A specialized form of recreational equipment, the item in question consists of footwear fitted with wheels, allowing the user to glide along surfaces. This apparatus facilitates movement and provides an enjoyable physical activity. Examples include models designed for artistic performance, speed racing, or casual use on paved trails.

The significance of this wheeled footwear lies in its versatility as a means of exercise, transportation, and artistic expression. Its benefits encompass cardiovascular health improvements, enhanced coordination, and opportunities for social interaction. Historically, early iterations were rudimentary, evolving over time into the sophisticated designs available today, incorporating advancements in materials and engineering.

The following sections will delve into specific applications, technological innovations, and safety considerations related to this popular wheeled activity. Discussions will include maintenance guidelines and comparisons among various models to aid in informed decision-making for potential enthusiasts.

Guidance for Optimal Wheeled Footwear Use

The following provides practical advice to maximize the enjoyment and safety associated with the recreational activity.

Tip 1: Prioritize Protective Gear. Helmet use is non-negotiable for head injury prevention. Wrist guards, elbow pads, and knee pads offer crucial protection against abrasions and fractures.

Tip 2: Conduct Pre-Use Inspection. Before each session, verify wheel integrity, bearing functionality, and brake responsiveness. Address any deficiencies before engaging in the activity.

Tip 3: Select Appropriate Surfaces. Opt for smooth, paved surfaces free from debris or significant obstacles. Avoid areas with heavy pedestrian or vehicular traffic.

Tip 4: Master Fundamental Skills. Develop proficiency in basic maneuvers such as starting, stopping, turning, and maintaining balance. Practice in a controlled environment before attempting advanced techniques.

Tip 5: Maintain a Balanced Stance. Distribute weight evenly over both feet, bending the knees slightly to lower the center of gravity. This posture enhances stability and control.

Tip 6: Practice Progressive Skill Development. Gradually increase speed and complexity of maneuvers as competence improves. Avoid overconfidence and adhere to personal skill limitations.

Tip 7: Implement Regular Maintenance. Clean bearings, rotate wheels, and tighten hardware periodically to ensure optimal performance and longevity of the equipment.

Adhering to these guidelines promotes safety, extends equipment lifespan, and enhances the overall experience.

The subsequent section offers a comprehensive overview of different equipment types and their suitability for various skill levels and intended uses.

1. Maneuverability

Maneuverability, in the context of specialized wheeled footwear, refers to the ease and precision with which a user can change direction and navigate various terrains. It is a critical attribute influencing performance, safety, and the overall user experience.

- Frame Length and Wheelbase

Shorter frames and wheelbases generally enhance agility and turning capabilities. This configuration allows for quicker responses to directional changes, benefiting activities like slalom or artistic skating. Conversely, longer frames provide increased stability, potentially sacrificing some agility but improving control at higher speeds.

- Wheel Configuration and Rockering

The arrangement of wheels on the frame significantly impacts maneuverability. “Rockering,” where the front and rear wheels are slightly elevated, facilitates tighter turns by reducing the contact area with the surface. A flat wheel configuration offers greater stability and is suited for straight-line speed and distance skating.

- Boot Stiffness and Ankle Support

The rigidity of the boot and the level of ankle support directly influence the transfer of force from the user’s body to the frame and wheels. Stiffer boots provide more immediate and precise control, allowing for quicker reactions and more forceful turns. However, they may also reduce comfort and range of motion compared to softer, more flexible boots.

- User Skill and Experience

While equipment design plays a crucial role, the user’s skill level and experience are paramount in maximizing maneuverability. Proficiency in techniques such as edge control, weight shifting, and cross-stepping enables skaters to exploit the design characteristics of the footwear and navigate complex environments effectively.

The interplay between these facets demonstrates that optimal maneuverability is not solely a function of equipment but also of user proficiency and the intended application. Selecting equipment with appropriate maneuverability characteristics, coupled with dedicated skill development, ensures a safe and enjoyable experience for the user.

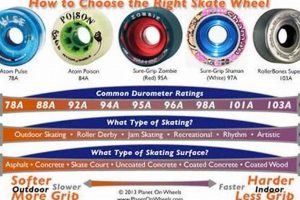

2. Wheel Durometer

Wheel durometer is a critical property of the wheels used in specialized wheeled footwear, directly influencing performance, comfort, and durability. Measured on the Shore A scale, it quantifies the hardness of the wheel material, impacting grip, speed, and suitability for various surfaces.

