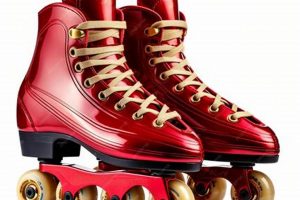

The focus of this article pertains to specialized footwear designed for gliding movement across surfaces. These items are constructed with a boot or shoe attached to a chassis equipped with wheels, facilitating recreational or competitive activity. These devices enable users to experience mobility and agility beyond standard ambulation. For instance, individuals might use these to engage in activities such as rink skating, jam skating, or roller derby.

The significance of these wheeled devices lies in their capacity to provide both enjoyment and physical exercise. Historically, such equipment has evolved significantly, reflecting advancements in materials and design. They cater to diverse needs, from beginner models prioritizing stability to high-performance options emphasizing speed and maneuverability, therefore, offering users a wide spectrum of potential benefits depending on their skills and interests.

The subsequent sections will delve into the various components, types, and applications associated with these specific items, further elucidating the factors influencing their selection and utilization. Discussions will include aspects of construction materials, wheel configurations, sizing considerations, and maintenance practices to ensure optimal performance and longevity.

Guidance for Optimal Use

The following recommendations are provided to maximize performance, safety, and longevity when utilizing the equipment under discussion. Adherence to these guidelines is crucial for both novice and experienced users.

Tip 1: Proper Fit Assessment: Selecting the correct size is paramount. Ill-fitting footwear can lead to discomfort, reduced control, and potential injury. Consult sizing charts and, when possible, seek professional fitting advice.

Tip 2: Wheel Durometer Consideration: Wheel hardness, measured in durometers, significantly impacts performance. Softer wheels offer enhanced grip on smooth surfaces, while harder wheels provide greater speed on less forgiving terrain. Choose based on intended use and skill level.

Tip 3: Regular Bearing Maintenance: Bearings are essential for smooth rolling action. Periodically clean and lubricate them to remove dirt and debris that can impede performance. Neglecting this can result in reduced speed and increased effort.

Tip 4: Secure Lacing Technique: Proper lacing ensures a snug and supportive fit. Tighten laces evenly, paying particular attention to the ankle area for optimal stability. Avoid overly tight lacing, which can restrict circulation.

Tip 5: Ankle Support Reinforcement: Assess the level of ankle support provided by the boot. Consider adding aftermarket ankle supports if additional stabilization is required, particularly for individuals prone to ankle instability.

Tip 6: Consistent Hardware Inspection: Regularly inspect all hardware, including nuts, bolts, and chassis mounting points. Tighten any loose components to prevent unexpected failures that could lead to accidents.

Tip 7: Controlled Environment Training: New users should initially practice in controlled environments, such as rinks or smooth, flat surfaces. This allows for gradual skill development and reduces the risk of injury in unpredictable conditions.

Following these tips will not only enhance the user experience but also contribute to the longevity of the items themselves. Diligence in maintenance and informed decision-making are key to responsible use.

The subsequent section will explore the variety of models available, each tailored for specific applications and user profiles.

1. Boot Construction

Boot construction forms the foundational aspect of “riedell roller skates,” directly influencing performance, comfort, and durability. The materials, design, and manufacturing techniques employed in the boot’s creation dictate the skate’s overall characteristics and suitability for specific skating styles. For example, a high-end model intended for artistic skating typically features a stiff leather boot that provides exceptional ankle support and responsiveness. This rigidity allows for precise movements and controlled landings during jumps and spins. Conversely, a recreational skate might incorporate a softer, more flexible boot, prioritizing comfort for extended use and ease of maneuvering for beginners.

The choice of materials in boot construction significantly impacts the skate’s longevity and resistance to wear and tear. Leather boots, while requiring more maintenance, generally offer superior durability and can mold to the skater’s foot over time, enhancing comfort and fit. Synthetic materials, on the other hand, may be more water-resistant and require less upkeep, but might not provide the same level of customization or long-term durability. The design also accounts for ventilation; boots with breathable linings minimize moisture buildup and prevent discomfort during prolonged use. Furthermore, reinforcement in high-stress areas, such as around the ankles and toe box, bolsters protection against impacts and abrasions, crucial in competitive disciplines.

In summary, boot construction represents a critical element affecting the overall performance and usability. Understanding the nuances of boot materials, design features, and intended application empowers users to make informed decisions. These choices contribute to a more enjoyable and safe skating experience. Failure to consider boot construction can lead to discomfort, impaired performance, and a reduced lifespan of the complete system.

