skill level.

In figure skating, stiffer boots are paramount for executing complex jumps and landings. The rigidity minimizes ankle flexion, providing a stable platform for generating the necessary power and controlling rotations. Insufficient stiffness can lead to ankle instability, increasing the risk of injury and hindering the skater’s ability to maintain proper form. Hockey players, however, may favor slightly more flexible boots to facilitate agility and quick turns. The added flexibility allows for greater ankle articulation, enabling them to maneuver swiftly on the ice. The interplay between boot stiffness and blade design is critical. A stiff boot paired with a shorter, more curved blade promotes quick turns and acceleration, while a more flexible boot works well with a longer, straighter blade for increased stability and glide.

Ultimately, the ideal boot stiffness is a function of individual preferences, skating style, and the demands of the specific discipline. A properly fitted boot with appropriate stiffness characteristics enhances performance, reduces the risk of injury, and contributes to a more enjoyable skating experience. Understanding the interplay between boot stiffness, blade design, and skating technique is essential for selecting equipment that aligns with individual needs and goals.

3. Ankle Support Mechanisms

Ankle support mechanisms represent a critical design element within ice skates, directly influencing skater stability, control, and injury prevention. These mechanisms are engineered to mitigate excessive ankle movement, enhancing performance while safeguarding against potential sprains and strains.

- Boot Height and Cuff Design

The vertical extension of the boot, coupled with cuff rigidity, provides primary lateral support to the ankle joint. Higher boot heights restrict excessive inversion and eversion, limiting the range of motion that could lead to injury. Stiffer cuffs, typically constructed from reinforced polymers, further augment stability, particularly during sharp turns and jumps. Conversely, lower-cut boots offer greater freedom of movement, favored by some hockey players requiring enhanced agility, but potentially at the expense of ankle protection.

- Lacing Systems and Power Straps

Lacing configurations and integrated power straps serve to secure the foot and ankle within the boot. Properly tightened laces distribute pressure evenly across the instep and ankle, minimizing slippage and maximizing support. Power straps, often positioned around the mid-ankle, provide an additional layer of stabilization, particularly during forceful movements. The material and design of the laces themselves contribute to their effectiveness, with textured surfaces and specialized weaves preventing loosening during prolonged use.

- Internal Padding and Heel Counter

Strategically placed internal padding, often composed of memory foam or gel, conforms to the contours of the ankle, providing cushioning and reducing friction. The heel counter, a rigid structure encompassing the heel, prevents excessive pronation and supination, further enhancing stability. The density and placement of internal padding are critical, as insufficient padding can result in discomfort and pressure points, while excessive padding may compromise responsiveness.

- Hinged Ankle Designs

Certain specialized ice skates, particularly those used in some freestyle skating disciplines, incorporate hinged ankle designs. These designs allow for a controlled range of forward flexion, facilitating deeper knee bends and enhanced maneuverability. However, hinged ankle designs also necessitate robust lateral support mechanisms to prevent instability during side-to-side movements. The design and placement of the hinge are carefully calibrated to optimize range of motion while maintaining adequate ankle protection.

The effectiveness of ankle support mechanisms within ice skates is a multifaceted consideration, encompassing boot height, lacing systems, internal padding, and, in some cases, hinged designs. The optimal configuration is dependent on the skater’s skill level, skating style, and the specific demands of their chosen discipline. Proper evaluation and fitting are essential to ensure adequate support and minimize the risk of injury, contributing to a safer and more enjoyable skating experience.

4. Blade Sharpening Techniques

Maintaining a properly sharpened blade is paramount for optimal performance. Sharpening directly influences glide efficiency, edge control, and the overall safety of a skating implement. Improperly sharpened blades can compromise the ability to execute precise maneuvers and increase the risk of falls. The following details the key facets of maintaining a sharp edge.

- The Sharpening Process

The sharpening process involves removing microscopic imperfections from the blade’s edges to create a clean, consistent “bite.” This is typically achieved using a specialized sharpening machine equipped with a grinding wheel. Skilled technicians carefully control the pressure and angle of the blade against the wheel to achieve the desired edge profile. Incorrect technique can result in uneven edges, blade damage, or premature wear.

- Hollow Depth

Hollow depth refers to the concavity ground into the bottom of the blade. This concavity creates two distinct edges that grip the ice. The depth of the hollow significantly impacts the skater’s ability to turn and maintain control. A deeper hollow provides more aggressive edges, favored by figure skaters for executing jumps and spins. A shallower hollow offers greater glide and is often preferred by hockey players seeking speed and agility. The choice of hollow depth is a matter of personal preference and skating style.

- Sharpening Frequency

The frequency with which blades require sharpening depends on several factors, including the quality of the steel, the skater’s skill level, and the ice conditions. More frequent use, exposure to abrasive ice, and improper storage can accelerate edge degradation. Regular inspection of the blade’s edges is essential to determine when sharpening is necessary. A dull blade will exhibit a rounded or uneven edge, and the skater will notice a decrease in edge control and glide efficiency.

