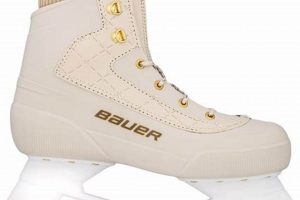

The subject refers to specialized footwear designed for gliding across a frozen water surface. These products, often associated with the named manufacturer, are engineered for performance in activities such as ice hockey, figure skating, and recreational skating. These specific items generally incorporate a rigid boot construction for ankle support, coupled with a blade attached to the sole, facilitating movement on ice.

Their importance stems from enabling efficient and controlled movement on ice, a characteristic crucial for competitive and recreational pursuits. Throughout history, advancements in design and materials have enhanced the performance, comfort, and safety offered by these products. Improved blade materials, more supportive boot designs, and refined lacing systems all contribute to the experience and effectiveness of gliding and maneuvering on frozen surfaces.

The ensuing sections will explore the specific models available, technologies employed in manufacturing, and factors to consider when selecting appropriate equipment for different skating disciplines and skill levels. Additional focus will be given to maintenance procedures necessary to ensure longevity and optimal performance, along with an analysis of market trends and innovations within this product category.

Guidance for Optimal Performance

The following recommendations aim to enhance the user’s experience and extend the lifespan of specialized footwear for ice surfaces. Adherence to these suggestions will promote safety, comfort, and performance.

Tip 1: Proper Sizing and Fit: Ensure the equipment is appropriately sized to the foot. Ill-fitting equipment can lead to discomfort, reduced performance, and potential injury. Seek professional assistance for proper sizing.

Tip 2: Regular Blade Sharpening: The blade edge is critical for maintaining grip on the ice. Routine sharpening, performed by a qualified technician, is necessary to optimize performance and control.

Tip 3: Drying After Use: Moisture degrades the materials and contributes to rust formation on the blade. Thoroughly dry the equipment after each use, inside and out, to prolong its lifespan.

Tip 4: Blade Protection: Employ blade guards when walking on surfaces other than ice to prevent damage to the blade edge. Proper protection minimizes wear and tear and maintains the integrity of the blade profile.

Tip 5: Proper Lacing Technique: Distribute lace tension evenly to provide adequate ankle support and comfort. Avoid overtightening, which can restrict circulation and reduce flexibility.

Tip 6: Storage in a Dry Environment: Store the equipment in a cool, dry location away from direct sunlight and extreme temperatures. This will prevent material degradation and maintain structural integrity.

Tip 7: Periodic Inspection: Regularly inspect the equipment for signs of wear, damage, or loosening of components. Address any issues promptly to prevent further deterioration and potential safety hazards.

Implementing these recommendations will contribute to enhanced performance, increased comfort, and extended equipment longevity. Prioritizing maintenance and proper usage will ensure that the user benefits fully from the design and engineering invested in these specialized products.

The subsequent sections will delve into specific maintenance procedures, troubleshooting common issues, and selecting appropriate accessories to complement the equipment and optimize the overall skating experience.

1. Blade Steel Quality

Blade steel quality represents a fundamental factor influencing the performance and durability of skating equipment manufactured by Bauer. The composition and treatment of the steel directly affect the blade’s ability to maintain a sharp edge, resist corrosion, and withstand the stresses of repetitive use on ice surfaces. Blades constructed from lower-grade steel may dull quickly, requiring more frequent sharpening and potentially compromising a skater’s control and agility. In contrast, higher-grade steel alloys, often incorporating elements like carbon and chromium, offer improved edge retention, enhanced resistance to rust, and greater overall durability, leading to a more consistent and reliable skating experience.

The selection of appropriate blade steel significantly impacts the intended use case. For instance, recreational skaters may find a mid-grade steel sufficient, while elite-level athletes demand blades crafted from premium materials to optimize power transfer, responsiveness, and edge control during high-intensity maneuvers. Instances where blades made of inferior steel have failed prematurely during competitive events underscore the practical significance of steel quality. These failures can result in lost opportunities, injuries, and equipment malfunctions, highlighting the direct correlation between material selection and performance outcomes.

