These recreational footwear items feature four wheels arranged in a two-by-two configuration, often utilized for skating rinks, outdoor paths, or recreational activities. Designed for stability and ease of use, these products typically incorporate a supportive boot, durable chassis, and adjustable components. For instance, a beginner might select this type of equipment due to its relatively forgiving nature and straightforward learning curve.

The popularity stems from several factors, including accessibility, affordability, and aesthetic appeal. Their design allows for controlled movements and balancing, making them suitable for individuals of varying skill levels. Historically, similar designs have been a staple of skating culture, undergoing iterative improvements in materials and construction to enhance performance and comfort. These improvements have led to increased durability and a wider range of applications, from casual skating to choreographed routines.

Subsequent sections will delve into the construction materials, available models, maintenance procedures, and considerations for selecting appropriate sizes and styles to ensure optimal user experience and longevity of the product.

Essential Usage Guidelines

The following guidance addresses crucial considerations for maximizing the utility and lifespan of this equipment.

Tip 1: Protective Gear is Paramount. Prioritize safety by consistently employing helmets, knee pads, elbow pads, and wrist guards. Injuries can be mitigated significantly with proper protective measures.

Tip 2: Ensure Proper Fit. Correct sizing is crucial for stability and comfort. Refer to manufacturer guidelines and utilize measurement tools to ascertain the appropriate dimensions before use. Overly loose or tight fitting equipment can impede control and increase the risk of discomfort.

Tip 3: Routine Maintenance is Essential. Regularly inspect wheels, bearings, and other components for wear and tear. Cleaning and lubrication of bearings contribute to smooth rolling and prolonged lifespan. Replacement of worn parts prevents performance degradation.

Tip 4: Adapt to the Skating Surface. Varying surfaces demand adjustments in technique and equipment setup. Smooth surfaces require less effort, while rougher terrains may necessitate harder wheels for improved durability. Awareness of surface conditions enhances control and reduces potential hazards.

Tip 5: Master Fundamental Techniques. Building a solid foundation in basic skills, such as forward movement, stopping, and turning, is paramount. Practice and repetition refine control and confidence, minimizing the likelihood of accidents.

Tip 6: Storage Considerations. Store the skates in a cool, dry environment away from direct sunlight and extreme temperatures. Proper storage prevents degradation of materials and preserves the equipment’s structural integrity.

A proactive approach to safety, maintenance, and skill development optimizes the performance and longevity of the skating equipment. Consistent adherence to these guidelines contributes to a safer and more enjoyable skating experience.

The subsequent section will present a comprehensive analysis of common issues and their corresponding troubleshooting procedures.

1. Aesthetic Designs

Aesthetic designs represent a significant component of the commercial appeal and user adoption. The visual presentation directly influences initial perception and consumer choice. These designs often incorporate retro aesthetics, vibrant color palettes, and patterned elements to evoke nostalgia and individuality. Consequently, consumer preference is frequently dictated by aesthetic considerations, influencing purchasing decisions and brand loyalty. Examples include limited-edition colorways or collaborations with artists, enhancing the product’s desirability.

The visual appeal extends beyond mere decoration; it contributes to the perceived value and identity of the skating experience. A well-executed design can communicate a sense of style, personality, and affiliation with a particular skating culture. For instance, designs mirroring trends in fashion or music can broaden the product’s appeal to a wider demographic. The incorporation of specific design elements can also serve functional purposes, such as high-visibility colors for safety or ergonomic forms for improved grip.

Ultimately, the thoughtful integration of aesthetic designs enhances both the functional and emotional aspects of the skating experience. While performance and durability remain crucial, visual presentation functions as a critical differentiator in a competitive market. Challenges involve maintaining a balance between stylistic trends, brand identity, and timeless design principles. A successful aesthetic strategy contributes to increased market share and sustained consumer engagement.

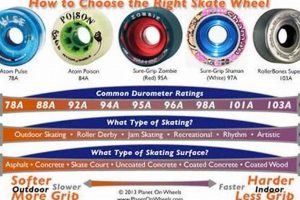

2. Wheel Composition

The performance characteristics of the skates are intrinsically linked to the materials and construction of their wheels. Predominantly composed of polyurethane (PU) with varying degrees of hardness, these wheels directly influence factors such as grip, roll speed, and durability. A higher durometer rating (measured on the Shore A scale) indicates a harder wheel, resulting in faster roll speed but diminished grip, suitable for smooth surfaces. Conversely, softer wheels with lower durometer ratings offer enhanced grip but reduced speed, making them preferable for rougher terrains or beginners seeking greater control. This relationship creates a direct cause-and-effect dynamic impacting maneuverability and rider confidence. An example would be selecting wheels with a durometer of 82A for indoor rink skating versus 78A wheels for outdoor use on asphalt.