- Grip and Surface Adhesion

Lower durometer wheels (e.g., 78A-82A) exhibit greater flexibility and conform more readily to surface irregularities, providing enhanced grip. This is advantageous on rough or uneven surfaces, ensuring stability and control. For instance, outdoor recreational use often benefits from softer wheels that maintain contact on imperfect pavement.

- Rolling Resistance and Speed

Higher durometer wheels (e.g., 84A-90A) are more rigid and offer reduced rolling resistance, resulting in increased speed on smooth surfaces. These wheels are commonly favored in environments such as indoor rinks or polished concrete floors, where maximizing velocity is paramount. However, the trade-off is diminished grip and a potentially harsher ride on rough terrain.

- Durability and Wear Rate

Wheel durometer also affects the lifespan of the wheels. Softer wheels, while providing superior grip, tend to wear down more quickly, particularly under heavy use or on abrasive surfaces. Harder wheels offer greater durability and resistance to wear, making them suitable for frequent use or challenging environments.

- Vibration Absorption and Comfort

Softer wheels absorb more vibrations and provide a smoother, more comfortable ride, particularly on uneven surfaces. This reduces fatigue and enhances the overall skating experience. Harder wheels transmit more vibrations, which can lead to discomfort and reduced control on rough surfaces.

The selection of appropriate wheel durometer is contingent upon the intended use, skating environment, and individual preferences. Consideration of these factors ensures optimal performance, comfort, and safety for users of specialized wheeled footwear.

3. Bearing Precision

Bearing precision, a critical attribute of specialized wheeled footwear, directly impacts performance, efficiency, and longevity. The tolerance to which bearings are manufactured dictates their rotational smoothness and speed capabilities, influencing the overall experience. Deviations from established standards can result in diminished performance and premature equipment failure.

- ABEC Rating System

The Annular Bearing Engineering Committee (ABEC) rating system, while not specifically designed for wheeled footwear, is commonly used to classify bearing precision. Ratings range from ABEC-1 to ABEC-9, with higher numbers indicating tighter tolerances. Higher ABEC ratings generally correspond to smoother rotation and higher potential speeds. However, ABEC ratings alone do not account for factors such as materials, lubrication, or bearing construction, which also significantly affect performance. For example, bearings used in speed skating applications often utilize higher ABEC ratings to minimize friction and maximize velocity.

- Impact on Rolling Resistance

Bearing precision directly influences rolling resistance. Imprecise bearings exhibit increased friction due to imperfections in the raceways and balls, resulting in energy loss and reduced speed. High-precision bearings minimize friction, allowing for more efficient energy transfer and sustained momentum. This effect is particularly noticeable during extended use, where the cumulative impact of even small amounts of friction can significantly reduce performance. The lower rolling resistance translates to less effort required to maintain a given speed, increasing endurance and reducing fatigue.

- Influence on Bearing Lifespan

Bearing precision affects durability and lifespan. Tighter tolerances reduce stress on the bearing components, minimizing wear and tear. Imprecise bearings are more susceptible to damage from impacts, contaminants, and uneven loading, leading to premature failure. Regular maintenance, including cleaning and lubrication, can mitigate the effects of lower precision, but high-precision bearings generally exhibit greater longevity under similar operating conditions. For instance, bearings exposed to outdoor environments with abrasive particles benefit from higher precision and robust sealing to prolong their service life.

- Correlation with Wheel Performance

Bearing precision interacts with wheel characteristics to determine overall performance. High-precision bearings enable wheels to rotate more freely and consistently, maximizing the benefits of wheel design features such as durometer and profile. Conversely, imprecise bearings can negate the advantages of high-quality wheels by introducing unwanted friction and vibration. The optimal combination of bearing precision and wheel characteristics depends on the intended application. For example, artistic skating often benefits from a balance of bearing precision and wheel grip, while speed skating prioritizes minimal rolling resistance and maximum velocity.

In conclusion, bearing precision is a fundamental determinant of the performance, durability, and overall quality of specialized wheeled footwear. The selection of appropriate bearings, considering factors such as ABEC rating, materials, and intended use, is crucial for optimizing the user experience and ensuring the longevity of the equipment. The interplay between bearing precision and other components highlights the importance of a holistic approach to equipment design and maintenance.

4. Boot Support

Boot support within specialized wheeled footwear directly influences stability, control, and injury prevention. The structural integrity of the boot, its capacity to provide lateral and medial stability, and its interface with the foot are all critical factors. Insufficient boot support can lead to ankle instability, reduced power transfer, and an increased risk of sprains or fractures. Conversely, excessive rigidity can restrict movement and reduce comfort. The ideal level of boot support is contingent upon the intended application, the user’s skill level, and their biomechanical characteristics. For instance, aggressive skating requires boots with substantial ankle reinforcement to withstand high-impact landings and lateral forces, whereas recreational skating may prioritize comfort and flexibility.