2. Chassis Material

Chassis material constitutes a critical determinant of performance characteristics. The choice of material significantly impacts the overall weight, strength, and responsiveness, affecting handling capabilities and suitability for specific skating styles.

- Aluminum Alloys: High-Performance Applications

Aluminum alloys offer a high strength-to-weight ratio, making them prevalent in performance-oriented applications. These chassis materials exhibit excellent energy transfer, enhancing responsiveness and control during rapid maneuvers and jumps. For example, skaters engaged in artistic or roller derby disciplines frequently rely on aluminum chassis to achieve the necessary precision and agility. However, aluminum alloys can be more susceptible to bending or damage upon high-impact collisions compared to other materials.

- Nylon Composites: Recreational and Entry-Level Usage

Nylon composites, often reinforced with fiberglass, provide a cost-effective alternative for recreational and entry-level models. These materials offer sufficient strength for general skating purposes while absorbing vibrations effectively, leading to a more comfortable ride. While nylon composites are less rigid than aluminum alloys, they are more forgiving and resistant to permanent deformation from minor impacts, making them suitable for beginners and casual skaters.

- Magnesium Alloys: Specialized Performance Considerations

Magnesium alloys, although less common, present a unique combination of lightweight and high damping characteristics. These materials are favored in specialized applications where vibration reduction is paramount, such as speed skating or inline skating. However, magnesium alloys are more expensive and require careful treatment to prevent corrosion, limiting their widespread adoption in typical designs.

The selection of chassis material represents a critical decision, influencing the overall performance, durability, and cost. Aluminum alloys offer superior performance for competitive skating, while nylon composites provide a more accessible option for recreational use. Understanding the trade-offs associated with each material is essential for making an informed choice. Failure to consider these factors could result in compromised performance, reduced durability, or unnecessary expense.

3. Wheel Durometer

Wheel durometer, a measure of a wheel’s hardness, represents a pivotal parameter influencing the performance characteristics of the skate. Its selection directly affects grip, speed, and overall skating experience. Understanding the relationship between durometer and skating surface is crucial for optimizing performance.

- Grip and Traction

Softer wheels, characterized by lower durometer ratings (e.g., 78A-85A), provide increased grip and traction on smooth surfaces like indoor rinks. This enhanced grip is advantageous for maneuvers requiring precise control and quick stops, such as artistic skating or roller derby. However, softer wheels tend to wear more rapidly and may feel sluggish at higher speeds.

- Speed and Roll

Harder wheels, indicated by higher durometer ratings (e.g., 95A-101A), exhibit reduced rolling resistance, facilitating higher speeds on smoother surfaces. These wheels are commonly favored in speed skating and outdoor applications where maintaining momentum is paramount. The trade-off lies in diminished grip, potentially compromising control on slick or uneven surfaces.

- Surface Compatibility

The optimal wheel durometer correlates directly with the skating surface. Indoor rinks typically demand softer wheels for maximum grip, while outdoor environments may necessitate harder wheels to withstand abrasion and maintain speed. Mismatched durometer can lead to reduced control, increased wear, or compromised performance.

- Skating Style Adaptation

Different skating styles necessitate specific durometer ranges. Artistic skaters often prefer softer wheels for intricate footwork, while speed skaters prioritize harder wheels for maximizing velocity. Roller derby skaters frequently utilize intermediate durometers to balance grip and speed requirements. Therefore, selecting the appropriate wheel durometer is an essential aspect of optimizing performance.

Wheel durometer significantly influences performance and is therefore important. Proper selection, considering surface conditions and skating style, directly affects control, speed, and overall skating enjoyment. Ignoring this factor can lead to suboptimal performance and even potential safety hazards.

4. Bearing Precision

Bearing precision in “riedell roller skates” directly influences rolling resistance and attainable speed. Bearings, positioned within the wheel hubs, facilitate smooth rotation. Their manufacturing tolerances, quantified by ABEC (Annular Bearing Engineers’ Committee) ratings, determine the level of precision. Higher ABEC ratings (e.g., ABEC-7, ABEC-9) indicate tighter tolerances and consequently reduced friction. This reduction in friction translates to a smoother, faster glide with less effort expended by the skater. For instance, a speed skater competing at an elite level typically employs skates equipped with high-precision bearings to maximize velocity and minimize energy loss. Conversely, recreational models often feature bearings with lower ABEC ratings, prioritizing cost-effectiveness over ultimate performance. A practical demonstration of this effect involves comparing two similar models, one with ABEC-1 bearings and the other with ABEC-7 bearings; the latter will consistently exhibit a noticeably longer and smoother roll when propelled with the same initial force.

