Equipment designed for gliding across ice surfaces, particularly in the sport of ice hockey and recreational skating, often features a rigid boot attached to a metal blade. These specialized boots provide ankle support and facilitate efficient movement on the ice. The steel blade allows for precise turns, stops, and acceleration, essential for both athletic performance and leisurely enjoyment.

The quality and design of skating equipment significantly impact performance, comfort, and safety. Durable construction and advanced features contribute to enhanced control, reduced risk of injury, and overall improved skating experience. Developments in materials and manufacturing processes have led to lighter, more responsive, and better-fitting options that cater to a range of skill levels and preferences. Understanding the historical context of skate design and technological advancements provides valuable insight into the evolution of these crucial tools.

The subsequent sections will delve into specific aspects of skate construction, sizing guidelines, maintenance procedures, and comparisons between different models, providing a comprehensive guide for selecting and caring for ice skating equipment.

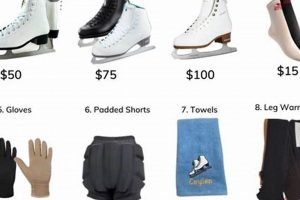

Skating Equipment Recommendations

The following are recommendations designed to maximize performance, longevity, and user satisfaction when selecting and utilizing skating equipment.

Tip 1: Proper Fit Assessment: Ensure precise boot fitting. Incorrect sizing can lead to discomfort, blisters, and compromised performance. Professional fitting services are advised.

Tip 2: Blade Sharpness Maintenance: Regular blade sharpening is crucial for optimal edge control and glide. The frequency of sharpening depends on usage and ice conditions.

Tip 3: Boot Support Considerations: Select a boot with adequate ankle support appropriate for the skill level. Insufficient support can increase the risk of injury, while excessive stiffness may restrict mobility.

Tip 4: Drying After Use: Thoroughly dry equipment after each use to prevent rust and material degradation. Remove insoles and allow for complete air circulation within the boot.

Tip 5: Lacing Technique Standardization: Employ a consistent lacing technique to achieve uniform pressure distribution across the foot and ankle. Over-tightening can restrict circulation, while loose lacing compromises stability.

Tip 6: Blade Guard Utilization: Always use blade guards when walking off the ice surface to protect the blade edges from damage. This practice extends blade life and maintains performance.

Tip 7: Regular Hardware Inspection: Routinely inspect rivets and hardware for signs of wear or loosening. Address any issues promptly to prevent potential equipment failure during use.

Adherence to these recommendations promotes safety, extends equipment lifespan, and optimizes the overall skating experience.

The subsequent conclusion will summarize the key considerations for selecting and maintaining skating equipment.

1. Boot Stiffness

Boot stiffness is a critical determinant in ice skate performance, directly influencing energy transfer and control. In the context of skating equipment, variations in boot stiffness cater to different player positions and skill levels, dictating the responsiveness and support offered.

- Energy Transfer Efficiency

Stiffer boots facilitate more direct power transmission from the skater’s leg to the blade. This enhanced efficiency is crucial for maximizing speed and acceleration, especially beneficial for forwards requiring explosive movements. Conversely, less rigid boots, while sacrificing some power, offer greater flexibility and comfort for recreational skaters.

- Ankle Support and Stability

High boot stiffness provides substantial ankle support, reducing the risk of injury during sharp turns and rapid stops. This support is paramount for players executing complex maneuvers, particularly defensemen who require stability for defensive positioning and physical engagements. A balance must be struck, as excessive stiffness can restrict ankle articulation and agility.

- Responsiveness and Control

The degree of stiffness directly affects the responsiveness of the skate. Stiffer boots react instantaneously to the skater’s movements, providing precise control for intricate skating techniques. Players with advanced skating skills often prefer increased stiffness for maximum command over their movements. However, beginner skaters may find the sensitivity of a very stiff boot challenging to manage.

- Impact Absorption

Boot stiffness contributes to the absorption of impact forces generated during skating. Stiffer materials can dissipate energy from collisions and jumps, reducing stress on the skater’s joints. This cushioning effect is important for mitigating the risk of fatigue and injury, particularly during prolonged periods of intense skating activity.

The integration of boot stiffness characteristics is pivotal in tailoring skating equipment to specific needs and preferences. By strategically selecting a stiffness level that aligns with skating style and skill, users can optimize their performance, safety, and overall enjoyment on the ice.

2. Blade Material

The composition of the blade is a primary determinant of performance characteristics in skating equipment. Different alloys offer varying degrees of hardness, edge retention, and resistance to corrosion, influencing the skating experience.

