Defining superior recreational footwear involves considering several key performance indicators. These include comfort, durability, maneuverability, and safety features. For example, equipment that consistently scores highly across these categories, offering users an optimal experience, can be considered a top-tier choice.

Selecting high-quality rolling equipment can significantly impact the user’s experience, improving their ability to learn new skills, enhance physical fitness, and reduce the risk of injury. Historically, advancements in materials and design have led to increasingly sophisticated options, contributing to the growth and popularity of the activity.

Subsequent sections will examine the various types of equipment available, the factors to consider when making a purchase, and maintenance tips to ensure longevity and optimal performance.

Guidance for Optimal Equipment Selection

Selecting appropriate recreational rolling equipment requires careful consideration of several factors to ensure safety, performance, and longevity. The following guidance offers insights to aid in the decision-making process.

Tip 1: Determine Intended Use: Identify the primary purpose, such as recreational skating, artistic skating, or roller derby. Different disciplines require specialized equipment with varying wheel types, boot stiffness, and frame designs.

Tip 2: Assess Skill Level: Novice skaters benefit from supportive boots and stable frames, while experienced skaters may prefer more responsive equipment that allows for greater maneuverability. Match equipment specifications to the skater’s proficiency.

Tip 3: Prioritize Fit and Comfort: Ill-fitting equipment can lead to discomfort, blisters, and impaired performance. Measure foot size accurately and consider trying on different models to ensure a snug yet comfortable fit. Liners should provide adequate cushioning and support.

Tip 4: Evaluate Wheel Durometer: Wheel durometer, measured on the A scale, indicates hardness. Softer wheels (lower durometer) provide better grip on smooth surfaces, while harder wheels (higher durometer) offer increased speed and durability on rougher surfaces. Choose a durometer appropriate for the skating environment.

Tip 5: Inspect Bearings: Bearings influence the smoothness and speed of the roll. ABEC ratings indicate the precision of the bearings. Higher ABEC ratings generally signify greater accuracy and smoother rolling, although other factors, such as bearing material and lubrication, also play a role.

Tip 6: Consider Frame Material: Frames are typically made from aluminum or plastic. Aluminum frames offer greater stiffness and responsiveness, enhancing energy transfer and control. Plastic frames are more flexible and absorb vibrations, providing a smoother ride.

Tip 7: Check Brake System: Ensure the equipment features a reliable and easily accessible braking system. Regular inspection and replacement of brake pads are essential for maintaining safe stopping power.

Careful adherence to these guidelines will contribute to a more enjoyable and safer experience. Prioritizing quality and appropriate specifications is crucial for maximizing performance and minimizing the risk of injury.

The next section will delve into the maintenance procedures necessary to prolong the lifespan and optimal functionality of recreational rolling equipment.

1. Durability

Durability is a critical attribute of superior recreational rolling equipment. It directly influences the lifespan of the equipment, the user’s safety, and the overall value proposition. Specifically, the choice of materials and construction techniques directly impacts the equipment’s ability to withstand repetitive stress, impacts, and environmental factors. Insufficient durability leads to premature wear and tear, increasing the risk of equipment failure during use. This, in turn, presents a safety hazard to the user. For example, a frame constructed from low-grade plastic may crack under stress, potentially leading to a fall and injury. Conversely, frames made from high-quality aluminum alloys offer significantly greater resistance to deformation and fracture.

The selection of components, such as wheels and bearings, also contributes to overall durability. Wheels manufactured from inferior polymers may wear down rapidly, compromising grip and control. Similarly, bearings with inadequate sealing are susceptible to contamination, leading to increased friction and eventual failure. Consider the example of a recreational skater who regularly uses their equipment on outdoor surfaces. Inferior wheels may require frequent replacement, increasing the overall cost of ownership and causing inconvenience. In contrast, wheels made from durable urethane compounds exhibit greater resistance to abrasion, extending their lifespan and reducing the need for frequent replacements.

In summary, durability is an essential characteristic of high-quality recreational rolling equipment, providing long-term value and ensuring user safety. Equipment that exhibits robust construction and utilizes high-quality materials will withstand the rigors of regular use, minimizing the risk of failure and injury. Understanding the principles of durability assists consumers in making informed purchasing decisions, ultimately leading to a more satisfying and safer experience. Furthermore, ongoing maintenance and timely replacement of worn components are crucial for preserving the longevity and performance characteristics of rolling equipment.