Therefore, the quality of the blade steel constitutes a critical element in the overall value proposition of skating equipment. Understanding the characteristics and performance attributes associated with different steel grades empowers consumers to make informed purchasing decisions tailored to their individual skill level, skating style, and budgetary constraints. While premium blade steel may entail a higher initial investment, the benefits of enhanced performance, increased longevity, and reduced maintenance frequency often outweigh the added cost in the long run. The interplay between steel quality and equipment performance is a crucial consideration for maximizing the user experience and extending the lifespan of specialized footwear.

2. Boot Stiffness Rating

Boot stiffness rating is a critical specification that defines the level of support and responsiveness provided by hockey or figure skating equipment manufactured by Bauer. The stiffness directly impacts the skater’s ability to transfer energy, maintain stability, and execute specific movements. A rating system, often numerical, quantifies the rigidity of the boot structure, allowing skaters to select equipment aligned with their skill level and playing style.

- Energy Transfer Efficiency

A higher boot stiffness rating allows for more efficient transfer of energy from the skater’s leg to the ice. This is particularly important for advanced skaters who require immediate responsiveness during explosive movements such as accelerating, stopping, and turning. Conversely, a softer boot allows for greater ankle flexion, enabling increased agility and more nuanced control. Incorrect stiffness impedes the skaters skill development and power. For instance, a powerful skater in stiff skates might experience greater acceleration compared to one in softer skates.

- Ankle Support and Injury Prevention

The stiffness rating influences the degree of ankle support provided. Stiffer boots offer greater stability and protection against ankle injuries, making them suitable for players involved in high-impact collisions or skaters performing complex jumps and landings. However, overly stiff boots can restrict ankle movement, potentially leading to discomfort or fatigue. Young skaters and beginners should seek more flexible boots which allow for greater mobility and a natural skating stance.

- Skating Style and Performance

Different skating styles necessitate varying levels of boot stiffness. Offensive players in hockey who rely on speed and agility may benefit from a moderately stiff boot that balances support and maneuverability. Defensive players, who require stability and power, may prefer a stiffer boot for enhanced energy transfer. In figure skating, boot stiffness is carefully calibrated to the specific discipline, with freestyle skaters generally requiring stiffer boots than ice dancers to withstand the forces generated during jumps.

- Skill Level and Development

The appropriate boot stiffness rating depends on the skater’s skill level. Beginners often benefit from softer, more flexible boots that promote ankle flexion and allow for a more natural skating motion. As skaters progress and develop more advanced skills, they may require stiffer boots to provide the necessary support and responsiveness for executing complex maneuvers and maximizing performance. It is common to see an athlete upgrading to stiffer equipment as their skills evolve and strengthen.

The boot stiffness rating is a primary element when selecting specialized footwear. Factors such as skill level, playing style, and injury history need careful consideration. Understanding the nuanced impact of boot stiffness on skating performance allows for making equipment choices that improve effectiveness and reduce risk. Consulting with a knowledgeable retailer or skating coach can provide valuable guidance in determining the optimal boot stiffness rating for individual needs and goals.

3. Ankle Support Design

Ankle support design in specialized skating equipment represents a critical engineering element that directly influences performance, safety, and comfort. This aspect of footwear design, particularly in models from manufacturers like Bauer, addresses the need to stabilize the ankle joint during demanding physical activities performed on ice. Effective ankle support mitigates the risk of injury, enhances control, and allows for efficient energy transfer during skating maneuvers.

- Boot Shell Construction and Materials

The rigidity and composition of the boot shell form the foundation of ankle support. Stiffer materials, such as reinforced polymers or composite laminates, provide a more robust structure that resists deformation and prevents excessive ankle pronation or supination. However, the design must also allow for a degree of flexibility to facilitate natural movement and prevent chafing. For example, high-end hockey equipment often features carbon fiber shells molded to provide an anatomical fit, maximizing support while minimizing weight.

- Internal Padding and Liners

The internal padding and liner system contribute significantly to ankle stabilization and comfort. Dense foams, gel inserts, or thermo-moldable materials conform to the contours of the ankle, filling voids and minimizing slippage. These components also provide cushioning to absorb impact forces and reduce pressure points. In specialized figure skating equipment, the liner often incorporates additional reinforcement around the ankle area to provide enhanced support during landings from jumps.