The practical significance of understanding bearing precision extends beyond speed. Tighter tolerances contribute to enhanced durability and longevity. High-precision bearings, manufactured with greater accuracy and using higher-quality materials, are less susceptible to wear and tear from the repetitive stress of skating. Contaminants, such as dirt and debris, are also less likely to penetrate and degrade the internal components of high-precision bearings, further extending their lifespan. This is particularly relevant for skaters who frequently skate outdoors or in environments with abrasive surfaces. The initial investment in higher-precision bearings can, therefore, yield long-term cost savings by reducing the frequency of replacement and maintenance.

In summary, bearing precision plays a crucial role in determining performance and longevity. While higher ABEC ratings offer noticeable advantages in terms of speed and efficiency, the selection ultimately depends on intended use and budget constraints. Challenges include balancing the cost of high-precision bearings with the anticipated benefits, considering the skater’s skill level and skating environment. Optimizing bearing choice contributes to a better skating experience and a longer lifespan for the equipment.

5. Intended Use

The “Intended Use” forms a foundational determinant in the selection and configuration of “riedell roller skates”. It dictates the specific features, construction materials, and performance characteristics required to optimize the skating experience. The direct consequence of mismatched intended use is compromised performance, increased risk of injury, or accelerated equipment wear. For example, using a recreational model, designed for casual rink skating, in a demanding roller derby competition will likely result in equipment failure and potential harm to the skater due to inadequate support and durability. Therefore, the identification of the intended use is paramount before considering any other factor.

Diverse disciplines necessitate distinct skate configurations. Artistic skating demands high maneuverability and precise control, leading to the selection of skates with stiff leather boots for superior ankle support and responsive chassis. Speed skating prioritizes velocity and efficiency, resulting in skates designed with lightweight materials, aerodynamic profiles, and high-precision bearings to minimize rolling resistance. Roller derby requires robust construction, agility, and protective features, influencing the choice of durable boots, reinforced chassis, and specialized toe stops for quick starts and stops. Each discipline necessitates a unique blend of features to maximize performance and mitigate risk. Failure to align equipment with its intended application compromises the skater’s capabilities and increases the likelihood of injury or equipment failure.

In summary, the “Intended Use” acts as a critical determinant in selecting appropriate “riedell roller skates”. It dictates required features, construction, and performance characteristics. Ignoring this factor can lead to sub-optimal performance, increased risk of injury, and accelerated equipment degradation. Understanding the specific demands of each skating discipline is essential for making informed decisions, ensuring both safety and optimal performance. The challenge lies in accurately assessing the skater’s skill level, skating environment, and intended discipline to select the most appropriate configuration.

6. Sizing Accuracy

Sizing accuracy represents a foundational element in the selection process for “riedell roller skates.” Precise fitting directly impacts comfort, performance, and safety. An ill-fitting boot can lead to discomfort, blisters, impaired control, and an elevated risk of injury. Therefore, meticulous attention to sizing is critical.

- Performance Implications

An incorrectly sized boot compromises performance by hindering proper foot placement and control. Excess space within the boot allows the foot to move, reducing responsiveness during maneuvers and hindering precise movements. Conversely, an undersized boot restricts blood flow, leading to discomfort and impaired muscle function. Both scenarios negatively impact a skater’s ability to execute techniques effectively.

- Injury Prevention

Sizing inaccuracies increase the risk of injuries. Excessive movement within the boot leads to friction and potential blister formation. Moreover, a poorly fitted boot can compromise ankle support, increasing the likelihood of sprains and other joint-related injuries. Proper sizing ensures that the foot is securely positioned, providing adequate support and minimizing the risk of injury.

- Sizing Charts and Measurement Techniques

Accurate sizing requires adherence to standardized measurement techniques and consultation of manufacturer-specific sizing charts. Foot length and width should be measured precisely, and these measurements should be compared to the manufacturer’s size guidelines. Furthermore, it is advisable to consider foot shape and volume when selecting the appropriate size, as these factors can influence the overall fit. Professional fitting services can also provide valuable assistance in determining the correct size.

- Long-Term Comfort and Durability

Selecting the correct size contributes to long-term comfort and extends the lifespan of the skates. A properly fitted boot distributes pressure evenly across the foot, minimizing discomfort during extended use. Additionally, a well-fitted boot reduces stress on the skate’s components, prolonging its overall durability. Conversely, an ill-fitting boot can accelerate wear and tear due to excessive friction and stress on specific areas.