2. Comfort

Comfort is a fundamental determinant of overall user satisfaction and performance with recreational rolling equipment. Prolonged use of ill-fitting or uncomfortable equipment can lead to discomfort, blisters, and even injury, negatively impacting the user’s experience and potentially discouraging further participation.

- Boot Design and Padding

The anatomical design of the boot plays a crucial role in comfort. Boots should conform to the natural shape of the foot, providing adequate support without constricting movement. Padding, typically constructed from foam or gel materials, cushions pressure points and minimizes friction. Insufficient padding can lead to blisters and discomfort, particularly during extended use. Conversely, excessive padding can restrict airflow and cause overheating.

- Liner Material and Breathability

The liner material directly impacts moisture management and breathability. Liners made from breathable fabrics, such as mesh or moisture-wicking synthetics, help to dissipate sweat and prevent the buildup of moisture, reducing the risk of blisters and odor. Non-breathable materials can trap moisture, creating a damp and uncomfortable environment.

- Closure System and Fit Adjustment

A secure and adjustable closure system is essential for achieving a comfortable and customized fit. Closure systems typically consist of laces, buckles, and straps. Laces allow for precise adjustments across the entire foot, while buckles and straps provide quick and easy fastening. Inadequate closure systems can result in slippage and instability, compromising comfort and performance.

- Ventilation and Airflow

Adequate ventilation is crucial for maintaining a comfortable temperature inside the boot. Ventilation systems, typically consisting of strategically placed vents and breathable materials, promote airflow and dissipate heat. Insufficient ventilation can lead to overheating and discomfort, particularly during strenuous activity. Proper ventilation helps regulate temperature and moisture, enhancing comfort and performance.

In conclusion, comfort is an indispensable element of high-quality recreational rolling equipment. Attentive consideration of boot design, liner material, closure system, and ventilation contributes to a more enjoyable and productive experience, encouraging users to engage in the activity for extended periods without discomfort or injury.

3. Maneuverability

Maneuverability, in the context of recreational rolling equipment, signifies the ease and precision with which a skater can control direction, speed, and overall movement. Equipment exhibiting superior maneuverability enhances the user’s ability to navigate various terrains, execute complex maneuvers, and maintain stability. This attribute is a critical differentiator among various models and directly impacts the user’s experience, safety, and potential for skill development.

- Frame Geometry and Wheelbase

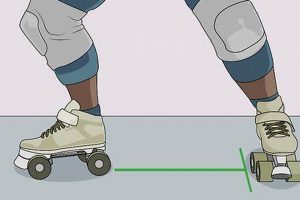

Frame geometry and wheelbase directly influence turning radius and responsiveness. Shorter wheelbases typically allow for tighter turns and increased agility, while longer wheelbases provide greater stability at higher speeds. The frame’s angle and design also contribute to the skater’s ability to initiate and maintain turns. For instance, a frame with a lower center of gravity promotes greater stability and control, whereas a more aggressive frame angle facilitates quicker and sharper turns. The selection of an appropriate frame depends on the skater’s skill level, intended use, and preferred skating style.

- Wheel Configuration and Rockering

The configuration of the wheels, including their size, placement, and the presence of rockering, affects maneuverability. Rockering refers to the practice of positioning one or more wheels slightly higher than the others, effectively reducing the contact surface with the ground. This configuration enhances agility and allows for quicker turns at the expense of stability. Flat wheel configurations, where all wheels make equal contact with the ground, provide greater stability but may reduce maneuverability. Wheel size also influences rolling speed and responsiveness; smaller wheels generally offer quicker acceleration and tighter turns, while larger wheels provide higher top speeds and smoother rolling over uneven surfaces.

- Boot Stiffness and Ankle Support

The stiffness of the boot and the level of ankle support significantly impact the skater’s ability to transfer energy and control the equipment. Stiffer boots provide greater responsiveness and allow for more precise control, particularly during advanced maneuvers. However, overly stiff boots can restrict movement and lead to discomfort, especially for novice skaters. Adequate ankle support is crucial for maintaining stability and preventing injuries, particularly during lateral movements and high-impact landings. The optimal level of boot stiffness and ankle support depends on the skater’s skill level, skating style, and personal preferences.

- Bearing Quality and Wheel Rotation

Bearing quality and wheel rotation efficiency directly influence rolling speed and responsiveness, indirectly affecting maneuverability. High-quality bearings with low friction allow for smoother and faster wheel rotation, enabling the skater to maintain momentum and execute maneuvers with greater ease. Bearings that are poorly lubricated or contaminated with dirt and debris can significantly reduce rolling speed and increase resistance, hindering maneuverability. Regular maintenance and cleaning of bearings are essential for preserving their performance characteristics and ensuring optimal maneuverability.