- Stainless Steel Composition

Stainless steel is a common material choice due to its inherent corrosion resistance and acceptable edge retention. Blades made from stainless steel require less maintenance compared to carbon steel variants. However, the relative softness of stainless steel necessitates more frequent sharpening to maintain optimal performance.

- Carbon Steel Enhancement

Carbon steel blades offer superior edge hardness and retention capabilities. This translates to sharper edges and improved glide. However, carbon steel is susceptible to corrosion, requiring diligent drying and protective measures after each use to prevent rust formation.

- Surface Coating Technologies

Advanced surface coatings, such as titanium or nickel plating, enhance blade properties. These coatings improve wear resistance, reduce friction, and provide an additional layer of corrosion protection. Coated blades often exhibit prolonged edge life and require less frequent maintenance.

- Rockwell Hardness Scale

The Rockwell hardness scale quantifies the resistance of a material to indentation, providing a standardized measure of blade hardness. Higher Rockwell hardness values indicate greater resistance to wear and deformation, resulting in longer-lasting edges and improved performance under demanding conditions.

The selection of an appropriate blade material hinges on balancing performance requirements with maintenance considerations. Players prioritizing edge sharpness and glide efficiency may opt for carbon steel variants, while those seeking lower maintenance requirements might prefer stainless steel options, potentially with surface coatings to enhance durability.

3. Ankle Support

Ankle support is a critical structural element in skating equipment, directly influencing stability, control, and injury prevention. In these skates, the design and materials used in the boot construction are engineered to provide varying degrees of support tailored to different skating styles and skill levels. Insufficient ankle support can lead to instability, increasing the risk of sprains and other injuries, while excessive rigidity may restrict mobility and hinder performance. The effectiveness of ankle support in skating equipment determines the user’s ability to execute maneuvers precisely and maintain balance, which are essential for both competitive and recreational skating.

The specific design of the ankle support system in skates involves a combination of factors, including the height of the boot, the stiffness of the materials used, and the presence of internal or external support structures. Advanced models often incorporate features such as heat-moldable materials and adjustable support elements, allowing for a customized fit that conforms to the unique anatomy of the skater’s foot and ankle. The integration of these features enhances comfort and optimizes performance by minimizing friction and maximizing stability. For example, a skater recovering from an ankle injury may benefit from a boot with increased lateral support to prevent re-injury, while a seasoned player may prioritize flexibility to improve agility and responsiveness.

Therefore, the relationship between ankle support and these skates highlights the importance of selecting equipment that matches individual needs and skating style. Proper assessment of ankle stability and range of motion is crucial for choosing a skate that provides the right balance of support and flexibility. Ignoring this consideration can lead to discomfort, decreased performance, or increased risk of injury. By carefully evaluating the ankle support features and prioritizing a proper fit, skaters can optimize their experience on the ice and minimize the potential for complications.

4. Heat Molding

Heat molding represents a critical customization process in modern skating equipment, enabling a more precise and comfortable fit for the user. This process is particularly relevant to brands like the keyword, where performance and personalized fit are emphasized.

- Conformity and Anatomical Adaptation

Heat molding utilizes thermal energy to soften the boot materials, allowing them to conform closely to the unique contours of an individual’s foot. This adaptation eliminates pressure points and reduces the likelihood of blisters or discomfort during extended use. For example, a skater with bunions or other foot irregularities can achieve a more accommodating fit through the heat molding process, enhancing overall comfort and performance.

- Performance Enhancement and Energy Transfer

A properly heat-molded skate boot ensures optimal contact between the foot and the interior of the skate. This tight interface maximizes energy transfer from the skater’s leg to the blade, enhancing responsiveness and power. A loose or poorly fitting boot can lead to energy loss and reduced control, impacting performance on the ice. Heat molding mitigates this issue by creating a snug, efficient connection.

- Material Responsiveness and Durability

The effectiveness of heat molding depends on the composition and properties of the materials used in the skate boot. Advanced composite materials are often employed to facilitate the molding process while maintaining structural integrity and durability. These materials must be capable of softening under heat without compromising the boot’s long-term performance characteristics. The integration of such materials represents a significant technological advancement in skating equipment design.

- Professional Fitting Services and Accessibility

While some skaters may attempt to heat-mold their skates at home, professional fitting services are generally recommended to ensure optimal results and prevent damage to the equipment. Trained technicians possess the expertise and specialized equipment necessary to execute the process correctly. Furthermore, professional fitting ensures that the heat molding is tailored to the skaters specific needs and performance goals, maximizing the benefits of this customization technique. The availability of these services enhances the accessibility of heat-molded skates to a wider range of users.

The heat-molding process, therefore, is a crucial element in optimizing both comfort and performance. Its successful application relies on material science, skilled technicians, and understanding of anatomical variations, ultimately providing a customized fit that enhances the skating experience.