The selection of appropriate wheel composition directly affects the longevity of the component and the overall skating experience. Continuous use on abrasive surfaces with softer wheels accelerates wear, necessitating more frequent replacements. The integration of high-rebound PU formulations can enhance energy return and reduce rolling resistance, contributing to a smoother and more efficient skating experience. In practical application, understanding these properties enables informed decisions based on intended usage environments and skating styles. Maintenance, including regular cleaning to remove debris and inspection for signs of wear, directly extends the lifespan of the wheels.

In summary, the composition of the wheel dictates multiple performance attributes integral to the effectiveness of the skates. Choosing the right material hardness and construction optimizes the user’s ability to navigate various surfaces and maintain control. While aesthetic factors contribute to market appeal, the wheels material properties are crucial for a positive skating experience. Challenges lie in balancing durability, grip, and speed to cater to a broad spectrum of user preferences and skating environments, which affects overall satisfaction and performance.

3. Boot Material

The selection of boot material directly influences the comfort, support, and durability of quad roller skates. Material choices, such as vinyl or synthetic leather, impact foot stability and control during use. For instance, a rigid boot provides enhanced ankle support, crucial for beginners or individuals with weaker ankles, while a more flexible material allows for greater range of motion and comfort for experienced skaters. This relationship exemplifies a direct cause-and-effect dynamic between material properties and user experience. The selection of the boot material also affects the weight of the overall construction. The design choices related to this component determines user safety and skating performance.

Practical applications illustrate the significance of boot material. For recreational purposes, a padded boot constructed from a breathable material enhances comfort and minimizes fatigue during extended use. High-performance skating, conversely, often necessitates a stiffer boot material that offers superior energy transfer and precise control. Considerations also extend to weather resistance and maintenance requirements; leather boots necessitate regular conditioning, while synthetic materials offer easier cleaning and improved water resistance. In addition, the boot’s lining impacts breathability and moisture management, factors contributing to long-term comfort. Boot material designs also account for the need for laces or adjustable straps to securely place the foot inside the footwear.

In summary, boot material selection is integral to the overall functionality and user satisfaction. It addresses comfort, support, durability, and performance. Challenges relate to balancing these factors within cost constraints and catering to diverse user needs. The proper understanding of boot material properties facilitates informed purchasing decisions, enhancing the skating experience and promoting equipment longevity.

4. Chassis Strength

Chassis strength constitutes a critical determinant of the structural integrity and performance characteristics of the mentioned skating equipment. The chassis, typically constructed from materials such as aluminum or reinforced nylon, provides the foundational support for the boot, wheels, and axles. A robust chassis directly translates to improved stability, enhanced energy transfer during propulsion, and increased resistance to deformation under stress. A compromised chassis can lead to instability, reduced control, and premature failure of the skates. For instance, a chassis manufactured from a low-grade polymer may be susceptible to cracking or bending under the repeated impact forces associated with skating, rendering the equipment unusable. Inversely, high-quality aluminum alloy chassis offer superior durability and resilience.

The practical application of this knowledge is evident in the selection of appropriate skates for various skating styles and environments. Aggressive skating, characterized by jumps, grinds, and other demanding maneuvers, necessitates a chassis engineered for high impact resistance and torsional rigidity. Recreational skating, conversely, may require a less robust chassis, prioritizing weight reduction and affordability. Manufacturers commonly specify the maximum weight capacity and intended usage parameters for their equipment, providing valuable guidance for consumers. Furthermore, regular inspection of the chassis for signs of damage, such as cracks or distortions, is essential for maintaining safety and prolonging the lifespan of the skates. Failure to address structural weaknesses in the chassis can result in hazardous situations, including loss of control and potential injury.

In summary, chassis strength is a paramount consideration in the selection and maintenance of these skating products. Its direct influence on stability, energy transfer, and durability underscores its importance as a core component. Challenges involve balancing the need for structural integrity with factors such as weight and cost, necessitating careful material selection and engineering design. A comprehensive understanding of chassis strength empowers consumers to make informed decisions and ensure the safe and effective utilization of this recreational equipment.

5. Bearing Precision

Bearing precision directly impacts the performance and user experience of the specified recreational skates. Bearings, small circular components housed within the wheels, facilitate smooth rotation, and their level of precision influences roll speed, efficiency, and overall maneuverability. Higher precision bearings contribute to a more effortless and enjoyable skating experience.

- ABEC Rating and its Significance

The Annular Bearing Engineering Committee (ABEC) rating system quantifies the manufacturing tolerances of bearings, with higher numbers (e.g., ABEC 7, ABEC 9) indicating tighter tolerances and, theoretically, greater precision. Bearings with a higher ABEC rating are typically associated with smoother, faster rolls. However, the benefits of higher ABEC ratings may be less discernible in recreational skating compared to more demanding applications, such as speed skating. For instance, standard recreational skates may utilize ABEC 5 or ABEC 7 bearings, providing a satisfactory balance between performance and cost. The implication is that while higher precision bearings can enhance performance, their marginal utility may diminish beyond a certain threshold for casual users.