The materials and construction techniques employed in boot manufacturing significantly impact the level of support provided. High-quality boots often incorporate carbon fiber or composite materials for enhanced rigidity and responsiveness. Features such as adjustable buckles, laces, and power straps enable users to fine-tune the fit and optimize support. Furthermore, the internal padding and liner materials contribute to comfort and shock absorption, minimizing pressure points and reducing the risk of blisters. Properly fitted boots, coupled with appropriate lacing techniques, ensure that the foot is securely held in place, preventing excessive pronation or supination. Real-world examples of insufficient boot support include instances where users experience ankle roll or difficulty maintaining balance, particularly during quick turns or abrupt stops. These scenarios highlight the practical significance of selecting footwear with adequate boot support for the intended activity.

In summary, boot support is an indispensable component of specialized wheeled footwear, directly affecting safety and performance. The optimal level of support is determined by the interplay of various factors, including skating style, skill level, and individual biomechanics. Prioritizing proper boot fit, construction, and adjustment is essential for mitigating injury risk and maximizing the enjoyment of the activity. Future advancements in boot design may focus on incorporating dynamic support systems that adapt to the user’s movements, providing customized stability and control in real-time. The understanding of boot support principles is therefore critical for both manufacturers and users seeking to optimize the effectiveness of specialized wheeled footwear.

5. Frame Material

The frame material in specialized wheeled footwear directly influences performance characteristics such as weight, stiffness, vibration absorption, and durability. The selection of frame material represents a critical design consideration, impacting the overall responsiveness and longevity of the equipment. A frame’s ability to effectively transfer energy from the skater’s foot to the wheels is paramount; therefore, material properties are chosen to optimize this transfer while minimizing energy loss through flex or deformation. Aluminum alloys are commonly employed due to their favorable strength-to-weight ratio, providing a balance between rigidity and agility. Carbon fiber frames offer superior stiffness and vibration damping but often at a higher cost. Plastic or composite frames are also used, typically in entry-level models, offering a lower cost but potentially compromising performance and durability. A real-world example illustrates this: a skater using aluminum-framed equipment experiences more immediate power transfer compared to a skater using a less rigid plastic frame, especially during rapid acceleration or high-impact maneuvers. Understanding the properties of frame material is thus of practical significance for both equipment manufacturers and users.

The impact of frame material extends to the skater’s comfort and fatigue levels. Materials with enhanced vibration absorption, such as carbon fiber or certain composite blends, can reduce the transmission of road vibrations to the skater’s feet and legs, minimizing fatigue during extended sessions. Frame stiffness, determined by the chosen material and its geometry, affects the skater’s control and stability. Stiffer frames provide a more direct and responsive feel, allowing for precise maneuvering and improved power transfer during pushes. However, excessive stiffness can also lead to increased stress on the joints, particularly the ankles and knees. For example, skaters participating in long-distance events often prioritize frame materials with vibration-damping properties to mitigate fatigue and maintain efficiency over extended periods. The practical applications are clear in the equipment choices made by professionals versus recreational users.

In conclusion, the choice of frame material is a crucial factor determining the performance, comfort, and durability of specialized wheeled footwear. Balancing weight, stiffness, vibration absorption, and cost requires careful consideration of the intended application and the user’s skill level. While aluminum alloys offer a good compromise for many skaters, carbon fiber provides superior performance for those willing to invest in higher-end equipment. Challenges remain in developing materials that offer both high stiffness and excellent vibration damping at a reasonable cost. This aspect of material choice remains central to the ongoing evolution of specialized wheeled footwear design.

6. Braking System

The braking system constitutes a fundamental safety component within specialized wheeled footwear, directly influencing the ability to control speed and prevent collisions. Its effectiveness is paramount in diverse operating environments and varying skill levels.

- Heel Brake Mechanism

The heel brake, a common configuration, involves a braking pad affixed to the rear of one boot, typically the right. Activation occurs through plantar flexion, lowering the heel to engage the pad with the ground. This system offers simplicity and intuitive operation; however, its effectiveness diminishes on steep inclines or at high speeds, and it may require a significant shift in weight distribution. For example, beginners often find heel brakes easier to learn initially, but experienced users may prefer alternative systems for greater control in advanced maneuvers.