In conclusion, maneuverability is a multifaceted attribute of high-performing recreational rolling equipment. The interplay between frame geometry, wheel configuration, boot stiffness, and bearing quality determines the equipment’s responsiveness and the skater’s ability to control movement. Understanding these factors empowers consumers to make informed purchasing decisions, selecting equipment that aligns with their skill level, skating style, and intended use, ultimately enhancing their overall experience and maximizing their potential for skill development. Equipment that combines these elements effectively offers users an enhanced level of control, precision, and agility, transforming the skating experience into one of effortless motion and enhanced performance.

4. Wheel Durometer

Wheel durometer is a crucial characteristic of roller skate wheels, impacting performance and suitability for diverse skating environments. Its relevance to the selection of superior roller skates lies in its direct influence on grip, speed, and durability.

- Grip and Surface Compatibility

Wheel durometer, measured on the A scale, quantifies the wheel’s hardness. Softer wheels, typically ranging from 74A to 84A, provide enhanced grip on smooth indoor surfaces, such as wooden rinks. This increased grip translates to improved control and maneuverability, particularly beneficial for artistic skating or roller derby. Conversely, harder wheels (85A and above) offer reduced grip but increased rolling speed on smoother surfaces.

- Speed and Rolling Efficiency

Harder wheels possess lower rolling resistance, enabling higher speeds with less effort. This characteristic makes them advantageous for outdoor skating on asphalt or concrete, where speed and efficiency are prioritized. However, harder wheels transmit more vibrations from rough surfaces, potentially reducing comfort and control. For example, a skater primarily using their equipment for outdoor fitness purposes may benefit from harder wheels, while a rink skater would favor softer wheels.

- Durability and Wear Resistance

Wheel durometer influences wear resistance and overall wheel longevity. Harder wheels generally exhibit greater resistance to abrasion and wear, making them suitable for use on abrasive surfaces. Softer wheels, while offering superior grip, tend to wear down more quickly, particularly when used outdoors. The choice between durability and grip necessitates a compromise based on the skater’s primary environment and skating style.

- Vibration Absorption and Comfort

Softer wheels offer enhanced vibration absorption, providing a smoother and more comfortable ride on rough surfaces. This is particularly important for skaters who prioritize comfort over speed or those who frequently skate on uneven terrain. Harder wheels, while offering increased speed and durability, transmit more vibrations, which can lead to fatigue and discomfort during extended skating sessions. The optimal wheel durometer balances the need for speed and durability with the desire for a comfortable and controlled ride.

The selection of appropriate wheel durometer is pivotal in optimizing roller skate performance for specific applications. The “best roller skates” are, therefore, those equipped with wheels that match the skater’s skill level, intended use, and typical skating environment, ensuring an optimal balance between grip, speed, durability, and comfort.

5. Bearing Precision

Bearing precision significantly influences the performance and overall quality of rolling equipment. Within the context of identifying superior roller skates, bearing precision is a critical factor affecting speed, smoothness, and longevity.

- ABEC Rating and Manufacturing Tolerances

The Annular Bearing Engineers’ Committee (ABEC) rating system, although not universally adopted in the roller skate industry, provides a benchmark for bearing precision. Higher ABEC ratings (e.g., ABEC-7, ABEC-9) indicate tighter manufacturing tolerances and increased accuracy in the bearing’s internal components. Reduced tolerances minimize friction and promote smoother rotation, directly impacting the skater’s ability to maintain speed and conserve energy. Bearings with lower ABEC ratings, or those lacking a rating, typically exhibit greater manufacturing variations, resulting in increased friction and reduced performance. For example, a skater using equipment with high-precision bearings will experience a noticeably smoother and faster roll compared to equipment with lower-precision bearings.

- Bearing Materials and Hardness

The materials used in bearing construction, such as steel or ceramic, influence durability and performance. Harder materials, like chrome steel, resist deformation and wear, extending bearing lifespan and maintaining precision over time. Ceramic bearings, while more expensive, offer superior hardness, reduced friction, and resistance to heat. These characteristics contribute to increased speed and efficiency. The bearing’s hardness affects its ability to withstand impacts and stresses, impacting the equipment’s performance under demanding conditions. Roller skates intended for aggressive use or high-speed skating benefit from bearings constructed with high-quality, durable materials.