- Material Composition and Durability

Bearing materials, typically steel or ceramic, affect durability and resistance to wear. Steel bearings are common due to their cost-effectiveness and adequate performance for recreational use. Ceramic bearings, while more expensive, offer superior hardness, reduced friction, and increased longevity. Impurities or imperfections in the material can compromise bearing precision and lifespan, leading to reduced roll efficiency. The choice of material impacts the maintenance frequency and overall cost of ownership. For example, skaters who frequently expose their equipment to moisture or dirt may benefit from the corrosion resistance offered by ceramic bearings, despite the higher initial investment.

- Lubrication and Maintenance

Proper lubrication is crucial for maintaining bearing precision and optimizing performance. Lubricants, such as grease or oil, reduce friction between the bearing’s internal components, facilitating smooth rotation and preventing premature wear. Insufficient or contaminated lubricant can lead to increased friction, reduced roll speed, and potential bearing failure. Regular cleaning and lubrication are essential maintenance tasks that prolong bearing life and preserve their precision. A practical example involves removing bearings from the wheels, cleaning them with a solvent, and re-lubricating them with a specialized lubricant designed for skating applications.

- Impact on Skating Performance

Bearing precision plays a role in the overall skating experience. Higher precision bearings can contribute to a smoother, faster, and more effortless ride. For example, a skater using equipment with high-precision bearings may experience less resistance when pushing off and maintaining momentum, leading to increased speed and reduced fatigue. In contrast, worn or low-precision bearings can result in a sluggish and less enjoyable skating experience. The subjective perception of bearing precision varies among skaters, with experienced individuals often more sensitive to subtle differences in roll speed and smoothness.

In conclusion, bearing precision influences the performance characteristics and overall quality of the specific quad roller skates. While factors such as ABEC rating, material composition, lubrication, and maintenance contribute to bearing performance, the practical benefits of higher precision bearings may be more apparent in specialized skating applications. Informed decisions regarding bearing selection and maintenance practices can enhance the skating experience and prolong the lifespan of the equipment.

Frequently Asked Questions

The subsequent section addresses common inquiries regarding the equipment, providing concise and informative responses.

Question 1: What factors determine the suitable size selection?

Proper sizing is contingent upon accurate foot measurements. Refer to the manufacturer’s sizing chart and measure foot length in millimeters. Consider width and volume to ensure a comfortable fit, potentially requiring adjustments from standard sizing. A snug, but not constricting, fit is recommended for optimal performance and safety.

Question 2: What is the recommended maintenance schedule?

Routine maintenance entails regular inspection of wheels, bearings, and hardware. Clean wheels and bearings every 10-20 hours of use, or more frequently in dusty conditions. Check and tighten all nuts and bolts before each use. Replace worn components promptly to maintain performance and prevent potential hazards.

Question 3: What are the key differences between indoor and outdoor wheels?

Indoor wheels typically feature a higher durometer (hardness) rating for optimal roll on smooth surfaces. Outdoor wheels possess a lower durometer, offering improved grip and shock absorption on rougher surfaces. Selecting the appropriate wheel type is crucial for performance and comfort on the intended skating environment.

Question 4: How does bearing ABEC rating impact performance?

ABEC rating indicates the manufacturing tolerances of bearings. Higher ABEC ratings (e.g., ABEC 7, ABEC 9) theoretically imply greater precision and smoother roll. However, the discernible performance difference may be minimal for recreational skating. ABEC 5 or ABEC 7 bearings typically provide a suitable balance of performance and cost for general use.

Question 5: What safety equipment is essential for usage?

Mandatory safety equipment comprises a helmet, knee pads, elbow pads, and wrist guards. These protective measures mitigate the risk of injury in the event of falls or collisions. Proper fit and secure fastening of all safety gear are imperative for optimal protection.

Question 6: How should the equipment be stored to prolong its lifespan?

Store the skates in a cool, dry environment away from direct sunlight and extreme temperatures. Remove dirt and debris before storage. Loosen laces or straps to prevent deformation of the boot. Utilize a carrying bag or container to protect the equipment from dust and physical damage.

Adherence to these guidelines promotes user safety, enhances performance, and extends the lifespan of the equipment.

The subsequent section offers a comparison of various models.

Final Assessment

The preceding analysis examined diverse facets of Impala quad roller skates, ranging from core construction materials to usage guidelines and maintenance protocols. Evaluation encompassed aesthetic considerations, wheel composition intricacies, boot material characteristics, chassis strength determinants, and bearing precision implications. A comprehensive understanding of these elements informs responsible acquisition and prolonged product lifecycle.

Ultimately, informed utilization predicated on diligent research and consistent adherence to safety recommendations ensures both optimal performance and minimized risk. Continued advancements in materials science and manufacturing processes portend further refinements in this category, warranting ongoing assessment of evolving technological enhancements. This ongoing process will ultimately maximize user satisfaction and safety, thus improving the overall skating experience.