5. Blade Radius

The blade radius, a critical specification in skating equipment, significantly impacts maneuverability and skating style. Its curvature dictates how easily a skater can execute turns and maintain balance on the ice, influencing overall performance and control within the skating equipment ecosystem.

- Turning Agility and Edge Engagement

A smaller blade radius enables tighter turns due to increased curvature. This sharper curvature allows the blade to engage the ice more aggressively, facilitating quick pivots and rapid changes in direction. For example, a forward requiring agility in close quarters might benefit from a smaller radius, enhancing their ability to evade defenders and create scoring opportunities. Conversely, a larger radius promotes stability during straight-line skating.

- Glide Efficiency and Speed Maintenance

A larger blade radius optimizes glide efficiency due to the increased surface area in contact with the ice. This extended contact reduces friction and allows skaters to maintain speed with less effort. Defensemen often favor larger radii to enhance their ability to cover ground quickly and efficiently, providing better defensive coverage. A smaller radius, while advantageous for turning, can reduce top speed.

- Skating Style Accommodation and Customization

The selection of blade radius should align with the skater’s individual style and preferences. Aggressive skaters may favor a smaller radius for heightened maneuverability, while those emphasizing speed and stability might opt for a larger radius. Manufacturers such as the keyword offer customization options to accommodate diverse skating styles. This customization allows skaters to fine-tune their equipment to maximize personal performance.

- Radius of Hollow (ROH) and Blade Profile

The radius of hollow (ROH) refers to the concave groove ground into the bottom of the blade, complementing the blade radius. The ROH affects the edge grip and glide characteristics of the blade. A deeper ROH provides more aggressive edge engagement, while a shallower ROH offers smoother glide. The interaction between blade radius and ROH is critical for optimizing skating performance. Adjusting both parameters can significantly alter the feel and responsiveness of skates on the ice.

The interrelation of blade radius, ROH, and blade profile directly affects skating performance. The keyword offers options that account for these factors. Understanding these elements is crucial for equipment selection and maintenance. Equipment selection is necessary for both novice and professional users.

6. Liner Comfort

Liner comfort within skating equipment constitutes a significant factor affecting performance, endurance, and overall user satisfaction. The materials, design, and construction of the inner boot directly influence the skater’s experience, particularly during extended periods of use.

- Material Composition and Moisture Management

The materials utilized in the liner play a pivotal role in mitigating moisture buildup and regulating temperature within the boot. Advanced synthetic fabrics with moisture-wicking properties help to draw perspiration away from the foot, preventing discomfort and reducing the risk of blisters. For instance, liners incorporating antimicrobial treatments inhibit bacterial growth, minimizing odor and enhancing hygiene. In the context of skates, the effectiveness of these materials directly impacts the skater’s ability to maintain focus and perform optimally, especially during intense or prolonged activity.

- Padding Distribution and Anatomical Support

Strategic padding placement within the liner is essential for providing targeted support and cushioning to key areas of the foot and ankle. High-density foam padding around the ankle bone reduces friction and prevents chafing, while contoured footbeds offer arch support and enhance stability. Skates designed with anatomical considerations in mind minimize pressure points and promote a more natural foot position, reducing fatigue and enhancing overall comfort. This is especially relevant for figure skates, where precision and control are paramount.

- Seamless Construction and Friction Reduction

Seamless construction techniques are employed to minimize friction and irritation within the skate boot. By eliminating seams in high-contact areas, manufacturers reduce the potential for rubbing and blistering. Liners with smooth, low-friction surfaces allow the foot to move freely within the boot, promoting circulation and enhancing comfort. This design element is particularly important for hockey skates, where players require unrestricted movement and agility.

- Thermal Moldability and Custom Fit

Thermal moldability enhances the ability to conform to the unique contours of the skater’s foot, creating a personalized fit that maximizes comfort and performance. The application of heat allows the liner materials to soften and adapt to the individual’s foot shape, eliminating gaps and optimizing support. This feature is particularly valuable for skaters with irregular foot shapes or specific fitting requirements, providing a customized solution that enhances overall comfort and reduces the risk of discomfort or injury. Certain lines of these skates offer varying degrees of thermal moldability to cater to a diverse range of preferences.

The integration of these elements contributes to a superior skating experience. Through mindful design and material selection, liners directly impact user comfort. This focus on detail enhances performance and the longevity of use, solidifying the position of skating equipment within the marketplace.

7. Size Precision

Size precision is a foundational element in the selection and performance of ice skates. Proper fit directly affects comfort, control, and injury prevention, establishing its critical role within the skating equipment domain.