Sizing accuracy directly correlates with the overall experience. Precise measurement, utilization of sizing charts, and consideration of individual foot characteristics are essential for selecting the correct size. Neglecting these factors can compromise performance, increase the risk of injury, and reduce the longevity of “riedell roller skates”.

7. Maintenance Regimen

A structured maintenance regimen forms an inextricable link to the performance and longevity of “riedell roller skates.” The mechanical components, including wheels, bearings, and chassis, are subject to wear and degradation from friction, impact, and environmental contaminants. Neglecting systematic maintenance protocols accelerates this process, leading to diminished performance, increased risk of equipment failure, and potential injury. For example, failure to regularly clean and lubricate wheel bearings results in increased rolling resistance, necessitating greater physical exertion and reducing overall speed. Similarly, neglecting to inspect and tighten chassis hardware can lead to instability and a compromised skating experience. Therefore, incorporating a proactive maintenance schedule constitutes a fundamental aspect of responsible ownership.

The practical significance of adhering to a consistent maintenance regimen extends beyond performance enhancement. Regular inspection allows for the early detection of potential issues, such as worn wheels, loose hardware, or damaged components. Addressing these issues proactively prevents minor problems from escalating into major repairs or, more critically, hazardous situations. For instance, identifying and replacing worn toe stops on a roller derby skate minimizes the risk of unexpected falls during critical maneuvers. Furthermore, proper cleaning and lubrication of bearings not only improve rolling efficiency but also prevent corrosion and extend their lifespan. These actions exemplify how preventative maintenance safeguards both the equipment and the skater.

In conclusion, a comprehensive maintenance regimen is an essential component of ownership. It directly impacts performance, safety, and the overall lifespan of “riedell roller skates.” A proactive approach, encompassing regular cleaning, lubrication, inspection, and timely repairs, ensures sustained performance, mitigates risks, and maximizes the return on investment. Challenges to implementing a robust maintenance regimen include time constraints and a lack of knowledge regarding proper procedures. Overcoming these challenges requires education, dedication, and a commitment to responsible equipment management.

Frequently Asked Questions

The following addresses common inquiries concerning “riedell roller skates” and provides detailed responses to clarify various aspects of their selection, maintenance, and utilization.

Question 1: What constitutes the primary difference between artistic and roller derby models?

Artistic models are characterized by their high level of maneuverability and ankle support, designed for intricate footwork and precise movements. Roller derby models prioritize durability and impact resistance, built to withstand the rigors of competitive gameplay and frequent collisions.

Question 2: How frequently should wheel bearings be cleaned and lubricated?

Bearing maintenance frequency is dependent on usage and environmental conditions. However, a general guideline suggests cleaning and lubrication every 20-40 hours of skating or when a noticeable decrease in rolling efficiency occurs.

Question 3: What factors influence the selection of wheel durometer?

Wheel durometer selection is dictated by the skating surface and desired performance characteristics. Softer wheels provide enhanced grip on smooth surfaces, while harder wheels offer increased speed on smoother surfaces and outdoor terrain.

Question 4: How does chassis material impact performance?

Chassis material significantly affects weight, strength, and responsiveness. Aluminum chassis offer superior energy transfer and are preferred for performance applications, while nylon chassis provide a more comfortable ride at a lower cost.

Question 5: Is it possible to replace individual components, such as wheels or bearings, independently?

Yes, individual components are typically replaceable. This allows for customization and maintenance without requiring the purchase of an entirely new set.

Question 6: What are the indicators that a boot requires replacement?

Indicators include significant wear and tear, compromised ankle support, or persistent discomfort despite proper sizing. Structural damage, such as cracks or tears, also necessitates replacement.

Understanding these FAQs offers insight into the critical aspects of the skates. This knowledge empowers informed decision-making, optimizing user experience and extending product lifespan.

The following will address the historical context of the “riedell roller skates”.

Riedell Roller Skates

This exploration of “riedell roller skates” has traversed the critical domains influencing their performance, longevity, and suitability. From the foundational boot construction to the nuanced selection of wheel durometer and bearing precision, each element contributes to the overall user experience. Understanding the interplay between intended use and meticulous maintenance practices is paramount for responsible and effective utilization. It is vital to emphasize the crucial role of sizing accuracy, influencing both comfort and the mitigation of potential injuries.

The continued advancement of materials science and engineering promises further refinements in the design and construction of these devices. As technology progresses, “riedell roller skates” are positioned to evolve, potentially offering enhanced performance characteristics and increased user safety. Individuals are encouraged to apply the insights gained to make informed decisions, ultimately optimizing their skating pursuits while maintaining a commitment to responsible equipment stewardship.