- Lacing System and Closure Mechanisms

The lacing system plays a crucial role in securing the foot and ankle within the boot. A well-designed lacing system distributes tension evenly, allowing the skater to customize the fit and adjust the level of support according to their preferences and skating style. Features such as lace locks, power straps, or integrated closure mechanisms further enhance ankle stabilization and prevent unwanted movement. Certain models incorporate asymmetrical lacing patterns to better accommodate the anatomical structure of the ankle.

- Heel Counter and Tendon Guard

The heel counter, a reinforced structure located at the rear of the boot, provides critical support to the heel and ankle joint. A rigid heel counter prevents heel slippage and maintains proper foot alignment. A tendon guard, often extending upwards from the heel counter, protects the Achilles tendon from abrasion and impact. In hockey equipment, the tendon guard may be articulated to allow for greater ankle flexion while still providing protection against stick checks and puck impacts.

Collectively, these design elements integrate to deliver appropriate ankle support. By understanding these components within the context of specialized equipment manufactured by Bauer, users and industry professionals can better evaluate the suitability of specific equipment models for diverse skating applications and requirements. Optimal ankle support translates into improved performance, reduced risk of injury, and increased comfort, thereby enhancing the overall skating experience.

4. Lacing System Integrity

Lacing system integrity, concerning specialized footwear designed for ice surfaces, significantly influences performance and safety. A well-maintained lacing system ensures secure foot and ankle stabilization within the boot. This secure fit optimizes energy transfer from the skater’s body to the ice, facilitating efficient strides, precise turns, and controlled stops. Conversely, a compromised lacing system, characterized by worn laces, damaged eyelets, or inadequate design, can lead to instability, reduced power output, and increased risk of injury. A skater with loose or broken laces may experience difficulty maintaining balance, making the likelihood of falls greater. Furthermore, the improper distribution of pressure caused by a faulty system can cause discomfort, affecting the skater’s focus and performance.

The importance of this systems robustness is evidenced by the range of lacing system designs and materials employed in professional-grade skating equipment. High-end models often feature reinforced eyelets, durable laces constructed from high-tensile-strength materials, and strategically placed lace locks. These features are intended to withstand the repetitive stress of frequent use and the forces generated during intense skating activities. For instance, a hockey player performing rapid pivots and changes of direction relies heavily on a secure lacing system to maintain ankle stability and prevent potential sprains or strains. Similarly, a figure skater executing complex jumps and landings requires a lacing system that provides unwavering support and prevents the boot from shifting during impact.

In conclusion, the connection between lacing system integrity and performance outcomes on ice is irrefutable. Regular inspection and maintenance of this system are essential for preserving the equipments functionality and safeguarding the skater’s well-being. Ignoring signs of wear or damage can lead to performance degradation, increased risk of injury, and ultimately, the premature failure of the equipment. Therefore, attention to detail in lace selection, proper lacing technique, and timely replacement of worn components are crucial for optimizing the skating experience and maintaining a competitive edge. The longevity of performance equipment hinges on maintaining each and every part that will enable the user from being safe.

5. Thermal Moldability Feature

Thermal moldability represents a significant advancement in the design and construction of performance ice skates, particularly those manufactured by Bauer. This feature allows for a customized fit, enhancing comfort and optimizing performance by adapting the boot’s internal structure to the specific contours of the skater’s foot.

- Customized Fit and Comfort

Thermal moldability utilizes heat-sensitive materials within the boot’s construction. When exposed to a controlled heat source, these materials soften, allowing the boot to be molded to the precise shape of the foot. This process minimizes pressure points, reduces friction, and creates a snug, comfortable fit that maximizes the skater’s feel for the ice. An example includes a skater with asymmetrical foot dimensions achieving a balanced fit through thermal adjustment, which standard skates might not accommodate.

- Enhanced Performance and Energy Transfer

A customized fit achieved through thermal moldability promotes efficient energy transfer from the skater’s foot to the blade. By eliminating gaps and ensuring a secure connection between the foot and the boot, energy loss is minimized, resulting in more powerful strides and improved agility. Consider an elite hockey player gaining enhanced acceleration and responsiveness due to the direct connection facilitated by a thermally molded boot.

- Reduced Break-in Time

Traditional ice skates often require a significant break-in period, during which the boot gradually conforms to the skater’s foot through use. Thermal moldability accelerates this process, creating a personalized fit in a fraction of the time. This reduces discomfort and potential for blisters or other foot issues during the initial stages of use. For instance, a skater transitioning to a new pair of thermally moldable boots experiences immediate comfort and performance benefits, avoiding the typical break-in period.