- Lubrication and Maintenance

Proper lubrication is essential for maintaining bearing precision and performance. Lubricants reduce friction and dissipate heat, preventing premature wear and ensuring smooth rotation. Over time, lubricants degrade or become contaminated with dirt and debris, increasing friction and reducing bearing efficiency. Regular cleaning and lubrication are necessary to preserve bearing precision and extend its lifespan. The type of lubricant used, such as oil or grease, also influences performance. Oil-based lubricants offer lower friction but require more frequent application, while grease-based lubricants provide longer-lasting protection but may increase rolling resistance. Consistent maintenance is crucial for ensuring that roller skates retain their performance characteristics over time.

- Sealing and Contamination Resistance

Bearing seals protect internal components from contaminants, such as dirt, dust, and moisture, which can degrade performance and reduce lifespan. Effective seals prevent the ingress of foreign particles, maintaining bearing precision and minimizing friction. Bearings with inadequate seals are more susceptible to contamination, leading to increased wear and reduced rolling efficiency. Different types of seals, such as rubber or metal shields, offer varying levels of protection. Roller skates used in outdoor environments require bearings with robust seals to withstand exposure to environmental contaminants. Effective sealing is an integral component of high-quality roller skate bearings.

In conclusion, bearing precision is a pivotal attribute that significantly contributes to the overall quality and performance of recreational rolling equipment. The cumulative effect of ABEC rating, material quality, lubrication, and sealing impacts the speed, smoothness, and durability of the equipment. The “best roller skates” are those that incorporate high-precision bearings, maintained through proper lubrication and protected from contamination, ensuring a superior skating experience.

Frequently Asked Questions Regarding Superior Recreational Rolling Equipment

The following section addresses common inquiries and misconceptions related to the selection and maintenance of high-quality roller skates.

Question 1: What distinguishes premium recreational rolling equipment from standard models?

Premium roller skates exhibit superior construction, utilizing durable materials and incorporating precision components. Key differentiators include enhanced comfort features, optimized maneuverability, and improved safety characteristics.

Question 2: Is a higher price point necessarily indicative of superior quality in rolling equipment?

While price often correlates with quality, it is not the sole determinant. Independent research and thorough evaluation of product specifications are essential to ascertain true value. Focus should be placed on material quality, construction techniques, and component precision.

Question 3: How frequently should the wheels on recreational rolling equipment be replaced?

Wheel replacement frequency depends on usage patterns, skating surface conditions, and wheel durometer. Regular inspection for wear and tear is recommended, with replacement occurring when performance diminishes or safety is compromised.

Question 4: What role does bearing precision play in the overall performance of recreational rolling equipment?

Bearing precision directly impacts rolling speed, smoothness, and efficiency. High-precision bearings minimize friction, enabling skaters to maintain momentum with less effort. The Annular Bearing Engineers’ Committee (ABEC) rating system, while not definitive, provides a general indication of bearing precision.

Question 5: What are the essential maintenance procedures for prolonging the lifespan of recreational rolling equipment?

Regular maintenance includes cleaning bearings, lubricating moving parts, inspecting and replacing worn components, and ensuring proper alignment. Adherence to manufacturer-recommended maintenance schedules is critical for maximizing equipment longevity and performance.

Question 6: How does wheel durometer affect the suitability of recreational rolling equipment for different skating environments?

Wheel durometer, measured on the A scale, indicates wheel hardness. Softer wheels offer greater grip on smooth indoor surfaces, while harder wheels provide increased speed and durability on outdoor surfaces. Selection of appropriate wheel durometer is essential for optimizing performance and safety in specific skating environments.

Prioritizing quality materials, precision engineering, and consistent maintenance contributes to a more enjoyable and safer skating experience.

The following section will explore advanced techniques for maximizing performance and enhancing the skating experience.

Conclusion Regarding High-Quality Recreational Rolling Equipment

The preceding analysis has elucidated the critical factors that define superior recreational rolling equipment. Attributes such as durability, comfort, maneuverability, wheel durometer, and bearing precision are essential considerations when evaluating potential purchases. Optimization of these factors is crucial for ensuring user safety, maximizing performance, and prolonging equipment lifespan.

The acquisition of high-quality rolling equipment represents a strategic investment in both physical well-being and recreational enjoyment. Individuals are encouraged to leverage the insights presented herein to make informed purchasing decisions and prioritize equipment maintenance. Continued advancements in materials science and engineering promise further enhancements in recreational rolling equipment, fostering even greater performance and user satisfaction. The principles discussed here will continue to be relevant as the technology progresses.