- Maintaining Blade Sharpness

Beyond professional sharpening, there are steps skaters can take to prolong blade sharpness. Wiping the blades dry after each use prevents rust formation. Using blade guards when walking off the ice protects the edges from damage. Avoiding contact with abrasive surfaces, such as concrete or metal, is also crucial. Proper storage in a dry environment minimizes corrosion and extends the lifespan of the blade’s edges. Regular maintenance helps preserve the investment in quality equipment and ensures consistent performance on the ice.

These techniques are crucial for preserving the blade’s integrity and performance, directly impacting the skater’s ability to perform maneuvers and maintain balance. A well-maintained blade contributes to both safety and enhanced enjoyment of the sport.

5. Fit and Sizing Precision

The performance and safety characteristics of ice skating equipment are inextricably linked to precise fit and sizing. The effectiveness of energy transfer, the stability of the ankle, and the overall comfort experienced during skating depend critically on selecting correctly sized implements.

- Foot Measurement and Boot Selection

Accurate foot measurement is the foundational step in determining appropriate boot size. Length and width must be considered, often necessitating the use of specialized sizing tools. Selecting a boot that corresponds precisely to these measurements is paramount. Overly large boots compromise ankle support and control, while undersized boots can cause discomfort and restrict circulation. Real-world examples include skaters experiencing blisters and numbness due to poorly fitting boots, hindering their performance and increasing the risk of injury. Boot selection should account for the specific shape of the foot, considering factors such as arch height and instep volume.

- Lacing System Adjustment

The lacing system plays a crucial role in securing the foot within the boot and optimizing fit. Correctly adjusted laces distribute pressure evenly across the foot and ankle, providing necessary support without restricting movement. Over-tightening can lead to discomfort and circulatory issues, while under-tightening compromises stability. The lacing pattern itself can be tailored to accommodate individual foot shapes and skating styles. For instance, a “surgeon’s knot” at the ankle can provide additional lockdown and prevent heel lift, a common problem in skaters with narrow heels. This customization enhances the overall fit and responsiveness.

- Insole Customization

Insoles contribute significantly to fit and comfort by providing cushioning and arch support. Standard insoles often lack the necessary support for individual foot types, leading to discomfort and fatigue. Custom insoles, molded to the specific contours of the foot, can address these issues and improve overall alignment. Examples include skaters with flat feet benefiting from orthotic insoles that provide arch support and reduce pronation, improving stability and power transfer. Insole customization allows for fine-tuning the fit and optimizing comfort for extended skating sessions.

- Heat Molding and Custom Fitting

Some advanced implements offer heat-moldable boots, allowing for further customization. The boots are heated, either in a specialized oven or through body heat, and then molded to the individual’s foot shape. This process creates a highly personalized fit, eliminating pressure points and maximizing comfort. Custom fitting, performed by experienced professionals, involves assessing the skater’s foot, analyzing their skating style, and making adjustments to the boot to optimize performance and fit. These advanced techniques ensure a precise and comfortable fit, minimizing discomfort and maximizing the potential of the skater.

The principles of fit and sizing precision are fundamental to realizing the full potential of specialized skating equipment. By prioritizing accurate foot measurement, careful boot selection, proper lacing techniques, insole customization, and, when appropriate, heat molding or custom fitting, skaters can optimize performance, minimize the risk of injury, and enhance their overall skating experience. Attention to these details transforms specialized footwear from mere equipment into a personalized extension of the skater’s body, enabling seamless movement and control on the ice.

6. Maintenance Procedures

The operational lifespan and performance of ice skating equipment are significantly influenced by adherence to consistent maintenance procedures. These procedures are not merely ancillary tasks but are integral to preserving the structural integrity and functionality of bladed boots. The direct correlation between diligent maintenance and the longevity of such equipment is readily observable. For example, failure to remove moisture from blades after each use invariably leads to corrosion, compromising the blade’s edge and necessitating premature replacement. Similarly, neglect of boot support can result in deformation, affecting ankle stability and control. The cost implications of neglecting such procedures underscore their importance. Replacement costs are substantially higher than the cost of proper maintenance, making preventative care an economically sound strategy.

Specific maintenance protocols vary depending on the type of implement and its constituent materials. Carbon steel blades, prized for their superior edge retention, are particularly susceptible to rust and require meticulous drying and oiling. Stainless steel blades offer greater corrosion resistance, yet still benefit from regular cleaning. Boot maintenance includes cleaning and conditioning the leather or synthetic uppers to prevent cracking and maintaining the integrity of the lacing system. Regular inspection for loose rivets or worn stitching is also crucial for ensuring safety and preventing catastrophic failures. Practical applications of maintenance are evident in competitive skating environments where meticulously maintained equipment is essential for optimal performance. A properly maintained skate allows for more precise movements, increasing the athlete’s chances of success.