- Inline Brake Systems

Some designs integrate braking mechanisms directly into the frame, often employing a hand-activated lever or a T-stop technique. Hand-activated brakes, similar to those found on bicycles, offer modulated braking force and are independent of foot positioning. The T-stop, a technique requiring dragging one foot perpendicularly to the direction of motion, relies on friction between the wheel and the surface. While effective, T-stops can cause significant wheel wear and require considerable skill to execute safely. High-performance models often forgo traditional braking systems in favor of advanced techniques, emphasizing agility and control over immediate stopping power.

- Material Composition and Performance

The materials used in braking components significantly impact performance and durability. Brake pads are typically constructed from rubber compounds or polymers designed to maximize friction while minimizing wear. The frame material supporting the braking mechanism must withstand substantial forces; therefore, aluminum or reinforced composites are commonly employed. The effectiveness of the braking system is directly correlated with the friction coefficient of the pad material, the surface condition, and the applied pressure. For instance, wet or oily surfaces can significantly reduce braking performance, necessitating the use of more aggressive braking techniques or specialized pad materials.

- Maintenance and Reliability

Regular maintenance is essential to ensure the reliability and effectiveness of braking systems. Brake pads wear down over time and require periodic replacement. Cables and levers, in the case of hand-activated systems, should be inspected for fraying or damage and adjusted as needed. Neglecting maintenance can compromise braking performance and increase the risk of accidents. Properly maintained systems offer consistent and predictable braking force, enhancing user confidence and safety. A real-world example is a skater experiencing brake failure due to worn pads, resulting in a loss of control and a potential collision.

The braking system is integral to the safe operation of specialized wheeled footwear, necessitating careful consideration of design, materials, and maintenance. Varied braking system attributes align with different skill levels and user needs. The selection of an appropriate system, coupled with diligent maintenance practices, directly impacts user safety and the overall performance.

Frequently Asked Questions Regarding the Use of Wheeled Footwear

The following addresses common inquiries and misconceptions concerning the selection, maintenance, and safe operation of the equipment.

Question 1: What constitutes the primary determinants of rolling resistance in wheeled footwear?

Rolling resistance is primarily influenced by wheel durometer, bearing precision, and surface conditions. Softer wheels and less precise bearings generally result in higher rolling resistance, while smoother surfaces reduce it.

Question 2: How frequently should the bearings be cleaned and lubricated to maintain optimal performance?

Bearing maintenance frequency depends on usage conditions. Under typical recreational use, cleaning and lubrication are recommended every 20-30 hours of use or after exposure to wet or dusty environments.

Question 3: What are the recommended safety precautions to mitigate the risk of injury?

The use of appropriate protective gear, including helmets, wrist guards, elbow pads, and knee pads, is mandatory. Furthermore, users should operate the equipment in designated areas, avoid hazardous surfaces, and maintain awareness of their surroundings.

Question 4: How does boot stiffness impact control and maneuverability?

Stiffer boots provide greater support and responsiveness, enabling more precise control and enhanced power transfer. However, excessive stiffness can restrict movement and reduce comfort. The optimal stiffness level is contingent on the user’s skill level and intended application.

Question 5: What are the key considerations when selecting wheel durometer for specific skating environments?

Softer wheels (lower durometer) offer greater grip and are suitable for rough or uneven surfaces. Harder wheels (higher durometer) provide lower rolling resistance and are ideal for smooth, indoor surfaces. The selection should be based on the prevailing surface conditions.

Question 6: How can the longevity of wheeled footwear be maximized?

Regular maintenance, including cleaning, lubrication, wheel rotation, and inspection for wear or damage, is essential for maximizing the lifespan of the equipment. Proper storage in a dry and protected environment also contributes to longevity.

This information aims to provide clarity and promote informed decision-making regarding the utilization of wheeled footwear.

The subsequent section will delve into the historical evolution and technological advancements related to this specialized equipment.

Concluding Remarks on incredi-roll skate

The preceding discourse has comprehensively explored the various facets of incredi-roll skate, encompassing their operational principles, safety protocols, maintenance procedures, and the critical attributes that govern their performance. A detailed examination of components such as frame materials, wheel durometer, and braking systems has illuminated the interplay between design and functionality. Emphasis has been placed on the user’s responsibility to prioritize safety through the adoption of appropriate protective gear and adherence to established guidelines.

The sustained evolution of incredi-roll skate technology necessitates a commitment to ongoing research and development. Future advancements should focus on enhancing safety features, improving energy efficiency, and expanding the versatility of these devices. A continued dedication to education and responsible usage will ensure that the benefits of incredi-roll skate are realized while mitigating potential risks. The collective effort of manufacturers, users, and regulatory bodies is essential for fostering a safe and sustainable future for this mode of recreation and transportation.