- Long-Term Durability and Support

While primarily focused on initial fit, thermal moldability also contributes to the long-term integrity and support of the boot. By creating a precise fit that minimizes internal movement and friction, thermal molding reduces wear and tear on the boot’s internal components. This extends the lifespan of the skates and maintains consistent performance over time. A skater using thermally molded boots may experience prolonged support and structural integrity compared to those using non-molded alternatives, especially with rigorous use.

The integration of thermal moldability into Bauer’s skating equipment underscores a commitment to performance optimization and user comfort. This feature directly addresses the need for personalized fit, contributing to enhanced energy transfer, reduced break-in time, and improved long-term durability. By adapting to the individual characteristics of the skater’s foot, thermal moldability represents a significant advancement in ice skate technology, benefiting both recreational and competitive athletes.

Frequently Asked Questions

The subsequent section addresses common inquiries and concerns regarding specialized equipment designed for gliding across frozen water surfaces, specifically focusing on products associated with the manufacturer Bauer. The information presented aims to provide clarity and facilitate informed decision-making.

Question 1: What distinguishes different models within the Bauer line of ice skates?

Variations exist across models in boot stiffness, blade materials, lacing systems, and intended usage. High-end models often feature stiffer boots constructed from composite materials, enhanced blade steel, and customizable lacing systems designed for competitive skaters. Entry-level models typically offer softer boots, standard blade materials, and simpler lacing configurations suitable for recreational use.

Question 2: How frequently should the blades be sharpened on ice skates?

Sharpening frequency depends on usage intensity and ice conditions. Competitive skaters may require sharpening after every few sessions, while recreational skaters may only need sharpening a few times per season. Dull blades compromise edge control and gliding efficiency, necessitating timely sharpening.

Question 3: What factors should be considered when selecting ice skates for a beginner?

Beginners should prioritize comfort and ankle support. Softer boots allow for greater ankle flexion, promoting a more natural skating motion. A proper fit is crucial to prevent discomfort and potential injuries. Professional fitting services can assist in determining the appropriate size and model for novice skaters.

Question 4: How does boot stiffness impact skating performance?

Boot stiffness directly affects energy transfer and ankle support. Stiffer boots provide greater energy transfer, enabling more powerful strides and enhanced responsiveness. However, overly stiff boots can restrict ankle movement and cause discomfort. The optimal boot stiffness depends on the skater’s skill level, skating style, and physical conditioning.

Question 5: What are the recommended maintenance procedures for ice skates?

Proper maintenance includes drying the blades and boots after each use, using blade guards when walking on surfaces other than ice, and storing the equipment in a dry environment. Regular inspection for signs of wear or damage is also essential to prevent premature failure and ensure safety.

Question 6: Can ice skate blades be replaced?

Yes, ice skate blades are replaceable. The process typically requires specialized tools and expertise. Replacing blades allows skaters to upgrade to higher-quality steel, repair damage, or customize the blade profile to suit their specific needs. Professional skate technicians can perform blade replacement and ensure proper alignment.

The information presented herein emphasizes the importance of proper equipment selection, maintenance, and understanding of performance-related factors associated with specialized skating footwear. Adhering to these guidelines will contribute to enhanced performance, reduced risk of injury, and extended equipment lifespan.

The next section will offer guidance on troubleshooting common issues encountered with ice skates, addressing topics such as blade alignment, boot fit adjustments, and lacing system repairs.

Conclusion

The preceding analysis has examined the salient attributes of “bauer skates ice,” encompassing design characteristics, maintenance protocols, and performance considerations. Factors such as blade steel quality, boot stiffness rating, ankle support design, lacing system integrity, and thermal moldability feature are critical determinants of equipment efficacy. Understanding the interplay of these elements enables informed selection and usage, which optimizes the skating experience.

Continued refinement in materials science and manufacturing processes promises further advancements in this equipment. Prioritizing informed purchasing decisions, meticulous maintenance, and adherence to safety protocols remains paramount. The ongoing pursuit of innovation and informed application will define the future of specialized footwear for ice surfaces and those who use it.