In conclusion, adherence to proper maintenance protocols is not merely a matter of preference but a critical determinant of the longevity, performance, and safety of ice skating apparatus. Consistent attention to blade care, boot maintenance, and regular inspection significantly mitigates the risk of equipment failure and extends the operational lifespan of these specialized implements. The financial implications of neglecting maintenance, coupled with the performance benefits of well-maintained equipment, underscore the importance of prioritizing preventative care as an integral aspect of skating.

7. Discipline-Specific Design

The design of ice skating implements is heavily influenced by the specific discipline for which they are intended. The performance requirements in figure skating, ice hockey, and recreational skating necessitate distinct design characteristics to optimize functionality. These variances are not arbitrary; rather, they are the direct result of the biomechanical demands placed on the equipment by each discipline. The success of a skater is often predicated on employing implements tailored to their activity.

Figure skates, for instance, prioritize ankle support and blade precision. Stiff boot construction enhances control during jumps and spins, while the presence of toe picks facilitates intricate footwork. Conversely, hockey skates emphasize protection, agility, and speed. Reinforced boot materials shield against impacts, and a shorter, more curved blade allows for rapid acceleration and maneuverability. Recreational skates typically represent a compromise between these extremes, offering a balance of comfort, support, and ease of use. Failing to use the appropriate equipment for a given discipline can result in diminished performance and increased risk of injury. Attempting advanced figure skating maneuvers in hockey skates, for example, would be significantly more difficult and dangerous due to the lack of toe picks and reduced ankle support.

Understanding the influence of discipline-specific design is crucial for both novice and experienced skaters. Selecting equipment that aligns with their intended activity ensures optimal performance, reduces the risk of injury, and enhances overall enjoyment. While crossover between disciplines is possible, specialized equipment provides a distinct advantage in meeting the unique demands of each skating form. Continued innovation in material science and engineering will likely further refine discipline-specific designs, pushing the boundaries of performance and safety in the realm of ice skating.

Frequently Asked Questions

This section addresses common inquiries regarding equipment associated with ice skating, providing clear and concise information to enhance understanding and promote informed decision-making.

Question 1: What constitutes a suitable material for the blade component?

Appropriate blade materials include carbon steel and stainless steel. Carbon steel offers superior edge retention, while stainless steel exhibits enhanced corrosion resistance. The selection hinges on usage intensity and maintenance capabilities.

Question 2: How does boot stiffness impact skating performance?

Boot stiffness directly influences force transfer and stability. Stiffer boots provide greater control and responsiveness, advantageous for complex maneuvers. More flexible boots offer increased agility, though potentially at the expense of precision.

Question 3: What mechanisms provide optimal ankle support?

Ankle support is provided by boot height, cuff design, lacing systems, and internal padding. These mechanisms limit excessive ankle movement, enhancing stability and preventing injuries.

Question 4: How frequently should skating blades be sharpened?

Sharpening frequency depends on usage intensity, ice conditions, and blade material. Regular inspection is recommended to identify signs of dullness or damage, indicating the need for professional sharpening.

Question 5: What factors determine proper boot fit and sizing?

Accurate foot measurements, lacing system adjustments, and insole customization are critical for achieving proper fit. A snug, supportive fit enhances comfort, performance, and safety.

Question 6: What are the essential maintenance procedures?

Essential procedures encompass drying blades after each use, protecting edges with guards, and regularly inspecting the equipment for wear and tear. Adherence to these practices prolongs equipment lifespan and maintains performance.

In summary, thoughtful material selection, appropriate boot stiffness, reliable ankle support, regular sharpening, precise fit, and consistent maintenance are indispensable for optimizing functionality and safety.

The subsequent section will offer additional tips for equipment selection and maintenance.

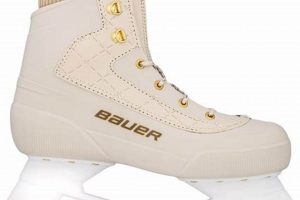

Columbia Ice Skate

The preceding discourse has explored the multifaceted considerations surrounding equipment for navigating frozen surfaces. Key points include the critical role of blade material, boot stiffness, ankle support mechanisms, sharpening techniques, fit precision, and maintenance protocols. These elements collectively determine the user experience, performance ceiling, and safety profile of the equipment in question.

As advancements in material science and biomechanical engineering continue, the design and construction of such implements will undoubtedly evolve. A comprehensive understanding of existing principles, coupled with an ongoing engagement with emerging technologies, remains paramount for both participants and equipment developers seeking to optimize the interaction between individuals and frozen environments. Therefore, continued diligence in research and practice is warranted to enhance safety, elevate performance, and refine the overall experience.