- Performance Optimization

Precise sizing facilitates optimal energy transfer from the skater’s foot to the blade. Skates that are too large result in foot slippage, reducing control and agility. Conversely, skates that are too small can cause discomfort and restrict circulation, hindering performance. Accurate sizing ensures a secure and responsive fit, allowing skaters to execute maneuvers with greater precision and efficiency. Professional athletes often undergo meticulous fitting processes to guarantee optimal performance outcomes.

- Injury Prevention

Ill-fitting skates significantly increase the risk of blisters, lace bite, and other foot-related injuries. Loose skates allow excessive foot movement, leading to friction and irritation. Overly tight skates can compress nerves and blood vessels, causing pain and discomfort. Precise sizing minimizes these risks, providing a stable and secure platform for the foot and ankle. Implementing correct sizing protocols is crucial for mitigating the incidence of skating-related injuries.

- Comfort and Endurance

A properly sized skate enhances comfort, enabling skaters to maintain focus and endurance during extended periods of use. Skates that conform to the natural shape of the foot minimize pressure points and reduce fatigue. The selection of appropriate sock thickness and the use of heat-moldable liners can further refine the fit, optimizing comfort and performance. Recreational skaters benefit significantly from prioritizing comfort to maximize enjoyment and prolong skating sessions.

- Standardized Sizing Systems

Manufacturers often employ standardized sizing systems to guide the selection process. However, variations exist between brands, necessitating careful measurement and fitting. Consulting sizing charts and seeking professional fitting advice is recommended to ensure accurate size determination. The adoption of consistent sizing standards would enhance clarity and simplify the selection process for consumers. This ensures the skater gets the best possible experience with their chosen boot and blade combination.

The significance of size precision underscores the importance of meticulous fitting practices. By prioritizing accurate measurement and seeking expert guidance, skaters can optimize performance, prevent injuries, and enhance their overall experience. The synergy between appropriate sizing and technological advancements in skate design culminates in superior comfort and performance, highlighting the critical role of size precision within the field of ice skating equipment.

Frequently Asked Questions About Skating Equipment

The following section addresses common inquiries regarding the selection, maintenance, and performance characteristics of skating equipment. It aims to clarify misconceptions and provide authoritative guidance to users.

Question 1: What factors primarily determine the appropriate size?

The length and width of the foot are the primary determinants. Measurement should be conducted while wearing socks appropriate for skating. Consult the manufacturer’s sizing chart for specific guidelines, as sizing varies between brands and models.

Question 2: How frequently should blades be sharpened?

Sharpening frequency depends on usage intensity, ice quality, and skating style. Blades should be sharpened when edge degradation is noticeable, typically indicated by reduced grip or difficulty in executing turns. Professional sharpening services are recommended to ensure proper blade geometry.

Question 3: What constitutes adequate ankle support?

Adequate ankle support provides sufficient stability to prevent excessive ankle movement during skating. The level of support required varies based on skill level and skating style. Beginner skaters typically require more rigid support, while advanced skaters may prefer greater flexibility.

Question 4: How can equipment lifespan be extended?

Equipment lifespan can be extended through proper maintenance practices. After each use, skates should be thoroughly dried to prevent rust and material degradation. Blade guards should be used when walking off the ice surface. Regular inspection of hardware and prompt repair of any issues is also essential.

Question 5: What distinguishes different blade materials?

Blade materials vary in hardness, edge retention, and corrosion resistance. Stainless steel offers good corrosion resistance but may require more frequent sharpening. Carbon steel provides superior edge hardness but is susceptible to rust. Surface coatings can enhance blade properties and extend lifespan.

Question 6: How does blade radius affect skating performance?

Blade radius influences maneuverability and glide efficiency. A smaller radius enhances turning agility, while a larger radius promotes speed and stability. The appropriate radius depends on skating style and preferences. Customization options are available to tailor blade radius to individual needs.

These answers address prevalent concerns and offer actionable guidance. Prioritizing informed decision-making is critical for optimizing the skating experience and prolonging equipment utility.

The succeeding section will explore strategies for comparing and contrasting specific equipment models.

Conclusion

The preceding exploration of equipment design and attributes has illuminated the nuanced considerations involved in optimizing on-ice performance. Parameters such as boot stiffness, blade material, and size precision directly impact maneuverability, energy transfer, and user safety. The significance of selecting appropriate equipment, therefore, cannot be understated. These elements, when considered holistically, contribute to a synergistic relationship between skater and equipment.

The long-term utility and performance of skating equipment hinges upon informed decision-making and diligent maintenance. As technology continues to advance, awareness of these elements facilitates optimal utilization. Users must understand the interaction of design, materials, and personal preferences to derive maximum benefit from their equipment. Continued investigation and analysis are encouraged to foster a deeper understanding of equipment design and its influence on ice skating performance.